In oil-filled transformers, maintaining proper oil levels and ensuring reliable cooling and insulation are critical for safe and efficient operation. A conservator tank is an essential component designed to manage the expansion and contraction of transformer oil caused by temperature variations.

What Is a Conservator in an Oil-Filled Transformer?

Oil-filled transformers rely on insulating oil for both cooling and dielectric strength. However, this oil expands and contracts with temperature changes during load variations and ambient fluctuations. If unmanaged, this would cause pressure build-up, oil leakage, or even transformer damage. To solve this, a conservator system is used as an expansion chamber that ensures proper oil management and prolongs transformer life.

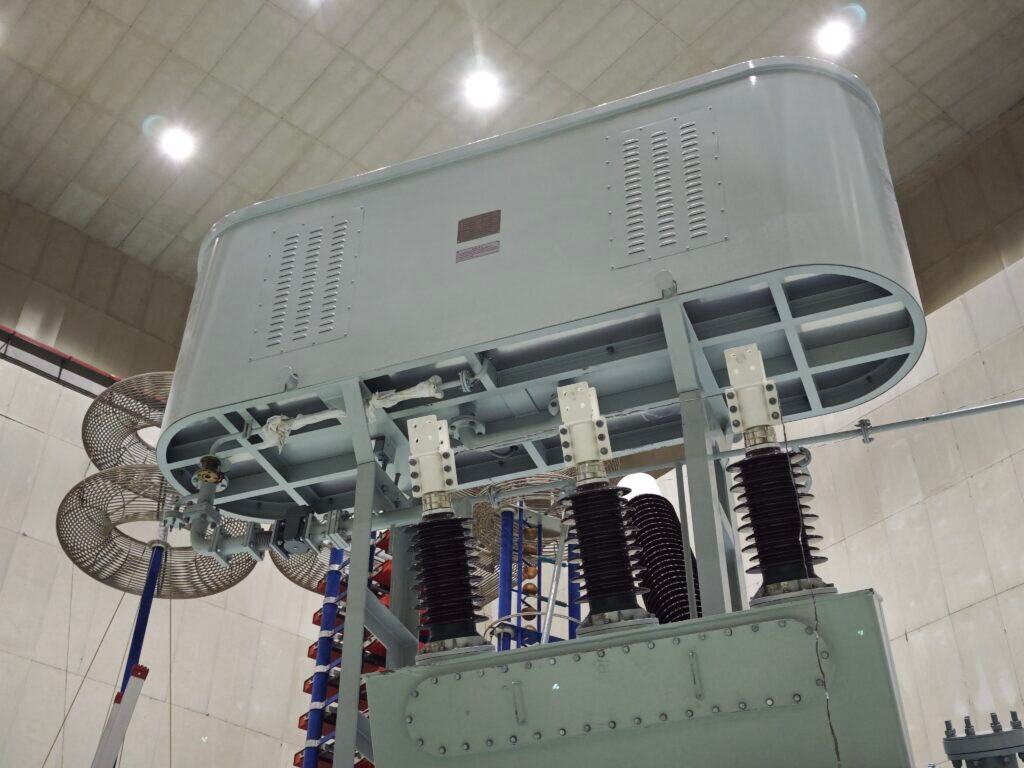

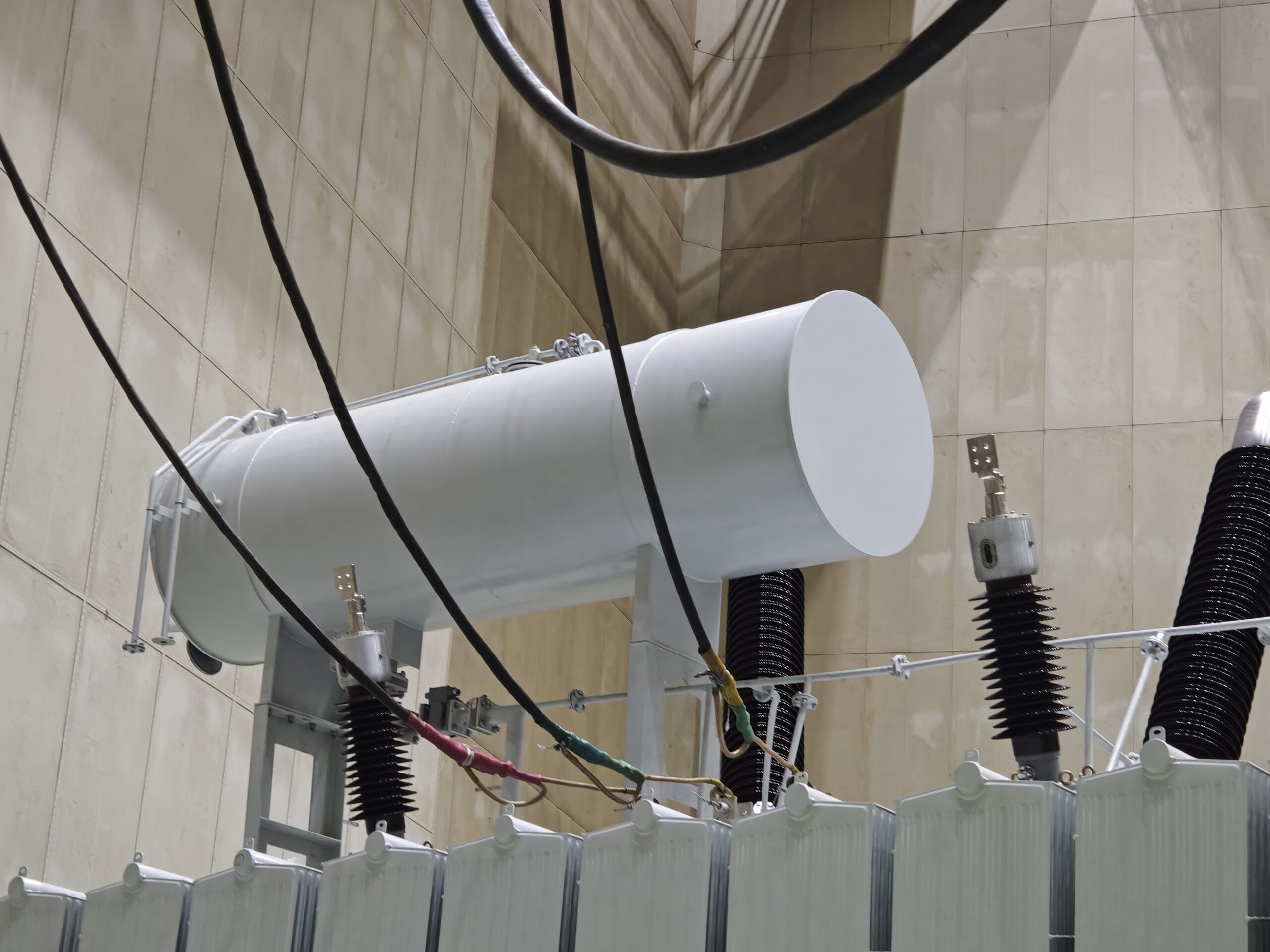

A conservator in an oil-filled transformer is a cylindrical tank mounted above the main tank that provides space for transformer oil expansion and contraction. It maintains proper oil levels in the transformer, prevents excessive pressure, and works with a breather system to keep the oil free from moisture and contamination.

This simple yet essential component makes oil-filled transformers safer, more reliable, and longer-lasting.

A conservator is used to store spare oil for refilling the transformer manually.False

A conservator is not a storage tank; it dynamically manages oil expansion and contraction due to load and temperature changes.

The conservator helps maintain constant oil levels and prevents moisture entry with the help of a breather.True

The conservator tank adjusts to oil volume changes and connects to a silica gel breather to keep the oil dry.

How the Conservator Works

Oil Expansion Management

- When load increases, transformer temperature rises → oil expands.

- Excess oil flows into the conservator instead of stressing the main tank.

Oil Contraction Management

- When load decreases or temperature drops → oil contracts.

- Oil flows back from the conservator into the main tank to maintain levels.

Breather System Integration

- Conservator connects to a silica gel breather.

- Breather filters and dries the air entering the conservator, preventing moisture contamination.

📊 Key Features of Conservator in Oil-Filled Transformers

| Component | Function | Benefit |

|---|---|---|

| Conservator Tank | Expansion chamber | Prevents pressure buildup |

| Oil Level Indicator | Shows oil volume | Assists in maintenance |

| Breather (Silica Gel) | Filters air | Keeps oil moisture-free |

| Buchholz Relay (in conservator line) | Detects faults | Protects against internal failures |

Types of Conservator Designs

- Plain Conservator: Simple cylindrical tank for oil expansion/contraction.

- Conservator with Oil Seal/Bladder: Uses a rubber bladder to isolate oil from air, reducing oxidation and moisture ingress.

Benefits of a Conservator

- Prevents transformer oil leakage and tank deformation.

- Reduces oxygen exposure, minimizing oil degradation.

- Works with protective devices (like Buchholz relay) to detect internal faults.

- Extends transformer life and improves reliability.

Example in Practice

A 132 kV, 50 MVA power transformer with a conservator maintains stable oil levels year-round despite ambient temperature changes from –10°C to +45°C. Without the conservator, the transformer would face high stress, oil oxidation, and possible leakage under varying loads.

How Does a Conservator Manage Oil Expansion and Contraction?

One of the biggest challenges in operating oil-filled transformers is the thermal expansion and contraction of insulating oil. Transformer oil expands as the temperature rises during heavy load or high ambient conditions, and contracts as it cools when load decreases. Without a way to manage this, the transformer would experience dangerous pressure build-up, oil leaks, or air ingress, which can compromise insulation and cooling. The conservator system solves this problem by providing an automatic buffer that accommodates oil volume changes.

A conservator manages oil expansion and contraction by acting as an expansion chamber: when the oil heats and expands, excess volume flows into the conservator tank, and when the oil cools and contracts, the oil flows back into the main tank. This keeps oil pressure stable, prevents tank deformation or leakage, and ensures insulation oil always fully covers transformer windings.

This system ensures long-term transformer reliability and protects both the insulation and cooling functions of the oil.

The conservator permanently stores excess transformer oil that is not in use.False

The conservator does not store spare oil but dynamically accommodates expansion and contraction during transformer operation.

The conservator ensures that transformer oil always maintains proper levels despite thermal fluctuations.True

By adjusting oil volume, the conservator prevents air pockets, maintains insulation, and supports safe operation.

How Oil Expansion and Contraction Works

Expansion Phase (High Load/Temperature)

- Transformer windings heat up → oil temperature increases.

- Oil expands and rises into the conservator tank.

- Conservator absorbs this excess, preventing stress on the main tank.

Contraction Phase (Low Load/Temperature Drop)

- Load decreases or ambient cools → oil temperature drops.

- Oil contracts, reducing volume in the main tank.

- Conservator releases stored oil back into the transformer.

📊 Oil Volume Change Example (50 MVA Transformer)

| Operating Condition | Average Oil Temp (°C) | Oil Volume Change (%) | Conservator Action |

|---|---|---|---|

| Light Load, Cold Weather | 15°C | Baseline | Oil drawn from conservator |

| Full Load, 35°C Ambient | 75°C | +5–7% | Oil pushed into conservator |

| Load Drop Overnight | 25°C | –3% | Oil returns from conservator |

Role of Breather and Oil Seal

- Breather (Silica Gel): Conservator breathes air in and out as oil volume changes. The breather filters and dries incoming air to keep moisture away from the oil.

- Sealed Bladder (in modern designs): Some conservators use a rubber bladder to separate oil from air, eliminating direct contact and reducing oxidation.

Benefits of Conservator in Oil Volume Control

- Keeps the oil level consistent around windings.

- Prevents air pockets, which can reduce dielectric strength.

- Reduces mechanical stress on the transformer tank.

- Minimizes oxidation and moisture absorption, protecting oil quality.

Why Is a Conservator Important for Transformer Reliability and Safety?

Oil-filled transformers are designed to operate under varying loads and environmental conditions, which cause their insulating oil to expand and contract. If these fluctuations are not properly managed, the transformer may suffer from pressure build-up, leaks, oil oxidation, or insulation failure—all of which reduce lifespan and increase the risk of catastrophic faults. The conservator system is the safeguard that ensures oil stability, quality, and protection of the transformer’s internal components.

A conservator is important for transformer reliability and safety because it automatically regulates oil expansion and contraction, prevents air pockets, reduces mechanical stress on the main tank, and works with breathers and protective devices to keep the oil clean and moisture-free. This ensures consistent insulation, cooling, and fault detection, directly enhancing both reliability and safety.

In other words, the conservator is not just an accessory but a core safety feature of oil-filled transformers.

A transformer can safely operate at high loads without a conservator system.False

Without a conservator, thermal expansion of oil would cause leaks, tank stress, or insulation issues under load.

The conservator improves safety by stabilizing oil levels and enabling early fault detection through the Buchholz relay.True

The conservator provides controlled oil movement and integrates with protective relays for safer operation.

Key Roles of the Conservator in Reliability and Safety

Stable Oil Levels

- Keeps transformer windings fully submerged, preventing air gaps that can reduce dielectric strength.

- Ensures insulation integrity under varying load cycles.

Mechanical Stress Relief

- Absorbs volume changes in oil, avoiding pressure stress or deformation of the main tank.

- Reduces risk of leaks and mechanical failures.

Moisture and Contamination Control

- Works with the silica gel breather to dry incoming air.

- In bladder-type designs, isolates oil from air entirely, minimizing oxidation.

Integration with Protection Systems

- The Buchholz relay (mounted in the conservator pipeline) detects gas bubbles from internal faults.

- Provides early warning of insulation breakdown, arcing, or overheating.

📊 Reliability Benefits of a Conservator System

| Function | Issue Without Conservator | Protection With Conservator |

|---|---|---|

| Oil Expansion/Contraction | Tank stress, leaks | Stable volume control |

| Oil Quality | Oxidation, moisture ingress | Dried, filtered air entry |

| Insulation | Air pockets, reduced dielectric strength | Full immersion maintained |

| Fault Detection | No gas accumulation warning | Buchholz relay early alarm |

Case Example

In a 100 MVA grid transformer, sudden load peaks during summer caused frequent oil leakage and overheating before a conservator system upgrade. After installation of a bladder-type conservator with breather and Buchholz relay, oil levels stabilized, leakage was eliminated, and early warnings from the relay prevented two major failures over a 5-year period.

What Additional Features Are Typically Associated with Conservators (e.g., Breathers, Oil Level Indicators)?

In oil-filled transformers, the conservator tank is far more than just an oil expansion chamber. To ensure safe, efficient, and long-term operation, it is integrated with several supporting features and protective devices. These attachments safeguard transformer oil quality, provide monitoring for operators, and offer early fault detection. Without them, the conservator would not fully deliver its reliability and safety benefits.

The additional features typically associated with conservators include breathers (to control moisture ingress), oil level indicators (to monitor oil volume), Buchholz relays (for fault detection), and sometimes bladder seals (to prevent direct air contact with oil). Together, these devices ensure stable oil management, protect insulation quality, and enhance transformer safety.

This means the conservator works as a central hub for transformer reliability systems.

A conservator tank alone is sufficient for safe transformer operation without accessories.False

The conservator requires breathers, indicators, and relays to maintain oil quality and detect issues.

The breather and oil level indicator are standard attachments to conservator tanks.True

Nearly all conservators are equipped with these features for oil monitoring and moisture control.

Key Features Associated with Conservators

Breather (Silica Gel Breather)

- Purpose: Filters and dries air entering the conservator during oil contraction.

- Function: Prevents moisture from contaminating oil, which could reduce dielectric strength.

- Benefit: Keeps oil dry, extends insulation life.

Oil Level Indicator (OLI)

- Purpose: Measures and displays the oil level inside the conservator.

- Function: Helps operators monitor oil balance under load/temperature changes.

- Benefit: Prevents oil shortage that could expose windings and cause failures.

Buchholz Relay (mounted on pipeline between conservator and main tank)

- Purpose: Fault detection system for internal gas generation.

- Function: Detects gas accumulation from insulation breakdown or arcing, triggers alarms or trip signals.

- Benefit: Provides early warning of dangerous internal faults.

Bladder/Diaphragm Seal (in sealed conservators)

- Purpose: Isolates transformer oil from direct contact with atmospheric air.

- Function: Reduces oxidation and moisture contamination.

- Benefit: Improves oil longevity, especially in humid environments.

📊 Typical Conservator Features and Functions

| Feature | Function | Benefit for Transformer |

|---|---|---|

| Breather | Filters/drys air | Prevents moisture contamination |

| Oil Level Indicator | Displays oil volume | Ensures proper insulation coverage |

| Buchholz Relay | Fault gas detection | Early fault warning and protection |

| Bladder Seal | Isolates oil from air | Reduces oxidation and extends oil life |

How These Features Work Together

- Breather and Bladder Seal → Protect oil quality.

- Oil Level Indicator → Guides maintenance and operation.

- Buchholz Relay → Enhances safety through early fault alarms.

- All combined, they transform the conservator from a passive tank into an active reliability system.

Conclusion

Conservators are vital in oil-filled transformers because they provide a reservoir for oil expansion and contraction, preventing leakage, pressure buildup, and air contamination inside the main tank. By stabilizing oil conditions, conservators enhance transformer performance, extend service life, and improve safety.

FAQ

Q1: Why are conservators used in oil-filled transformers?

A conservator tank provides space for oil expansion and contraction due to temperature variations. As transformer load increases, oil heats up and expands; the conservator prevents excessive pressure buildup, reducing stress on the main tank.

Q2: What is the function of the conservator tank?

Absorbs oil expansion caused by temperature rise.

Maintains oil level by supplying oil when temperature drops.

Prevents main tank damage by reducing internal pressure fluctuations.

Works with a breather (silica gel) to keep the oil moisture-free.

Q3: How does the conservator improve transformer efficiency and lifespan?

By stabilizing oil levels and preventing air and moisture ingress, the conservator ensures:

Better insulation performance of transformer oil.

Reduced risk of oxidation and sludge formation.

Longer service life of both oil and insulation system.

Q4: What safety features are associated with conservators?

Buchholz relay: Detects gas accumulation from faults and protects against internal failures.

Oil level indicators: Monitor oil volume to prevent under or overfilling.

Breather system: Filters moisture from the air before it enters the conservator.

Q5: Do all transformers have conservators?

No. Small distribution transformers often use sealed or hermetically sealed tanks instead of conservators. Conservators are typically used in large power transformers where significant oil expansion must be managed.

References

IEC 60076 – Power Transformer Standards: https://webstore.iec.ch

IEEE C57 – Guide for Transformer Operation: https://ieeexplore.ieee.org

Electrical4U – Conservator in Transformer Explained: https://www.electrical4u.com

EEP – Purpose of Conservator in Transformer: https://electrical-engineering-portal.com

National Grid – Transformer Oil System Overview: https://www.nationalgrid.com