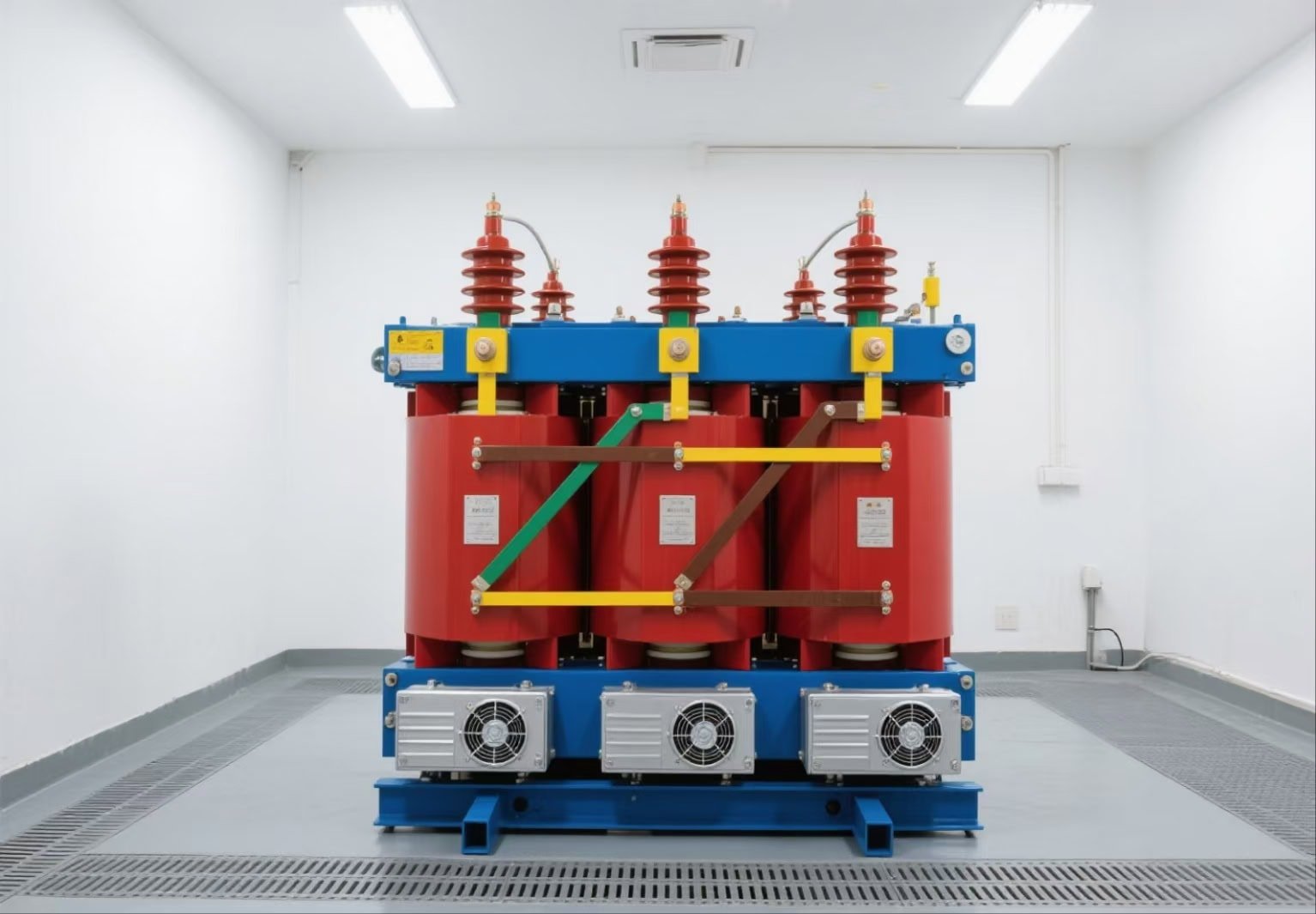

In environments like commercial buildings and data centers, safety, reliability, and ease of maintenance are top priorities. Dry type transformers—which use air or solid insulation instead of liquid dielectric oil—offer significant advantages in these applications. They minimize fire risks, require less maintenance, and adapt well to indoor installations, making them a popular choice for critical infrastructure.

What Are the Safety Advantages of Dry Type Transformers?

In high-occupancy and sensitive environments such as commercial complexes, schools, data centers, or underground facilities, transformer safety is paramount. Oil-filled transformers, while reliable, introduce risks like oil leakage, fire hazards, and environmental contamination. The dry type transformer addresses these concerns with a design that eliminates flammable liquid insulation. Neglecting this option in safety-critical projects can result in elevated fire risk, costly protective measures, and compliance complications.

Dry type transformers offer significant safety advantages including zero risk of oil leaks, reduced fire hazard due to solid insulation, minimal environmental contamination potential, lower explosion risk, and suitability for installation in public or confined spaces without extensive fireproofing measures.

Dry type transformers use flammable liquid for insulation.False

Dry type transformers use air or solid resin insulation instead of flammable liquids, eliminating the risk of oil fires or leaks.

1. Fire and Explosion Risk Mitigation

- No combustible oil means no oil-based fire hazard.

- Cast resin insulation is self-extinguishing and has high thermal stability.

- Suitable for indoor installations in areas with high human traffic.

| Safety Factor | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Fire Risk | Very low | Moderate to high |

| Explosion Risk | Very low | Possible if oil vapors ignite |

| Fireproof Room Requirement | Often not required | Usually required |

2. Environmental Safety

- No oil leakage into soil or water sources.

- No need for oil containment pits or drainage systems.

- Easier to comply with EPA and environmental protection standards.

3. Installation in Sensitive Locations

- Safe for basements, high-rise buildings, tunnels, offshore platforms, and public facilities.

- Reduced need for auxiliary fire suppression systems.

- Lower insurance premiums in some cases due to lower hazard classification.

4. Maintenance-Related Safety

- No handling or disposal of insulating oil.

- Less risk for maintenance crews—no oil contamination or vapor inhalation.

- Visual inspections are straightforward, reducing human error in safety checks.

5. Compliance and Standards

- Meets IEC 60076-11, IEEE C57.12.01, and NFPA 70/850 safety requirements for dry type installations.

- Frequently chosen for projects requiring strict fire safety codes.

What Are the Space and Installation Benefits of Dry Type Transformers?

In urban developments, commercial towers, data centers, and underground installations, space is often the most expensive commodity. Oil-filled transformers require fireproof rooms, oil containment pits, and large clearances for cooling and maintenance, all of which consume valuable real estate. Dry type transformers, on the other hand, are designed for compact, safe, and direct integration into building spaces without extensive infrastructure modifications. Ignoring their spatial benefits can lead to higher construction costs and longer installation times.

Dry type transformers offer space and installation benefits including reduced footprint, no need for oil containment systems, simplified indoor installation without fire-rated vaults, lower clearance requirements, and flexible mounting options, making them ideal for space-constrained or retrofitted environments.

Dry type transformers always require outdoor installation due to ventilation needs.False

Dry type transformers are well-suited for indoor use and can be installed in compact, enclosed spaces with proper ventilation.

1. Compact Footprint

- No oil tank means smaller overall dimensions.

- Fits into tight electrical rooms or alongside other equipment.

- Can be integrated into multi-use technical spaces.

| Feature | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Average Clearance Requirement | Low | High |

| Fireproof Room Needed | Not usually | Yes |

| Oil Pit Needed | No | Yes |

2. Flexible Mounting and Placement

- Can be installed closer to load centers, reducing cable length.

- Options for floor-mounted, wall-mounted, or enclosure-integrated designs.

- Suitable for rooftop or basement locations without major structural reinforcement.

3. Reduced Civil Engineering Costs

- No oil containment pit construction.

- No specialized fireproof vaults required in most cases.

- Lower HVAC load compared to oil-filled units in enclosed spaces.

4. Faster Installation

- Fewer ancillary systems mean reduced installation time.

- Pre-fabricated enclosures allow plug-and-play deployment.

- Lighter weight simplifies transportation into confined or elevated spaces.

5. Ideal for Retrofit Projects

- Fits into existing electrical rooms without major building alterations.

- Perfect for upgrades in aging commercial or public buildings where space is already limited.

- Avoids downtime from large-scale civil modifications.

What Are the Low Maintenance Requirements of Dry Type Transformers?

For many facilities, maintenance costs can rival or even surpass initial equipment investment over the long term. Oil-filled transformers require regular oil testing, filtering, leak checks, and replacement, all of which demand specialized labor, downtime, and expensive consumables. In contrast, dry type transformers, using solid insulation and air cooling, eliminate most of these maintenance-intensive tasks. Overlooking this advantage can mean unnecessarily high operational expenses and resource allocation for routine servicing.

Dry type transformers require minimal maintenance because they have no oil to test or replace, no risk of leakage, reduced need for complex cooling system servicing, and straightforward visual inspections, resulting in lower operational costs and less downtime over their service life.

Dry type transformers require regular oil sampling and filtration to maintain performance.False

Dry type transformers do not contain insulating oil, so oil testing, filtration, and replacement are unnecessary.

1. No Oil-Related Servicing

- No insulating oil means no sampling, testing, or purification.

- Eliminates risk of oil oxidation, sludge formation, or contamination.

- No need for oil spill containment maintenance.

| Maintenance Task | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Oil Testing | Not applicable | Every 6–12 months |

| Oil Filtration | Not applicable | As needed |

| Leak Checks | Not applicable | Regularly required |

2. Simple Inspection Routines

- Visual inspection for dust buildup, cracks in resin, or loose connections.

- Can be performed without draining or shutting down cooling systems.

- Quick checks mean minimal disruption to operations.

3. Lower Risk of Wear-Related Failures

- Fewer moving parts and no oil pumps (in natural-cooled types).

- Less corrosion risk due to absence of oil moisture ingress.

- Longer intervals between major servicing activities.

4. Reduced Maintenance Costs

- Fewer specialized technicians needed.

- No recurring costs for oil, filters, and disposal.

- Shorter service windows reduce labor hours.

5. Easier Predictive Maintenance

- Can integrate with thermal sensors and IoT monitoring for proactive fault detection.

- Dust and temperature trends are easier to track than oil quality metrics.

- Suitable for unattended or remote installations.

What Are the Environmental and Regulatory Compliance Advantages of Dry Type Transformers?

In today’s regulatory landscape, businesses face increasingly strict environmental laws and safety compliance requirements. Oil-filled transformers, while efficient, can present environmental hazards through potential oil leaks, fire risks, and PCB contamination in older units. These hazards can result in costly fines, environmental remediation, and reputational damage. Dry type transformers, on the other hand, use solid insulation and air cooling, eliminating oil-related spill risks and easing compliance with fire safety, environmental protection, and occupational safety regulations. Ignoring these benefits can mean higher liability exposure and more complex permitting processes.

Dry type transformers have clear environmental and regulatory advantages because they do not require oil containment, eliminate the risk of hazardous leaks, comply more easily with fire and safety codes, and meet stringent green building and energy efficiency standards, reducing both environmental impact and compliance costs.

Dry type transformers are exempt from all electrical safety regulations.False

While dry type transformers reduce certain environmental and safety risks, they still must comply with relevant electrical safety and performance regulations.

1. No Oil = No Spill or PCB Risk

- Solid insulation removes oil leak contamination hazards.

- Avoids environmental cleanup liabilities.

- Eliminates PCB handling concerns found in older oil-filled units.

| Compliance Factor | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Oil Spill Containment | Not required | Mandatory |

| PCB Risk | None | Possible in legacy units |

| Hazardous Waste Disposal | Minimal | Oil and filters |

2. Easier Fire Safety Compliance

- Low flammability of resin insulation.

- Often does not require fire-rated vaults indoors.

- Suitable for high-occupancy buildings under NFPA guidelines.

3. Simplified Environmental Permitting

- No oil containment pit or spill plan needed.

- Fewer environmental impact assessments during installation.

- Streamlined approval for urban and indoor projects.

4. Compatibility with Green Standards

- Meets LEED and other green building certifications.

- Energy-efficient designs reduce lifetime carbon footprint.

- Qualifies for incentives in energy conservation programs.

5. Lower Regulatory Burden in Sensitive Areas

- Safe for use in schools, hospitals, data centers, and underground facilities.

- Accepted in marine, mining, and offshore applications without complex oil-handling procedures.

- Helps meet ISO 14001 environmental management compliance targets.

What Is the Performance of Dry Type Transformers in High-Reliability Applications?

In environments such as data centers, hospitals, offshore rigs, semiconductor fabs, and defense installations, electrical infrastructure must operate with near-zero tolerance for failure. Any downtime can translate into lost productivity, financial loss, safety hazards, or compromised national security. Traditional oil-filled transformers, while efficient, present risks from oil leaks, fire hazards, and maintenance downtime. Dry type transformers—using solid insulation and natural or forced air cooling—offer inherent safety, low maintenance, and stable thermal performance, making them a strong candidate for continuous duty in mission-critical facilities.

Dry type transformers are well-suited for high-reliability applications due to their low fire risk, absence of oil-related failures, strong insulation stability under thermal stress, minimal maintenance needs, and compatibility with redundant power and monitoring systems, ensuring consistent performance and operational continuity.

Dry type transformers are unsuitable for mission-critical operations due to their lower efficiency.False

Modern dry type transformers can achieve efficiencies above 98%, meeting or exceeding the reliability requirements of critical operations when properly specified and maintained.

1. Stability Under Continuous Load

- High thermal endurance of epoxy or cast resin insulation.

- Handles continuous operation near rated load without accelerated degradation.

- Stable dielectric performance even in humid or dusty environments.

| Parameter | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Fire Risk | Very low | Moderate |

| Continuous Load Capability | High | High |

| Cooling System Maintenance | Minimal | Regular oil system servicing |

2. Low Fire and Contamination Risk

- No combustible liquid insulation.

- Eliminates risk of oil fires or toxic smoke emissions.

- Can be installed close to sensitive loads without special containment.

3. Integration with Monitoring Systems

- Easily equipped with temperature sensors, vibration monitors, and IoT connectivity.

- Enables predictive maintenance in real time.

- Supports redundancy planning in critical power distribution.

4. Minimal Maintenance Downtime

- No oil sampling or filtration required.

- Visual inspections and thermal scanning can be performed while in service.

- Suitable for 24/7 operation with limited shutdown windows.

5. Proven Use Cases

- Data centers: Stable load handling and minimal service interruptions.

- Hospitals: Continuous power for life-support systems without oil hazard.

- Industrial process plants: Withstands harsh indoor conditions without performance drop.

What Are the Cost and Lifecycle Considerations for Dry Type Transformers?

When selecting a transformer, many buyers focus heavily on upfront price, but for high-value electrical infrastructure, the true decision-making factor should be total cost of ownership (TCO) over its operational life. A transformer’s lifecycle includes acquisition, installation, operation, maintenance, energy losses, and end-of-life disposal. Dry type transformers may cost more initially than oil-filled equivalents, but they can yield lower maintenance expenses, reduced compliance costs, and minimal environmental risk liabilities—all of which influence the long-term financial picture. Misjudging lifecycle cost can result in higher operational expenses and premature equipment replacement.

The cost and lifecycle considerations of dry type transformers involve balancing a higher initial purchase price with lower maintenance requirements, reduced risk-related expenses, compliance advantages, and long operational life, often resulting in competitive or lower total ownership cost compared to oil-filled units in the right applications.

Dry type transformers always cost less to purchase than oil-filled transformers.False

While dry type transformers generally have a higher initial cost, their reduced maintenance and compliance expenses can make them more cost-effective over their lifecycle in suitable applications.

1. Initial Capital Cost

- Generally 15–35% higher purchase price for dry type vs. oil-filled of similar rating.

- Cost influenced by insulation type (cast resin, VPI), cooling method (AN, AF), and protection class.

| Transformer Type | Typical Cost per kVA (USD) | Notes |

|---|---|---|

| Dry Type (VPI) | $25–$40 | Indoor, low to medium voltage |

| Dry Type (Cast Resin) | $30–$50 | Higher protection, better for harsh environments |

| Oil-Filled | $18–$35 | Outdoor-friendly, needs containment |

2. Installation and Compliance Costs

- No oil containment pit or fire-rated vault needed (savings in civil works).

- Lower insurance premiums in some facilities.

- Easier permitting in urban and environmentally sensitive areas.

3. Operating Costs

- Slightly higher no-load losses in some designs, but offset by reduced maintenance overhead.

- No oil sampling, filtering, or spill management costs.

4. Maintenance and Service Life

- Typical service life: 25–35 years with proper load management.

- Low maintenance requirements—mostly visual inspections and thermal monitoring.

- Lower unplanned outage costs compared to oil-filled units in indoor applications.

5. Lifecycle Cost Breakdown Example

Sample 1 MVA Indoor Transformer, 30-Year Operation

| Cost Category | Dry Type (USD) | Oil-Filled (USD) |

|---|---|---|

| Purchase & Install | $400,000 | $340,000 |

| Compliance & Civil | $10,000 | $40,000 |

| Maintenance | $30,000 | $80,000 |

| Downtime Risk Costs | $20,000 | $50,000 |

| Disposal & Decommissioning | $5,000 | $15,000 |

| Total Lifecycle | $465,000 | $525,000 |

6. End-of-Life and Disposal

- Easier disposal due to absence of hazardous oil waste.

- Higher potential for material recycling (copper, steel, resin).

- Reduced environmental liability during decommissioning.

Conclusion

Dry type transformers are preferred in commercial buildings and data centers because they combine safety, reliability, and low maintenance with compliance to modern environmental standards. Their oil-free design reduces operational hazards, while their compact footprint suits indoor, high-density electrical rooms. For facilities where uptime and safety are non-negotiable, dry type transformers offer a practical and future-ready solution.

FAQ

Q1: Why are dry type transformers safer for commercial use?

Dry type transformers use air or resin for cooling instead of flammable oil, significantly reducing fire risk. This makes them a safer option for populated areas like commercial buildings and data centers, where safety regulations are strict.

Q2: How do dry type transformers benefit data centers?

They provide high reliability, low fire risk, and reduced maintenance, which are crucial for data centers that require continuous power availability. Their design also supports operation in clean, climate-controlled environments.

Q3: Are dry type transformers more environmentally friendly?

Yes, since they do not use oil, there’s no risk of oil leaks contaminating soil or water. Many dry type transformers also comply with eco-design standards, making them more sustainable for green building projects.

Q4: Do dry type transformers require less maintenance?

Dry type transformers generally require less maintenance because they lack oil that needs testing and replacement. Routine inspections mainly involve checking ventilation, insulation, and dust accumulation.

Q5: Are there any drawbacks to using dry type transformers?

The main drawbacks are higher upfront costs and slightly lower efficiency compared to oil-filled transformers. However, the safety, environmental, and maintenance advantages often outweigh these disadvantages for commercial and data center applications.

References

IEEE - Dry Type Transformer Applications: https://ieeexplore.ieee.org

NEMA - Dry Type Transformer Standards: https://www.nema.org

Electrical4U - Dry Type Transformer Advantages: https://www.electrical4u.com

EEP - Why Choose Dry Type Transformers: https://electrical-engineering-portal.com

Energy.gov - Transformer Efficiency Guidelines: https://www.energy.gov

All About Circuits - Dry vs Oil Filled Transformers: https://www.allaboutcircuits.com

Engineering Toolbox - Transformer Types Overview: https://www.engineeringtoolbox.com