Distribution transformers play a crucial role in stepping down voltage for safe delivery to residential, commercial, and industrial users. For buyers, understanding the price structure is essential, as costs vary depending on technical specifications, materials, efficiency standards, and market conditions. This guide highlights the main factors that influence distribution transformer prices and helps buyers make informed purchasing decisions.

What Role Does Capacity (kVA Rating) Play in Cost?

When utilities, industries, or commercial facilities purchase a transformer, one of the most critical specifications is its capacity, expressed in kilovolt-amperes (kVA). Choosing the wrong capacity can have serious consequences: an undersized transformer overheats, suffers premature failure, and disrupts operations, while an oversized unit leads to unnecessary investment and higher no-load losses. This makes capacity not only a technical decision but also a direct cost driver. Buyers often struggle with balancing upfront cost, long-term efficiency, and future scalability. Understanding the link between kVA rating and transformer cost is essential for smart procurement and lifecycle optimization.

The capacity (kVA rating) of a transformer directly influences its cost, since higher kVA ratings require more core steel, copper or aluminum windings, larger insulation systems, stronger cooling mechanisms, and more robust structural design. As kVA increases, both material and manufacturing costs rise almost proportionally, making high-capacity transformers significantly more expensive than smaller units. However, the cost per kVA typically decreases with size, meaning larger transformers are more cost-effective per unit of capacity.

In other words, transformer capacity and cost are interdependent: higher ratings mean higher absolute costs but improved economies of scale in capacity utilization.

The cost of a transformer increases with its kVA rating.True

Larger transformers need more core steel, winding material, insulation, and cooling, driving higher manufacturing costs.

A larger transformer always costs more per kVA than a smaller one.False

Although total cost is higher, the cost per kVA decreases at larger capacities due to design efficiencies and economies of scale.

1. How kVA Rating Influences Cost Drivers

| Component | Impact of Higher kVA Rating | Cost Effect |

|---|---|---|

| Core | Requires larger cross-sectional area and laminated steel | More material, higher cost |

| Windings | Thicker or more turns of copper/aluminum to handle higher current | Increases conductor cost |

| Insulation | Greater dielectric strength to withstand higher voltages | Adds material and complexity |

| Cooling System | Larger radiators, fans, or oil pumps to dissipate heat | Increases auxiliary equipment cost |

| Tank & Structure | Stronger mechanical strength for larger units | Higher fabrication costs |

2. Cost Scaling of Transformers by Capacity

| Transformer Capacity (kVA) | Typical Application | Approximate Cost Range (USD)* | Cost per kVA (USD/kVA) |

|---|---|---|---|

| 100 kVA | Small commercial loads | $3,000 – $5,000 | $30 – $50 |

| 500 kVA | Industrial facilities | $10,000 – $20,000 | $20 – $40 |

| 2,500 kVA | Medium substation | $50,000 – $90,000 | $18 – $36 |

| 10,000 kVA | Utility substation | $200,000 – $400,000 | $20 – $30 |

| 50,000 kVA+ | Extra high-voltage transmission | $1M+ | $15 – $25 |

*Costs vary by region, design type (oil-immersed vs dry-type), material market prices, and efficiency class (IEC/DOE).

3. Economies of Scale in Transformer Capacity

- Absolute cost rises steeply with kVA rating because of material and engineering needs.

- Relative cost (per kVA) decreases since design efficiency improves at larger sizes.

- Procurement decisions must balance current demand with projected future load growth.

4. Practical Considerations for Buyers

- Undersizing risk: Shortens transformer life, increases O\&M costs.

- Oversizing risk: Higher upfront cost and unnecessary no-load losses.

- Optimal sizing: Matching kVA rating to demand profile with a small margin (10–20%) for growth.

- Efficiency standards: Larger transformers may justify premium high-efficiency designs, lowering lifecycle cost.

How Do Materials and Design Affect Pricing?

When organizations purchase a transformer, the price is not determined by capacity (kVA) alone. Materials and design choices play a fundamental role in shaping cost, reliability, and efficiency. Buyers often face the challenge of comparing seemingly similar transformers that differ significantly in price. The difference usually comes from materials used (core steel, copper vs aluminum windings, insulation type, oil vs dry cooling) and design decisions (core geometry, cooling system, efficiency class, protection features). These factors influence not only the upfront cost but also the long-term operating expenses and lifespan of the transformer.

Materials and design affect transformer pricing because premium materials like copper windings, amorphous steel cores, and advanced insulation significantly raise manufacturing costs, while design features such as shell-type cores, enhanced cooling systems, and low-loss configurations add engineering complexity. Although these increase initial price, they reduce losses, improve efficiency, extend lifespan, and lower total ownership cost, making them cost-effective in long-term operation.

This means that when comparing prices, buyers must look beyond purchase cost and consider total lifecycle value.

Copper-wound transformers are always cheaper than aluminum-wound transformers.False

Copper has higher conductivity but is more expensive than aluminum, so copper-wound transformers usually cost more upfront but are more efficient.

Using amorphous steel instead of silicon steel in transformer cores reduces no-load losses but increases initial price.True

Amorphous steel is costlier to process but improves energy efficiency, reducing lifetime costs.

1. Material Choices and Cost Impact

| Material | Options | Cost Impact | Pros | Cons |

|---|---|---|---|---|

| Windings | Copper vs Aluminum | Copper ↑ higher cost | High conductivity, compact size, long life | Expensive, heavier |

| Core Steel | Grain-Oriented Silicon Steel vs Amorphous | Amorphous ↑ higher cost | Lower no-load losses, energy-efficient | Higher price, brittle material |

| Insulation | Paper/oil vs Epoxy resin (dry-type) | Dry-type ↑ cost | Safer, eco-friendly | Higher purchase cost, lower efficiency |

| Cooling Medium | Mineral oil vs Synthetic ester vs Air | Ester ↑ higher cost | Fire-safe, biodegradable | Costlier than mineral oil |

2. Design Factors That Influence Pricing

| Design Factor | Options | Cost Effect | Example Impact |

|---|---|---|---|

| Core Geometry | Core-type vs Shell-type | Shell-type ↑ | Stronger mechanical withstand, but more complex to manufacture |

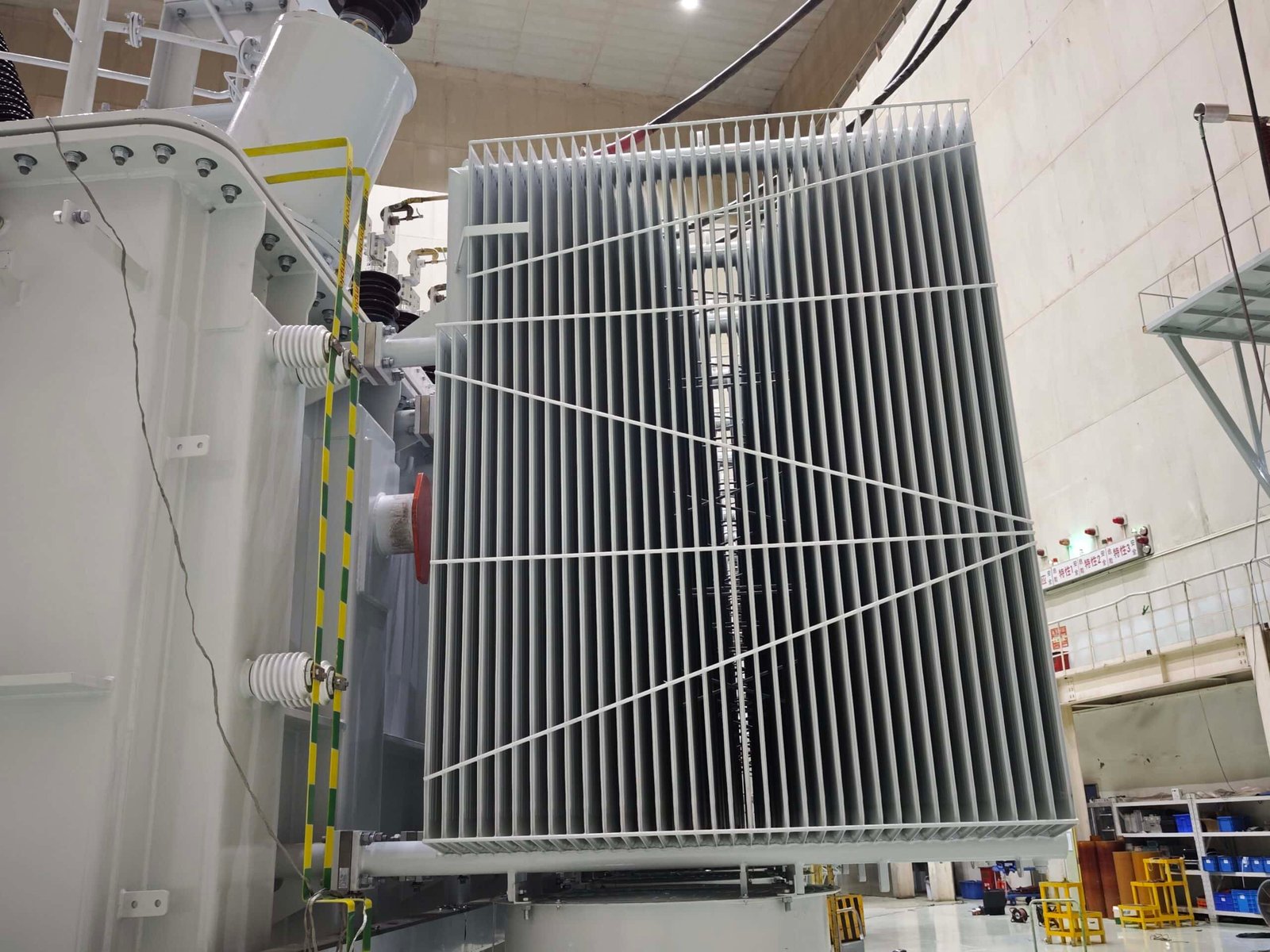

| Cooling System | ONAN, ONAF, OFAF, OFWF | Forced cooling ↑ | Fans/pumps add cost but allow higher capacity |

| Efficiency Class | IEC Tier 1 vs Tier 2 vs Tier 3 | Higher tiers ↑ | Meets eco-design directives, reduces lifetime losses |

| Protection Features | Basic relays vs Digital sensors/IoT | Advanced features ↑ | Enables predictive maintenance, lowers downtime |

3. Pricing Example by Design and Material

| Transformer Type | Capacity | Winding & Core | Cooling | Approximate Cost (USD)* |

|---|---|---|---|---|

| Standard Oil-Immersed | 1000 kVA | Aluminum + Silicon Steel | ONAN | $20,000 – $30,000 |

| Premium Oil-Immersed | 1000 kVA | Copper + Amorphous Steel | ONAF | $30,000 – \$45,000 |

| Dry-Type Cast Resin | 1000 kVA | Copper + Silicon Steel | Air (AN) | $40,000 – $55,000 |

| Eco-Friendly Ester-Filled | 1000 kVA | Copper + Silicon Steel | ONAN | $35,000 – $50,000 |

*Prices vary by region, efficiency requirements, and raw material market fluctuations.

4. Balancing Cost with Value

- Short-term savings: Aluminum windings, silicon steel, and simpler cooling reduce initial cost.

- Long-term savings: Copper windings, amorphous cores, ester oils, and digital monitoring lower lifecycle cost.

- Market-driven pricing: Raw material volatility (especially copper) can heavily impact pricing.

- Compliance costs: Meeting IEC/DOE eco-design efficiency standards increases upfront price but ensures regulatory compliance.

What Is the Impact of Cooling Type and Insulation?

When engineers or procurement managers evaluate a transformer, two of the most decisive design elements are its cooling type and insulation system. These factors directly affect price, efficiency, fire safety, environmental compliance, and long-term reliability. An inappropriate choice can lead to overheating, insulation breakdown, higher energy losses, or even catastrophic failures. This makes understanding cooling and insulation impacts critical for balancing technical performance with lifecycle cost and operational safety.

Cooling type and insulation strongly impact transformer performance and cost because they determine how effectively heat is dissipated and how well electrical stresses are managed. Oil-immersed transformers with paper-oil insulation and radiator cooling offer high efficiency and long life at a relatively low cost, while dry-type transformers with cast resin or epoxy insulation are safer and environmentally friendly but more expensive and less efficient. Forced cooling systems improve loading capacity but increase price and complexity, while insulation choice affects fire resistance, environmental risk, and maintenance needs.

Oil-immersed transformers are always safer than dry-type transformers.False

Oil-immersed designs are efficient but carry risks of leaks and fire hazards, while dry-type designs are safer in indoor or fire-sensitive environments.

Forced cooling systems allow transformers to handle higher loads without overheating.True

Adding fans or oil pumps increases heat dissipation, raising loading capacity and stability.

1. Cooling Types and Their Impact

| Cooling Type | Code | Features | Impact on Cost & Performance |

|---|---|---|---|

| Natural Oil, Natural Air | ONAN | Passive cooling via oil circulation and radiators | Cost-effective, reliable, limited overload handling |

| Oil Natural, Air Forced | ONAF | Oil circulates naturally, air cooled by fans | Higher cost, supports higher load |

| Oil Forced, Air Forced | OFAF | Pumps + fans enhance oil & air cooling | Expensive, high reliability, supports heavy-duty use |

| Oil Forced, Water Forced | OFWF | Uses water heat exchangers | Very high cost, compact for large ratings, suitable in space-limited substations |

| Dry Type (Air Natural, Air Forced) | AN/AF | No oil, relies on natural or forced air | Safe, eco-friendly, less efficient, higher cost per kVA |

2. Insulation Types and Their Impact

| Insulation Type | Typical Application | Advantages | Limitations | Cost Impact |

|---|---|---|---|---|

| Mineral Oil + Paper | Standard oil-immersed | High dielectric strength, cost-effective | Fire risk, environmental hazard | Lower cost |

| Synthetic Ester Fluids | Indoor/eco-sensitive | Fire-safe, biodegradable | Higher viscosity, higher cost | Medium-high cost |

| Natural Ester Fluids | Renewable/eco-friendly | Biodegradable, safe, sustainable | Limited availability, higher cost | Higher cost |

| Cast Resin / Epoxy | Dry-type | Fire-safe, indoor-friendly, low maintenance | Sensitive to moisture, higher losses | High cost |

3. Combined Impact on Pricing and Operation

| Transformer Type | Cooling + Insulation | Efficiency | Safety | Cost Level |

|---|---|---|---|---|

| Standard Oil-Immersed | ONAN + Mineral Oil | Very high | Moderate (fire risk) | $$ |

| Enhanced Oil-Immersed | ONAF/OFAF + Ester Fluid | Very high | High (fire-safe) | $$$ |

| Dry-Type Cast Resin | AN/AF + Epoxy | Medium | Very high (indoor safe) | $$$$ |

| Large-Scale Utility | OFWF + Mineral Oil | Highest | Medium | $$$$ |

4. Practical Implications for Buyers

- Efficiency vs Safety Trade-off: Oil designs are cheaper and more efficient but riskier in fire-sensitive areas. Dry-type designs are safer but pricier.

- Cooling Impacts Loading Flexibility: Forced cooling allows transformers to handle peak loads, reducing the need for oversizing.

- Insulation Defines Compliance: Ester oils or resin systems are often required to meet fire safety or environmental standards.

- Lifecycle Costs Differ: Lower upfront cost of oil-immersed may be outweighed by higher insurance, fire-suppression, and environmental cleanup costs if leaks occur.

How Do Efficiency Standards and Losses Influence Price?

When evaluating transformer prices, one of the most overlooked but critical factors is compliance with efficiency standards and the impact of losses. Many buyers initially focus on kVA rating or insulation type, but transformers are 24/7 operating assets, meaning even small efficiency differences translate into huge lifecycle costs. Stricter standards (such as EU Ecodesign Tier 2, DOE efficiency levels, and IEC/IEEE loss requirements) mandate lower no-load and load losses, but achieving them requires premium materials, tighter manufacturing tolerances, and advanced design. This directly affects upfront pricing, though it often reduces total ownership cost.

Efficiency standards and transformer losses influence price because higher-efficiency designs require more expensive core materials (e.g., amorphous or high-grade silicon steel), thicker windings, and optimized cooling systems. While these raise initial costs, they significantly cut operating expenses by reducing no-load and load losses, making premium transformers more cost-effective over their lifetime despite higher purchase prices.

A transformer with higher efficiency always costs less than a lower-efficiency model.False

High-efficiency models require costly materials and design improvements, so initial price is higher, but long-term costs are lower due to reduced losses.

Efficiency standards such as EU Ecodesign and U.S. DOE set minimum loss levels for transformers sold in those regions.True

Regulatory frameworks require manufacturers to meet specific no-load and load loss thresholds to improve energy sustainability.

1. Types of Transformer Losses and Their Cost Relevance

| Loss Type | Description | Key Influencing Factors | Cost Implications |

|---|---|---|---|

| No-Load Losses (Core Losses) | Energy lost in the magnetic core even under no load | Core steel grade, lamination thickness, amorphous vs silicon steel | Lower losses require premium steel, increasing cost |

| Load Losses (Copper Losses) | Losses in windings due to resistance under load | Copper vs aluminum windings, conductor cross-section | More copper reduces losses but raises material cost |

| Stray Losses | Eddy currents in tank, clamps, leads | Structural design, shielding | Better designs add cost but reduce inefficiencies |

| Cooling Losses | Energy for fans/pumps in forced cooling systems | Cooling design, auxiliary load | More efficient cooling reduces OpEx but adds CapEx |

2. Cost vs Efficiency Trade-Off

| Efficiency Standard | Loss Requirements | Impact on Price | Long-Term Impact |

|---|---|---|---|

| IEC Tier 1 | Basic loss limits | Lower upfront cost | Higher lifetime energy losses |

| IEC Tier 2 / EU Ecodesign | Stricter no-load/load loss limits | Higher upfront cost | Lower OpEx, faster payback |

| U.S. DOE Efficiency Standards | Among strictest globally | Increases material & design cost | Saves millions in energy over lifespan |

| Amorphous Core Transformers | Very low no-load loss | High upfront price | Best for 24/7 base load operation |

3. Illustrative Example: 1000 kVA Distribution Transformer

| Design | No-Load Losses (W) | Load Losses (W) | Purchase Price (USD)* | 20-Year Energy Cost (USD)* | Total Ownership Cost |

|---|---|---|---|---|---|

| Standard Silicon Steel (Tier 1) | 2,000 | 12,000 | $25,000 | $180,000 | $205,000 |

| High-Efficiency Silicon Steel (Tier 2) | 1,500 | 10,000 | $30,000 | $150,000 | $180,000 |

| Amorphous Core | 800 | 9,000 | $38,000 | $120,000 | $158,000 |

*Values approximate, vary by energy tariffs, load factor, and regional market.

4. Practical Implications for Buyers

- High efficiency = higher price, lower lifecycle cost. Buyers should not judge transformers on purchase cost alone.

- Standards compliance may be mandatory. EU and U.S. markets require Tier 2/DOE-level transformers—non-compliance is not an option.

- Energy tariffs determine ROI. In high-cost electricity regions, premium efficiency pays back faster.

- Applications matter. For 24/7 base load, low-loss transformers save more; for intermittent or backup duty, lower-cost models may suffice.

What Role Do Certifications and Compliance Requirements Play?

When procuring power transformers, buyers often compare kVA ratings, cooling types, and efficiency classes, but one crucial element that directly influences safety, reliability, and market access is certifications and compliance requirements. Without proper certifications, a transformer may fail regulatory inspections, void insurance coverage, or even be barred from installation. The financial risks of non-compliance—penalties, recalls, accidents, or system failures—far outweigh the cost of ensuring certification. For end-users, compliance provides assurance that the equipment has been manufactured, tested, and documented according to internationally recognized standards.

Certifications and compliance requirements play a vital role in transformer procurement because they confirm that the equipment meets mandatory international, regional, and industry-specific standards for safety, efficiency, and environmental protection. Certified transformers ensure interoperability across markets, reduce liability risks, guarantee quality, and often enable energy savings incentives, making compliance a key factor in both technical and financial decision-making.

Certifications are optional for transformer deployment in regulated power networks.False

In most regions, compliance with standards like IEC, IEEE, or DOE is mandatory for grid-connected transformers.

Compliance certifications also influence insurance, financing, and long-term asset valuation.True

Certified equipment reduces risk, enabling better insurance coverage and higher asset value.

1. Key Certification and Compliance Standards

| Certification / Standard | Scope | Role in Compliance |

|---|---|---|

| IEC (International Electrotechnical Commission) | Global | Defines transformer design, testing, and efficiency standards (IEC 60076 series) |

| IEEE / ANSI | USA & Americas | Sets performance, safety, and testing standards widely used in North America |

| EU Ecodesign Directive | Europe | Mandates minimum efficiency and eco-design requirements |

| DOE Efficiency Standards | USA | Defines minimum efficiency levels for distribution transformers |

| UL / CE Marks | Product Safety (USA/EU) | Certifies compliance with electrical safety regulations for market access |

| RoHS / REACH | Environmental | Restricts hazardous substances, ensures safe materials |

| ISO 9001 / 14001 / 45001 | Quality, Environmental, Safety Management | Confirms manufacturer quality systems and compliance practices |

2. How Compliance Impacts Price and Value

| Factor | Effect on Price | Long-Term Benefit |

|---|---|---|

| Testing & Certification Costs | Adds upfront cost | Guarantees safety and reliability |

| Design Adjustments for Efficiency Standards | Increases material and engineering costs | Reduces lifetime energy losses |

| Environmental Compliance (PCB-Free, RoHS, REACH) | Higher procurement cost for safe materials | Protects against legal fines & cleanup costs |

| Market Access | Certification fees raise price | Enables entry into regulated markets (EU, US, Asia, Africa) |

3. Practical Benefits for Customers

- Safety Assurance → Reduces risk of fire, explosion, or insulation failure.

- Legal Compliance → Meets local and international laws, avoiding fines or rejection.

- Financial Security → Certified equipment is insurable, financeable, and retains asset value.

- Operational Reliability → Ensures transformers perform consistently under required load conditions.

- Sustainability & ESG → Meets eco-regulations, supporting environmental goals and corporate responsibility.

4. Case Example

A European utility once rejected a shipment of medium-voltage transformers from a supplier because they lacked EU Ecodesign Tier 2 certification. The non-compliant units had to be returned at the manufacturer’s cost, delaying the project by six months and incurring millions in penalties. This demonstrates how certifications directly affect business outcomes.

How Do Market Conditions and Customization Options Affect Cost?

When buyers compare transformer prices, they often assume capacity (kVA rating) or efficiency standards are the main cost drivers. While those are critical, market conditions and customization requirements can cause price swings of 20–40% or more. Global raw material markets (especially copper, aluminum, and electrical steel) heavily influence transformer pricing. At the same time, buyer-specific customization—whether for cooling type, insulation, smart monitoring, or regulatory compliance—adds engineering complexity, longer production time, and higher costs. This combination makes understanding both external market pressures and internal design demands essential for accurate budgeting.

Market conditions and customization options affect transformer cost by driving fluctuations in raw material prices, supply chain stability, and compliance with regional standards, while customer-specific design requests (e.g., copper vs aluminum windings, ester oil, advanced monitoring, or compact geometry) add engineering, testing, and manufacturing expenses. This means two transformers of the same kVA rating can differ significantly in price depending on when and how they are ordered.

Transformer prices remain stable regardless of copper and steel market conditions.False

Copper and electrical steel are major cost components, and global price fluctuations directly impact transformer pricing.

Customized design features such as special cooling, eco-friendly insulation, or digital monitoring increase transformer cost.True

Customization requires additional engineering, premium materials, and testing, which increase overall cost.

1. Market Conditions Affecting Transformer Cost

| Market Factor | Influence on Cost | Example Impact |

|---|---|---|

| Copper Prices | Directly affect winding costs | A 20% rise in copper increases medium-voltage transformer price by 8–12% |

| Electrical Steel Supply | Impacts core costs | Shortages of grain-oriented steel can delay projects and increase prices |

| Oil & Resin Prices | Affect insulation/cooling costs | Ester fluids cost 2–3× more than mineral oil |

| Global Supply Chain | Shipping, logistics, and tariffs | Port delays or tariffs can add 10–15% to delivered cost |

| Energy Efficiency Regulations | Push higher material use | EU Ecodesign Tier 2 requires more copper/steel, raising unit cost |

2. Customization Options That Influence Pricing

| Custom Feature | Cost Impact | Buyer Benefit |

|---|---|---|

| Copper vs Aluminum Windings | Copper ↑ higher cost | Better efficiency, longer life |

| Insulation Choice (Mineral Oil vs Ester vs Resin) | Ester/Resin ↑ higher cost | Fire safety, eco-compliance |

| Cooling System (ONAN vs ONAF/OFAF/OFWF) | Forced cooling ↑ | Higher overload capacity |

| Core Design (Silicon vs Amorphous Steel) | Amorphous ↑ | Lower no-load losses, higher efficiency |

| Smart Monitoring & IoT Sensors | Advanced systems ↑ | Predictive maintenance, improved reliability |

| Compact or Special Geometry | Custom engineering ↑ | Space savings, unique installations |

3. Example: Price Impact of Market + Customization

| Transformer Type | Base Cost (USD)* | Market Impact | Customization Impact | Final Cost Range (USD)* |

|---|---|---|---|---|

| 1000 kVA, Standard Oil-Immersed | $25,000 | +$3,000 (copper spike) | +$5,000 (ester oil) | $33,000 |

| 2500 kVA, Utility Substation | $60,000 | +$6,000 (steel shortage) | +$10,000 (smart monitoring + ONAF cooling) | $76,000 |

| 10,000 kVA, Industrial | $200,000 | +$20,000 (tariffs/logistics) | +$25,000 (amorphous core + IoT) | $245,000 |

*Approximate market-based estimates; real prices vary by supplier and region.

4. Buyer Implications

- Timing Matters: Ordering during stable copper/steel markets lowers cost.

- Customization Should Be Justified: Premium features add cost but can reduce long-term losses, insurance fees, or maintenance costs.

- Regional Standards Drive Design: EU Ecodesign, DOE, and IEEE/ANSI compliance may require additional materials.

- Lifecycle vs Upfront Cost: A more expensive customized transformer often pays for itself in energy savings and reliability.

Conclusion

The price of a distribution transformer is determined by multiple factors, including its size, materials, efficiency, and regulatory compliance. While initial cost is important, buyers should also consider long-term operating expenses such as energy losses and maintenance. By evaluating these key factors, customers can balance upfront investment with lifecycle performance, ensuring both cost-effectiveness and reliability.

FAQ

Q1: What factors influence the price of a distribution transformer?

Key factors include:

Capacity (kVA rating): Higher ratings increase material and manufacturing costs.

Voltage class: Higher voltage insulation requires more advanced designs.

Efficiency standards: Eco-design and DOE-compliant models cost more upfront but reduce lifetime energy losses.

Materials: Copper windings are more expensive than aluminum; core materials (grain-oriented steel, amorphous steel) also affect price.

Cooling type: Oil-filled units are usually cheaper than dry-type transformers with advanced safety features.

Q2: How does transformer capacity affect pricing?

Distribution transformers are priced roughly on a per kVA basis. For example:

Small units (25–100 kVA) may cost a few thousand dollars.

Medium units (500–2000 kVA) can reach tens of thousands.

Higher capacities (above 2500 kVA) significantly increase costs due to size, materials, and transportation.

Q3: Are dry-type distribution transformers more expensive than oil-filled ones?

Yes. Dry-type transformers typically cost more due to fire safety, low maintenance, and environmental benefits. Oil-filled transformers are more economical upfront but require oil testing and leak management over their lifetime.

Q4: How do efficiency and standards compliance impact cost?

Meeting higher efficiency levels (DOE, IEC, EU Ecodesign Tier 2) raises the initial price but lowers operating costs. Compliance with UL, ANSI, CSA, and IEC standards also adds testing and certification costs but ensures safety and reliability.

Q5: What hidden costs should buyers consider?

Transportation and installation costs for large units.

Testing and commissioning fees.

Spare parts and accessories (tap changers, protection relays).

Maintenance and oil replacement (for oil-filled models).

Considering total life-cycle cost (LCC) is essential for accurate budgeting.

References

IEEE C57 – Distribution Transformer Standards: https://ieeexplore.ieee.org

IEC 60076 – Distribution Transformer Guidelines: https://webstore.iec.ch

NEMA – Distribution Transformer Pricing and Standards: https://www.nema.org

DOE – Distribution Transformer Efficiency Standards: https://www.energy.gov

European Commission – Ecodesign Requirements for Transformers: https://ec.europa.eu

Electrical4U – Distribution Transformer Price Factors: https://www.electrical4u.com

EEP – Cost Considerations in Transformer Selection: https://electrical-engineering-portal.com