Oil-immersed transformers are essential in power transmission and distribution systems, but they also carry potential risks due to the presence of high voltage, flammable insulating oil, and mechanical components. Ensuring safety during their operation is crucial to prevent electrical faults, oil leaks, fires, and equipment failure. This article outlines the critical safety precautions that operators and maintenance teams must follow to maintain safe and reliable transformer operation.

Why Is Safety Important When Operating Oil-Immersed Transformers?

Oil-immersed transformers are engineered to handle high voltage and power loads, making them essential to utility, industrial, and renewable energy networks. However, because they contain flammable insulating oil and operate under extreme electrical and thermal conditions, they pose serious safety risks if improperly specified, operated, or maintained. Transformer failures can lead to fire, explosion, oil leakage, environmental damage, or prolonged power outages, often with costly consequences.

Safety is crucial in oil-immersed transformer operation because these units contain flammable oil, operate under high voltage, and can experience internal faults or overpressure. Without proper protection systems—like Buchholz relays, pressure relief valves, fire barriers, and grounding—transformers can pose risks to personnel, equipment, and the environment. Rigorous safety measures ensure operational integrity, regulatory compliance, and protection of life and property.

Transformer safety is not optional—it’s a core requirement for sustainable and secure power infrastructure.

Oil-immersed transformers are inherently safe and do not require external safety devices.False

Oil-immersed transformers must be equipped with protective devices like Buchholz relays, pressure relief valves, and fire barriers to manage oil-related and electrical hazards.

Key Safety Risks Associated with Oil-Immersed Transformers

| Risk Type | Description |

|---|---|

| Fire Hazard | Mineral oil is combustible; arcing or overheating may ignite oil |

| Explosion Risk | Internal arcing causes gas buildup and overpressure |

| Oil Leakage | Can lead to environmental contamination and fire exposure |

| Electric Shock | High voltage terminals must be properly shielded and grounded |

| Environmental Impact | Oil spills may violate regulations and damage ecosystems |

Essential Safety Features and Systems

| Safety Feature | Function |

|---|---|

| Buchholz Relay | Detects gas buildup from internal faults; shuts down transformer |

| Pressure Relief Device | Releases excessive pressure to prevent tank rupture |

| Oil Containment Pit | Prevents soil/water pollution in case of leakage or fire |

| Grounding System | Prevents dangerous voltage rise during fault conditions |

| Temperature Sensors (RTDs) | Monitors winding and oil temperature for thermal protection |

| Fire Suppression Systems | Water mist or CO₂ systems in indoor or compact stations |

Operational Safety Practices

| Safety Protocol | Purpose |

|---|---|

| Routine Oil Testing | Ensures dielectric strength and detects contaminants |

| DGA (Dissolved Gas Analysis) | Identifies internal electrical faults via gas signature |

| Infrared Thermography | Detects overheating components during live operation |

| Regular Maintenance | Prevents tank corrosion, insulator failure, and contact faults |

| Clearance and Barriers | Prevents accidental contact with high-voltage components |

Real-World Example – Prevented Catastrophic Failure

- Site: 220/66 kV utility transformer

- Observation: Pressure relief valve activated after thermal relay tripped

- Cause: Internal arcing from degraded winding insulation

- Response: DGA confirmed fault; unit isolated before tank rupture

Outcome: Avoided explosion, fire, and grid outage—saved \$1M+ in recovery costs

Regulatory and Design Compliance

| Standard / Regulation | Safety Aspect Covered |

|---|---|

| IEC 60076-7 | Loading and temperature safety |

| NFPA 850 / IEEE 979 | Fire protection for substations |

| ISO 14001 | Environmental protection and spill containment |

| IEEE C57.12.00 & C57.91 | Thermal and dielectric design margins |

Safety and Monitoring Integration

| System | Function |

|---|---|

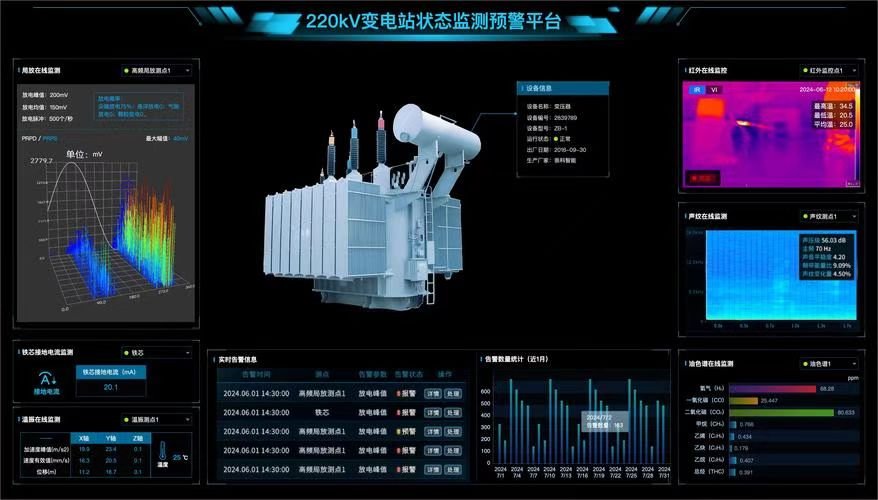

| Smart Transformer Monitoring | Real-time alerts for temperature, gas buildup, oil level |

| SCADA Integration | Remote shutdown and status reporting |

| Arc Flash Sensors | Detects internal flash events and triggers fast trip |

| Anti-theft and Vandal Protection | Secures critical outdoor transformers |

What Are the Pre-Operation Inspection Requirements for Oil-Immersed Transformers?

Before energizing an oil-immersed transformer, a comprehensive pre-operation inspection is critical to ensure the unit is safe, functional, and compliant with specifications. Skipping or inadequately performing these checks can lead to startup failure, insulation damage, internal arcing, fire hazards, or warranty violations. Pre-energization protocols verify both the mechanical and electrical readiness of the transformer system.

Pre-operation inspection for oil-immersed transformers involves verifying oil level and quality, checking terminal connections and grounding, testing protective devices (e.g., Buchholz relay, pressure relief valve), confirming cooling system functionality, inspecting for transport damage or oil leaks, and reviewing insulation resistance and transformer ratio tests. These checks ensure safe energization and prevent premature failures.

Following a standardized checklist mitigates commissioning risk and supports long-term operational reliability.

Oil-immersed transformers can be energized immediately upon delivery without inspection.False

All oil-immersed transformers must undergo pre-energization inspections to check for transit damage, verify protective systems, and confirm electrical and mechanical readiness.

Complete Pre-Operation Inspection Checklist

| Inspection Area | Task Description |

|---|---|

| Visual Inspection | Check for paint damage, dented tanks, broken bushings, oil leakage, loose bolts |

| Oil Level Check | Ensure oil is at rated level on the gauge; verify conservator tank status |

| Oil Quality Test | Perform dielectric breakdown test (BDV), moisture analysis if required |

| Gasket and Seal Check | Inspect for signs of seepage or deterioration in flange gaskets and valves |

| Bushing Condition | Confirm no cracks, clean surface, tight connections |

| Grounding System | Verify main tank, neutral, and core grounding continuity and tightness |

| Terminal Connections | Ensure all HV and LV terminals are secure, torque checked, and correctly labeled |

| Cooling System | Inspect radiators, check fans (ONAF) or pumps (OFAF), verify thermostat function |

| Protective Devices | Test Buchholz relay, pressure relief device, oil level and temperature alarms |

| Insulation Resistance (IR) | Perform megger test between windings and to ground (per IEEE/IEC standards) |

| Transformer Turns Ratio (TTR) | Verify turns ratio between HV and LV windings using test set |

| Polarity and Vector Group | Confirm correct vector configuration (e.g., Dyn11) matches specifications |

| Nameplate Verification | Check all nameplate data matches specification and site documentation |

Electrical Testing Summary Table

| Test Type | Acceptance Criteria |

|---|---|

| Insulation Resistance | ≥1000 MΩ for LV; ≥5000 MΩ for HV (adjust for kV level) |

| TTR (Turns Ratio) | Within 0.5% of nameplate ratio |

| Polarity Test | Confirm dot marking or phase shift matches vector group |

| Continuity Test | No open circuits in windings or terminal connections |

Cooling and Safety Device Checks

| Device | Inspection Task |

|---|---|

| Buchholz Relay | Float movement, gas release port clear, wiring continuity |

| Pressure Relief Valve | Movement test, reset function, tightness of mounting |

| Oil Level Indicator | Float operation, gauge accuracy |

| Thermometers/RTDs | Calibrated readout, alarm relay contacts tested |

| Fans/Pumps (if ONAF/OFAF) | Manual test run, direction of rotation, vibration check |

Documentation and Safety Review

| Review Area | Checklist Items |

|---|---|

| Drawings and Schematics | Confirm terminal markings, grounding points, protection settings |

| Pre-Energization Report | Complete inspection form with technician signatures |

| Safety Protocols | PPE check, lockout/tagout readiness, fire suppression in place |

| Environmental Controls | Spill containment, bunding, and oil pit inspection |

Real-World Example – 33/11 kV 10 MVA Transformer

- Site: Urban substation commissioning

- Pre-operation issues: Improper fan rotation (3-phase reversal), low oil level in conservator, IR value below threshold on HV winding

- Actions: Corrected phase wiring, topped up with filtered oil, heated windings to dry moisture

- Result: Passed all tests, energized without trip, 3-year zero-fault operation

Shows the value of rigorous commissioning in preventing early-life failures

How Should Personnel Handle Transformer Oil Safely?

Transformer oil is essential to the function of oil-immersed transformers, serving as both an electrical insulator and a cooling medium. However, it must be handled with care due to its flammability, potential environmental impact, and chemical degradation sensitivity. Mishandling oil can lead to fire hazards, contamination of equipment, regulatory violations, and health risks to maintenance personnel.

Transformer oil should be handled with strict adherence to safety protocols, including the use of personal protective equipment (PPE), proper transfer and filtration methods, contamination prevention, secure storage, and environmentally compliant disposal. Personnel must be trained to avoid direct contact, fire exposure, and moisture ingress while managing sampling, filling, draining, and testing procedures.

Effective transformer oil handling minimizes operational risks, prolongs insulation life, and ensures workplace and environmental safety.

Transformer oil is non-hazardous and requires no special handling.False

Transformer oil, especially mineral oil, is combustible and subject to contamination. It requires PPE, spill containment, and proper storage/handling procedures.

Essential Safety Practices for Handling Transformer Oil

| Safety Task | Description |

|---|---|

| Wear Appropriate PPE | Use gloves, safety goggles, flame-resistant coveralls, and rubber boots |

| Avoid Open Flames | Keep oil away from welding, smoking, or high heat sources |

| Ground All Containers | Prevent electrostatic discharge during oil transfer |

| Use Closed Transfer Systems | Employ hoses, filters, and pumps to minimize spills and exposure |

| Maintain Clean Tools | All equipment must be oil-compatible and contamination-free |

| Label Oil Drums Clearly | Indicate type (mineral, ester), test date, and condition |

| Avoid Water Contact | Ensure all drums and tanks are sealed—moisture severely degrades oil |

Personal Protective Equipment (PPE) Guidelines

| Task | Required PPE |

|---|---|

| Oil Sampling | Gloves, goggles, flame-retardant clothing |

| Oil Filling or Draining | Chemical-resistant gloves, goggles, face shield, apron |

| Oil Filtration (Online) | Full PPE, ear protection if near running equipment |

| Disposal or Spill Response | Spill kit, respiratory mask (if fumes), gloves, boots |

Oil Handling Procedures

1. Oil Sampling

- Use clean, dry glass or metal containers with sealable caps

- Label sample with date, location, and transformer ID

- Avoid exposure to air and moisture

- Clean sampling port before and after collection

2. Oil Filling

- Use vacuum dehydration system for new oil fill to remove air bubbles

- Filter through 5-micron filters to remove particles

- Fill slowly to avoid turbulence and maintain static grounding

- Monitor oil level indicators during filling

3. Draining Oil

- Collect drained oil in bonded containers or spill-proof tanks

- Avoid draining onto soil or uncontained surfaces

- Cap all drain ports immediately after use

4. Oil Storage

- Store in bunded areas with leak-proof floors

- Use fire-rated containers for mineral oil

- Rotate stock to use oldest oil first (FIFO method)

Environmental and Fire Safety Measures

| Measure | Purpose |

|---|---|

| Spill Containment Kit | Immediate response to accidental leaks or drum puncture |

| Oil-Water Separator System | Prevents discharge of oil-contaminated water |

| Secondary Containment | Required for >1000 liters stored; bund walls, drain traps |

| Fire Extinguishers | Class B (foam or dry chemical) available at all oil areas |

| Ventilation and Signage | Ensure fumes don’t accumulate; label hazards clearly |

Real-World Safety Scenario – Oil Filtration Operation

- Task: Offline filtration of 40 MVA 132 kV transformer

- Setup: Double-stage filter cart with vacuum pump, RTDs on oil temperature

- Incident Prevention: Static bonding cable used, operator wore full PPE, ground crew placed spill tray

- Outcome: No contamination, no fire risk, dielectric value improved from 43 kV to 65 kV

Demonstrates how controlled handling procedures protect personnel and equipment during high-volume operations

What Fire Protection Measures Should Be in Place for Oil-Immersed Transformers?

Oil-immersed transformers contain flammable insulating fluids that pose a serious fire risk if a failure or leak occurs. Internal arcing, overheating, or external ignition sources can rapidly escalate into oil fires, tank explosions, or environmental disasters. Therefore, robust fire protection measures are essential to safeguard life, critical infrastructure, and surrounding ecosystems.

Fire protection for oil-immersed transformers should include physical containment (bund walls or pits), automatic fire suppression systems (foam, water mist, or inert gas), flame and heat detection sensors, safe spacing, fire barriers, emergency shutdown mechanisms, and compliance with fire protection standards (e.g., NFPA 850, IEEE 979). These measures help isolate, detect, suppress, and prevent the spread of transformer fires.

Proper fire risk mitigation is a legal and operational necessity in any transformer installation.

Oil-immersed transformers are inherently fireproof and don’t require fire protection systems.False

Oil-immersed transformers use flammable insulating fluids like mineral oil. Fire protection systems are critical to manage ignition and explosion risks.

Primary Fire Hazards with Oil-Immersed Transformers

| Fire Hazard Type | Risk Description |

|---|---|

| Internal Arcing | Can rupture windings and ignite surrounding oil |

| Tank Overpressure | Explosion hazard from gas accumulation |

| Oil Leaks | Spill ignites from adjacent heat or arc sources |

| Overheating | Sustained high load causes thermal degradation and ignition |

| Lightning/Surge Events | External energy surges trigger insulation breakdown |

Essential Fire Protection Measures

| Fire Protection System | Function |

|---|---|

| Bund Wall or Containment Pit | Captures leaking oil, prevents environmental spill |

| Flame/Heat Sensors | Detect early-stage combustion or overheating |

| Automatic Suppression (Foam or Water Mist) | Extinguishes fire at ignition stage |

| Pressure Relief Devices | Safely vents pressure to avoid tank rupture |

| Fire Barriers (Refractory Panels) | Prevents flame spread to adjacent equipment |

| Safe Equipment Spacing | Reduces fire propagation risk |

| Manual and Remote Shutoff | Enables emergency system disconnection |

| Warning Signage and Access Control | Keeps unauthorized personnel away from risk zones |

Common Suppression System Types

| System Type | Best For | Pros | Limitations |

|---|---|---|---|

| Foam Deluge | Outdoor substations with bunded pits | Smothers oil fires quickly | Requires maintenance, cleanup |

| Water Mist (High Pressure) | Indoor vaults, transformers <20 MVA | Minimal water damage, fast cooling | May require sealed enclosure |

| Inert Gas (N₂/CO₂) | Critical indoor installations | No residue, effective in enclosures | Asphyxiation hazard, limited ventilation |

| Dry Chemical | Small vaults, temporary stations | Low cost, portable | Not suitable for large-scale oil fires |

NFPA and IEEE Guidelines for Fire Protection

| Standard | Scope of Fire Protection Recommendations |

|---|---|

| NFPA 850 | Fire protection for electric generating plants and substations |

| IEEE 979 | Guidelines for substation transformer fire protection |

| IEC 60076-22-1 | Fire behavior of transformers |

| ISO 14001 | Environmental containment and oil spill prevention |

These standards define minimum clearance, barrier design, fire suppression system types, and risk assessment frameworks.

Layout and Design Requirements

| Site Design Feature | Fire-Safe Configuration Example |

|---|---|

| Minimum Spacing | ≥3 m between transformers or fire walls ≥1.5 m high |

| Oil Volume Containment | Bunds must hold 110% of oil volume of the largest transformer |

| Slope Drainage | Bund floor sloped to oil-water separator or sump |

| Access Pathways | Must allow fire department or suppression team access |

| Barrier Materials | Fire-resistant concrete, steel, or intumescent-coated panels |

Real-World Case – Urban Substation Fire Suppression

- Location: City-grid 66/11 kV substation

- Equipment: 3 × 16 MVA oil-filled transformers, mineral oil, ONAF

- Fire Measures: Concrete bunds with foam nozzles, thermal flame sensors, auto shutoff breakers

- Incident: Short-circuit arc in tap changer compartment

- Result: Flame detected within 8 seconds, foam released automatically, fire suppressed before oil breach

Losses minimized to <2 hours downtime, no asset replacement required—illustrates the value of automated containment and suppression systems

What Are the Guidelines for Routine Monitoring and Maintenance of Oil-Immersed Transformers?

Oil-immersed transformers are long-life assets, but their performance and insulation integrity depend heavily on routine monitoring and proactive maintenance. Neglecting small issues—such as undetected moisture, loose terminals, or deteriorated gaskets—can escalate into catastrophic failures or unplanned outages. A disciplined inspection and maintenance program extends equipment life, reduces downtime, and improves safety and reliability.

Routine monitoring and maintenance of oil-immersed transformers includes scheduled inspections of oil condition, insulation resistance, cooling systems, protective devices, and mechanical integrity. Regular tests such as Dissolved Gas Analysis (DGA), IR values, thermographic scans, and visual assessments help detect developing faults early and maintain optimal transformer health.

Preventive maintenance transforms transformer management from reactive to predictive—delivering reliability and cost savings.

Oil-immersed transformers are maintenance-free and do not require regular monitoring.False

Oil-immersed transformers require periodic testing, oil sampling, and equipment checks to maintain insulation quality and prevent failure.

Recommended Maintenance Schedule

| Frequency | Task Category | Key Activities |

|---|---|---|

| Daily/Weekly | Monitoring (SCADA/RTU) | Oil temp, load, alarms, fan/pump status |

| Monthly | Visual Inspection | Check for leaks, rust, oil level, fan operation |

| Quarterly | Minor Service | Clean bushings, inspect gaskets, check grounding, fan test |

| Biannually | Operational Testing | IR test, cooling control check, Buchholz and PRV relay testing |

| Annually | Comprehensive Maintenance | DGA, BDV test, acidity/moisture in oil, TTR test, tap changer |

| 3–5 Years | Deep Overhaul (offline if needed) | Full oil filtration, gasket replacement, insulation drying |

Core Monitoring and Inspection Points

| Component | What to Inspect/Test |

|---|---|

| Transformer Oil | BDV (breakdown voltage), moisture content, acidity, sludge |

| Buchholz Relay | Relay response, gas release port function |

| Temperature Indicators | Functionality, accuracy, alarm contact status |

| Pressure Relief Device | Operation test, vent clearance, gasket condition |

| Cooling System | Radiator blockage, fan/pump performance, thermal relays |

| Bushings | Surface cleanliness, corona marks, partial discharge traces |

| Winding Resistance | Ohmic measurement for detecting conductor or contact faults |

| Insulation Resistance | Megger test to ground and between windings |

| Tap Changer | Contact wear, carbon buildup, motor mechanism check |

Key Diagnostic Tests and Their Purpose

| Test | Purpose | Frequency |

|---|---|---|

| Dissolved Gas Analysis | Detects incipient faults (e.g., overheating, arcing) | Yearly or as needed |

| BDV (Breakdown Voltage) | Measures oil’s dielectric strength | Yearly |

| Moisture Content (PPM) | Identifies oil contamination and aging | Yearly |

| Infrared Thermography | Locates hot spots in bushings, terminals, and radiators | Biannually |

| Turns Ratio Test (TTR) | Validates transformer ratio integrity | Annually |

| Furan Analysis | Measures paper insulation degradation | Every 2–3 years |

Digital and Online Monitoring Options

| Monitoring Tool | Parameter Monitored |

|---|---|

| Online DGA Sensor | Hydrogen, acetylene, methane, ethylene levels |

| RTDs/Temp Sensors | Winding and oil temperature |

| Moisture Sensors | Water-in-oil ppm values |

| Smart Breathers | Tracks silica gel saturation and air exchange cycles |

| SCADA Integration | Remote data access, alarm response, trend analysis |

Common Preventable Issues Detected by Routine Checks

| Issue Detected | Potential Risk Prevented |

|---|---|

| Low BDV or high acidity | Internal flashover or accelerated insulation breakdown |

| Loose terminal or ground | Arc faults, EMF rise, local overheating |

| Fan failure | Rapid temperature rise, accelerated oil aging |

| PRV stuck closed | Transformer tank rupture under pressure |

| Sludge buildup in oil | Cooling inefficiency, hotspot formation |

Real-World Case – 66/11 kV, 20 MVA Transformer

- Routine IR scan detected uneven radiator temperature

- Maintenance confirmed one cooling fan failure

- Oil BDV test also showed 30 kV, below acceptable threshold

- Actions: Replaced fan, filtered oil with Fuller's earth unit

- Result: Oil dielectric restored to 64 kV, fan temperature profile normalized

Outcome: Avoided thermal failure, extended oil life by 5+ years with basic preventive maintenance

How to Respond to Emergencies Involving Oil-Immersed Transformers?

Oil-immersed transformers, while highly reliable, can present serious emergency risks if a fault, fire, or oil leak occurs. Because they contain flammable oil and operate under high voltage, incidents can escalate rapidly—posing threats to life, infrastructure, and the environment. Effective emergency response requires quick recognition, safe shutdown procedures, and well-rehearsed containment protocols.

Emergency response for oil-immersed transformers involves immediate isolation of power, activation of fire suppression systems, oil spill containment, on-site personnel evacuation, and communication with emergency services. Pre-established response plans, trained operators, and integrated safety systems are essential to limit damage, protect lives, and ensure regulatory compliance.

Preparedness, speed, and coordination are key to managing transformer emergencies.

Oil-immersed transformer emergencies can be safely handled without any training or planning.False

Transformer emergencies require trained personnel, detailed response plans, safety gear, and coordination with emergency services to ensure safe containment and recovery.

Common Transformer Emergency Scenarios

| Emergency Type | Description |

|---|---|

| Transformer Fire | Ignition of insulating oil due to arcing, overheating, or fault |

| Tank Explosion | Overpressure or internal fault leads to rapid tank rupture |

| Oil Spill/Leak | Mechanical failure or seal rupture causes oil escape |

| Electrical Fault | Internal short circuit or external flashover |

| Cooling System Failure | Fan/pump malfunction causes overheating and potential fire |

Immediate Emergency Response Checklist

| Step | Action |

|---|---|

| 1. Isolate Transformer | Trip HV and LV breakers; activate SCADA emergency shutdown |

| 2. Trigger Fire Suppression | Activate foam deluge, CO₂, or water mist system |

| 3. Evacuate Personnel | Clear all non-essential staff; activate area alarm systems |

| 4. Notify Authorities | Inform fire services, facility security, and utility control |

| 5. Contain Oil Leakage | Use spill kits, absorbent booms, or oil-water separators |

| 6. Block Drainage Paths | Prevent oil from reaching stormwater or groundwater systems |

| 7. Monitor from Safe Distance | Use thermal camera or SCADA for incident tracking |

| 8. Initiate Emergency Log | Record time, incident type, actions taken, personnel involved |

Required Safety Equipment

| Equipment | Purpose |

|---|---|

| PPE Kit (FR clothing, gloves, goggles, respirators) | Protects responders from heat and oil exposure |

| Fire Extinguishers (Class B foam) | For initial response to oil fire before suppression system engages |

| Emergency Spill Kit | Oil pads, containment booms, disposal bags |

| Thermal Camera or IR Scanner | Detects residual heat and hot spots post-incident |

| First Aid Station | Treat minor burns, oil contact, or respiratory irritation |

Coordination with Emergency Services

| Service | Coordination Role |

|---|---|

| Fire Department | Suppress fire, inspect scene, ensure structural safety |

| Environmental Agency | Inspect for oil pollution and mandate remediation |

| Utility Operator | Restore safe power, isolate damaged sections, reroute loads |

| Substation Engineers | Assess transformer damage, supervise removal and repair |

Preventive Measures That Support Response

| Measure | Benefit |

|---|---|

| Thermal Sensors & DGA Monitors | Early detection reduces emergency escalation |

| Pressure Relief & Buchholz Relays | Prevent tank rupture and signal internal faults |

| Bund Walls & Oil Pits | Contain oil to prevent environmental spread |

| Automated Fire Suppression | Responds faster than manual systems |

| Emergency Response Training | Ensures coordinated, calm actions under stress |

Real-World Example – Contained Transformer Explosion

- Incident: 220/33 kV transformer exploded due to tap changer arc

- Actions: Buchholz relay triggered breaker trip, foam deluge auto-engaged

- Oil captured in concrete bund; fire department responded within 10 minutes

- Personnel followed evacuation and shutdown SOP

Outcome: No injuries, zero pollution, transformer replaced in 8 days with no system-wide blackout

Conclusion

Operating oil-immersed transformers safely requires strict adherence to inspection, maintenance, and emergency protocols. The combination of high voltage and combustible oil makes it essential to monitor equipment condition, maintain proper grounding, and have fire protection systems in place. By implementing comprehensive safety practices, operators can ensure not only equipment longevity but also the protection of personnel and surrounding infrastructure.

FAQ

Q1: Why are safety precautions necessary for oil-immersed transformers?

A1: Oil-immersed transformers operate under high voltage and contain flammable insulating oil, which can lead to:

Fire or explosion hazards

Oil leaks or environmental contamination

Electrical shocks and arc flash risks

Therefore, following strict safety protocols is vital for operator protection, equipment reliability, and regulatory compliance.

Q2: What are the fire safety precautions for oil-immersed transformers?

A2: Key fire prevention steps include:

Installing fire barriers, blast walls, or oil containment pits

Using fire-resistant fluids (natural esters or silicone-based oils) where applicable

Ensuring adequate distance from flammable materials

Integrating fire detection and suppression systems, such as nitrogen injection or sprinklers

Maintaining clearances and ventilation for heat dissipation

Q3: How should oil be handled safely?

A3: Safe oil handling practices:

Use personal protective equipment (PPE): gloves, goggles, flame-resistant clothing

Perform oil sampling and top-up only when de-energized

Use grounded containers and oil transfer systems to avoid static discharge

Avoid spills by sealing drums and using oil catch basins or bund walls

Dispose of used oil through licensed hazardous waste services

Q4: What routine safety checks should be performed?

A4: Regular inspections should include:

Oil level, color, and leak detection

Temperature and pressure gauges

Buchholz relay, conservator breather, and pressure relief device functionality

Grounding integrity and insulation resistance tests

Thermal imaging to detect hotspots

Preventive maintenance reduces the likelihood of failure and extends service life.

Q5: What electrical protection systems enhance transformer safety?

A5: Essential protective devices include:

Differential and overcurrent relays

Surge arresters and lightning protection

Buchholz relay for gas detection

Pressure relief valves to vent excessive internal pressure

Temperature sensors and alarms for winding and oil temperature

These systems help isolate faults and protect the transformer from damage or catastrophic failure.

References

"Safe Operation of Oil-Filled Transformers" – https://www.electrical4u.com/transformer-safety

"IEEE C57.12.00: Standard for Safety in Oil-Immersed Transformers" – https://ieeexplore.ieee.org/document/8896213

"Doble: Transformer Fire Risk and Maintenance" – https://www.doble.com/transformer-fire-prevention

"NFPA 850: Fire Protection for Electrical Substations" – https://www.nfpa.org/850

"ScienceDirect: Oil-Filled Transformer Failure Analysis and Safety Measures" – https://www.sciencedirect.com/transformer-safety-analysis