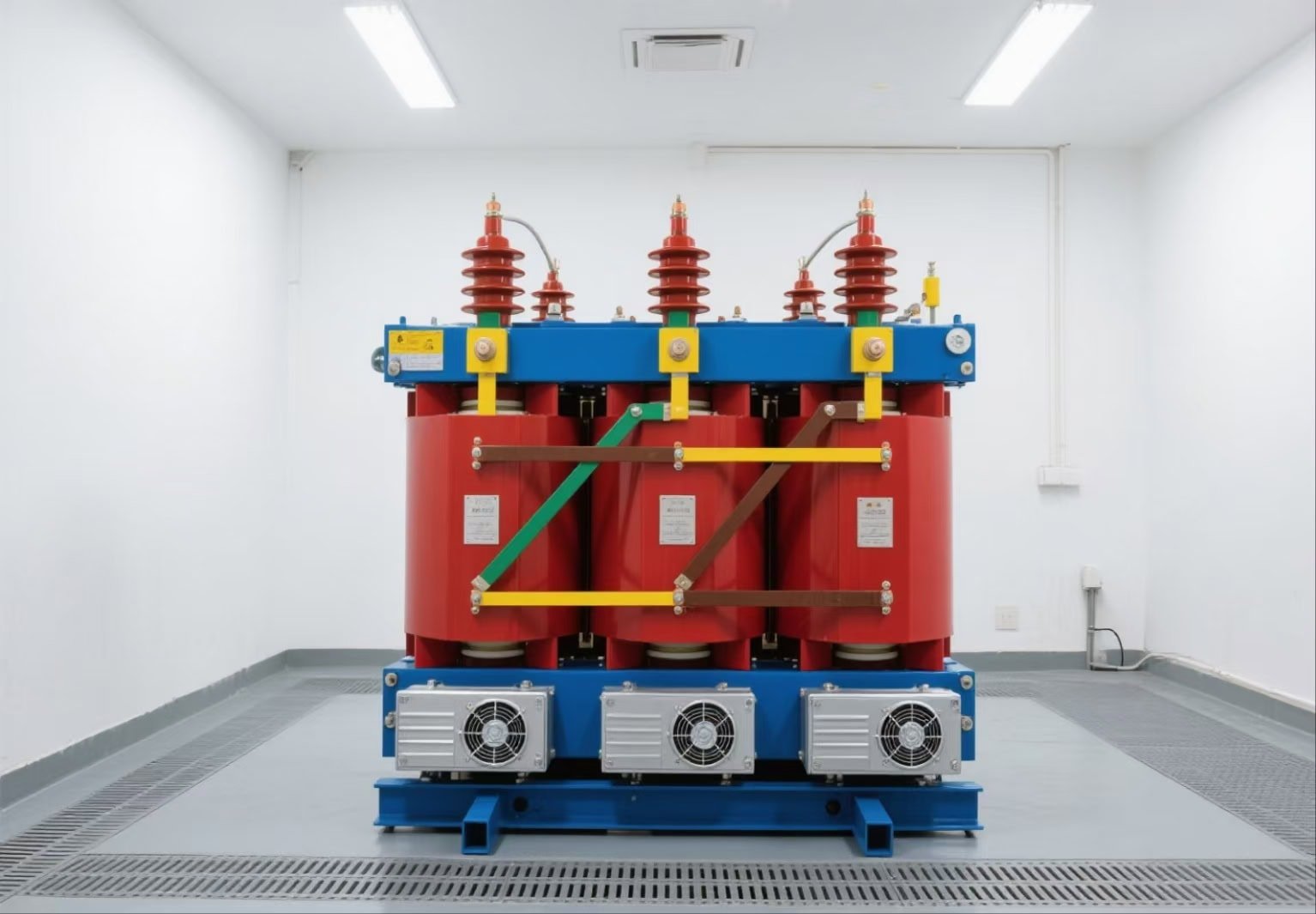

Dry-type transformers have gained significant popularity in modern electrical systems due to their safety, reliability, and eco-friendly features. However, when evaluating their use, one crucial question often arises: Are they cost-effective in the long run? While the initial investment in a dry-type transformer is typically higher than that of an oil-immersed unit, long-term savings in maintenance, safety, and operational efficiency can make them a smart financial choice—especially in commercial, industrial, and renewable energy applications.

How Does the Initial Cost of Dry Type Transformers Compare to Oil-Immersed Units?

When sourcing power transformers, one of the most common concerns from project owners, EPC contractors, and procurement teams is the difference in initial cost between dry-type transformers and oil-immersed transformers. Many buyers assume that the cheapest upfront option will guarantee the best value, but this is rarely true. Choosing a transformer based purely on initial cost can introduce long-term risks—such as higher maintenance expenses, shorter lifespan, and reduced reliability—that ultimately increase total project cost. Understanding how the initial price is structured, why the two designs differ, and what you truly get for the investment is essential for making a financially sound decision.

Dry-type transformers typically have a higher initial cost—often 20% to 40% more than oil-immersed units—due to their more complex insulation systems, resin casting processes, and specialized materials. Oil-immersed transformers, by contrast, are usually cheaper upfront because they use conventional cellulose-and-oil insulation systems with simpler manufacturing requirements. However, the initial cost difference must always be analyzed in relation to long-term reliability, maintenance needs, installation complexity, and operational demands.

This comparison becomes especially important when transformers operate in buildings, hospitals, commercial complexes, renewable energy stations, tunnels, or fire-sensitive environments. Keep reading to explore a detailed breakdown of how these cost structures are formed and how to make the most cost-effective purchase decision—not only today, but over the entire lifecycle of your transformer.

Dry-type transformers are always cheaper than oil-immersed transformers.False

Dry-type transformers generally cost more upfront due to resin insulation and specialized production processes.

Oil-immersed transformers usually offer the lowest initial purchase price.True

Their materials and manufacturing processes are simpler and more economical, reducing upfront cost.

Understanding What Determines Initial Cost Differences

1. Material and Insulation System Costs

Dry-type transformers use epoxy resin, cast-coil insulation, fiberglass reinforcements, and air-cooling systems. These materials are more expensive than the cellulose-paper and mineral-oil systems used in conventional oil-immersed transformers. In addition, the resin casting process requires specialized vacuum equipment and curing chambers, increasing manufacturing complexity and cost.

| Component/Material | Dry-Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Insulation | Epoxy resin, fiberglass, cast coil | Paper + mineral oil |

| Cooling medium | Air (AN/AF) | Oil (ONAN/ONAF) |

| Production complexity | High | Moderate |

| Material cost | Higher | Lower |

Result: Dry-type units cost more to build, especially in medium-to-high-capacity applications.

2. Manufacturing Process and Production Technology

Dry-type production involves precision robotic winding, vacuum casting of coils, controlled curing cycles, and extensive testing to ensure thermal stability, fire resistance, and partial discharge suppression. These steps require more energy, labor, and specialized machinery.

Oil-immersed transformers benefit from long-established manufacturing processes, simpler assembly, and lower production costs.

| Process Factor | Dry-Type | Oil-Immersed |

|---|---|---|

| Automation level | High | Medium |

| Casting process | Required | Not applicable |

| Oil processing | Not required | Required (but lower cost) |

| Labor intensity | Higher | Lower |

| Overall production cost | Higher | Lower |

3. Capacity Range and Cost Sensitivity

Dry-type transformers are most cost-competitive at lower capacities (typically below 5 MVA). As capacity increases, dry-type designs become disproportionately expensive due to higher resin volume, winding size, and cooling limitations.

Oil-immersed designs scale more efficiently, so the cost gap widens with higher kVA/MVA ratings.

Example Cost Comparison (Typical Market Ranges):

| Transformer Rating | Dry-Type Cost | Oil-Immersed Cost | Difference |

|---|---|---|---|

| 500 kVA | 30–45% higher | Baseline | Moderate |

| 1,000 kVA | 20–35% higher | Baseline | Significant |

| 2,500 kVA | 25–40% higher | Baseline | Large |

| ≥5 MVA | Often impractical | Standard | Very large |

This is why dry-type solutions are mostly seen in commercial buildings, industrial facilities, and renewables, while large utility-scale sites still favor oil-immersed units.

4. Installation Location and Application Requirements

Some installation environments require strict fire resistance and environmental protection. These often mandate dry-type transformers, which can raise initial project cost but reduce overall installation expenses.

Examples:

- Underground substations ⇒ Dry type preferred

- Hospitals & schools ⇒ Fire code compliance → Dry type

- Offshore wind nacelles ⇒ Oil-free environment → Dry type

- Outdoor substations ⇒ Oil immersed more economical

In strict environments, expensive fire-proof rooms, oil containment pits, and spill-prevention systems are required for oil-immersed units—costs that often exceed the dry-type transformer’s higher purchase price.

5. Accessories, Standards, and Safety Requirements

Dry-type transformers require:

- Temperature sensors

- Forced-air cooling fans (for higher load)

- Specialized resin formulations

- Partial discharge testing

Oil-immersed transformers require:

- Oil conservator systems

- Breathers

- Bushings

- Tap changers

- Oil monitoring gauges

Depending on the configuration, either design can be more expensive, but dry types often include premium safety features by default.

Detailed Table: Initial Cost Comparison Factors

| Category | Dry-Type Transformers | Oil-Immersed Transformers | Impact on Initial Cost |

|---|---|---|---|

| Material Cost | High (resin, fiberglass) | Moderate (oil, cellulose) | Higher for dry-type |

| Cooling System | Simple but larger core | Oil + pumps for higher loads | Comparable |

| Fire Protection | Built-in | Requires external measures | Oil-immersed cost increases with fire requirements |

| Installation Requirements | Lower | Higher (oil pits, fire walls) | Dry type saves cost |

| Capacity Range | Limited for large MVA | Efficient at all sizes | Oil-immersed cheaper for large units |

| Testing Requirements | More complex | Standard | Slightly higher dry-type cost |

What Are the Long-Term Maintenance and Operational Savings?

In many power projects, buyers focus heavily on the initial purchase cost of a transformer while overlooking the far more influential factor—long-term maintenance and operational savings. This oversight often leads to higher lifecycle costs, unexpected downtime, and increased energy losses that continue for decades. When maintenance is neglected or inefficient, failures or accelerated aging can lead to expensive repairs, emergency replacements, and significant production interruptions. The good news is that by understanding the long-term performance characteristics of your transformer, you can make smarter decisions that reduce maintenance burden, minimize energy losses, and maximize return on investment. This article unpacks the real savings you can achieve over the transformer’s lifetime and explains how maintenance strategies, efficiency levels, and design selection can help you optimize long-term operational value.

Long-term maintenance and operational savings come from reduced inspection requirements, lower failure risks, minimized downtime, improved energy efficiency, longer insulation and winding life, stable thermal performance, and reduced need for consumables or oil management. These savings often exceed the initial price difference between transformer types, making lifecycle analysis essential for buyers.

As you explore the following sections, you will discover why choosing the right transformer type—along with proper maintenance planning—can save your project massive costs over 20–30 years of service life. Keep reading to understand how these savings truly accumulate and how they influence the overall economic performance of your power system.

Transformers with higher initial efficiency ratings generally lead to meaningful long-term cost savings.True

Higher efficiency reduces core and load losses, directly lowering electricity bills over the transformer's lifetime.

Dry-type transformers require frequent oil testing and filtration.False

Dry-type transformers contain no oil, eliminating the need for oil testing, oil replacement, or leak-related maintenance.

Long-Term Cost Components in Transformer Operation

Long-term savings are influenced by several cost categories. The table below provides a concise overview:

| Cost Category | Dry-Type Transformer | Oil-Immersed Transformer | Impact on Long-Term Savings |

|---|---|---|---|

| Cooling System Maintenance | Minimal | Moderate to high | Dry type saves cost over lifetime |

| Oil Management | None | Required | Significant savings for dry type |

| Inspection Frequency | Low | Medium | Lower operational cost |

| Energy Efficiency | Medium to high | Medium to high (varies by design) | Both can save but depends on spec |

| Failure Risk | Low in clean environments | Low to medium | Reduced downtime saves cost |

| Environmental Compliance | Simple | Complex | Dry type avoids oil containment and leak mitigation |

Below is a second table showing typical inspection intervals:

| Maintenance Task | Dry-Type | Oil-Immersed | Cost Difference |

|---|---|---|---|

| Visual Inspection | Every 6–12 months | Every 3–6 months | Moderate saving |

| Oil Testing | Not applicable | Annual | Large saving |

| Cooling Fan Check | Annual | Annual | Equal |

| Thermal Imaging | Annual | Annual | Equal |

| Leak Inspection | Not applicable | Required frequently | High savings |

Reduced Maintenance Requirements

Dry-type transformers offer significantly reduced maintenance needs because they eliminate oil-related tasks entirely. This removes the need for tests such as dielectric strength measurements, moisture analysis, dissolved gas analysis (DGA), or sludge cleaning. For oil-immersed units, these processes are necessary at regular intervals to ensure safe operation. In long-term operation—spanning 20 to 30 years—these oil-related procedures accumulate substantial recurring costs. Additionally, dry-type units require less cleaning and have fewer components susceptible to corrosion or contamination. The simplification in maintenance not only lowers cost but also minimizes the need for specialized technicians, which is especially beneficial in remote or desert-based renewable energy projects.

Improved Energy Efficiency and Lower Losses

Operational savings are heavily influenced by the transformer’s efficiency class. A transformer operates continuously, meaning even small improvements in core losses can translate to major long-term savings. In many applications, energy losses represent more than 75% of total lifetime cost, outpacing the initial purchase price. Investing in low-loss designs—such as amorphous metal cores or optimized winding geometries—substantially reduces energy bills. These reduced losses also limit heat generation, which contributes to longer insulation life and reduced thermal stress. Over 25 years, a high-efficiency transformer can save tens of thousands of dollars in electricity losses.

Longer Equipment Lifespan and Fewer Failures

Long-term operational savings depend heavily on extending the equipment life beyond its nominal expectancy. Dry-type transformers, especially cast-resin units, perform exceptionally well in environments with dust, humidity, or chemical exposure. Because they contain no oil and have fewer points of failure, they are less prone to leaks, deterioration, or contamination. Oil-immersed units can achieve long life as well, but they require more stringent monitoring and protective systems to avoid oil oxidation, moisture ingress, or gas formation. Every avoided failure prevents costly downtime—especially critical in industrial, hospital, or renewable installations with high uptime demands.

Reduced Downtime and Enhanced Operational Reliability

Unplanned outages are one of the most expensive consequences of inadequate transformer maintenance. Dry-type transformers have faster recovery times after overloads due to superior heat dissipation and simpler construction. By contrast, oil-immersed units must consider oil temperature gradients and moisture behavior before returning to full load after disturbances. Additionally, dry-type units typically exhibit better resilience against short circuits and mechanical stress. With fewer variables affecting performance, they require fewer interventions, resulting in better overall uptime and operational continuity.

Eliminated Environmental and Compliance Costs

Oil-immersed transformers require systems for spill containment, environmental monitoring, and leak detection, especially when installed in populated or water-sensitive areas. These compliance measures carry ongoing cost implications. Dry-type transformers completely remove oil-related environmental hazards, simplifying their permitting and reducing operational cost. This advantage is particularly significant in renewable energy, underground substations, public buildings, and offshore applications where environmental risk management is costly and highly regulated.

Lower Cooling System Operation Costs

Energy consumption from cooling systems contributes to operational cost, especially under continuous full-load conditions. Dry-type transformers often operate with natural air cooling (AN or ANAN design), requiring no pumps or oil circulation systems. In contrast, oil-immersed units must maintain continuous cooling—either ONAN, ONAF, or forced-oil systems—leading to higher auxiliary power consumption over the equipment’s lifetime. This seemingly minor difference can create substantial cost savings over decades of operation.

How Does Energy Efficiency Affect Lifetime Operating Costs of Power Transformers?

Energy efficiency is one of the most critical factors in determining the lifetime operating costs of a power transformer. While many buyers focus on initial purchase price, the reality is that energy losses over a transformer’s 25–35-year service life cost far more than the transformer itself. Even small improvements in efficiency can translate into tens of thousands—or even hundreds of thousands—of dollars in savings.

Understanding how efficiency works, which loss components matter most, and how to evaluate lifecycle costs enables buyers, EPC contractors, and asset managers to make smarter, more economical investment decisions.

1. The Two Types of Transformer Losses That Shape Operating Costs

Transformer energy efficiency is determined by two main loss categories:

① No-Load Losses (Core Losses)

These occur 24 hours a day, even with zero load. They result from:

- Hysteresis loss

- Eddy current loss

- Magnetizing current

Impact on lifetime cost:

Since core losses are always present, they accumulate massively over 25–35 years. High-efficiency silicon steel or amorphous metal cores can reduce these losses by 20–70%, offering significant savings.

② Load Losses (Copper/Stray Losses)

These occur only when the transformer is loaded. They include:

- I²R losses (resistive heating in windings)

- Stray flux losses

- Eddy losses in conductors and structural parts

Impact on lifetime cost:

Higher load factors mean load losses dominate the energy bill. For utility and industrial transformers with 50–80% average loading, load-loss optimization provides major long-term value.

2. Why Efficiency Has a Massive Impact Over the Transformer’s Lifetime

A small loss reduction = huge lifetime savings

Example:

A 1,000 kVA distribution transformer with:

- 350 W lower no-load losses

- 750 W lower load losses

At a typical electricity cost of $0.12/kWh, lifetime savings (30 years) often exceed:

👉 $40,000–$80,000 in avoided energy costs.

In many cases, the annual energy loss cost equals 5–15% of the transformer’s purchase price, every year.

3. Efficiency Classes and Their Financial Impact

High-efficiency transformer standards such as:

- DOE 2016 (USA)

- Ecodesign Tier 1 / Tier 2 (EU)

- Energy Labeling (Asia, Middle East)

These standards require manufacturers to use:

- Improved core steel

- Larger conductor cross-sections

- Better winding geometry

- Lower-loss magnetic materials

- Optimized cooling arrangements

Higher-efficiency transformers cost more upfront but reduce operating expenses dramatically.

Typical premium for high-efficiency transformer:

+5% to +15% purchase price

Typical lifetime cost savings:

10–40× the premium

Conclusion: Higher efficiency pays for itself early in the transformer’s operational life—often within the first 2–5 years.

4. How Loading Conditions Influence Energy Cost Impact

The real economic benefit of efficiency depends on how your transformer operates:

| Loading Level | Impact on Losses | Efficiency Benefit |

|---|---|---|

| Low load (<30%) | Core losses dominate | Focus on low no-load losses (amorphous core) |

| Medium load (30–70%) | Balanced losses | Balanced design (core + copper optimization) |

| High load (>70%) | Load losses dominate | Larger conductors, advanced cooling needed |

For renewable energy stations (solar, wind), with fluctuating loads, choosing a low no-load-loss transformer can drastically reduce lifetime costs.

5. Cooling Method Influence on Efficiency

Oil-Immersed Transformers

- Better heat dissipation

- Lower temperature rise

- Lower load losses

- Higher efficiency at medium/high load

Dry-Type Transformers

- Higher thermal stress

- Slightly higher load losses

- Often require higher-efficiency materials to compensate

Oil-immersed units usually offer better energy efficiency per dollar in high-capacity systems.

6. Total Ownership Cost (TOC): The Smart Way to Compare Transformers

Smart buyers evaluate transformers using the TOC model, which includes:

TOC = Initial Price + (No-Load Loss × A) + (Load Loss × B)

Where:

- A and B are loss capitalization factors

- Based on energy rates, load profile, expected service life

This model shows:

- The cheapest transformer upfront is rarely the cheapest over its lifetime.

- A slightly higher-efficiency transformer is an excellent long-term investment.

7. Real-World Example: Lifetime Cost Difference

Scenario:

1,600 kVA oil-immersed transformer

- Standard losses: 1,600 W no-load / 12,000 W load losses

- High-efficiency losses: 1,200 W / 9,500 W

Lifetime (30 years) savings:

- Energy cost reduction: $120,000+

- Reduced heating improves insulation life

- Lower load losses reduce operating temperature and extend life expectancy

Net effect: High-efficiency models reduce total project cost significantly.

What Role Do Safety and Insurance Benefits Play in Cost Savings for Power Transformers?

Safety is often viewed as a regulatory necessity, but in the transformer industry it is also a direct cost-saving factor, influencing operational reliability, risk mitigation, insurance premiums, and long-term asset protection. Whether using oil-immersed or dry-type transformers, the safety characteristics built into the design can significantly affect total ownership cost over the transformer's 25–35-year service life.

1. Reduced Fire Risk = Lower Insurance Premiums

Transformer-related fires are rare, but when they occur, the consequences are severe—equipment destruction, grid outages, business interruption, environmental cleanup, and even property damage.

Why safety lowers insurance cost:

Dry-type transformers (especially cast-resin types) are recognized as self-extinguishing, which can result in:

- Lower property insurance premiums

- Reduced mandated fire-protection systems

- Lower building construction costs (no containment pit, no fire-rated room)

Oil-immersed transformers, especially mineral-oil units, require:

- Fire suppression systems (sprinklers, gas systems, foam)

- Fire barriers

- Oil containment pit

- Higher insurance coverage

Many global insurers apply risk-based pricing, meaning safer technology leads to lower recurring insurance costs.

2. Enhanced Personnel Safety Reduces Liability Exposure

Safety features protect operators, electricians, and maintenance technicians.

Features that directly reduce liability and costs:

- Touch-safe enclosures

- Temperature monitoring and trip protection

- Arc-flash mitigation

- Overload and fault protection

- Low-smoke, halogen-free insulation (for indoor installations)

Lower risk of accidents = fewer workplace injury claims, lower compensation fees, and fewer regulatory penalties.

3. Improved Thermal Safety = Longer Aging Life and Reduced Replacement Cost

When a transformer operates safely within its thermal limits, its insulation system ages more slowly. This directly affects replacement cost and downtime.

Key safety-related thermal factors:

- Temperature rise class

- Cooling class (AN, AF, ONAN, ONAF, etc.)

- Hot-spot control

- Digital monitoring and thermal modeling

Safe thermal design can extend insulation life by 20–40%, delaying costly replacements and reducing unplanned outages.

4. Better Safety Design Minimizes Failure Rate and Repair Costs

Most transformer failures come from stress, overheating, moisture, or insulation breakdown. Enhanced safety features reduce these risks.

Cost savings from improved safety engineering:

- Fewer catastrophic failures (saves from multi-million-dollar outages)

- Lower maintenance frequency

- Reduced spare parts consumption

- Extended service life

Even a single avoided failure can save:

- $50,000–$300,000 (medium-voltage units)

- $500,000–$5 million (high-voltage power transformers)

5. Environmental Safety Reduces Compliance Costs

Regulators are increasingly strict about environmental protection. Compliance failures can lead to large fines and cleanup costs.

Examples:

- Oil spills require immediate containment and soil remediation

- PCB contamination requires hazardous-material disposal

- High-noise units require sound barriers

Dry-type transformers eliminate oil and therefore eliminate:

- Spill cleanup

- Oil-handling permits

- Containment infrastructure

This makes them especially cost-effective for indoor, commercial, renewable, and public buildings.

6. Safety Certifications Improve Insurability and Lower Risk Ratings

Standards such as:

- IEC 60076

- IEEE C57

- UL/CSA certifications

- Ecodesign & DOE efficiency and safety rules

- EN 50541 (distribution transformers)

- ISO 45001 (safety management)

help insurers classify the equipment as low risk, which can:

- Reduce premiums

- Reduce documentation requirements

- Speed up insurance approval for industrial or utility projects

Transformers without recognized certification often require:

- Higher insurance fees

- Additional testing

- Independent safety audits

7. Digital Safety Systems Further Reduce OPEX

Modern transformers integrate digital protection that prevents failure:

- Temperature sensors

- Online oil analysis (for oil units)

- Partial discharge monitoring

- Thermal imaging

- Overload prediction algorithms

These systems:

- Prevent damage

- Reduce maintenance visits

- Minimize emergency service costs

- Ensure safe operation under variable loads (common in solar/wind systems)

The result is a measurable drop in operational expenditure over time.

How Does Durability and Reliability Impact Long-Term Value in Power Transformers?

Durability and reliability are two of the strongest predictors of long-term value in power transformer investments. While buyers often compare units based on upfront price or efficiency, the true cost of ownership—spanning 25 to 40 years—depends heavily on how well the transformer withstands electrical, thermal, mechanical, and environmental stresses throughout its life cycle. A durable, reliable transformer not only avoids expensive breakdowns but also delivers stable performance that protects the entire power system.

This article explains how durability and reliability directly affect long-term economic value, maintenance cost, and asset performance.

1. Fewer Failures = Massive Cost Avoidance

Transformer failures are extremely costly—far more than the price of the transformer itself.

Failure costs may include:

- Emergency shutdown of equipment or entire facilities

- Production losses

- Expedited replacement fees

- Environmental cleanup (oil leaks)

- Damage to switchgear, cabling, or structures

- Grid instability or blackouts

A single transformer failure can cost:

- $20,000–$200,000 for a distribution transformer

- $500,000–$5,000,000+ for high-voltage units

High durability reduces these risks dramatically.

2. Longer Service Life = Higher ROI

Durability directly determines how long the unit can operate safely without replacement.

Typical lifespans:

- Dry-type transformers: 20–30 years

- Oil-immersed transformers: 30–40 years

A durable transformer with strong insulation, high-grade copper/steel, and optimized thermal design can easily outlast cheaper alternatives by 5–15 years.

Why this matters:

- Delays capital replacement

- Increases return on investment

- Reduces disposal or overhaul costs

A long-lasting transformer spreads its cost over more service years, lowering the annualized cost of ownership.

3. Better Materials = More Stable Performance

Durability is largely determined by the quality of materials and manufacturing.

Key components influencing reliability:

- High-quality grain-oriented silicon steel

- Amorphous metal core (reduces heat → longer life)

- Class F or H insulation systems

- High-conductivity copper windings

- Epoxy resin or Nomex for thermal endurance

- Robust coil clamping & mechanical reinforcement

- Moisture-resistant designs

Each improvement enhances long-term stability and reduces internal stress that leads to premature failure.

4. Reliability Ensures Consistent Electrical Performance

A reliable transformer maintains stable parameters such as:

- Voltage regulation

- Impedance characteristics

- Temperature rise

- Partial discharge levels

- Load-handling capability

This protects sensitive loads such as:

- Data centers

- Renewable energy inverters

- Hospitals

- Industrial motors

- High-voltage equipment

Reliable performance prevents voltage dips, equipment shutdowns, and harmonics-related failures.

5. Stronger Thermal Design = Reduced Aging

Heat is the number one enemy of transformers. Every 6–8°C increase in operating temperature can halve insulation life.

Reliable transformers incorporate:

- Better cooling design

- Lower temperature rise (65°C/55°C)

- Optimized oil circulation or forced-air cooling

- Hot-spot monitoring

- Thermal sensors and alarms

Lower operating temperature = slower insulation aging = much longer life.

6. Mechanical Durability Protects Against Short-Circuit Forces

Short-circuit currents can create enormous mechanical forces on windings—sometimes 20–40 times rated current.

Durable transformers include:

- Stronger winding bracing

- Better coil clamping pressure

- Resin-cast structural support (dry type)

- High-strength conductor geometry

This prevents coil deformation, which is a major cause of early transformer failure.

7. Reliability Reduces Maintenance Needs

Durable transformers require less maintenance, saving long-term operational costs.

Lower maintenance includes:

- Fewer inspections

- Less thermal monitoring

- Reduced downtime

- Fewer repairs or part replacements

Oil-immersed units also experience:

- Lower risk of sludge formation

- Better moisture control

- More stable dielectric strength

This lowers maintenance cost over decades.

8. Durability Improves Resilience in Harsh Environments

In challenging conditions—heat, humidity, dust, salt mist, altitude—durability plays an even greater role.

Conditions affecting performance:

- Desert heat

- Coastal corrosion

- High altitude (reduced cooling efficiency)

- Heavy industrial dust

- Continuous vibration

- Renewable energy load cycling

Transformers designed for durability can operate safely without derating or excessive thermal stress.

9. Reliable Transformers Maintain Higher Resale and Reuse Value

A durable transformer with a strong health index (HI) can be:

- Reinstalled

- Sold in the used market

- Repurposed for secondary applications

Units with excellent reliability records often maintain 40–60% of their value even after 10–15 years.

In Which Applications Are Dry Type Transformers Most Cost-Effective?

Dry type transformers are not always the cheapest option upfront, but in many applications they offer significant long-term cost advantages through reduced fire-protection requirements, lower installation expenses, minimal maintenance, and enhanced safety. Their value becomes especially clear in environments where oil containment, fire barriers, and maintenance access add major costs to oil-immersed solutions. Below is a detailed breakdown of the applications where dry type transformers provide the highest cost-effectiveness per life cycle.

1. Indoor Installations Where Fire Safety Drives Cost Savings

One of the strongest cost advantages of dry type transformers is their self-extinguishing, non-flammable insulation, which eliminates or reduces the need for:

- Fire suppression systems

- Fire-rated transformer rooms

- Oil containment pits

- Spill management systems

- Insurance surcharges

This makes them ideal for:

- Commercial buildings

- Hospitals

- Schools and universities

- Shopping malls

- Airports

- Railway stations

- High-rise buildings

Why cost-effective:

Avoiding fire-rated construction alone can save 20–40% of installation costs.

2. Renewable Energy Projects (Wind & Solar)

Dry type transformers are widely used in renewable power stations due to:

- High resistance to moisture and dust

- Ability to operate in fluctuating load profiles

- Low maintenance in remote areas

- Higher tolerance for vibration (especially cast resin types)

Cost-effective for:

- Wind turbine nacelles

- Wind tower base stations

- Solar inverter stations

- Solar containerized power blocks

Why cost-effective:

No oil means no spill risk, no environmental permits, and lower long-term service costs.

3. Industrial Facilities with Harsh or Polluted Environments

Cast resin dry type transformers perform exceptionally well in:

- Chemical plants

- Oil & gas processing facilities

- Cement factories

- Mining operations

- Steel mills

- Food processing plants

Benefits:

- Moisture-resistant

- Dust-resistant

- No risk of oil contamination

- Less maintenance needed

Cost advantage:

Oil-filled units require sealing systems, frequent oil checks, and monitoring equipment; dry type units avoid these ongoing costs.

4. Underground, Substation-in-Building, and Confined Areas

Where ventilation, safety, and access are limited, dry type units shine.

Ideal locations:

- Metro stations

- Underground substations

- Tunnels

- Parking garages

- Basements of commercial buildings

Cost benefit:

No oil means:

- No ventilation-for-flammable-liquids requirement

- Lower fire regulation burden

- Easier integration into building architectures

5. Marine, Offshore, and Coastal Installations

Dry type transformers offer strong performance in:

- Ships

- Offshore platforms

- Coastal substations

- Ports

Why cost-effective:

- Resin insulation resists salt mist

- No oil leakage into marine environments

- Lower service cost for corrosion protection

Environmental compliance savings can be significant.

6. Data Centers and IT Facilities

These facilities prioritize:

- Fire safety

- Low smoke emission

- High reliability

- Low maintenance

Dry type transformers reduce the risk of:

- Downtime

- Fire spread

- Oil contamination

- Insurance penalties

Long-term value:

Reducing fire protection infrastructure saves hundreds of thousands in data center construction.

7. Hospitals and Medical Facilities

Hospitals require:

- Zero fire risk

- High reliability

- Quiet operation

- Low maintenance

- Indoor installation

Dry type transformers meet all of these without requiring oil barriers, ventilation for hazardous liquids, or environmental monitoring.

8. Commercial & Residential Distribution Networks

For city utilities or developers, dry type transformers offer:

- Smaller installation space

- Lower civil engineering costs

- Safer indoor or underground placement

- Less regulatory burden

This makes them cost-effective in urban distribution grids.

Conclusion

While dry-type transformers require a higher upfront investment, their long-term advantages—such as reduced maintenance costs, enhanced fire safety, minimal risk of oil leaks, and high operational efficiency—make them cost-effective over their lifespan. They are particularly advantageous in environments with strict safety regulations, such as data centers, hospitals, and renewable energy facilities. Over time, the total cost of ownership tends to be lower than oil-immersed alternatives, proving that dry-type transformers are not only a safer and cleaner choice but also an economically sound investment for the future.

FAQ

Q1: Are dry type transformers cost-effective over their service life?

Yes—dry type transformers are highly cost-effective over the long term, despite having a higher initial purchase price compared to oil-immersed units. Their low maintenance requirements, oil-free design, and high safety standards significantly lower total operating expenses across their typical 25–35 year lifespan. With no oil to sample, filter, or replace, owners save on routine service and environmental management. Additionally, their lower fire risk reduces the need for expensive fire-suppression systems in indoor settings such as data centers, hospitals, and commercial buildings. Over time, these combined savings generally outweigh the higher upfront cost, making dry type units an economical solution for many applications.

Q2: How do maintenance costs compare with oil-immersed transformers?

Maintenance costs for dry type transformers are substantially lower. They do not require:

Oil sampling, DGA testing, or oil filtration

Oil leak repairs

Oil replacement or disposal

On-site containment structures

Instead, typical maintenance involves simple visual inspections, cleaning, and temperature monitoring. This can reduce maintenance expenses by 30–60% over the lifecycle. For operators in remote or high-risk areas, these savings can be even more significant due to reduced labor requirements and service downtime.

Q3: Do dry type transformers offer long-term energy savings?

Dry type units can achieve high efficiency ratings—especially cast resin transformers designed to meet IEC Tier 2 or DOE 2026 standards. Their low-load and no-load losses directly lower electricity consumption over life expectancy. In facilities with continuous operation (e.g., industrial plants, renewables, data centers), these savings can amount to thousands of dollars per year. High-efficiency core materials, such as amorphous metal, further improve long-term savings by reducing losses at varying load conditions.

Q4: How does reliability affect long-term cost performance?

Reliability contributes greatly to long-term cost-effectiveness. Dry type transformers have fewer failure modes because they contain no flammable or degradable oil. Their moisture-resistant cast resin insulation improves durability in humid or dusty environments. Fewer failures mean reduced repair costs, shorter downtimes, and minimized operational interruptions. For critical applications like hospitals, airports, or renewable energy systems, this reliability directly translates into measurable financial benefits.

Q5: In which applications do dry type transformers deliver the greatest cost advantages?

Dry type transformers are especially cost-effective in:

Indoor installations where fire safety reduces building costs

Commercial buildings and hotels requiring low noise and minimal maintenance

Data centers where uptime is critical and oil poses risks

Hospitals and schools where environmental safety is a priority

Renewable energy projects with demanding climate conditions

Underground or confined spaces where oil containment is impractical

In these environments, the combination of safety, reduced operational expenses, and high reliability makes dry type transformers the optimal long-term financial choice.

References

IEC 60076-11 – Dry Type Transformers Standard — https://www.iec.ch

DOE Transformer Efficiency Standards — https://www.energy.gov

EEP – Dry Type vs Oil Transformer Cost Comparison — https://electrical-engineering-portal.com

IEEE — Transformer Maintenance and Lifecycle Analysis — https://ieeexplore.ieee.org

Global Market Insights – Dry Type Transformer Market Study — https://www.gminsights.com