Enhancing the reliability and performance of dry type transformers is essential for ensuring stable power distribution, minimizing downtime, and extending equipment lifespan. Because these transformers are widely used in commercial buildings, data centers, industrial plants, and renewable energy systems, maintaining high reliability directly impacts safety and operational efficiency. Several design, installation, and maintenance practices can significantly improve their long-term performance.

What Design Features Improve the Durability and Reliability of Dry Type Transformers?

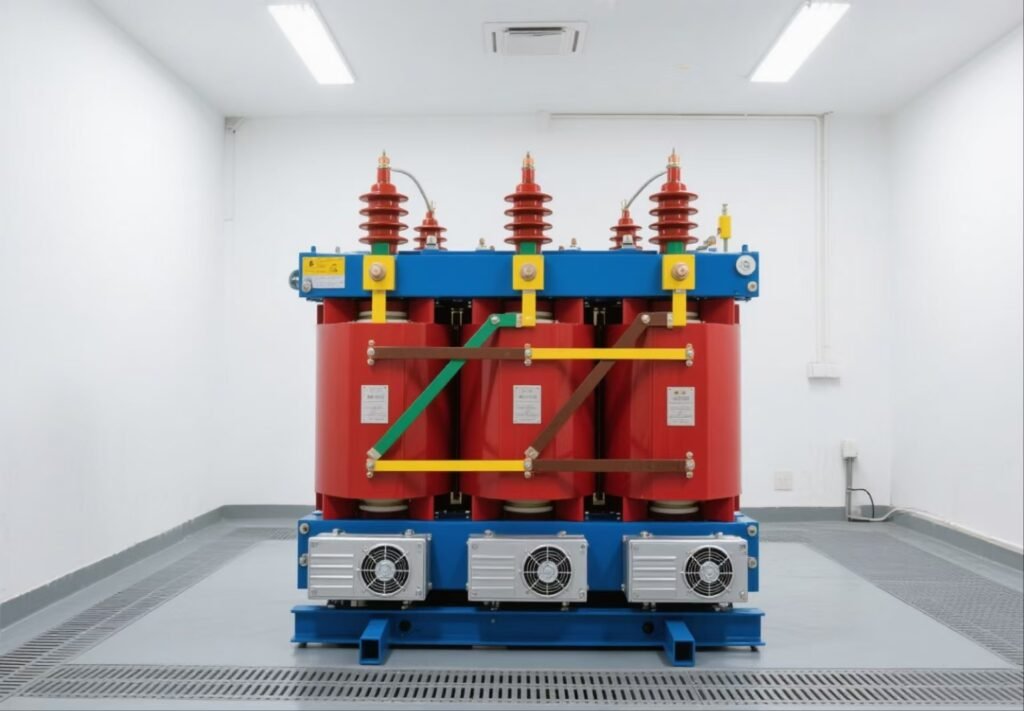

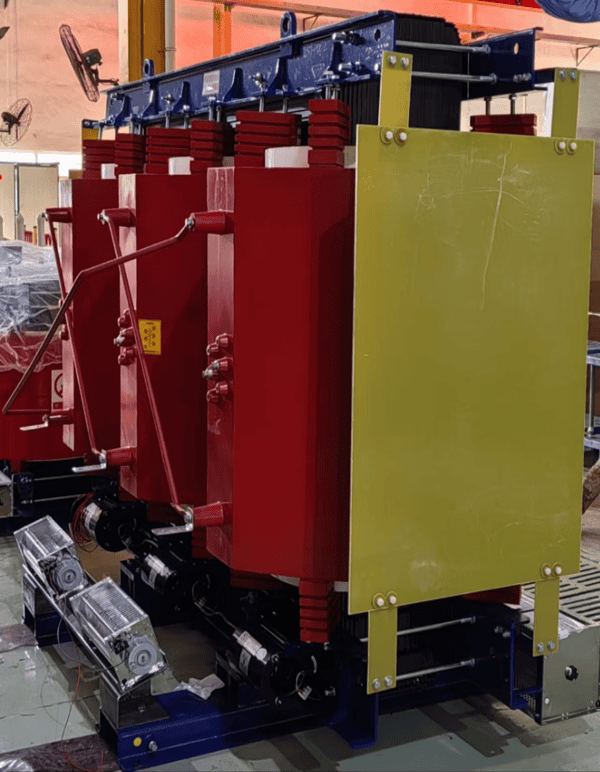

Dry-type transformers are widely used in commercial buildings, industrial plants, renewable energy systems, and environments where fire safety and low maintenance are critical. Their durability and reliability depend heavily on design choices that protect the transformer from thermal stress, electrical stress, vibration, moisture, and environmental contaminants. High-quality engineering not only extends service life but also ensures stable performance under demanding operating conditions.

1. Advanced Core Materials and Precision Core Assembly

The magnetic core is central to transformer performance, and its design influences both thermal behavior and long-term reliability.

Key durability-enhancing features include:

- High-grade grain-oriented silicon steel to minimize core losses and reduce heating.

- Step-lap or precision mitred joints that reduce localized flux concentration and vibration.

- Rigid core clamping systems to prevent mechanical loosening over time.

- Low-noise core construction that reduces vibration-induced fatigue.

A well-designed core reduces heat, vibration, and mechanical stress—three major contributors to premature aging.

2. Robust Winding Construction and Thermal-Resistant Materials

The windings experience high electrical and thermal stress, making their design crucial for long-term durability.

Key design features include:

- Cast resin (epoxy) insulated windings that resist moisture, dust, and chemical exposure.

- Polyester-imide or epoxy-coated copper/ aluminum conductors for enhanced thermal endurance.

- High mechanical strength to withstand short-circuit forces, especially important in industrial or renewable applications with fast-varying loads.

- Vacuum pressure impregnated (VPI) windings for improved bonding, reduced vibration, and moisture resistance.

The right winding design prevents deformation under fault conditions and ensures stable insulation over decades.

3. Optimized Cooling Pathways for Better Heat Management

Excessive heat is one of the most common causes of transformer aging. Improved cooling design directly enhances reliability.

Durability-focused cooling features include:

- Air channels strategically integrated between winding layers to maximize airflow.

- Open ventilation ducts that enhance natural convection.

- Fan-assisted cooling options for heavy loads or high ambient temperature zones.

- Temperature sensors and thermal protection systems that prevent overheating and provide operational data.

A transformer that stays cool maintains insulation strength and reduces thermal fatigue.

4. Moisture and Contaminant Protection for Harsh Environments

Dry-type transformers can be exposed to dust, humidity, chemicals, and corrosive agents in various industries.

Design features that enhance protection include:

- Encapsulated cast-resin coils for near-hermetic insulation performance.

- Tropicalized coatings for environments with high humidity or airborne corrosives.

- Ingress-protected enclosures (IP-rated) to prevent dust and water intrusion.

- Anti-corrosion treatments on metal structures for coastal or industrial areas.

These features are essential for applications such as mining, marine platforms, tunnels, and chemical plants.

5. Reinforced Mechanical Structure and Vibration Control

Mechanical stresses increase during short circuits, transportation, and daily load cycles. A robust mechanical structure ensures long-lasting stability.

Important design elements include:

- Rigid frames and tie rods that prevent movement of coils and core.

- Vibration-damping mounts to reduce mechanical resonance.

- Short-circuit-proof winding supports, especially in VPI and cast-resin types.

- High-strength epoxy systems that bond coils tightly, reducing internal movement.

Mechanical stability directly correlates with long-term reliability and safety.

6. High-Quality Insulation Systems with Extended Thermal Class

The insulation system determines the transformer's resistance to heat and aging.

Key longevity-focused features include:

- Thermal Class F or H insulation for higher temperature tolerance.

- Controlled resin curing processes to ensure consistent mechanical and electrical properties.

- Partial discharge–free design, achieved by precise winding geometry and resin impregnation.

- Creepage and clearance optimization to prevent insulation breakdown under high humidity or pollution.

Strong insulation design safeguards the transformer from electrical failures.

7. Smart Monitoring and Predictive Maintenance Capabilities

Modern dry-type transformers increasingly incorporate digital tools that elevate reliability.

These features include:

- Temperature and humidity sensors embedded in windings or enclosures.

- IoT connectivity for remote health monitoring.

- Predictive analytics that identify stress patterns and optimize loading conditions.

- Early warning systems for overloads, abnormal temperature rise, or ventilation blockage.

Digitally enhanced monitoring extends transformer life and reduces unplanned outages.

8. Compliance with Global Standards and Testing Requirements

Durability often comes from adherence to proven engineering guidelines.

Relevant standards include:

- IEC 60076-11 (dry-type transformers)

- IEEE C57 series

- Fire safety and environmental regulations depending on region

Comprehensive type testing, routine testing, and quality assurance procedures help ensure long-term performance.

How Does Proper Installation Influence Long-Term Performance?

Proper installation is one of the most overlooked yet most critical factors that determine whether a transformer performs reliably for 20–30 years or fails prematurely within a few years. Many end users focus heavily on specifications, materials, and purchase price—but installation errors can instantly negate even the highest manufacturing quality. Problems such as overheating, insulation deterioration, vibration damage, partial discharge, and electrical failures often originate not from manufacturing defects but from incorrect placement, poor ventilation, improper connections, or inadequate grounding. The good news is that when a transformer is installed according to engineering standards, the risks of failure drop drastically, operational efficiency increases, and long-term maintenance costs become significantly lower. This article explains in depth how proper installation affects long-term performance and what technical steps buyers must prioritize to ensure safe, stable, and cost-effective operation.

Proper installation directly influences long-term transformer performance by ensuring optimal cooling, electrical safety, mechanical stability, and insulation integrity, all of which prevent premature aging, reduce failure rates, and maintain efficiency throughout its lifecycle. When the installation environment, cable connections, grounding network, ventilation layout, and load conditions are professionally engineered, the transformer operates within its design limits, resulting in longer service life and lower operating costs.

Achieving long-term transformer reliability starts with correct installation practices. Many failures that appear years later—such as winding deformation, terminal overheating, insulation breakdown, and harmonic-related issues—trace back to installation mistakes that were not addressed early. Understanding how installation influences performance helps buyers make better decisions, assess supplier competency, and build confidence in long-term ownership.

Most transformer failures are caused by manufacturing defects rather than installation issues.False

Studies show that installation, operation, and environmental conditions are responsible for a large percentage of transformer failures, often exceeding manufacturing-related causes.

Environmental Conditions and Site Preparation Strongly Dictate Transformer Performance

A transformer's operational life begins with the physical environment in which it is installed. Temperature, humidity, altitude, airflow, and contamination levels determine whether the transformer can operate within engineered limits. Poor site preparation leads to immediate operating stress. For dry-type transformers, the ambient temperature should remain within the specified range of –25°C to +40°C unless rated otherwise. Excessive heat accelerates insulation degradation, while humidity fuels partial discharge and surface tracking. Uneven or non-leveled foundations cause structural stress on the core and windings. Additionally, altitude impacts cooling efficiency; installations above 1,000 meters may require derating to prevent overheating. From an electrical standpoint, proper foundation grounding eliminates stray currents that can damage insulation or create safety hazards. In environments with dust, chemicals, or corrosive gases, inadequate enclosure protection allows contaminants to penetrate the core and windings, reducing dielectric strength and causing hotspots. These environmental influences show that long-term performance is directly linked to preparation quality.

Ventilation, Cooling Paths, and Heat Dissipation Determine Thermal Stability

A transformer’s lifespan is closely tied to temperature management. Proper installation ensures that cooling airflow is unobstructed and that heat can dissipate efficiently. Dry-type transformers rely primarily on natural air cooling (AN) or fan-assisted cooling (AF). If installed too close to walls or inside sealed rooms without sufficient ventilation, internal temperatures rise quickly, weakening insulation and causing resin or varnish deterioration. Clearance distances—often 30–50 cm or more, depending on model—must be respected around all sides to allow convection to occur. In addition, the room’s air changes per hour (ACH) must match the heat output of the transformer. When multiple transformers are installed in a single room, poor airflow design leads to heat accumulation, especially near ceilings where hot air traps. Proper ducting, exhaust systems, and temperature sensors help maintain stable operation. Failures like accelerated winding aging, resin cracking, and thermal hotspots are almost always linked to inadequate cooling caused by poor installation conditions.

Electrical Connections, Cable Routing, and Torque Control Prevent Overheating and Failures

Cable termination quality has one of the strongest impacts on transformer longevity. Loose connections cause excessive temperature rise, arcing, and terminal burning. Over-torqueing damages terminals and conductor strands. Proper installation requires calibrated torque tools, manufacturer-recommended settings, and mechanical strain relief to prevent cables from pulling on terminals. Incorrect cable routing creates electromagnetic forces that stress bushings and windings during short circuits. Phase reversal or incorrect vector group connections lead to system instability and harmonic distortion. Furthermore, improper tightening of busbars increases resistive losses. Professional installation teams follow detailed tightening sequences, verify phase alignment, ensure correct polarity, and measure contact resistance. These steps prevent catastrophic failures such as terminal melting, bushing cracking, and winding deformation.

Grounding and Bonding Systems Enhance Safety and Reduce Electrical Stress

Transformer grounding ensures fault current dissipation, stabilizes voltage, and protects the insulation system. If grounding is poorly executed, the transformer becomes vulnerable to dangerous touch voltages, partial discharge, insulation breakdown, and resonance problems. Proper grounding practices include: connecting the transformer's neutral according to system requirements; bonding metallic enclosures with low-resistance conductors; maintaining equipotential bonding across the installation site; and integrating grounding conductors into the facility’s fault protection system. High-impedance grounding and isolated neutral systems require special configuration. In dry-type transformers, improper grounding often leads to insulation flashover and overheating at terminal interfaces. A well-installed grounding system ensures both operational safety and insulation longevity.

Mechanical Fixing, Vibration Control, and Structural Stability Protect Windings and Core

Improper mechanical installation results in vibration, displacement, and long-term structural weakening. Transformers must be firmly mounted on vibration-dampening pads or rails to minimize resonance. During short-circuit events, electromagnetic forces can reach tens of thousands of Newtons; if coil alignment shifts or supports loosen, windings deform, and insulation cracks occur. Anchoring systems must account for seismic activity, especially in regions with earthquake risks. Core clamping structures must remain stable to avoid increased noise and vibration. Even transportation-induced stress must be addressed by re-tightening structural fasteners upon arrival. Mechanical installation quality is strongly correlated with long-term transformer survival, particularly in industrial and renewable applications where load fluctuations are frequent.

Load Matching, Harmonic Conditions, and System Integration Ensure Efficient Operation

Improper integration into the electrical system places excessive load or harmonic stress on a transformer. Load imbalance, persistent overloads, or harmonic distortion (commonly caused by VFDs, EV chargers, and data center equipment) accelerates heating and insulation aging. Proper installation includes verifying load profiles, harmonics levels, and power quality conditions. Reactors, filters, or K-factor rated transformers may be required in harmonic-rich environments. System protection coordination—including relays, breakers, and surge arresters—must be installed correctly to prevent damage during faults or switching events. These aspects ensure the transformer operates efficiently without encountering electrical stress beyond design limits.

Monitoring Systems and Commissioning Tests Validate Installation Quality

Full commissioning is the final and most crucial step. Infrared thermal scanning, insulation resistance testing, turns ratio testing (TTR), winding resistance testing, and partial discharge detection verify that installation was done correctly. Improper installation almost always shows up during initial testing. Digital monitoring systems such as IoT sensors for temperature, humidity, dust levels, and harmonic analysis help ensure long-term reliability. Proper installation includes integrating these monitoring devices and calibrating protection settings before energization.

Transformers can be safely operated without commissioning tests as long as they are new.False

Commissioning tests are essential to verify mechanical, electrical, and thermal integrity after transportation and installation, regardless of transformer age.

What Role Does Ventilation and Cooling Management Play?

Effective ventilation and cooling management is one of the most decisive factors in determining whether a transformer will operate reliably for decades—or fail prematurely due to overheating, insulation breakdown, and accelerated aging. Many failures mistakenly attributed to “manufacturing defects” are actually caused by improper ventilation, blocked airflow, high ambient temperature, or poor thermal planning. When air cannot circulate freely, even the highest-quality transformer experiences dramatic temperature rise, which directly reduces lifespan and increases maintenance costs. Fortunately, proper cooling design ensures stable temperatures, protects insulation systems, improves energy efficiency, and guarantees long-term operational reliability. The following in-depth analysis explains exactly why ventilation and cooling management are critical for transformer performance.

Ventilation and cooling management ensure that a transformer maintains safe operating temperatures, prevents insulation aging, avoids hot-spot formation, reduces energy losses, and supports long-term reliability by keeping heat within design limits. Proper airflow, room sizing, heat removal, and environmental control are essential for maintaining thermal stability and preventing premature failure.

Understanding the impact of ventilation and cooling encourages buyers and engineers to pay close attention to installation conditions rather than relying solely on the transformer’s inherent design. Many high-performance units fail early simply because the cooling system of the installation site was poorly engineered or never optimized.

Air-cooled dry-type transformers do not require ventilation planning.False

Dry-type transformers generate significant heat, and without proper ventilation, temperatures rise quickly, leading to insulation damage and reduced service life.

Ambient Temperature Directly Determines Aging Rate and Insulation Life

Ambient temperature is the first and most influential factor in transformer thermal performance. Every 6–8°C increase above the rated temperature cuts insulation life by roughly half. Dry-type transformers typically operate within a maximum ambient temperature of 40°C unless specially designed for high-temperature conditions. When the installation site lacks proper ventilation or is exposed to direct sunlight, the ambient temperature inside the room rises significantly, pushing the transformer toward its thermal limit.

If ventilation is inadequate:

- Coils operate closer to maximum hot-spot temperatures

- Resin or varnish insulation suffers accelerated deterioration

- Load capacity must be derated

- Fan-cooled (AF) systems run more frequently, consuming more power

- Overload tolerance decreases dramatically

This means that even moderate heat accumulation can reduce the expected service life of a dry-type transformer from 30 years to fewer than 10. Proper ventilation prevents this cascading deterioration.

Airflow Paths and Clearance Distances Ensure Efficient Heat Dissipation

Cooling performance is determined by how efficiently air can move around and through the transformer. Natural air cooling (AN) relies on unobstructed convection paths. When transformers are installed too close to walls, grouped too tightly, or placed in rooms with stagnant air, heat becomes trapped around the windings and core.

Key airflow considerations include:

- Maintaining sufficient clearance on all sides (typically 30–80 cm depending on model)

- Ensuring vertical airflow channels between windings remain unobstructed

- Designing the room so that cool air enters at the bottom and warm air exits at the top

- Avoiding ceiling-level hotspots that accumulate heat

Transformers installed without these airflow considerations operate consistently at higher temperatures, reducing efficiency and increasing the risk of insulation breakdown.

Exhaust Systems and Forced Ventilation Prevent Heat Accumulation

In many installations—especially indoor rooms, tunnels, basements, marine environments, and renewable energy control centers—natural airflow is insufficient to dissipate the heat produced by the transformer. Mechanical ventilation or exhaust systems are essential.

A proper cooling management system includes:

- Fresh air intake to supply cool ambient air

- Mechanical extraction fans to remove hot air

- Temperature-controlled fan activation

- Sufficient air changes per hour (ACH) to handle heat load

- Heat-resistant ducts and airflow tunnels

Without forced ventilation, heat builds up inside the room even if the transformer itself is designed for high thermal performance. This heat accumulation creates hotspots, raises coil temperatures, and forces fans to run constantly—decreasing efficiency and accelerating insulation aging.

Thermal Sensors, IoT Monitoring, and Protection Systems Maintain Thermal Stability

Modern dry-type transformers increasingly integrate smart thermal monitoring for reliable real-time temperature control. Accurate temperature monitoring prevents thermal runaway, detects ventilation blockages early, and optimizes the cooling system’s activation.

Key monitoring tools include:

- PT100 or thermistor sensors embedded in windings

- IoT-based temperature and humidity monitoring

- Infrared scanning for hotspot identification

- Programmable alarms and thermal relays

- Fan control systems based on real-time temperature data

When these systems are integrated and maintained correctly, they prevent overheating before it becomes severe enough to damage insulation or reduce loading capability.

Temperature sensors are optional accessories that do not affect transformer performance.False

Temperature sensors are essential components that detect overheating, prevent thermal damage, and enhance long-term reliability.

Humidity and Moisture Control Protect Insulation Integrity

Even though dry-type transformers do not use insulating oil, moisture poses a serious threat. High humidity combined with inadequate ventilation leads to:

- Surface tracking on insulation

- Increased partial discharge activity

- Lower dielectric strength

- Accelerated aging of resin-encapsulated coils

Data centers, coastal locations, and underground facilities are especially vulnerable. Dehumidifiers, controlled ventilation, and IP-rated enclosures help maintain insulation integrity. Proper room ventilation prevents moisture accumulation and maintains dielectric stability.

Cooling Management Directly Influences Load Capacity and Efficiency

A well-ventilated transformer is more efficient and can safely handle higher loads. Conversely, a poorly cooled one must be derated—even if the transformer is new and properly designed.

Proper ventilation increases long-term performance by:

- Reducing total losses

- Improving core and winding efficiency

- Maintaining stable hot-spot temperatures

- Supporting safe overload capability

- Ensuring stable harmonic performance

Poor cooling increases losses, increases noise levels, and severely restricts the operating window of the transformer.

How Can Routine Inspection and Preventive Maintenance Enhance Reliability?

Routine inspection and preventive maintenance are often underestimated in transformer management. Many operators believe that once a transformer is installed and commissioned, it should run indefinitely without intervention. Unfortunately, this misconception is one of the major causes of premature failures, overheating events, costly downtime, and insulation degradation. Common avoidable issues—such as loose terminals, blocked ventilation, moisture buildup, abnormal temperature rise, and increased partial discharge—start small but become severe if unnoticed. The good news is that regular inspection and preventive maintenance programs can detect these issues early, reduce failure rates dramatically, and extend transformer service life by many years. This article explains why routine inspections matter and how they improve long-term reliability.

Routine inspection and preventive maintenance enhance transformer reliability by identifying early signs of thermal, mechanical, electrical, and environmental stress, allowing corrective actions before failures occur. Proper maintenance keeps cooling systems efficient, terminals secure, insulation healthy, and operating conditions within design limits—ensuring stable performance and significantly extending service life.

Preventive maintenance is not simply a recommended practice—it is a strategic investment. By detecting small abnormalities early, operators avoid unplanned outages, expensive repairs, and catastrophic failures. This proactive approach ensures that transformers deliver consistent performance, higher efficiency, and stronger reliability throughout their entire lifecycle.

Transformers can operate safely for decades without maintenance.False

Transformers require routine inspection to prevent overheating, mechanical loosening, insulation aging, and environmental contamination—all of which can cause early failure.

Early Detection of Thermal Issues Prevents Insulation Damage and Aging

Overheating is one of the most common causes of transformer failure, especially in dry-type units. Routine inspections include checking temperature sensors, verifying airflow paths, and examining fan performance. Dust accumulation, blocked ventilation, and rising ambient temperature all lead to elevated hot-spot temperatures. Identifying and fixing these early prevents irreversible insulation damage.

Transformers with neglected thermal issues often exhibit:

- Gradual increase in operating temperatures

- Yellowing, cracking, or softening of resin

- Persistent fan operation

- Decreased overload capability

Routine thermal monitoring ensures that insulation runs well within its thermal class, maintaining dielectric strength and prolonging service life.

Mechanical Inspections Avoid Windings Shift, Vibration Damage, and Structural Stress

Transformers experience mechanical stress from load cycles, short-circuit forces, transportation, and vibration. Regular inspections prevent small mechanical issues from evolving into major structural failures.

Key mechanical checks include:

- Tightening core and coil support structures

- Inspecting anti-vibration mounts

- Verifying enclosure rigidity

- Ensuring transportation bolts have been removed

- Checking for noise changes indicating loose components

A loose winding or shifting core can lead to partial discharge, overheating, and catastrophic failure. Preventive mechanical inspections maintain internal stability, ensuring long-term reliability.

Electrical Testing Identifies Undetected Faults and Degradation

Electrical testing is one of the most powerful tools in preventive maintenance. Even transformers that appear visually perfect can have hidden electrical issues.

Essential tests include:

- Insulation resistance testing (IR) to evaluate insulation health

- Turns ratio testing (TTR) to ensure winding accuracy

- Winding resistance measurement to detect deformation or corrosion

- Partial discharge measurement to identify insulation stress

- Thermographic scanning to detect hotspots

These tests provide early warnings long before electrical failures occur. Electrical anomalies rarely disappear on their own—they worsen, often rapidly. Preventive electrical testing identifies problems at the earliest stage.

If a transformer passes its factory test, electrical testing is unnecessary during operation.False

Operational stress, environment, and load conditions change over time, making periodic electrical tests essential for detecting aging and faults.

Cleaning, Ventilation Maintenance, and Dust Removal Maintain Optimal Cooling

Dust, debris, and blockage are silent killers of dry-type transformers. They restrict cooling airflow, cause overheating, increase partial discharge activity, and reduce energy efficiency.

Routine maintenance includes:

- Removing dust from coils, ducts, and radiators

- Cleaning fans and checking airflow direction

- Ensuring cooling channels remain unobstructed

- Verifying ventilation room cleanliness

- Inspecting air filters in ventilated enclosures

Transformers with clean ventilation systems run cooler, quieter, and more efficiently. Neglecting ventilation significantly reduces lifespan.

Load Monitoring and Harmonic Assessment Protect Against Stress and Overload

Modern electrical systems—especially those involving EV chargers, inverters, VFDs, and data centers—introduce harmonic distortion and load fluctuations that stress transformers. Preventive maintenance involves recording load levels, analyzing power quality, and checking harmonic content.

Benefits include:

- Preventing overload-related heating

- Detecting load imbalance

- Avoiding harmonic overheating of windings

- Optimizing load sharing between units

- Maintaining efficiency and reducing losses

Routine load analysis ensures the transformer is not subjected to conditions beyond its design rating.

Environmental Control Prevents Moisture, Corrosion, and Contamination

Environmental factors have tremendous influence on transformer longevity. Moisture, corrosive gases, and dust accelerate insulation breakdown and surface tracking.

Preventive environmental maintenance includes:

- Humidity monitoring

- Checking for condensation or water ingress

- Inspecting air pathways for chemical contaminants

- Ensuring enclosure seals remain intact

- Verifying room temperature stability

Transformers in coastal, industrial, or underground sites require stricter environmental monitoring, as these areas are prone to accelerated degradation.

Documentation, Trend Analysis, and Predictive Maintenance Increase Reliability Over Time

Preventive maintenance becomes even more effective when combined with data tracking. Recording test results, temperature trends, load profiles, and maintenance history allows predictive analysis. Over time, patterns emerge that can indicate early failure modes.

Advantages include:

- Predicting future failures before they occur

- Scheduling maintenance during ideal downtime windows

- Optimizing cooling and load management

- Extending insulation life using data-driven decisions

- Reducing operational costs

A well-maintained transformer is not only more reliable but also more cost-efficient over its entire lifecycle.

What Environmental Protections Are Necessary for Different Applications?

Environmental strain is one of the most underestimated factors affecting transformer lifespan. Many failures occur not because of electrical defects, but because the operating environment slowly attacks insulation, metal structures, cooling systems, and protective surfaces. Moisture, dust, corrosive chemicals, extreme temperatures, vibration, and airborne contaminants all accelerate deterioration. When these conditions are not accounted for during specification, transformers face overheating, partial discharge, tracking, corrosion, and premature end-of-life. If each installation environment is not evaluated and protected individually, reliability collapses long before the expected service life.

Different environments demand different protection methods—including moisture control, corrosion resistance, dust mitigation, thermal management, and mechanical reinforcement—to ensure stable and reliable transformer operation across all applications. Proper environmental protection ensures insulation integrity, mechanical stability, and long-term performance regardless of climate or operating conditions.

Transformers do not survive harsh environments without intentional protection. Each installation setting introduces unique challenges that must be addressed through design, materials, and maintenance strategies.

All transformers require the same environmental protections.False

Environmental stresses vary significantly between coastal, industrial, desert, indoor, and underground applications. Each requires specialized protection systems to prevent insulation degradation, corrosion, and overheating.

Coastal and Offshore Applications: Moisture and Corrosion Control

Coastal environments introduce humidity, salt particles, and corrosive air that attack exposed metal parts and insulation. Salt accelerates corrosion, promotes surface tracking, and increases partial discharge risk.

Key protections include:

- Marine-grade anti-corrosion coatings

- Stainless-steel hardware and fasteners

- Epoxy or cast resin insulation resistant to salt contaminants

- IP54–IP66 enclosures depending on exposure level

- Dehumidification systems or internal heaters

- Increased creepage and clearance distances

Without these safeguards, corrosion compromises structural integrity and moisture contamination leads to electrical breakdown.

Industrial and Chemical Facilities: Contaminant and Chemical Resistance

Factories, refineries, paper mills, and steel plants expose transformers to abrasive dust, corrosive gases, high temperatures, and strong vibration. These stresses can crack insulation, clog cooling ducts, and corrode exposed parts.

Recommended protections:

- IP55–IP65 dustproof enclosures

- Resin systems resistant to acids, alkalis, and chemical vapors

- Vibration isolation mounts

- High-temperature insulation classes

- Reinforced coil and structural components

- Oversized cooling systems for heat-intensive environments

Industrial pollutants are conductive and chemical vapors are corrosive—without protection, insulation life is significantly shortened.

Indoor, Enclosed, and Underground Installations: Ventilation and Moisture Protection

Substations in basements, high-rise buildings, tunnels, or enclosed rooms often suffer from poor ventilation, high humidity, and restricted airflow.

Critical protections include:

- Forced-air cooling or enhanced ventilation

- Condensation prevention (heaters, temperature control)

- Fire-resistant insulation (F1 class for dry-type)

- Waterproof or moisture-resistant enclosure design

- Adequate spacing to maintain heat dissipation

- Continuous temperature and humidity monitoring

Improper ventilation results in chronic overheating; humidity causes insulation tracking and degradation.

Desert and High-Temperature Locations: Thermal and Dust Protection

Solar farms, desert grids, and mining sites expose transformers to extreme heat, sandstorms, and UV radiation. High temperatures accelerate insulation aging and reduce cooling efficiency.

Required protections:

- High-temperature insulation class (F or H)

- UV-resistant exterior coatings

- Sealed or filtered enclosures to block sand

- Oversized cooling ducts or forced-air systems

- Thermal derating or increased kVA margins

- Active thermal monitoring sensors

Dust infiltration blocks airflow and increases winding temperature, while desert heat further stresses insulation.

Cold Regions: Freeze, Condensation, and Thermal Shock Protection

Snowy and sub-zero environments stress transformers with freezing temperatures, condensation, and rapid thermal cycling.

Protection measures:

- Anti-condensation heaters

- Insulation rated for low-temperature resilience

- Enclosures preventing ice or snow accumulation

- Temperature-stable resin systems

- Thermal shock–resistant coil structures

Low temperatures make insulation brittle, while thaw cycles bring moisture that can lead to tracking.

Renewable Energy Sites: Variable Load and Harsh Environment Protection

Wind and solar installations introduce fluctuating loads, vibration, and outdoor exposure.

Required protections:

- Reinforced mechanical structure for vibration

- Outdoor-rated enclosures (IP55+)

- High-efficiency thermal management

- Moisture and dust protection

- Real-time monitoring due to load variability

Renewables operate in remote and harsh conditions—environmental protection is critical for uptime.

Urban and Commercial Buildings: Fire, Noise, and Indoor Air Quality Protections

Commercial spaces prioritize safety, low noise, and minimal contamination.

Key protections:

- Fire-resistant insulation and enclosure materials (F1 class)

- Noise-dampening structural design

- Clean-air ventilation paths

- Low-smoke, low-toxicity materials

Indoor public environments require elevated safety and environmental control standards.

How Do Monitoring Systems and Smart Diagnostics Improve Performance?

Modern power systems demand reliability, continuous operation, and precise control. Yet many transformer failures still originate from silent, gradual issues—thermal stress, insulation degradation, overload cycles, vibration, or moisture—that go unnoticed until a costly shutdown occurs. Without continuous monitoring or diagnostic intelligence, operators detect problems only after serious damage has occurred. This leads to unexpected downtime, accelerated aging, and higher lifecycle costs. Smart monitoring systems were developed to address exactly these vulnerabilities by providing real-time data, predictive maintenance capabilities, and advanced analytics. With the right monitoring strategy, users eliminate guesswork and ensure consistent performance throughout the transformer’s lifecycle.

Smart diagnostics and monitoring systems improve transformer performance by continuously tracking temperature, load, insulation condition, and environmental factors, enabling early fault detection, predictive maintenance, longer service life, and safer, more efficient operation. Through real-time data and automated alerts, operators can prevent failures, optimize usage, and maintain transformer health with unprecedented accuracy.

Once a monitoring system is installed, performance stops relying on assumptions and starts relying on hard data.

Smart monitoring systems only offer minor operational benefits.False

Transformer monitoring systems significantly reduce failure rates, extend service life, lower maintenance costs, and enable predictive diagnostics, making them highly valuable for long-term performance.

Why Monitoring Systems Are Essential for Modern Transformer Reliability

Monitoring systems serve as a transformer’s real-time “health tracker.” Instead of scheduled manual inspections, sensors and digital modules provide continuous insight into operating conditions. This eliminates blind spots and ensures that problems—overheating, insulation stress, abnormal load profiles—are flagged before damage occurs.

Key functionalities include:

- Early warning alarms

- Load forecasting

- Real-time thermal profiling

- Insulation degradation modeling

- Power quality analysis

- Event logging and trending

These features directly prevent unplanned outages and reduce costly emergency interventions.

Temperature Monitoring: The Foundation of Predictive Maintenance

Temperature is the most critical indicator of transformer health. Excessive heat accelerates insulation aging, increases load stress, and reduces lifespan.

Monitoring includes:

- Hot-spot temperature detection

- Ambient temperature correlation

- Winding temperature sensors (RTD or fiber optic)

- Thermal overload prediction algorithms

With real-time temperature profiles, operators prevent dangerous overheating and optimize load distribution.

Load Monitoring and Power Quality Analytics

Load variations heavily influence a transformer’s thermal and electrical stress. Monitoring systems evaluate:

- Real-time load percentage

- Historical load cycles

- Harmonic distortion

- Voltage imbalance

- Transient spikes

This helps avoid overloading and improves planning for future capacity needs.

Insulation Condition Diagnostics

Insulation degradation is gradual but devastating if undetected. Smart systems track early warning signs such as:

- Partial discharge activity

- Dielectric stress

- Moisture accumulation

- Surface tracking risk

- Resin or varnish deterioration indicators

Early detection allows interventions long before insulation failure becomes dangerous.

Environmental Monitoring for Harsh Conditions

Dry-type transformers deployed in coastal areas, deserts, factories, and tunnels face unique environmental threats.

Monitoring includes:

- Humidity and moisture levels

- Dust accumulation trends

- Vibration intensity

- Temperature fluctuations

- Airflow and ventilation status

These data points guide targeted environmental protection measures.

Predictive Maintenance Through Smart Diagnostics

With AI-driven analytics, monitoring systems can predict:

- Remaining insulation life

- Risk of thermal runaway

- Cooling system performance deterioration

- Load-related stress accumulation

- Mechanical loosening or vibration risk

Predictive maintenance reduces O&M costs and eliminates reactive maintenance culture.

Integration With SCADA, Cloud Dashboards, and IoT Platforms

Modern diagnostics systems integrate with:

- Building automation

- Smart grid networks

- SCADA control rooms

- Cloud-based analytics

- Remote monitoring centers

This allows centralized control over large transformer fleets, enabling coordinated asset management.

How Monitoring Improves Safety and Compliance

Monitoring systems ensure safe operation by:

- Preventing excessive temperatures

- Alerting operators to abnormal events

- Tracking fire-risk indicators

- Logging compliance-related data

Transformer fires, overheating incidents, and insulation breakdown accidents become far less likely.

Conclusion

Improving the reliability and performance of dry type transformers requires a combination of high-quality design, proper installation, effective cooling, routine maintenance, and environmental protection. Advanced monitoring systems and smart diagnostics further help prevent failures before they occur. By applying these practices, users can achieve higher operational efficiency, reduced downtime, and longer transformer lifespan, ensuring dependable performance across all applications.

FAQ

Q1: What design features improve the reliability of dry type transformers?

Dry type transformer reliability begins with the quality of materials, insulation systems, and core design. High-grade silicon steel or amorphous metal cores significantly reduce core losses and heat generation, improving long-term stability. Advanced epoxy resin systems (cast resin) or high-quality varnish in VPI units help prevent moisture absorption, partial discharge, and insulation degradation. Class F or H insulation increases thermal endurance, allowing the transformer to maintain performance even under elevated temperatures.

Structural enhancements—like strong clamping systems, rigid windings, and optimized cooling ducts—reduce vibration and withstand short-circuit forces. Partial discharge-resistant designs, improved surface creepage distances, and vacuum-casting techniques reduce the risk of insulation failure. By selecting a transformer built with premium materials and robust structural engineering, users achieve long-term reliability with minimal risk of internal faults or premature aging.

Q2: How does proper installation enhance transformer performance?

Proper installation is just as critical as design quality. Installing the transformer in a well-ventilated, clean, and dry environment helps maintain healthy cooling and prevents contamination. Adequate clearance around the transformer ensures optimal airflow—especially important for AN (Air Natural) and AF (Air Forced) cooling designs. Avoiding enclosed rooms with poor airflow or heat buildup prevents overheating and insulation stress.

Correct mounting and vibration isolation pads prevent mechanical fatigue. Ensuring proper grounding improves fault handling and reduces electrical stress on the windings. Additionally, positioning away from corrosive chemicals, dust, or humidity sources prevents long-term damage. By following manufacturer installation guidelines and aligning them with local electrical codes, users create stable operating conditions that support peak performance.

Q3: Why is cooling system management essential for performance and lifespan?

Cooling plays a major role in how long a dry type transformer lasts. Because these transformers rely on air (natural or forced) for cooling, proper temperature control is essential. Excessive heat accelerates insulation aging and increases load losses. Regular cleaning of air paths, filters, and fans ensures consistent airflow.

Adding temperature sensors and thermal monitoring devices helps track hot spots and load stress. In environments with high ambient temperatures or heavy loads, upgrading to forced-air cooling (AF) improves thermal stability and overload performance. Maintaining proper cooling ensures lower winding temperatures, reduced thermal expansion, and longer insulation life—directly boosting reliability and efficiency.

Q4: How does preventive maintenance improve reliability?

Dry type transformers require significantly less maintenance than oil-filled units, but preventive care is still crucial. Routine inspections should include tightening connections, removing dust from windings and cores, checking temperature sensors, and verifying proper grounding. Dust and debris can trap heat and create partial discharge conditions, reducing transformer life.

Thermal imaging scans help identify hot spots early. For VPI transformers, periodic varnish re-impregnation may be recommended after many years of service. Any abnormal noises, vibrations, or odor changes should be investigated immediately. Implementing a preventive maintenance schedule reduces unexpected failures and keeps the transformer performing at peak levels throughout its lifespan.

Q5: How does digital monitoring improve reliability and performance?

Smart monitoring systems significantly enhance transformer reliability. Sensors embedded in the transformer measure temperature, humidity, partial discharge, load variation, and vibration. Real-time data is analyzed through intelligent software platforms to detect trends and predict failures before they occur.

Predictive analytics can identify insulation aging, overloaded conditions, and cooling issues early. Digital twins—virtual models of transformers—allow performance simulation and stress analysis without interrupting operation. Remote monitoring is especially valuable for renewable energy sites, data centers, and industrial plants where uptime is critical. Adding digital monitoring transforms a dry type transformer from a passive device into an intelligent, proactive component of the electrical system.

References

IEC 60076-11 – Dry Type Transformer Standards — https://www.iec.ch

IEEE C57 Dry Type Transformer Guidelines — https://ieeexplore.ieee.org

Schneider Electric Transformer Installation Best Practices — https://www.se.com

Doble Engineering – Transformer Maintenance Strategies — https://www.doble.com

EEP – Dry Type Transformer Cooling & Installation Tips — https://electrical-engineering-portal.com

Global Market Insights – Dry Type Transformer Market Trends — https://www.gminsights.com

Statista – Transformer Industry Performance Data — https://www.statista.com