Transformers are vital assets in power distribution systems, designed to operate under specific environmental conditions. However, extreme weather events or site flooding can result in transformers being partially or fully submerged in water. Such incidents pose serious safety hazards, operational risks, and long-term damage to the equipment. This article explores what happens when a transformer is submerged, and what steps should be taken after such an event.

Why Is Water Ingress Dangerous for Transformers?

Water ingress is one of the most silent yet destructive threats to oil-filled transformers. Whether introduced via breather failure, leaking gaskets, condensation, or improper handling, water vapor or liquid inside the tank can rapidly degrade oil insulation properties, initiate partial discharges, and permanently damage cellulose-based insulation. Once moisture is absorbed, the transformer’s dielectric integrity and mechanical strength are compromised, increasing the risk of failure.

Water ingress is dangerous for transformers because it reduces the dielectric strength of insulation oil, accelerates the thermal aging and breakdown of cellulose paper insulation, promotes internal arcing and partial discharges, and increases the likelihood of catastrophic electrical failure. Even small amounts of moisture lead to rapid performance degradation and shorten transformer lifespan significantly.

Controlling moisture is critical to maintaining electrical safety, reliability, and asset longevity.

Water inside a transformer has no major impact on its operation.False

Even small quantities of water reduce the dielectric strength of oil and paper insulation, increasing the risk of partial discharges, aging, and transformer failure.

How Water Enters a Transformer

| Entry Pathway | Common Causes |

|---|---|

| Breather Saturation | Silica gel loses drying capacity, letting humid air enter |

| Gasket/Seal Leaks | Aging, weathering, or poor installation allows atmospheric moisture in |

| Tank Respiration (Conservator) | Daily heating and cooling draws in moist air without nitrogen seal |

| Condensation | Cooling cycles cause internal humidity to condense on tank walls |

| Poor Oil Handling | Contaminated drums, tools, or ambient conditions during refilling |

Direct Consequences of Moisture Inside Transformers

| Consequence | Explanation |

|---|---|

| Dielectric Breakdown | Moisture drastically lowers oil’s voltage withstand capability |

| Accelerated Aging of Insulation | Hydrolysis and oxidation of cellulose reduces its mechanical strength |

| Partial Discharges (PD) | Localized ionization leads to gas formation and insulation erosion |

| Gas Evolution | Moisture + heat leads to H₂, CO, CO₂ buildup—precursors to failure |

| Bubble Formation at Hot Spots | Steam bubbles form at >100 °C, displacing oil and triggering breakdown |

Quantified Impact of Moisture on Performance

| Moisture Level in Oil (ppm) | Dielectric Strength (kV) | Transformer Risk Level |

|---|---|---|

| <15 ppm | >60 kV | Safe |

| 30–40 ppm | 45–55 kV | Marginal; begin cellulose degradation |

| >50 ppm | <35 kV | High risk of arcing, PD, breakdown |

| >70 ppm | <25 kV | Critical failure risk |

Case Study – Failure from Water Ingress

- Transformer: 16 MVA, 66/11 kV outdoor unit

- Problem: Tripped due to internal fault after monsoon season

Diagnosis:

- Moisture in oil: 76 ppm

- Breakdown voltage: 21 kV

- DGA: High H₂, CO₂, and furanic compounds

- Root Cause: Failed breather + leaky lid gasket

- Result: Paper insulation degraded, winding shorted

Repair cost exceeded $30,000 and required complete insulation reconditioning.

Affected Transformer Components

| Component Affected | Damage Mechanism Due to Moisture |

|---|---|

| Cellulose Insulation | Loss of tensile strength, brittleness, acid-catalyzed hydrolysis |

| Mineral Oil | Emulsification, loss of dielectric integrity, sludging |

| Core and Windings | Short circuits, overheating from loss of insulation |

| Bushings and Tap Changers | Flashover and carbon tracking due to moisture bridging |

Detection and Prevention Methods

| Method | Purpose |

|---|---|

| Karl Fischer Titration | Accurately measures water in oil in ppm |

| Dielectric Strength Test | Confirms voltage withstand capability of insulating oil |

| DGA (Dissolved Gas Analysis) | Detects byproducts of water-induced decomposition |

| Breather Maintenance | Prevents moist air from entering during thermal cycling |

| Oil Preservation Systems | Bladder tanks or nitrogen-sealed conservators prevent tank breathing |

Moisture Limits from International Standards

| Standard | Maximum Moisture in Oil | Context |

|---|---|---|

| IEC 60422 | <35 ppm (in-service) | Based on voltage class and age |

| IEEE C57.106 | <25 ppm (ideal) | Guides moisture levels by voltage |

| IS 1866 | Regular monitoring advised if >30 ppm |

What Happens When an Oil-Immersed Transformer Is Submerged?

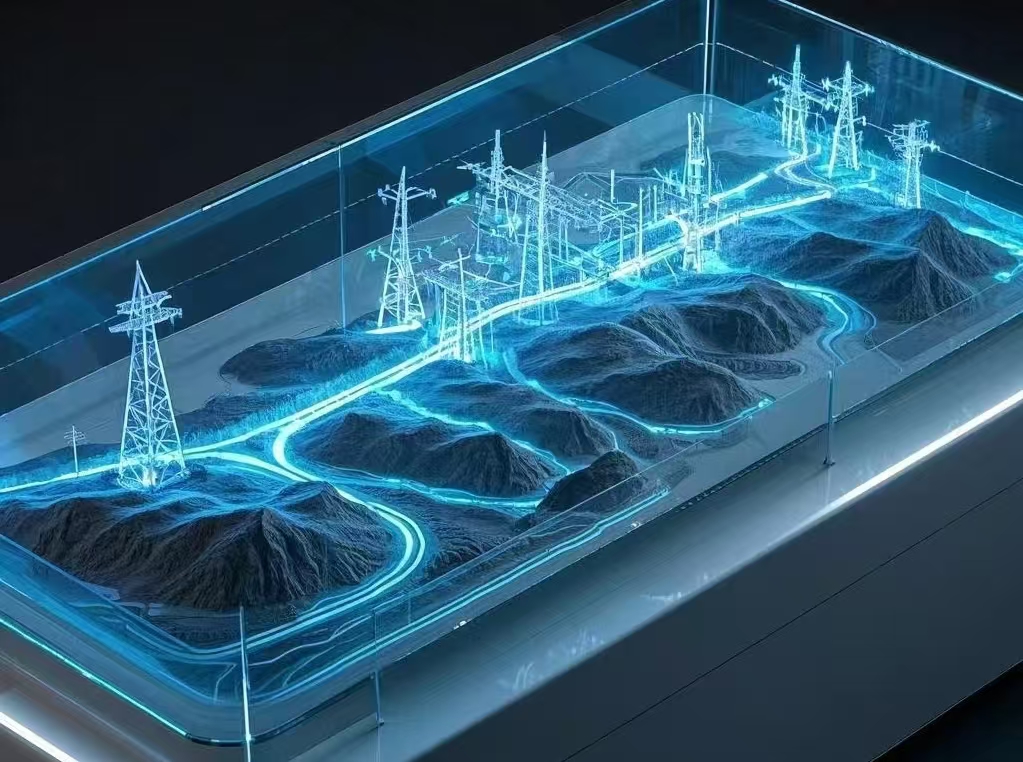

Floods and rising water levels pose a serious threat to oil-immersed transformers, which are typically designed for operation in dry or controlled environments. When submerged—either partially or fully—these units are exposed to water ingress through vents, gaskets, or bushings, leading to oil contamination, insulation failure, and eventual dielectric collapse. Depending on how long and how deep the unit is submerged, the consequences range from minor oil deterioration to total transformer failure.

When an oil-immersed transformer is submerged in water, moisture can enter the tank through breathing vents or compromised seals, contaminating the insulating oil and paper insulation. This reduces dielectric strength, leads to internal arcing, accelerates aging, and can render the transformer unsafe for further operation. In severe cases, full refurbishment or replacement is required.

Even short-term submersion can cause irreversible insulation degradation, especially if the unit was energized during flooding.

Oil-immersed transformers are waterproof and operate normally after submersion.False

Oil-immersed transformers are not hermetically sealed and typically breathe through a conservator tank or vent; submersion allows water ingress, which contaminates oil and damages insulation.

How Water Enters During Submersion

| Pathway | Mechanism |

|---|---|

| Breather Assembly | Allows water through saturated silica gel or open vent pipe |

| Gasket Seals (Aged/Cracked) | Water seeps through flange joints and inspection cover gaskets |

| Bushing Mounts | Water follows bushing surface tension into tank cavity |

| Conservator Pipe Ingress | Water travels through open breather and pipe into main oil body |

Immediate Effects of Submersion

| Condition | Transformer Status |

|---|---|

| Energized During Flood | High risk of arcing, core shorts, or bushing flashover |

| De-energized but Submerged | Water slowly contaminates oil and insulation paper |

| Short Submersion (<2 hrs) | May be recoverable if oil test results remain within standards |

| Prolonged Submersion (>6 hrs) | High risk of internal paper moisture >2%, requiring refurbishment |

Dangers of Post-Flood Operation

| Risk Factor | Potential Consequence |

|---|---|

| Moisture in Oil | Reduces breakdown voltage → flashover at low voltages |

| Water in Paper Insulation | Loss of tensile strength → mechanical collapse of winding supports |

| Corrosion of Core and Clamps | Weakens clamping pressure → audible vibration or deformation |

| Gas Evolution | Water reacts with cellulose → H₂, CO, and furanic compounds rise |

| Thermal Runaway | Oil loses cooling capacity → windings overheat faster |

Key Diagnostic Actions After Submersion

| Test or Inspection | What It Reveals |

|---|---|

| Visual Oil Check | Emulsion or cloudiness indicates moisture contamination |

| Karl Fischer Moisture Test | Quantifies ppm of water in oil (safe: <30 ppm) |

| Dielectric Strength Test | Confirms whether oil can withstand rated voltage |

| DGA (Dissolved Gas Analysis) | Detects internal arcing or decomposition caused by water ingress |

| Furan Analysis | Indicates irreversible cellulose degradation from water and heat |

Real-World Case – Flooded Transformer Recovery

- Transformer: 20 MVA, 33/11 kV in substation

- Submersion: 36 hours during typhoon-induced flood

Findings:

- Oil moisture: 72 ppm

- Breakdown voltage: 24 kV

- Furanic compounds elevated; insulation moisture ~2.3%

- Action Taken: Full oil replacement, insulation drying (90 hrs under vacuum)

- Result: Returned to service with monitoring; derated for first 6 months

Recovery cost: ~$18,000; full replacement avoided through timely testing.

What to Do After a Transformer Submersion

| Step | Description |

|---|---|

| Isolate the Unit | Disconnect all power to prevent short circuits |

| Inspect Oil Visually | Check for signs of water entry or discoloration |

| Sample and Analyze Oil | Perform KF moisture, BDV, DGA, and furan tests |

| Dehydrate or Replace Oil | Use vacuum dehydration or total oil replacement if contamination is high |

| Dry Internal Insulation | If paper is wet, a long vacuum dry-out cycle is required |

| Re-test Before Energizing | Only energize if insulation resistance and BDV meet OEM specs |

Long-Term Effects If Ignored

| Undetected Damage | Delayed Consequence |

|---|---|

| Residual Moisture in Paper | Insulation continues to decay, shortening lifespan by 40–70% |

| Low Dielectric Oil | Increased risk of future faults and reduced lightning impulse withstand |

| Internal Rust/Corrosion | Core clamps or bolts weaken, producing mechanical noise or deformation |

| Gas Pocket Formation | Hydrogen and CO accumulate, leading to fault events under load |

Preventive Measures Against Submersion Risk

| Strategy | Purpose |

|---|---|

| Elevated Platform Installation | Keeps transformer above historical flood levels |

| Breather Rerouting | Raises breather height above typical waterline |

| Sealed-Type Transformers | Consider for flood-prone indoor or outdoor areas |

| Flood Sensors and Alerting | Sends alarm to SCADA or mobile system during water-level rise |

| Perimeter Drainage Channels | Direct water flow away from transformer bases |

How Do Dry-Type Transformers React to Submersion?

Dry-type transformers are built to operate without oil, using air or cast-resin insulation for cooling and dielectric separation. Their construction makes them inherently less flammable and more environmentally friendly, which is why they are often installed in public buildings, basements, data centers, and substations. However, when submerged due to flooding or water ingress, they face serious risks to both electrical integrity and long-term reliability. Unlike oil-filled transformers, dry units lack a sealed tank, meaning moisture can penetrate directly into the insulation system.

When a dry-type transformer is submerged, water penetrates the coils, insulation, and internal components, leading to moisture absorption, reduced dielectric strength, tracking, corrosion, and potential short circuits. The epoxy or resin insulation may appear intact but can harbor trapped moisture, making post-submersion operation dangerous without thorough drying and testing.

Even brief submersion requires special handling, dehumidification, and insulation resistance checks before re-energization.

Dry-type transformers are waterproof and can resume operation immediately after a flood.False

Dry-type transformers are air-insulated and not sealed against water; submersion allows moisture into insulation, which must be dried and tested before safe use.

How Water Affects Dry-Type Transformer Components

| Component | Effect of Submersion |

|---|---|

| Resin/Epoxy Windings | Absorb moisture; microscopic cracks trap water |

| Core and Frame | Surface rust or corrosion on exposed steel parts |

| Terminal Connections | Oxidation, tracking, or loose contacts from water exposure |

| Insulation Materials | Dielectric breakdown or surface conductivity increase |

| Ventilation Pathways | Water intrusion complicates drying; creates humid zones inside |

Immediate Risks Post-Submersion

| Risk Type | Description |

|---|---|

| Dielectric Failure | Moisture lowers coil insulation resistance → arc flash possible |

| Tracking and Surface Flashover | Water residue creates conductive paths over resin or terminals |

| Internal Arcing | Even small voltage can bridge gaps through dampened insulation |

| Delayed Failure | Unit may start but fail under load once trapped moisture heats up |

| Insulation Degradation | Accelerated aging if resin integrity is breached by prolonged soak |

Case Study – Dry-Type Transformer in Flooded Basement

- Transformer: 500 kVA, 11/0.4 kV VPI dry-type unit

- Submersion: 20 cm water for 4 hours after basement drainage pump failure

Inspection Results:

- IR <1 MΩ (normal ≥200 MΩ)

- White salt deposits and surface tracking on terminal board

- Condensation inside coil end turns

- Action Taken: Dehumidification chamber drying + oven baking

- Outcome: Passed high-voltage test after 72 hrs of drying; reinstalled with IP-rated enclosure

Drying and testing saved the unit—early energization would have led to failure.

Drying and Recovery Procedure

| Step | Description |

|---|---|

| Disconnect and Isolate | Remove from power and secure area |

| Visual Inspection | Check for water lines, corrosion, tracking, and insulation breakdown |

| Initial IR Test | Use megohmmeter (≥1000 V) to measure insulation resistance of coils |

| Drying Process | Oven bake (60–80 °C), forced hot air drying, or humidity chamber drying |

| Repeat IR and HV Test | Ensure insulation has recovered before safe energization |

Guidelines for Re-Use After Submersion

| Test or Condition | Acceptable Value/Action |

|---|---|

| Insulation Resistance (IR) | >200 MΩ phase-to-phase and phase-to-ground |

| Dielectric Withstand Test | 3.0–5.0 kV for 1 minute (based on voltage class) |

| Moisture Signs in Resin | No bubbling, delamination, or discoloration |

| Core Rust Level | Surface rust permissible if not affecting magnetic path |

| Terminal Cleanliness | Must be dry, tight, and oxidation-free |

Long-Term Effects If Not Properly Dried

| Consequence | Description |

|---|---|

| Permanent Moisture Trapping | Resin-coated coils may absorb and retain moisture |

| Reduced Life Expectancy | Higher internal losses and faster thermal aging post-submersion |

| Hidden Weak Points | Weak spots only revealed under future thermal or voltage stress |

| Corrosion of Clamps and Core | Rust reduces mechanical integrity over time |

Best Practices for Flood-Prone Installations

| Design Feature or Action | Purpose |

|---|---|

| Elevated Mounting or Platform | Keeps transformer above flood level |

| IP54+ Rated Enclosure | Adds splash and dust resistance to dry-type unit |

| Drainage and Sump Pumps | Prevents water accumulation around transformer base |

| Humidity Sensor Alarms | Monitors internal moisture in electrical rooms |

| Annual IR Testing | Detects insulation degradation even without visible water |

Can a Submerged Transformer Be Recovered?

When a transformer is submerged—whether due to a flood, storm surge, or basement inundation—it raises serious questions about safety, reliability, and viability. Fortunately, depending on the type of transformer, depth and duration of submersion, and immediate response, a transformer may not always require replacement. With the right recovery procedures, equipment, and diagnostics, both oil-immersed and dry-type transformers can sometimes be safely refurbished and returned to service.

Yes, a submerged transformer can often be recovered, provided the oil, insulation, and internal components have not suffered irreversible damage. The recovery process involves isolation, oil sampling and dehydration, insulation drying, dielectric testing, and mechanical inspection. Transformers submerged for short durations or that remained de-energized have a higher chance of successful restoration.

Timely action is critical—delayed drying or energization can lead to permanent damage or unsafe operation.

A transformer must always be scrapped if submerged.False

While some submerged transformers may be beyond repair, many can be recovered through controlled oil dehydration, insulation drying, and post-restoration testing.

Key Factors That Determine Recoverability

| Factor | Influence on Recovery Outcome |

|---|---|

| Transformer Type | Oil-immersed units more likely recoverable than dry-type units |

| Submersion Duration | Shorter exposure reduces water penetration and degradation risk |

| Whether Energized | Energized units during flooding suffer higher internal damage |

| Seal Integrity | Well-maintained gaskets/breathers slow water entry |

| Response Time | Faster disconnection and drying boost recovery success |

Step-by-Step Recovery Process

| Phase | Key Actions |

|---|---|

| 1. Isolation & Inspection | Disconnect transformer; document water level, ingress points |

| 2. Oil Sampling (If Applicable) | Check for water, sludge, and gas contamination |

| 3. Oil Dehydration or Replacement | Use vacuum dehydration to restore oil quality or flush with new oil |

| 4. Insulation Dry-Out | Use hot air, vacuum ovens, or nitrogen-purging to dry internals |

| 5. Core and Coil Inspection | Look for rust, deformation, tracking, or moisture pockets |

| 6. Electrical Testing | IR, polarization index, BDV, DGA, and furan tests |

| 7. Load Testing and Monitoring | Return to service with reduced load and temporary monitoring |

Typical Diagnostic Targets for Recovery

| Parameter | Pass Criteria for Restoration |

|---|---|

| Insulation Resistance (IR) | >200 MΩ phase-to-ground (dry-type) / >500 MΩ (oil-filled) |

| Breakdown Voltage (BDV) | >50–60 kV for mineral oil |

| Karl Fischer Moisture (Oil) | <30 ppm ideal; <10 ppm for sensitive equipment |

| Furan Content (Oil) | <0.1 mg/L preferred for low-aged paper |

| DGA Gas Levels | No high acetylene or high hydrogen if not previously energized |

Recovery Feasibility by Transformer Type

| Transformer Type | Typical Recovery Outcome |

|---|---|

| Oil-Immersed (Sealed) | High recovery potential if not energized |

| Oil-Immersed (Conservator) | Recoverable with oil dehydration and paper dry-out |

| Dry-Type (Cast Resin) | Recoverable if not cracked or contaminated internally |

| Dry-Type (Open Air Cooled) | Risky unless drying and IR testing are conclusive |

Real-World Example – Oil Transformer Recovery

- Transformer: 25 MVA, 132/33 kV power transformer

- Submersion: 18 hours in 60 cm floodwater

Action:

- Vacuum dehydration of 1200 L oil

- 96-hour insulation vacuum oven cycle

- Replaced gaskets, breathers, and bottom bushing seals

- Tests: Passed IR, DGA, BDV; returned to service within 8 days

Total cost: 22% of replacement value; transformer has operated safely for 4 years post-recovery.

When Recovery Is Not Recommended

| Red Flag | Reason |

|---|---|

| Energized During Submersion | High likelihood of arc damage, bushing failure, or core burnout |

| Heavy Rust on Core/Windings | Indicates prolonged water ingress and insulation weakening |

| Furan >2.0 mg/L | Paper insulation may have lost tensile strength permanently |

| Persistent Low IR (<50 MΩ) | Sign of deep moisture entrapment |

| Cracked Epoxy Coils (Dry-Type) | Structural compromise—unsafe to reuse |

Post-Recovery Best Practices

| Practice | Benefit |

|---|---|

| Install Oil-Level and Moisture Sensors | Early alert if water re-intrusion occurs |

| SCADA-Linked DGA Monitoring | Tracks gas buildup during probation period |

| Routine IR and BDV Tests | Confirms long-term insulation stability |

| Replace All Gaskets and Seals | Prevent future moisture ingress |

| Load in Stages | Start with 50–70% load and monitor heat/load profile |

What Immediate Actions Should Be Taken After Submersion?

When a transformer has been submerged—whether due to a flood, burst pipe, or water ingress incident—speed and procedure are critical. What you do in the first 12–48 hours determines whether the transformer can be safely recovered or must be replaced. Immediate actions should focus on preventing energized failure, assessing internal contamination, and preserving insulation integrity. Acting without a defined protocol can lead to dangerous outcomes, including arcing, explosion, or permanent damage.

The immediate actions after a transformer submersion include isolating and de-energizing the unit, preventing unauthorized access, inspecting for physical damage, collecting oil or insulation samples for moisture and dielectric testing, starting dehydration and drying procedures, and documenting the event. Under no circumstance should the transformer be re-energized before passing safety diagnostics.

Quick, methodical action maximizes recovery potential and minimizes risk.

Transformers can be re-energized immediately after floodwater recedes.False

Post-submersion transformers must undergo oil or insulation testing, drying, and mechanical inspection before safe re-energization. Energizing a wet transformer is highly dangerous.

Priority Actions Within the First 24 Hours

| Action | Purpose and Outcome |

|---|---|

| 1. De-Energize Immediately | Prevent short circuits, internal arcing, or explosion risks |

| 2. Lockout and Tagout | Prevents accidental re-energization during inspection |

| 3. Restrict Access | Avoid electrocution risk or contamination from handling |

| 4. Visual Inspection | Look for water lines, rust, broken seals, oil spillage |

| 5. Sample Oil or Measure IR | Begin assessment of moisture, contamination, and insulation integrity |

| 6. Notify Maintenance or OEM | Report event for support and next-step evaluation |

| 7. Begin Drying Preparations | If oil is cloudy or coils are wet, initiate drying immediately |

Key Safety Considerations

| Safety Task | Importance |

|---|---|

| Ground the Transformer Frame | Protects from static buildup and possible live leakage |

| Use PPE for Wet Equipment | Rubber gloves, boots, and insulated tools mandatory |

| Check Bushing Integrity | Cracks or internal moisture can lead to flashover |

| Cordon Off Area | Prevents unqualified personnel from tampering or taking photos |

Diagnostic Sampling & Testing Priorities

| Sample/Test | Purpose |

|---|---|

| Oil Sampling (KF & BDV) | Determines moisture level and breakdown strength in oil |

| DGA (if applicable) | Detects gas generation from possible internal arcing |

| IR Test (Dry-Type) | Measures insulation resistance to assess drying needs |

| Visual Fluid Inspection | Cloudy or emulsified oil signals serious water contamination |

What Not to Do

| Prohibited Action | Reason |

|---|---|

| Do Not Energize | Risk of arcing, explosion, and irreversible damage |

| Do Not Open Covers Prematurely | May expose internals to more moisture or atmospheric humidity |

| Do Not Flush Oil Immediately | Retain sample for lab analysis before oil removal |

| Do Not Delay Action >24 Hrs | Water absorption into paper insulation increases exponentially |

Example of Successful Immediate Response

- Unit: 2.5 MVA oil-immersed transformer

- Submerged: 30 cm in floodwater for ~10 hours

Action:

- De-energized within 15 minutes

- Oil sampled: moisture = 64 ppm

- Vacuum dehydration started within 12 hours

- Unit tested and re-commissioned within 5 days

Outcome: No permanent damage, safe operation resumed with monitoring.

Temporary On-Site Equipment Needed

| Equipment | Function During Initial Response |

|---|---|

| Insulated HV Test Kit | Safe insulation resistance and leakage testing |

| Oil Sampler & Glass Bottles | Collect uncontaminated oil for KF and BDV lab analysis |

| Vacuum Dehydration Skid | Immediate removal of water and gases from oil (oil-immersed only) |

| Hot Air Blower/Dehumidifier | Starts coil drying (dry-type or open coils) |

| Moisture Meter | Monitors drying progress and confirms safe moisture levels |

Document and Report the Incident

| Information to Record | Why It Matters |

|---|---|

| Date and Duration of Submersion | Determines exposure risk |

| Transformer Serial and Location | Links data to asset for future reference |

| Weather/Event Cause | May influence insurance or disaster recovery protocols |

| Initial Visual Observations | Helps guide diagnostics and OEM consultation |

| Test Data & Photos | Create a traceable fault and repair history |

How Can Submersion Risks Be Prevented in the Future?

Floods and high water levels are increasingly common due to climate change, urban runoff, and storm surges, posing growing threats to both oil-immersed and dry-type transformers. Submersion events can lead to equipment damage, outages, fire risk, and costly recovery. Fortunately, these risks can be significantly minimized through engineering design, environmental monitoring, and proactive maintenance practices. Whether installing new equipment or retrofitting existing units, site-specific submersion prevention planning is essential.

Submersion risks can be prevented through strategic transformer siting, elevated platforms or plinths, sealed enclosures with IP ratings, site drainage improvements, sump pumps, real-time weather monitoring, and preventive maintenance of seals, breathers, and housing. Designing for historical flood levels and zoning transformers away from water pathways are also key mitigation measures.

Preventive infrastructure is often far less costly than the disruption, damage, and downtime caused by even one flood event.

Submersion risk is inevitable and cannot be mitigated.False

Submersion risks can be effectively prevented through site design upgrades, elevation, sealing, and monitoring systems tailored to flood-prone environments.

Engineering Controls for Submersion Prevention

| Preventive Measure | Function and Benefit |

|---|---|

| Elevated Platforms or Plinths | Lifts transformer above known flood levels to prevent water contact |

| IP-Rated Transformer Enclosures | Protects components from water spray or shallow flooding |

| Waterproof Bushing Seals and Gaskets | Blocks seepage into terminal and oil chamber interfaces |

| Conservator Rerouting (Oil-Type) | Elevates breather and piping above expected flood height |

| Drainage Channels and Berms | Direct water away from transformer pad and access roads |

Site Selection and Layout Optimization

| Factor | Preventive Value |

|---|---|

| Avoid Low-Lying Zones | Reduces flood exposure naturally |

| Analyze Historical Flood Maps | Ensures platform height exceeds 100-year water level mark |

| Install Away from Waterways | Keep transformers clear of drainage ditches or near wetlands |

| GIS Flood Risk Zoning | Use mapping tools to guide new site placement |

Utility Best Practices and Retrofit Strategies

| Action | Long-Term Impact |

|---|---|

| Raise Existing Units | Retrofit existing pads with plinth extensions |

| Install Submersible or Perimeter Pumps | Removes water buildup from around transformer site |

| Use Hermetically Sealed Transformers | Especially for underground or basement applications |

| Deploy Flood Monitoring Sensors | Notifies operators of rising water levels in real time |

| Maintain and Replace Seals | Keeps equipment watertight year after year |

Real-World Success Example

- Location: Coastal substation in hurricane zone

- Previous event: Flooded dry-type transformer in basement; $45,000 damage

Upgrade strategy:

- Replaced unit with IP55 cast resin transformer

- Elevated it 1.5 m above floor level on platform

- Added sump pump and flood alarm

- Result: Survived 2023 storm with zero damage or downtime

Investment: ~$9,000 | Savings: Prevented loss of full transformer and service disruption.

Preventive Drainage and Civil Engineering Solutions

| Civil Feature | Function |

|---|---|

| Sloped Concrete Base | Prevents water pooling around transformer footings |

| Stormwater Ducts | Channels runoff from heavy rain away from power yard |

| Perimeter Berms or Flood Walls | Acts as a physical barrier against water entry |

| Backflow Valves on Pipes | Stops sewage or drain water intrusion during storms |

| Access Ramps and Raised Switchgear | Ensures safe technician access during high water events |

Monitoring and Early Warning Systems

| System | Benefit |

|---|---|

| Flood Sensors with Alarms | Detect early water levels and trigger alerts |

| Weather Forecast Integration | Prepare crews and shut down units in advance of major events |

| Remote Oil Level/Pressure Monitors | Detects signs of submersion or seal breach |

| SCADA Connectivity | Enables visibility of flood-prone asset locations in real time |

Compliance and Design Guidelines

| Standard or Guidance | Relevance |

|---|---|

| IEEE 693 / ASCE 24 | Flood-resistant design for substations and electrical infrastructure |

| FEMA FIRM Maps | Zoning for base flood elevations and safe transformer siting |

| IEC 60076-22 (Environmental Factors) | Considers humidity and water risk in transformer deployment |

| Utility Flood Mitigation Plans | Regional best practices for asset protection |

Conclusion

Submersion in water can cause catastrophic failure in both oil-immersed and dry-type transformers. The risk of internal insulation failure, corrosion, and fire is high, and safety must be the top priority in response efforts. While some submerged transformers may be salvaged through thorough drying and testing, many require full replacement. Preventive planning, such as proper site selection and flood mitigation, is critical to avoid such high-impact events.

FAQ

Q1: What happens if a transformer is submerged in water?

A1: Submerging a transformer in water can cause:

Moisture ingress into insulation systems (oil or resin)

Loss of dielectric strength, increasing risk of internal arcing

Short circuits or ground faults

Core and coil corrosion, especially if energized

In oil-filled transformers, water can contaminate the oil, making it unsafe for operation. In dry-type units, moisture leads to tracking and insulation breakdown.

Q2: Can a submerged transformer be used again?

A2: Reuse depends on:

Type of transformer (oil vs. dry)

Duration and depth of submersion

Presence of contaminants (saltwater, mud, etc.)

Recovery requires:

Thorough drying and insulation testing

Oil filtering or complete replacement

IR testing, dielectric breakdown tests, and possibly winding resistance checks

If damage is extensive, replacement may be more cost-effective.

Q3: What are the immediate risks if a live transformer is submerged?

A3: If energized, it may:

Explode or catch fire due to insulation failure

Electrocute personnel nearby

Trigger grid faults and cascading outages

Immediate shutdown and isolation are critical for safety and damage control.

Q4: How can submerged transformers be safely recovered?

A4: Recovery process includes:

De-energizing and isolating the unit

Thorough drying using vacuum dehydration or oven drying

Oil testing and replacement (if oil-filled)

Electrical diagnostic tests (IR, DGA, BDV, SFRA)

Visual inspection for rust, damage, and water traces

Professional assessment is required before re-energizing.

Q5: How can flooding risks be mitigated for transformers?

A5: Mitigation strategies:

Elevated installation platforms

Waterproof enclosures or submersible designs for sensitive areas

Proper drainage systems and site grading

Remote monitoring systems for humidity and oil quality

Selecting dry-type transformers in flood-prone or indoor environments reduces water damage risk.

References

"What Happens When a Transformer Gets Wet?" – https://www.electrical4u.com/wet-transformer-effects

"IEEE C57.140: Guide for Evaluation and Reconditioning of Liquid-Immersed Transformers" – https://ieeexplore.ieee.org/document/8965624

"NREL: Disaster Recovery for Electrical Infrastructure" – https://www.nrel.gov/docs/transformer-flood-response.pdf

"Doble: Testing and Drying Water-Contaminated Transformers" – https://www.doble.com/transformer-flood-testing

"ScienceDirect: Analysis of Water Impact on Transformer Insulation" – https://www.sciencedirect.com/water-exposure-transformer-study