Although transformers are designed for high efficiency, they inevitably experience energy losses during operation. These losses are broadly classified into no-load losses, which occur when the transformer is energized but not supplying load, and load losses, which occur when current flows to the load. Understanding their causes is vital for transformer designers, operators, and maintenance teams to improve performance, minimize operational costs, and extend service life.

What Is the Definition of No-Load and Load Losses in Transformers?

In transformer operation, losses represent the portion of input power that is not converted into usable output power, instead being dissipated as heat. The two main categories are no-load losses and load losses, each arising from different physical mechanisms. Failure to understand and manage these losses can result in reduced efficiency, overheating, and higher operating costs over the transformer’s life.

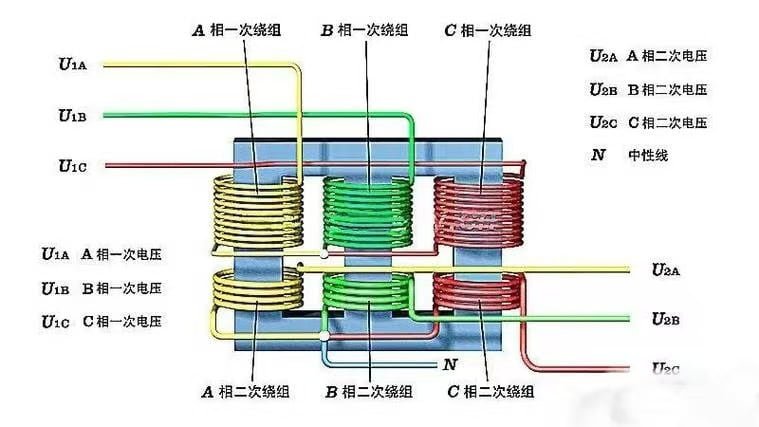

No-load losses are the constant power losses occurring in the transformer core when it is energized but not supplying load, mainly due to hysteresis and eddy currents in the core steel. Load losses are variable losses in the windings and structural parts that increase with the square of the load current, primarily due to copper resistance (I²R losses), stray flux, and eddy currents in conductors.

Understanding the distinction is essential because no-load losses are present 24/7 whenever the transformer is energized, while load losses only occur when current flows to the load.

No-load losses in transformers are caused by winding resistance.False

No-load losses are caused by core magnetization effects such as hysteresis and eddy currents, not by winding resistance.

Detailed Breakdown of Transformer Losses

| Loss Type | Caused By | Depends On | Typical Proportion of Total Loss | Measurement Standard |

|---|---|---|---|---|

| No-load losses | Hysteresis in core steel, eddy currents in laminations, dielectric losses | Voltage (core excitation) | 20–40% | IEEE C57.12.90, IEC 60076-1 |

| Load losses | Winding resistance (I²R), stray flux heating, eddy currents in conductors | Current (load level) | 60–80% | IEEE C57.12.90, IEC 60076-1 |

Mathematical Representation

No-load losses (P₀):

$$

P0 = P{\text{hysteresis}} + P{\text{eddy}} + P{\text{dielectric}}

$$

Where:

- $P{\text{hysteresis}} \propto f \cdot B{\text{max}}^n$ (n ≈ 1.6–2.0)

- $P{\text{eddy}} \propto (f \cdot B{\text{max}})^2 \cdot t^2$ (t = lamination thickness)

Load losses (P_load):

$$

P{\text{load}} = I^2 R + P{\text{stray}} + P_{\text{eddy-conductor}}

$$

Where:

- $I$ = load current

- $R$ = winding resistance (temperature dependent)

Comparison of Loss Behavior at Different Load Levels

| Load Level (% of Rated) | No-load Losses (kW) | Load Losses (kW) | Total Losses (kW) |

|---|---|---|---|

| 0% (energized, no load) | 5.0 | 0.0 | 5.0 |

| 50% | 5.0 | 7.5 | 12.5 |

| 100% | 5.0 | 30.0 | 35.0 |

| 125% (overload) | 5.0 | 46.9 | 51.9 |

Note: This table illustrates why no-load losses are a baseline cost of energizing a transformer, while load losses grow rapidly with increased current.

Reducing load current will lower no-load losses.False

No-load losses depend on applied voltage and core characteristics, not on the load current.

Practical Engineering Implications

- Energy Efficiency: For transformers operating continuously at low load, reducing no-load losses is more impactful for lifetime energy savings.

- Sizing Decisions: In high-load industrial applications, minimizing load losses is critical to avoid excessive heating.

- Core Material Selection: Grain-oriented silicon steel or amorphous steel can significantly reduce hysteresis and eddy current losses.

- Winding Design: Using larger conductor cross-sections or low-resistance materials like copper reduces I²R losses.

- Temperature Rise Control: Since load losses increase with temperature, cooling system design directly influences transformer efficiency.

What Are the Mechanisms Behind No-Load Losses in Transformers?

No-load losses in transformers occur whenever the transformer is energized, regardless of whether it is supplying load. These losses originate primarily in the transformer’s magnetic core and are a direct consequence of alternating magnetic flux. While their absolute value is typically smaller than load losses, their 24/7 nature makes them a significant contributor to lifetime operating costs. If unmanaged, they can cause unnecessary energy wastage, increase heat stress on the core, and shorten insulation life.

No-load losses are caused mainly by hysteresis losses, eddy current losses in the core laminations, and dielectric losses in insulation materials when the transformer is energized at rated voltage. Hysteresis losses are due to the repeated magnetization and demagnetization of the core material, while eddy current losses are caused by circulating currents induced in the steel laminations by alternating magnetic flux. Dielectric losses are small but occur in insulation subjected to alternating electric fields.

Since these mechanisms are voltage-dependent and essentially independent of load current, improving core material quality, lamination design, and insulation systems is the most effective way to reduce them.

No-load losses can be eliminated by turning off the transformer when not in use.True

Since no-load losses occur whenever the transformer is energized, de-energizing it eliminates these losses completely. However, this is not always practical in continuous service applications.

1. Hysteresis Loss Mechanism

Principle:

When the magnetic domains in the core realign with each AC cycle, energy is expended in overcoming the internal friction of the domains. This loss per cycle is proportional to the area of the material’s B-H hysteresis loop.

Equation:

$$

P{\text{hysteresis}} \propto f \cdot B{\text{max}}^n \cdot V_{\text{core}}

$$

Where:

- $f$ = supply frequency

- $B_{\text{max}}$ = maximum flux density

- $n$ ≈ 1.6–2.0 (Steinmetz coefficient)

- $V_{\text{core}}$ = volume of core material

Reduction Methods:

- Use grain-oriented silicon steel with low coercivity.

- Use amorphous metal cores to drastically reduce loop area.

- Operate at lower flux density.

2. Eddy Current Loss Mechanism

Principle:

Alternating flux induces voltage within the steel laminations, causing circulating currents that dissipate energy as heat.

Equation:

$$

P{\text{eddy}} \propto (B{\text{max}} \cdot f)^2 \cdot t^2 \cdot V_{\text{core}}

$$

Where:

- $t$ = lamination thickness

Reduction Methods:

- Use thin laminations to increase path resistance for currents.

- Apply high-quality insulating coatings between laminations.

- Use materials with higher electrical resistivity.

3. Dielectric Loss Mechanism

Principle:

Alternating electric fields in the transformer insulation cause displacement currents and molecular friction, producing small heat losses.

Reduction Methods:

- Use low-loss insulation materials with low dielectric loss factor (tan δ).

- Maintain proper drying and impregnation to avoid moisture ingress.

Comparative Contribution of Loss Mechanisms

| Loss Mechanism | Typical Contribution to No-Load Loss | Voltage Dependency | Temperature Sensitivity |

|---|---|---|---|

| Hysteresis Loss | 50–70% | ∝ Voltage^1.6–2.0 | Low |

| Eddy Current Loss | 30–50% | ∝ Voltage² | Moderate |

| Dielectric Loss | <5% | ∝ Voltage² | High (with moisture) |

Example Case Study – 1000 kVA Distribution Transformer

| Condition | No-Load Loss (kW) | Reduction from Baseline |

|---|---|---|

| Standard silicon steel core | 2.8 | Baseline |

| Grain-oriented silicon steel core | 2.1 | -25% |

| Amorphous metal core | 1.1 | -61% |

Practical Insights

- For transformers running lightly loaded but energized 24/7, no-load loss reduction can deliver major savings.

- Core upgrades during manufacturing or refurbishment yield long-term returns.

- In high-voltage distribution networks, no-load losses dominate idle standby transformers, making material selection critical.

What Are the Mechanisms Behind Load Losses in Transformers?

In transformer operation, load losses occur only when current is flowing through the windings—that is, when the transformer is supplying a load. While they disappear at no-load, their magnitude increases with load current and can significantly impact transformer efficiency and thermal performance. Excessive load losses generate heat in windings and structural parts, leading to higher winding temperatures, accelerated insulation aging, and in severe cases, premature failure.

Load losses are mainly caused by conductor I²R losses, eddy current losses in windings, and stray losses in structural components due to leakage flux. I²R losses are the resistive heating effect of load current in conductors, eddy current losses arise from circulating currents induced within the winding conductors themselves, and stray losses occur in metallic tank walls, clamps, and other structural parts exposed to leakage flux.

Since load losses are current-dependent and increase with the square of load, managing them requires careful conductor design, material selection, and electromagnetic optimization.

Load losses in transformers are constant regardless of load current.False

Load losses vary with the square of load current. At zero load, they are zero; at full load, they are at their rated value.

1. I²R (Winding Resistance) Losses

Principle:

When current flows through winding conductors, electrical resistance converts part of the electrical energy into heat.

Equation:

$$

P_{\text{I²R}} = I^2 \cdot R

$$

Where:

- $I$ = load current

- $R$ = DC resistance of winding at operating temperature

Reduction Methods:

- Use larger cross-section conductors to reduce resistance.

- Use high-conductivity materials such as electrolytic copper or high-purity aluminum.

- Optimize winding layout for minimum length per turn.

2. Eddy Current Losses in Windings

Principle:

Leakage magnetic flux induces circulating currents within the cross-section of conductors, producing additional heating beyond pure I²R losses.

Equation:

$$

P{\text{eddy}} \propto (B{\text{leakage}} \cdot f)^2 \cdot d^2

$$

Where:

- $B_{\text{leakage}}$ = leakage flux density

- $d$ = conductor strand thickness

Reduction Methods:

- Use transposed conductors (CTC – continuously transposed conductor).

- Reduce strand thickness.

- Optimize winding geometry to minimize leakage flux.

3. Stray Losses in Structural Parts

Principle:

Leakage flux from windings couples into metallic structural components (core clamps, tank walls, bracing), inducing eddy currents and heating.

Reduction Methods:

- Use magnetic shunts to redirect flux.

- Use non-magnetic stainless steel or laminated structural parts.

- Increase physical separation between windings and metal parts.

Comparative Contribution of Load Loss Mechanisms at Full Load

| Loss Mechanism | Typical Contribution | Load Dependency | Reduction Potential |

|---|---|---|---|

| I²R Winding Loss | 60–70% | ∝ Current² | High |

| Winding Eddy Loss | 20–30% | ∝ Current² | Medium |

| Stray Losses | 5–10% | ∝ Current² | Medium |

Example Case Study – 2500 kVA Transformer at 75% Load

| Condition | Total Load Loss (kW) | Reduction from Baseline |

|---|---|---|

| Standard copper windings | 18.0 | Baseline |

| Optimized conductor cross-section | 15.5 | -14% |

| CTC with magnetic shunts | 14.1 | -22% |

Practical Insights

- Load losses dominate in high-utilization transformers, such as industrial feeders running near rated load for extended periods.

- Thermal performance is critical—reducing load losses directly lowers winding hot-spot temperature.

- Load loss optimization often requires balancing cost vs. conductor size—oversizing conductors can be uneconomical unless energy savings justify it.

What Factors Affect the Magnitude of Transformer Losses?

Transformer losses—both no-load losses (core-related) and load losses (winding and stray)—are influenced by a combination of design, materials, operating conditions, and installation environment. Understanding these factors is crucial for maximizing efficiency, prolonging service life, and reducing operating costs. Ignoring them can lead to elevated temperatures, accelerated insulation aging, excessive energy bills, and even premature transformer failure.

The main factors affecting transformer losses include core material quality, magnetic flux density, winding conductor size, load profile, operating temperature, frequency, and harmonics. Each parameter influences loss mechanisms differently, meaning that both no-load and load losses must be optimized in parallel during transformer design.

Knowing these factors helps operators and engineers make informed procurement, operation, and maintenance decisions to achieve long-term reliability.

Transformer losses are fixed and cannot be reduced through design changes.False

Transformer losses can be reduced through improved core materials, optimized winding design, better cooling, and controlling harmonics.

1. Core Material and Quality

The type and grade of steel used in the core directly impact no-load losses.

- High-grade, grain-oriented silicon steel reduces hysteresis and eddy current losses.

- Amorphous metal cores can reduce no-load losses by up to 70%.

- Thinner laminations lower eddy currents.

| Core Material | Typical No-Load Loss Reduction vs. Conventional Steel |

|---|---|

| Conventional Grain-Oriented Steel | Baseline |

| High-Grade Grain-Oriented Steel | 15–20% reduction |

| Amorphous Alloy Steel | 60–70% reduction |

2. Magnetic Flux Density

Higher flux density increases core losses disproportionately.

- Core design aims to balance efficiency with size/cost.

- Over-fluxing during operation (overvoltage or frequency drop) significantly raises losses.

3. Winding Conductor Material and Size

Load losses depend heavily on conductor properties.

- Copper has ~40% lower resistivity than aluminum, lowering I²R losses.

- Larger cross-sectional area reduces resistance.

- Using CTC (Continuously Transposed Conductor) minimizes eddy current losses.

4. Load Level and Profile

Since load losses scale with the square of load current:

- Transformers operating near rated load for long periods experience higher average load losses.

- Lightly loaded transformers have proportionally higher no-load loss share.

Example:

| Load (%) | Relative Load Loss (I²R) | Relative No-Load Loss |

|---|---|---|

| 25% | 6.25% of rated load loss | 100% |

| 50% | 25% | 100% |

| 100% | 100% | 100% |

5. Operating Temperature

- Higher temperatures increase conductor resistance, raising I²R losses.

- Poor cooling design causes both no-load and load losses to translate into excessive thermal stress.

6. System Frequency

- Core losses rise with frequency due to higher hysteresis and eddy current effects.

- Standard designs are optimized for 50 Hz or 60 Hz; operating at non-design frequencies increases losses.

7. Harmonics in Load Current

- Harmonics increase eddy current losses in windings and stray losses in structural parts.

- Non-linear loads like VFDs, data centers, and LED lighting exacerbate this.

| Harmonic Order | Relative Eddy Loss Increase |

|---|---|

| 3rd | +10–15% |

| 5th | +15–25% |

| 7th | +20–30% |

8. Maintenance and Contamination

- Poor maintenance (blocked radiators, dust on windings) causes higher winding temperatures, indirectly increasing losses.

- Corroded connections increase contact resistance, adding to load losses.

How Are Transformer Losses Measured and Tested?

Transformer losses—comprising no-load losses and load losses—must be precisely measured to verify compliance with design specifications, efficiency requirements, and contractual guarantees. Inaccurate measurement can lead to financial penalties, efficiency shortfalls, and operational inefficiencies. Given that transformer losses directly impact lifetime operating cost, accurate testing under standardized conditions is a critical quality control step before installation.

Transformer loss testing typically involves two main tests: the open-circuit (no-load) test to measure core losses and the short-circuit (load) test to measure copper and stray losses, both performed according to standards like IEEE C57 and IEC 60076.

These tests not only ensure contractual compliance but also detect manufacturing defects, material inconsistencies, or assembly issues before the transformer is energized in the field.

Transformer loss measurements can be done after energizing the unit in full service.False

Accurate transformer loss testing is done under controlled factory or laboratory conditions, not in-service, to ensure repeatability and eliminate load variability.

1. Open-Circuit (No-Load) Loss Test

This measures core (iron) losses and magnetizing current.

- Setup: High-voltage winding energized at rated voltage, low-voltage winding left open.

- Equipment: Precision wattmeter or power analyzer, voltage and current transformers, frequency meter.

- Conditions: Ambient temperature recorded; voltage adjusted to rated value; frequency kept stable.

- Purpose: Determines hysteresis and eddy current losses at rated flux density.

| Parameter Measured | Typical Instrument |

|---|---|

| Voltage | Voltmeter/VT |

| Current | Ammeter/CT |

| Power | Wattmeter |

| Frequency | Frequency Meter |

2. Short-Circuit (Load) Loss Test

This measures winding (copper) losses and stray load losses.

- Setup: Low-voltage winding shorted, high-voltage winding energized with reduced voltage until rated current flows.

- Equipment: Wattmeter or digital power analyzer, CTs, temperature sensors.

- Conditions: Measurements corrected to 75°C or 85°C reference temperature per standards.

- Purpose: Identifies I²R losses and stray losses under full-load current.

| Parameter Measured | Purpose |

|---|---|

| Current | To set rated load condition |

| Voltage | Ensure safe energization level |

| Power | Calculate total load losses |

3. Temperature Correction of Losses

- Copper resistance varies with temperature, so load loss results are corrected to the specified reference temperature.

- Resistance temperature coefficient for copper ≈ 0.00393/°C.

Formula:

$$

P{75} = P{measured} \times \frac{R{75}}{R{measured}}

$$

4. Harmonic Loss Evaluation

When transformers serve non-linear loads, additional harmonic load loss testing may be performed:

- Uses waveform analysis to measure increased eddy current effects.

- May require special reference per IEEE C57.110.

5. Standard References

Loss measurement methods are defined in:

- IEC 60076-1 – General requirements

- IEC 60076-8 – Application guide for loads and losses

- IEEE C57.12.90 – Test code for loss and impedance

Example Factory Test Data Table

| Test Type | Voltage Applied | Current Measured | Power Loss (kW) | Temperature Reference |

|---|---|---|---|---|

| No-Load Test | 13.8 kV | 2.1 A | 4.25 | 20°C |

| Load Test | 900 V | 1200 A | 28.6 | 75°C |

What Design and Material Improvements Can Be Made to Reduce Transformer Losses?

Transformers inherently lose energy in the form of no-load (core) losses and load (winding) losses, both of which translate into operating costs and heat stress. Over decades of service, even a seemingly small reduction in loss can yield significant energy savings, lower cooling requirements, and extended equipment lifespan. Without targeted design and material improvements, these losses remain locked into the unit’s performance, impacting both economic and environmental efficiency.

Reducing transformer losses relies on advanced engineering measures, such as using low-loss core materials like amorphous steel, employing conductor transposition to reduce eddy currents, optimizing winding geometry for reduced resistance, and integrating enhanced cooling systems to maintain low operating temperatures.

Investing in such improvements during manufacturing or retrofit can lower total ownership costs, improve power quality, and meet stricter efficiency regulations like DOE 2016, EU Ecodesign, or MEPS.

Amorphous metal cores can reduce no-load losses by up to 70% compared to conventional silicon steel.True

Due to their non-crystalline atomic structure, amorphous alloys have lower hysteresis losses, significantly reducing no-load losses in distribution transformers.

1. Core Design Improvements

a) Material Selection

- Grain-Oriented Silicon Steel (GO): Lower hysteresis loss through controlled grain orientation.

- Amorphous Steel: Extremely low hysteresis due to random atomic structure; ideal for distribution transformers.

| Core Material | Relative No-Load Loss Reduction | Typical Application |

|---|---|---|

| Conventional GO Steel | Baseline | General-purpose |

| Hi-B GO Steel | 10–15% | High-efficiency units |

| Amorphous Alloy | 60–70% | Energy-conscious projects |

b) Lamination Thickness

- Thinner laminations (0.23–0.27 mm) reduce eddy current paths.

- High stacking factor and precise cutting reduce localized heating.

2. Winding Design Improvements

a) Conductor Material

- High-purity copper with increased cross-section reduces I²R losses.

- Aluminum conductors with improved cross-section for cost-effective designs.

b) Conductor Transposition

- Continuously Transposed Conductors (CTC) reduce circulating currents between strands.

| Winding Feature | Loss Reduction Benefit |

|---|---|

| CTC | Reduces eddy current & circulating loss |

| Foil Windings | Ideal for LV windings, minimizes skin effect |

| Multi-layer Windings | Balances thermal and electrical fields |

3. Cooling System Optimization

- Enhanced ONAF/ODAF systems lower winding temperature, reducing resistive losses.

- CFD simulations ensure airflow/oil flow efficiency.

Formula for resistive loss variation with temperature:

$$

P_{load} \propto R(T) \propto (1 + \alpha \Delta T)

$$

Where α ≈ 0.00393/°C for copper.

4. Manufacturing Precision

- Tight tolerances reduce mechanical vibration and hot spots.

- Laser-cut laminations prevent burrs that increase eddy losses.

- Vacuum pressure impregnation (VPI) improves insulation and thermal conductivity.

5. Advanced Coatings and Insulation

- High thermal class insulation (Class F or H) enables operation at higher efficiency points.

- Anti-oxidation coating prevents aging of core steel.

Example Case Study

| Design Upgrade | Loss Reduction (%) | Payback Period |

|---|---|---|

| Amorphous Core | 65% | 3–5 years |

| CTC in HV Windings | 10–15% | 4–6 years |

| Optimized Cooling Ducts | 5–8% | 2–3 years |

| High-Purity Copper | 5–10% | 5–7 years |

Conclusion

No-load losses are primarily caused by the magnetization of the transformer core and remain constant during energization, while load losses result from current flow in windings and structural parts, increasing with load level. Both types of losses contribute to reduced efficiency and higher operating costs. By accurately measuring these losses and adopting advanced materials and design techniques, manufacturers and operators can significantly improve transformer performance, reduce energy waste, and enhance reliability over its service life.

FAQ

Q1: What are no-load losses in a transformer?

A1: No-load losses occur when the transformer is energized but not supplying load current. They are mainly caused by:

Hysteresis loss: Energy consumed due to the repeated magnetization and demagnetization of the core.

Eddy current loss: Circulating currents in the core material caused by changing magnetic fields, producing heat.

No-load losses are constant and depend on voltage, frequency, and core material.

Q2: What causes load losses in a transformer?

A2: Load losses happen when the transformer is supplying load current. They include:

Copper (I²R) losses: Heat generated by current flowing through the winding resistance.

Stray losses: Additional heating caused by leakage flux inducing currents in the windings and structural parts.

Load losses increase proportionally to the square of the load current.

Q3: How do hysteresis losses occur?

A3: Hysteresis losses occur as magnetic domains in the core realign with each AC cycle. The energy required for this process depends on the type of core material, magnetic flux density, and supply frequency. Using materials like CRGO steel or amorphous metal can significantly reduce hysteresis losses.

Q4: How can no-load and load losses be minimized?

A4: Use high-grade core materials to reduce hysteresis.

Use thin, insulated laminations to cut eddy currents.

Increase conductor size to lower copper resistance.

Optimize transformer design to minimize stray magnetic losses.

Q5: Why is understanding these losses important?

A5: Minimizing transformer losses improves energy efficiency, reduces operational costs, and supports environmental sustainability by lowering wasted electricity in power systems.