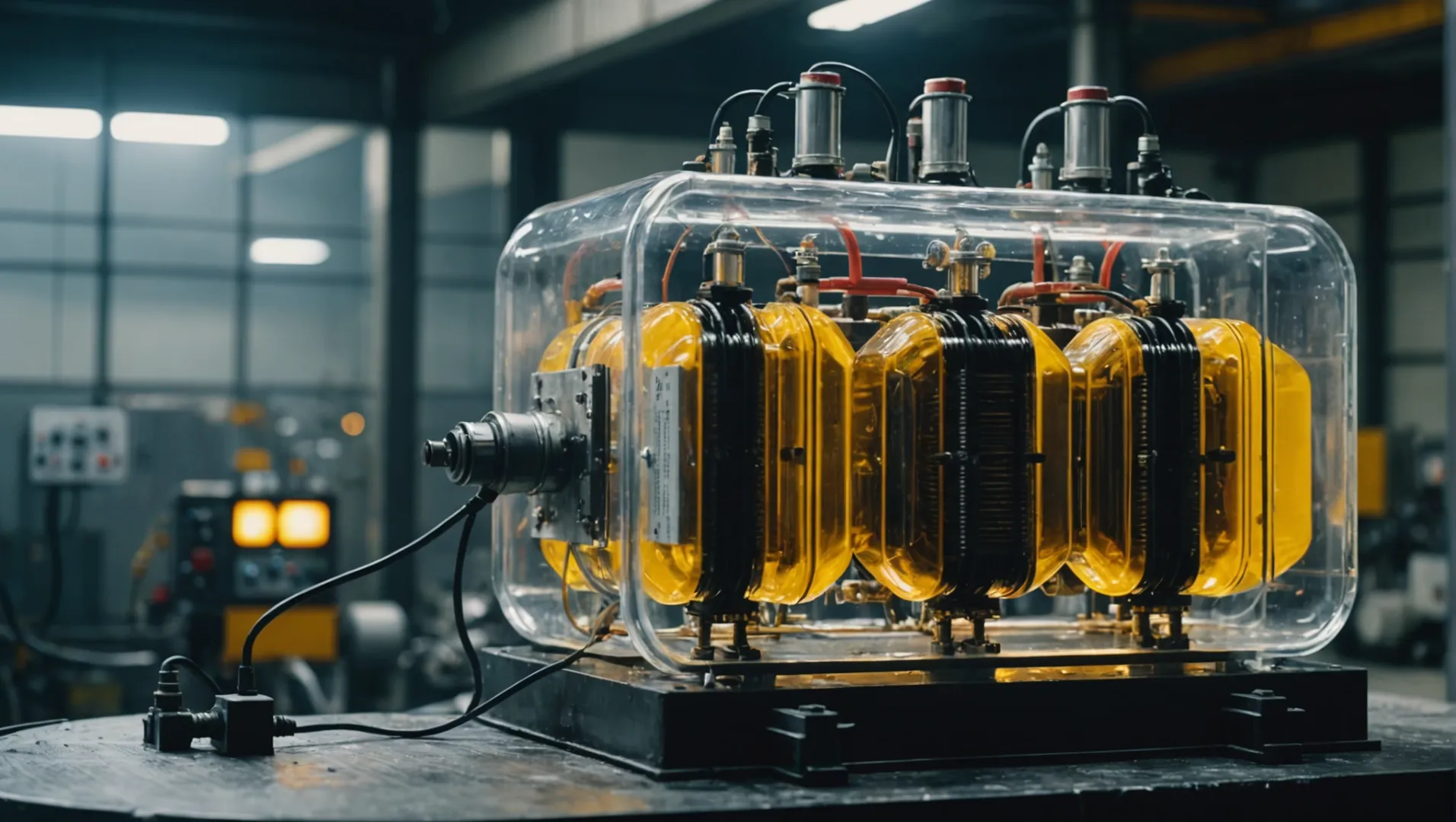

Have you ever wondered why transformers are submerged in oil? It's more than just a technical detail—it's a vital part of how they operate efficiently!

Transformers are submerged in oil to enhance their performance by providing insulation, cooling, and protection against environmental factors. This oil immersion helps dissipate heat generated during operation and prevents electrical faults, ensuring longevity and reliability of the transformers.

While this brief overview highlights the primary reasons for oil submersion, there’s much more to explore about the technical intricacies and benefits of this practice. Dive deeper to discover how oil enhances transformer efficiency and the role it plays in maintaining optimal performance.

Oil immersion enhances transformer insulation.True

Oil acts as a dielectric medium, preventing electrical discharges.

How Does Oil Insulate Transformers?

Oil plays a crucial role in insulating transformers, ensuring their safety and efficiency.

Oil insulates transformers by creating a barrier between conductive parts, preventing electrical discharges and short circuits. It acts as a dielectric medium, enhancing the insulation properties and improving overall transformer efficiency.

Understanding Transformer Insulation

In electrical transformers, insulation is vital for preventing electrical discharges that can lead to failures or damage. The high voltages involved in transformer operations necessitate robust insulating methods. Oil1 serves as an excellent insulating medium due to its dielectric properties, which allow it to withstand high voltage differences without conducting electricity.

Dielectric Properties of Transformer Oil

Transformer oil, typically mineral-based, exhibits impressive dielectric strength. This means it can effectively prevent electrical discharges by forming a non-conductive layer around the transformer components. The dielectric constant of oil is considerably higher than air, making it a superior insulating agent.

| Property | Transformer Oil | Air |

|---|---|---|

| Dielectric Strength | High | Low |

| Thermal Conductivity | Moderate | Very Low |

Protection Against Electrical Discharges

By enveloping the transformer's windings and other components, oil acts as a buffer against potential electrical discharges. It prevents arcing, which occurs when electricity jumps across gaps between conductors. Arcing can cause significant damage and lead to power outages or equipment failure. The use of oil insulation2 significantly reduces these risks by maintaining a stable and secure operational environment within the transformer.

Enhancing Transformer Efficiency

The insulating properties of oil not only provide protection but also improve the efficiency of transformers. By minimizing electrical losses and ensuring stable performance, oil helps maintain the transformer's operational integrity. This enhances overall system reliability and contributes to longer service life.

Understanding how oil insulates transformers provides insights into why it remains a preferred choice in high-voltage applications. The ability of oil to act as both an insulator and a coolant underscores its importance in transformer design and functionality.

Oil prevents electrical discharges in transformers.True

Oil's dielectric properties create a non-conductive barrier.

Air is a better insulator than oil for transformers.False

Oil has higher dielectric strength than air, making it superior.

What Role Does Oil Play in Heat Dissipation?

Oil plays a crucial role in managing heat within transformers, ensuring efficient operation and longevity.

In transformers, oil acts as a cooling agent by absorbing and transferring heat away from the transformer core and windings. This process prevents overheating, enhances performance, and reduces the risk of damage.

The Cooling Mechanism of Transformer Oil

Transformer oil functions primarily as a heat conductor, absorbing heat generated by electrical currents and transferring it to the transformer's external surfaces. This process aids in maintaining optimal operating temperatures, preventing overheating and subsequent damage. The ability of oil to circulate freely around the transformer components is critical in maintaining efficient heat dissipation.

Thermal Conductivity and Heat Transfer

Oil's thermal conductivity ensures that heat is evenly distributed and transferred efficiently. It circulates through the transformer's core and windings, absorbing excessive heat and moving it towards the cooler exterior surfaces where it can dissipate into the surrounding environment. This continuous cycle helps maintain a stable temperature within the transformer, which is essential for prolonging its operational life3.

Enhancing Transformer Reliability

By efficiently managing heat, transformer oil significantly enhances the reliability of the equipment. Excessive heat can degrade the transformer's internal components, leading to insulation breakdowns and electrical faults. Oil immersion helps mitigate these risks by ensuring that heat levels remain within safe limits, thus preventing potential failures4.

Comparing Different Types of Transformer Oils

Not all transformer oils are created equal. Mineral oils are commonly used for their cost-effectiveness and adequate performance; however, synthetic oils and natural esters offer superior thermal stability and environmentally-friendly options. Understanding the properties of different oils can guide decisions regarding oil selection for specific applications5. This choice impacts both the efficiency of heat dissipation and overall transformer performance.

Conclusion

While oil plays a vital role in heat dissipation, selecting the right type of oil is equally important for optimal transformer performance. Regular maintenance and monitoring further ensure that transformers operate safely and efficiently over their lifespan.

Oil acts as a heat conductor in transformers.True

Transformer oil absorbs and transfers heat, preventing overheating.

Mineral oils are the most thermally stable transformer oils.False

Synthetic oils and natural esters offer superior thermal stability.

Are There Different Types of Transformer Oils?

Transformer oils are essential for performance, but are they all the same?

Yes, there are different types of transformer oils, primarily categorized as mineral-based, silicone-based, and natural ester-based oils. Each type offers distinct properties that influence their application in various transformer settings.

Understanding the Varieties of Transformer Oils

When it comes to transformer oils, not all oils are created equal. The choice of oil can significantly impact a transformer's efficiency, safety, and lifespan. Here's a closer look at the different types:

Mineral-Based Oils

Mineral oils are the most common type used in transformers. Derived from refining crude oil, they offer excellent cooling and insulating properties. Advantages include cost-effectiveness and widespread availability. However, they are less environmentally friendly compared to other types.

| Property | Description |

|---|---|

| Cost | Lower than other types |

| Environmental Impact | Higher due to petroleum base |

| Availability | Widely available globally |

Silicone-Based Oils

Silicone oils are known for their stability at high temperatures. These oils are suitable for transformers operating in extreme conditions where temperature fluctuations are frequent. Advantages include non-flammability and excellent thermal stability.

| Property | Description |

|---|---|

| Thermal Stability | Excellent at high temperatures |

| Flammability | Non-flammable |

| Cost | Higher than mineral oils |

Natural Ester-Based Oils

Natural ester oils, also known as vegetable oils, are gaining popularity due to their eco-friendly nature. They are biodegradable and offer good insulation properties, making them an ideal choice for environmentally sensitive areas.

| Property | Description |

|---|---|

| Environmental Impact | Low; biodegradable |

| Insulation | Good |

| Availability | Less common than mineral oils |

Factors Influencing Oil Choice

- Temperature Range: High-temperature operations may require silicone or ester-based oils for better thermal stability.

- Environmental Concerns: In areas with stringent environmental regulations, natural ester oils may be preferred.

- Cost Considerations: Mineral oils are typically chosen for their cost-effectiveness, especially in large-scale applications.

In summary, the selection of transformer oil is driven by specific operational needs and environmental considerations. Understanding these differences can help in making informed decisions about transformer maintenance and upgrades.

Learn more about transformer oil specifications6 to choose the right type for your needs.

Mineral oils are the most eco-friendly transformer oils.False

Mineral oils have a higher environmental impact due to their petroleum base.

Silicone-based oils are non-flammable and stable at high temperatures.True

Silicone oils offer excellent thermal stability and are non-flammable, ideal for extreme conditions.

How Does Oil Maintenance Affect Transformer Longevity?

Regular oil maintenance is crucial for extending a transformer's lifespan and ensuring reliable performance.

Oil maintenance in transformers is essential for removing contaminants and moisture, thus preserving the oil's insulating properties and cooling efficiency. Regular testing and replacement of transformer oil prevent breakdowns, extend operational life, and reduce maintenance costs.

Understanding Transformer Oil Maintenance

Oil in transformers serves as both an insulator and a coolant. Over time, contaminants like moisture, acids, and sludge can accumulate, degrading these essential properties. Regular maintenance is vital to ensure the oil maintains its effectiveness.

The Importance of Testing and Analysis

Testing transformer oil periodically helps identify potential issues before they escalate. Key tests include:

- Dissolved Gas Analysis (DGA): This test detects gases produced by oil degradation and electrical faults, providing early warning signs of problems.

- Moisture Content Analysis: Moisture reduces dielectric strength and accelerates aging.

These tests allow for timely interventions, preventing damage to the transformer.

Benefits of Regular Oil Replacement

Replacing transformer oil at appropriate intervals helps maintain efficiency and reliability. Fresh oil restores insulation properties, improves cooling performance, and removes accumulated contaminants.

| Benefits | Description |

|---|---|

| Improved Insulation | Fresh oil prevents dielectric breakdowns and enhances electrical insulation. |

| Enhanced Cooling | Clean oil dissipates heat more effectively, reducing overheating risks. |

| Prolonged Transformer Life | Regular maintenance prevents wear and tear, extending operational lifespan. |

Implementing a Maintenance Schedule

Adopting a proactive maintenance schedule ensures transformers operate at peak performance. Factors influencing the schedule include transformer age, operational environment, and initial oil quality. Developing a maintenance plan7 tailored to specific conditions can significantly enhance longevity.

The Role of Filtration Systems

Advanced filtration systems help in maintaining oil purity by removing particulates and moisture continuously. These systems can be installed in transformers to provide ongoing protection without frequent oil changes.

Understanding the importance of oil maintenance in transformers not only helps in preventing costly repairs but also ensures efficient energy distribution across electrical networks. By implementing routine tests and replacements, operators can safeguard against unexpected failures and extend the service life of these critical components.

Oil maintenance reduces transformer breakdowns.True

Regular oil maintenance removes contaminants, preventing breakdowns.

Moisture increases transformer oil dielectric strength.False

Moisture decreases dielectric strength, leading to faster aging.

Conclusion

Understanding the role of oil in transformers not only enhances our knowledge but also highlights the importance of regular maintenance and the right choice of oil for optimal performance.

Learn how oil's dielectric properties prevent electrical discharges.: Transformer oil's primary functions are to insulate and cool a transformer. It must therefore have high dielectric strength, thermal conductivity, and ... ↩

Discover why oil is ideal for reducing electrical losses.: Its functions are to insulate, suppress corona discharge and arcing, and to serve as a coolant. Transformer oil is most often based on mineral oil, but ... ↩

Learn how oil enhances transformer durability by maintaining ideal temperatures.: Combined, the paper and oil yield a 23% increase in dielectric strength. The increase in dielectric strength makes this combination popular as ... ↩

Discover the role of oil in averting transformer malfunctions.: Failures in electrical transformers are inevitable. When this occurs, the temperature of the oil inside increases at the site of the failure. This results ... ↩

Explore various oils used in transformers and their specific benefits.: Types of transformer oil include mineral oil, FR3® fluid, and silicone oil. Find out which is best for your transformer. Written by: Ben Gulick, ... ↩

Understand specifications to select the most suitable transformer oil.: Oil cools a transformer's windings. Types of transformer oil include mineral oil, FR3® fluid, and silicone oil. Find out which is best for your ... ↩

Learn how to create effective maintenance schedules for transformers.: A power transformer requires various routine maintenance tasks including measurement and testing of different parameters of the transformer. ↩