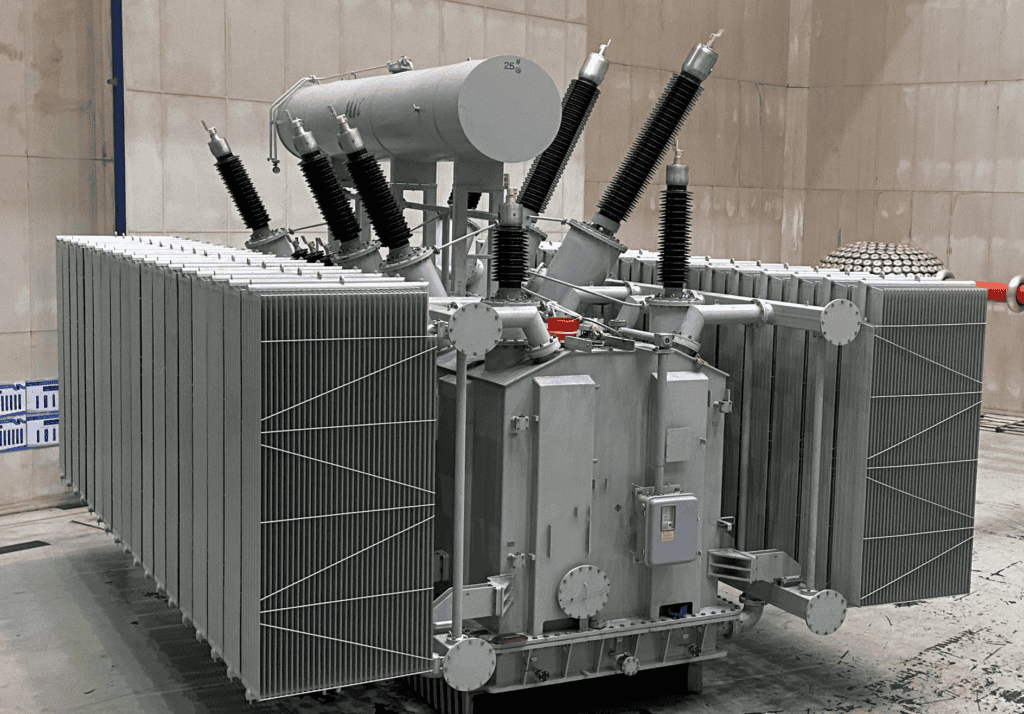

In the world of electrical engineering and transformer manufacturing, adherence to technical standards ensures safety, reliability, and interoperability. Two of the most recognized standard-setting bodies in the U.S. are the Institute of Electrical and Electronics Engineers (IEEE) and the American National Standards Institute (ANSI). While both play vital roles, they differ in purpose, scope, and global reach. This article explores how IEEE and ANSI standards compare, especially in the context of power transformers.

What Are IEEE and ANSI in Relation to Transformers?

In the electrical power industry, standards ensure reliability, safety, and compatibility across transformer designs, testing, installation, and operation. However, confusion often arises when referencing IEEE and ANSI—especially among buyers, engineers, and facility managers new to high-voltage equipment. Are they the same? Are they both required? What do they regulate? Misunderstanding their roles can lead to non-compliance, failed inspections, or even equipment mismatch. This article clearly explains what IEEE and ANSI are, how they differ, and how they relate specifically to transformers and their specifications.

IEEE (Institute of Electrical and Electronics Engineers) is a professional organization that publishes technical standards and guides for transformer design, testing, performance, and protection. ANSI (American National Standards Institute) accredits and approves national standards in the U.S., including many IEEE documents. In transformers, IEEE sets the technical content, while ANSI ensures the national consensus process and public accessibility.

Understanding IEEE and ANSI helps ensure that your transformer systems are engineered, installed, and maintained according to recognized U.S. industry standards.

ANSI and IEEE are the same organization.False

ANSI is a standards approval body that accredits various organizations, including IEEE. IEEE is a technical body that develops standards used in the electrical industry, many of which ANSI approves.

What Is IEEE?

🔧 Institute of Electrical and Electronics Engineers

- A global professional association of engineers

- Develops voluntary, consensus-based technical standards

- Standards are created by working groups of industry experts

- Covers power, electronics, communications, and computing

In the context of transformers, IEEE:

- Creates detailed technical specifications

- Guides testing, operation, safety, and maintenance

- Offers application-specific standards for different transformer types

Key IEEE Transformer Standards

| IEEE Standard | Title / Scope |

|---|---|

| IEEE C57.12.00 | General Requirements for Liquid-Immersed Distribution Transformers |

| IEEE C57.12.90 | Standard Test Code for Transformers |

| IEEE C57.91 | Guide for Loading Mineral-Oil-Immersed Transformers |

| IEEE C57.104 | Guide for DGA (Dissolved Gas Analysis) in Oil-Filled Transformers |

| IEEE C57.110 | Guide for Transformer Temperature Rise and Loading |

| IEEE C57.12.01 | Standard for Dry-Type Transformers |

| IEEE C57.13 | Standard for Current Transformers |

| IEEE C57.19.00/01 | Standards for Bushings |

What Is ANSI?

🏛️ American National Standards Institute

- A non-profit, non-governmental organization

- Oversees and approves national standards developed by organizations like IEEE, NEMA, NFPA

- Coordinates U.S. standardization with international bodies (e.g., ISO, IEC)

In the context of transformers, ANSI:

- Approves IEEE standards as national standards

- Provides a framework for public review and consensus

- Does not write technical content itself

Example:

- IEEE writes C57.12.00 technical content

- ANSI reviews and approves it → becomes ANSI/IEEE C57.12.00

ANSI creates technical content for transformer standards.False

ANSI is an accrediting and approval body; it does not write technical standards itself. Organizations like IEEE or NEMA provide the technical material.

IEEE vs. ANSI: Clear Distinction

| Feature | IEEE | ANSI |

|---|---|---|

| Type of Body | Technical organization | National accrediting organization |

| Function | Develops technical standards | Approves and coordinates national standards |

| Involved in Transformer Specs? | ✅ Yes – writes all U.S. technical specs | ✅ Yes – approves IEEE specs as U.S. standards |

| Standard Naming | IEEE C57.xx | ANSI/IEEE C57.xx |

| Global Reach | International (used in many countries) | Primarily U.S.-focused, aligns with ISO/IEC |

Why IEEE/ANSI Standards Matter for Transformers

✅ Design & Procurement

Transformer designs must conform to IEEE specs for:

- Temperature rise

- Dielectric withstand

- Impedance and loading

- Ensures compatibility with U.S. grid systems

✅ Testing & Factory Acceptance

IEEE C57.12.90 outlines mandatory testing procedures

- Turns ratio

- Insulation resistance

- Induced and applied voltage

- Temperature rise test

✅ Field Installation & Operation

IEEE C57.91 provides:

- Loading guides for ambient and emergency conditions

- Cooling class behavior (ONAN, ONAF, etc.)

IEEE C57.104 outlines:

- Gas threshold levels for oil analysis

- Interpretation methods for fault detection

✅ Regulatory Compliance

- Utilities, contractors, and inspectors often require IEEE/ANSI-compliant equipment

Non-compliant transformers may:

- Be rejected at site

- Invalidate insurance or safety approvals

- Fail to pass inspection or load tests

IEEE/ANSI vs. Other Standards Bodies

| Organization | Region | Relevance to Transformers |

|---|---|---|

| IEEE/ANSI | United States | Primary standards for North American grid |

| IEC | Global | Used internationally (Europe, Asia, etc.) |

| NEMA | U.S. | Focuses on enclosures, ratings, and construction |

| UL | U.S. | Certifies safety and fire performance |

| CSA | Canada | Often adopts IEEE/ANSI with Canadian amendments |

| GB/T | China | China's national transformer standard system |

How Are IEEE and ANSI Transformer Standards Developed and Maintained?

Understanding the development and maintenance of transformer standards—especially those from IEEE and ANSI—is essential for engineers, manufacturers, utilities, and regulators. Yet, many still believe that standards are written by a single committee or imposed top-down. This misconception leads to confusion about updates, revisions, and compliance. In reality, transformer standards are the result of global collaboration, rigorous consensus, and periodic review, ensuring they reflect current technology, safety, and application needs. In this article, we’ll walk through how IEEE and ANSI standards are created, reviewed, approved, and maintained in the electrical transformer industry.

Transformer standards from IEEE are developed by volunteer working groups composed of industry experts, utility representatives, academics, and manufacturers. These groups follow a consensus-driven process to draft, ballot, revise, and update technical standards. ANSI ensures the process meets national openness and fairness criteria, and officially approves the standard for use in the U.S. Standards are reviewed at least every 5 years to remain current.

This structured process ensures that standards stay relevant, technically valid, and aligned with emerging technologies and regulations.

IEEE transformer standards are written and published by a single engineering company.False

IEEE standards are developed collaboratively by committees of volunteers from across the electrical industry, including engineers, researchers, manufacturers, and utilities. No single entity controls the content.

Step-by-Step: How IEEE/ANSI Transformer Standards Are Developed

🛠️ 1. Proposal and Initiation

A new standard or revision is proposed based on:

- New technology (e.g., digital monitoring, dry-type materials)

- Field feedback or safety issues

- Regulatory or environmental requirements

A Project Authorization Request (PAR) is submitted to IEEE Standards Association (IEEE-SA) for approval.

Once approved, a Working Group (WG) is formed under the IEEE Transformers Committee (PES/TC).

| Key IEEE Committee | Role |

|---|---|

| IEEE PES/Transformers Committee | Oversees transformer standards |

| IEEE C57 Working Groups | Focus on specific documents (e.g., C57.12.90) |

👥 2. Working Group Drafting

WGs typically consist of:

- OEM engineers

- Utility experts

- Testing labs

- Academia and consultants

The group meets regularly to:

- Discuss scope and goals

- Draft new technical content or revisions

- Review field data and user experience

- Incorporate international alignment (e.g., IEC harmonization)

Drafts are developed section-by-section, including:

- Definitions

- Electrical/thermal parameters

- Testing methods

- Tables, diagrams, and calculation formulas

✅ 3. Consensus and Balloting

Once the draft is complete, it enters the IEEE-SA ballot process:

- Open to balanced stakeholders (manufacturers, users, general interest)

- Requires 75% minimum response rate

- Must achieve ≥75% affirmative vote

Comments are reviewed, addressed, and re-balloted if necessary

IEEE standards require formal consensus from a balanced group of stakeholders before publication.True

IEEE follows a formal ballot process requiring broad industry representation and consensus approval before finalizing any standard.

🏛️ 4. ANSI Approval

IEEE submits the approved standard to ANSI for national standard designation

ANSI reviews the process to ensure it was:

- Open and transparent

- Non-dominated by any one group

- Inclusive of public review periods

If approved, it becomes an ANSI/IEEE standard

| Example Title | Status |

|---|---|

| IEEE C57.12.00 | IEEE Standard (technical) |

| ANSI/IEEE C57.12.00 | National Standard (U.S.-approved) |

📅 5. Publication and Adoption

Published and made available through:

- IEEE Xplore Digital Library

- ANSI.org or IEEE-SA.org

- Transformer manufacturers' specifications

Utilities and engineering firms incorporate them into:

- Procurement specs

- Factory acceptance test (FAT) plans

- Installation and safety guidelines

How Standards Are Maintained and Updated

| Activity | Frequency / Trigger |

|---|---|

| Mandatory Review | Every 5 years (IEEE-SA policy) |

| Interim Amendments | As needed (e.g., technology updates) |

| User Feedback / Corrections | Collected via IEEE-SA and WG forums |

| Harmonization | Reviewed for IEC/ISO alignment |

| New Technology Additions | Integrated via revision or supplement |

Working Groups may reconvene to:

- Clarify ambiguous requirements

- Update aging test procedures

- Expand scope (e.g., to cover digital transformers)

Key IEEE Transformer Standards Maintenance Timeline (Examples)

| Standard Name | Last Update | Next Scheduled Review |

|---|---|---|

| IEEE C57.12.00 (General Requirements) | 2020 | 2025 |

| IEEE C57.12.90 (Test Code) | 2021 | 2026 |

| IEEE C57.104 (DGA Guide) | 2019 | 2024 |

| IEEE C57.91 (Loading Guide) | 2022 | 2027 |

| IEEE C57.110 (Temperature Guide) | 2020 | 2025 |

IEEE transformer standards are reviewed and updated on a regular cycle.True

IEEE mandates a review of each standard every five years to ensure relevance, incorporate new technology, and respond to user feedback.

International Collaboration and Harmonization

IEEE and ANSI also work with other global organizations to reduce technical duplication and streamline transformer interoperability:

| Partner Body | Role & Interaction with IEEE/ANSI |

|---|---|

| IEC | Joint development and alignment (e.g., IEC 60076) |

| NEMA | Ensures consistent construction and labeling |

| ISO | Quality and safety process alignment |

| CSA (Canada) | Adopts IEEE/ANSI with national adaptations |

How You Can Participate or Stay Updated

📘 For Engineers, Specifiers, and Inspectors:

- Purchase and read latest IEEE C57 series documents

- Join IEEE PES Transformers Subcommittee mailing list

- Attend technical conferences (e.g., IEEE PES T\&D Expo)

- Request clarification from Working Group members

🛠️ For Manufacturers and Test Labs:

- Participate in Working Groups

- Vote during balloting

- Submit test and field performance data

- Align internal QC procedures with new revisions

Which Areas of Transformer Design and Testing Do IEEE and ANSI Standards Cover?

Transformers are at the heart of electrical power systems—and due to their critical function, they must adhere to rigorous design and testing protocols. But who defines these protocols, and what exactly do they cover? In the U.S. and many other regions, IEEE and ANSI standards form the foundation for transformer design, testing, installation, and maintenance. However, many engineers and operators are unclear about the full scope of these standards. This confusion can lead to specification errors, failed compliance, or unsafe installations. This guide clearly outlines which areas of transformer engineering are governed by IEEE/ANSI standards and how each standard contributes to building and testing reliable transformer systems.

IEEE and ANSI standards cover nearly all critical aspects of transformer design and testing, including electrical ratings, temperature rise, insulation coordination, short-circuit strength, sound level, cooling methods, safety protections, testing protocols, monitoring systems, and loading practices. These standards ensure transformers perform reliably, safely, and consistently across various applications and environments.

Whether you're specifying a new unit or testing an existing one, adherence to IEEE/ANSI standards ensures your transformer meets the required operational, thermal, and dielectric performance criteria.

IEEE and ANSI standards cover only transformer manufacturing and not testing or performance.False

IEEE and ANSI standards define not only manufacturing requirements but also detailed testing procedures, performance criteria, protection, and application guidance.

Overview Table: IEEE/ANSI Standard Coverage by Transformer Function

| Design or Testing Area | Covered By IEEE/ANSI Standard(s) |

|---|---|

| General Construction & Ratings | IEEE C57.12.00, ANSI C57.12.01 |

| Electrical Performance | IEEE C57.12.90 (test code), C57.91 (loading), C57.110 (temperature rise) |

| Dielectric/Impulse Testing | IEEE C57.12.90 |

| Short-Circuit Withstand | IEEE C57.12.90, IEEE C57.109 |

| Temperature Rise Limits | IEEE C57.91, IEEE C57.110 |

| Insulation Classes | ANSI C57.12.00, IEEE C57.12.01 |

| Bushings | IEEE C57.19.00, C57.19.01 |

| Tap Changers | IEEE C57.131, IEEE C57.135 |

| Sound Levels & Vibration | IEEE C57.12.90 (Annex A), IEEE C57.136 |

| Cooling Methods & Ratings | IEEE C57.12.00, IEEE C57.12.90, IEEE C57.91 |

| Overload & Loading Guidelines | IEEE C57.91 |

| Condition Monitoring & Sensors | IEEE C57.104 (DGA), IEEE C57.143 (thermal aging), IEEE C57.139 (PD monitoring) |

| Fire Safety / Environmental Standards | IEEE C57.12.29 (corrosive env.), IEEE C57.163 (natural ester fluids) |

| Test Procedures | IEEE C57.12.90 (factory, routine, type, and special tests) |

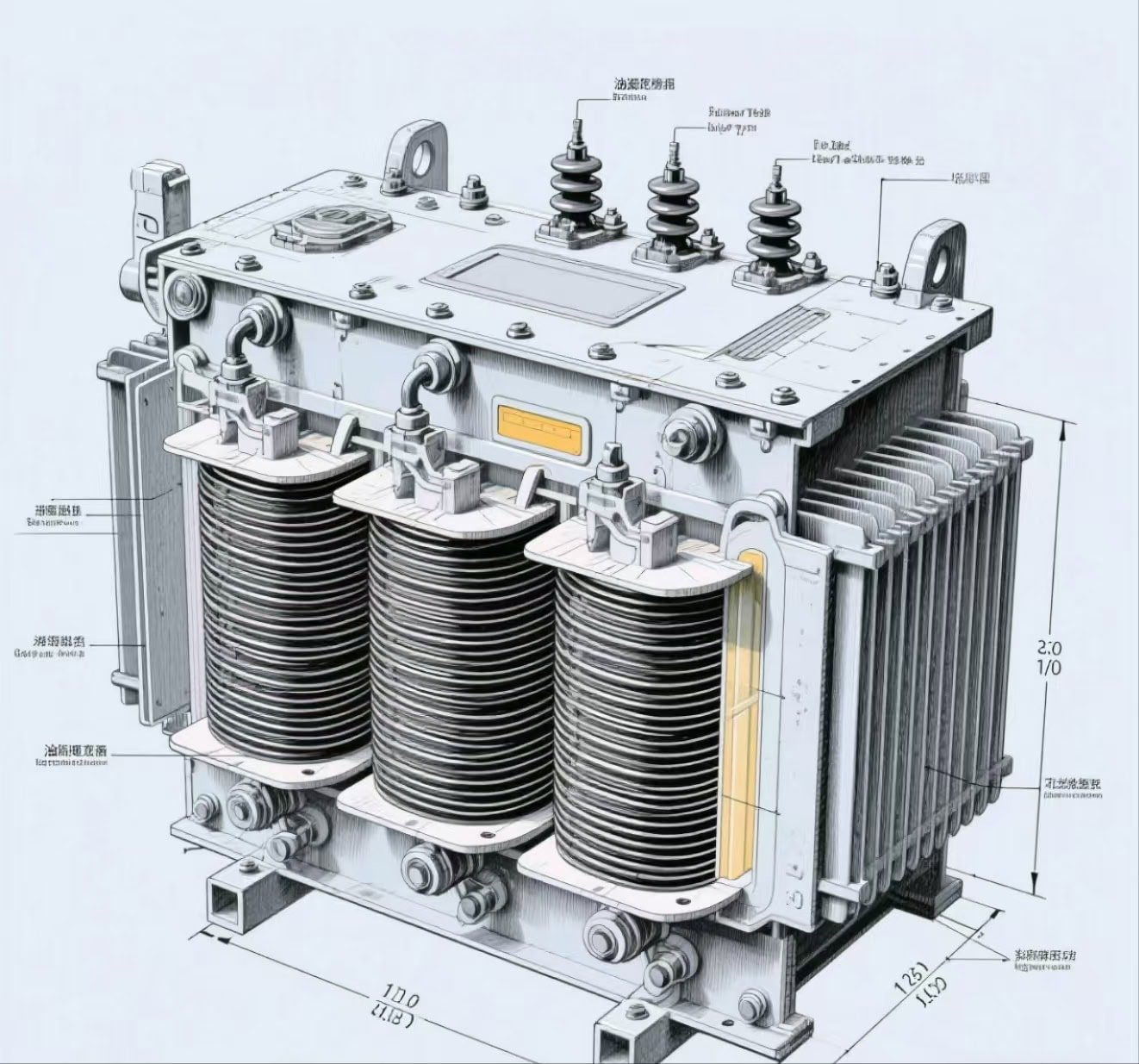

1. Mechanical and Electrical Design Specifications

Governed By:

- IEEE C57.12.00: General Requirements for Liquid-Immersed Transformers

- IEEE C57.12.01: General Requirements for Dry-Type Transformers

- ANSI/IEEE C57.12.10: Distribution Transformers 500 kVA and below

Key Aspects Covered:

- Rated voltage and current

- Impedance and load losses

- Vector group and connection symbols

- Phase configuration

- Dimensions, grounding, terminations, nameplate data

These standards define what a transformer must be able to do under nominal conditions.

2. Thermal and Temperature Rise Criteria

Governed By:

- IEEE C57.110: Temperature Rise and Insulation Classes

- IEEE C57.91: Loading Guide for Mineral-Oil-Immersed Transformers

Covered Parameters:

- Permissible hot-spot and top-oil temperatures

- Ambient correction factors

- Insulation class alignment (e.g., A, B, F, H)

- Guidelines for emergency and cyclic loading

- Cooling class definitions (e.g., ONAN, ONAF, OFAF, AF, AN)

| Insulation Class | Max Temp Rise | Total Allowed Temp |

|---|---|---|

| Class A | 55°C | 105°C |

| Class F | 65°C | 155°C |

| Class H | 80°C | 180°C |

IEEE transformer standards define insulation class and allowable temperature rise.True

IEEE C57.110 and C57.91 clearly specify insulation classes, maximum hot-spot temperatures, and guidelines for thermal loading and derating.

3. Dielectric Strength and Testing

Governed By:

- IEEE C57.12.90: Standard Test Code for Transformers

- IEEE C57.98: Guide for Transformer Impulse Testing

Dielectric Tests Include:

- Induced voltage withstand

- Applied voltage (AC dielectric) test

- Full wave lightning impulse test

- Switching impulse for HV transformers

- Insulation resistance and polarization index

These tests simulate electrical stresses such as lightning surges, switching events, and insulation breakdown scenarios.

4. Short-Circuit Strength & Mechanical Withstand

Governed By:

- IEEE C57.12.90 (short-circuit testing)

- IEEE C57.109: Guide for Short-Circuit Testing of Distribution Transformers

Covered Areas:

- Maximum fault current withstand (rms kA)

- Mechanical bracing and coil integrity under dynamic forces

- Duration and waveform of test fault

- Pass/fail criteria based on winding deformation or resistance change

5. Sound Level and Noise Emission

Governed By:

- IEEE C57.12.90 Annex A: Sound level limits

- IEEE C57.136: Guide for Sound Control for Dry-Type Transformers

Defined Metrics:

- Maximum dB(A) at 1 meter for given kVA rating

- Correction for ambient and enclosure effects

- Mitigation strategies: acoustic panels, isolation pads, fan control logic

6. Bushings, Tap Changers, and Accessories

Governed By:

- IEEE C57.19.00 and C57.19.01: Bushings

- IEEE C57.131: Guide for Tap Changers

- IEEE C57.135: Transformer Tap-Changer Controls

Includes:

- Thermal and mechanical ratings of bushings

- Insulation coordination

- Tap changer step voltage, range, and control logic

- OLTC vs. manual load tap changers

7. Testing Procedures and Acceptance Criteria

Governed By:

- IEEE C57.12.90

Test Types Covered:

| Test Type | Description |

|---|---|

| Routine Tests | Performed on every unit (e.g., ratio, impedance, resistance) |

| Type Tests | On design samples to verify design (e.g., dielectric, temperature) |

| Special Tests | Optional by client (e.g., impulse, sound level, DGA baseline) |

| Factory Acceptance | Based on IEEE/ANSI specs plus contract terms |

IEEE C57.12.90 provides the test methods and acceptance criteria for transformer testing.True

IEEE C57.12.90 is the authoritative standard for testing transformer electrical, thermal, and dielectric performance at the factory and field level.

8. Monitoring and Condition Assessment

Governed By:

- IEEE C57.104: Dissolved Gas Analysis (DGA)

- IEEE C57.143: Thermal Aging and Moisture Effects

- IEEE C57.139: Partial Discharge Monitoring

- IEEE C57.163: Natural Ester Fluid Performance

Parameters Monitored:

- Hydrogen, acetylene, methane (via DGA)

- Moisture-in-paper and oil condition

- Thermal life estimation

- PD activity detection via HF/UHF sensors

These standards enable predictive maintenance and life extension of transformers through data-driven monitoring.

How Do IEEE and ANSI Standards Differ from International Standards Like IEC?

When sourcing or specifying transformers globally, one of the most important considerations is the standardization framework they comply with—IEEE/ANSI (used primarily in the United States) versus IEC (International Electrotechnical Commission, used widely across Europe, Asia, Africa, and other regions). Although these standards often serve similar functions, they are not interchangeable, and failing to understand their key differences can lead to design mismatches, test failures, or code violations. In this article, we will break down how IEEE/ANSI standards differ from IEC, and what these differences mean in practical transformer applications.

IEEE/ANSI transformer standards are used mainly in North America and are highly prescriptive in defining design, testing, and performance specifications. IEC standards, used internationally, offer more flexibility and are structured around performance-based requirements. Key differences include cooling class nomenclature, temperature rise criteria, testing sequences, insulation levels, and acceptance tolerances.

Understanding these distinctions is vital when working across international projects, harmonizing procurement, or ensuring equipment compatibility in multi-national installations.

IEC standards are identical to IEEE/ANSI transformer standards.False

Although both cover similar technical domains, IEC and IEEE/ANSI differ in testing methodology, design practices, nomenclature, and acceptance criteria.

Geographic Application of Standards

| Region | Common Standard Body |

|---|---|

| United States, Canada | IEEE/ANSI |

| Europe | IEC |

| Asia | IEC |

| Africa & Middle East | IEC |

| Latin America | Mixed (IEC + ANSI) |

IEEE/ANSI: Primarily U.S.-based, but also used in Canada and parts of Latin America

IEC: Globally recognized and often a requirement in international tenders

Summary Table: Key Differences Between IEEE/ANSI and IEC Transformer Standards

| Feature / Area | IEEE/ANSI | IEC |

|---|---|---|

| Region of Origin | U.S.A. (IEEE), U.S. National Body (ANSI) | International (Switzerland HQ, global member states) |

| Standard Structure | Series (C57.x) by equipment type and function | Modular (IEC 60076 series) by performance category |

| Cooling Classification | ONAN, ONAF, OFAF, KNAN, etc. | Same base (ONAN), but fewer variants standardized |

| Temperature Rise Limits | Fixed by insulation class (e.g., 55/65°C) | Based on rated insulation temperature and hot-spot |

| Testing Philosophy | Descriptive and test-based | Performance-based with options and tolerances |

| Short-Circuit Testing | Mandatory for design validation (C57.12.90) | Optional unless contractually specified (IEC 60076-5) |

| Impulse Test Levels | Higher for same voltage class (e.g., 150 kV BIL at 69 kV) | Lower BIL due to risk-based rationale |

| Tap Changer Standards | C57.131, C57.135 (separate documents) | IEC 60214, integrated into IEC transformer series |

| Sound Level Standards | dB(A) limits defined by power class | Similar dB(A) limits but slightly different thresholds |

| Safety & Fire Guidelines | IEEE C57.163, UL integration (dry-type, flame class) | IEC 60076-11 and 60076-16 cover safety and fire tests |

| Marking / Labeling | ANSI nameplate format (kVA, impedance, temp rise) | IEC nameplate format with thermal class and duty |

| Acceptance Testing Requirements | Comprehensive (routine, type, special in C57.12.90) | Flexible and optional based on contract (IEC 60076-1) |

| Transformer Classes | Distribution, Power, Instrument, Dry-Type, etc. | Same, with standardized insulation coordination |

| Terminology Example | “Tap changer” | “On-load tap selector” |

| Standard Updates | Every 5 years (mandatory IEEE-SA rule) | Reviewed every 5 years (IEC TC14 working groups) |

Testing Approach: Mandatory vs Optional

IEEE/ANSI (e.g., C57.12.90):

- Highly structured testing with defined acceptance criteria

- All tests are typically mandatory for each unit

- Type, routine, and special tests detailed clearly

IEC (e.g., IEC 60076-1):

- Testing often depends on contractual agreement

- Performance-based testing, rather than prescriptive

- Short-circuit test (IEC 60076-5) optional unless specified

For example, an IEEE-compliant transformer must undergo impulse and temperature rise tests, while an IEC transformer might not unless specified by the buyer.

IEEE transformer testing is more prescriptive and rigid compared to IEC.True

IEEE outlines mandatory tests with fixed pass/fail criteria, while IEC allows performance flexibility based on application and contractual agreements.

Impulse Withstand Level (BIL) Differences

| Rated Voltage (kV) | IEEE BIL (kV) | IEC BIL (kV) |

|---|---|---|

| 69 | 350 | 325 |

| 115 | 550 | 450 |

| 138 | 650 | 550 |

| 230 | 900 | 750 |

| 400 | 1425 | 1050 |

Result: IEEE designs are generally more conservative for insulation and surge withstand, which may lead to larger clearances and higher cost but increased safety margins.

Cooling Class Comparison

| IEEE/ANSI Code | IEC Equivalent | Description |

|---|---|---|

| ONAN | ONAN | Oil Natural Air Natural |

| ONAF | ONAF | Oil Natural Air Forced |

| OFAF | OFAF | Oil Forced Air Forced |

| KNAN | KNAN | Ester-filled, air-cooled (bio-oil) |

| Dry AF | AF | Air-cooled with fans |

| Dry AA | AN | Air-cooled natural convection |

Both use similar terms but application and sizing criteria may differ in calculation and overload tolerance.

Temperature Rise and Insulation Ratings

| Insulation Class | IEEE/ANSI Max Rise | IEC Max Rise |

|---|---|---|

| A | 55°C | 60°C |

| B | 80°C | 80°C |

| F | 105°C | 100°C |

| H | 120°C | 125°C |

- IEEE emphasizes fixed max temperature rise

- IEC allows use of temperature monitoring systems to manage operating range dynamically

Practical Implications for Buyers and Engineers

✅ Use IEEE/ANSI standards when:

- Operating in North America

- Procuring transformers for U.S. utilities or critical infrastructure

- Factory testing and documentation must follow U.S. protocols

- Emphasis is on conservatism, safety margin, and prescriptive compliance

✅ Use IEC standards when:

- Exporting or sourcing globally

- Participating in international projects or tenders (e.g., Africa, Middle East, Europe)

- Emphasis is on flexibility, performance-based design, and interoperability

Transformers compliant with IEC standards are always compatible with IEEE systems.False

Due to differences in BIL ratings, temperature rise criteria, and test requirements, IEC-compliant transformers may not meet IEEE utility or grid requirements without modification.

Can Transformers Be Dual-Rated?

Yes. Many manufacturers produce dual-standard transformers that meet both IEEE/ANSI and IEC criteria. This is useful when:

- Supplying international clients from a U.S. factory

- Participating in global tenders requiring multiple certifications

- Harmonizing supply chain logistics

These transformers typically:

- Have dual nameplates

- Undergo combined testing programs

- Conform to the more conservative of the two standards for each parameter

Conclusion

IEEE and ANSI work closely together, but they serve different functions: IEEE develops technical standards, while ANSI approves and promotes them. In practice, ANSI standards in the transformer industry often refer directly to IEEE documents. Together, they ensure U.S.-based transformer designs and operations meet rigorous and consensus-driven engineering benchmarks. For global compatibility, engineers must also understand how these standards compare to IEC norms.

FAQ

Q1: What is the difference between IEEE and ANSI standards?

A1: IEEE (Institute of Electrical and Electronics Engineers) develops technical standards focused on practical engineering, performance, and testing procedures, especially for electrical and electronic systems.

ANSI (American National Standards Institute) serves as the coordinator and accreditor for U.S. voluntary consensus standards, including those developed by IEEE.

So, many IEEE transformer standards are also ANSI-approved, but IEEE provides more detailed engineering guidance.

Q2: Are IEEE and ANSI transformer standards interchangeable?

A2: In many cases, yes. Most IEEE transformer standards (like IEEE C57 series) are dual-designated as ANSI/IEEE, meaning they are recognized by both bodies. However:

IEEE focuses on technical performance and testing

ANSI emphasizes standardization and regulatory compliance

Thus, IEEE provides the technical basis, and ANSI endorses it for national use.

Q3: What are key IEEE standards related to transformers?

A3: Important IEEE transformer standards include:

IEEE C57.12.00 – General requirements for liquid-immersed transformers

IEEE C57.12.90 – Testing procedures

IEEE C57.91 – Loading guide for transformers

IEEE C57.104 – Guide for gas analysis (DGA) in transformers

IEEE C57.140 – Evaluation and reconditioning

These often carry ANSI/IEEE dual designation, such as ANSI/IEEE C57.12.00.

Q4: Do other regions use IEEE or ANSI standards?

A4: IEEE and ANSI are primarily used in the United States and parts of North America. Other regions adopt:

IEC standards (Europe, Asia, international projects)

IS standards (India), GB (China), or JIS (Japan)

However, IEEE standards are gaining global traction, especially in multinational power projects and academic research.

Q5: How do I choose between IEEE/ANSI and IEC standards?

A5: The choice depends on:

Project location and regulatory requirements

Utility or customer specifications

Compatibility with existing infrastructure

For U.S.-based projects, IEEE/ANSI is preferred. For international or export projects, IEC is often mandatory. Some transformer manufacturers design equipment to comply with both.

References

IEEE Standards Association – Transformer Standards

https://standards.ieee.org/ieee/c57/

ANSI Official Website – Electrical Standards Overview

https://www.ansi.org

NEMA – ANSI vs. IEEE Explanation

https://www.nema.org/standards/view/understanding-ansi-ieee

Electrical4U – Transformer Testing Standards

https://www.electrical4u.com/testing-of-transformer/

ScienceDirect – IEEE vs IEC Transformer Design Comparison

https://www.sciencedirect.com/science/article/pii/S1876610217322217

Doble Engineering – Industry Standard Testing Protocols

https://www.doble.com/resources/standards-comparison-ieee-ansi-iec/