Transformers generate significant amounts of heat during operation due to electrical losses in their core and windings. Effective cooling is essential to maintain the transformer's efficiency, protect its insulation, and extend its service life. Different transformers use different cooling systems based on their size, capacity, and application requirements. Understanding the types of cooling methods available helps in selecting the right system for specific operating environments and performance needs. This article explores the various types of cooling systems used in transformers, how they work, and their advantages and limitations.

Why Is Cooling Important in Transformer Operation?

Cooling is an absolutely critical aspect of transformer operation because transformers naturally generate significant heat during the process of voltage transformation. Without effective cooling, the internal temperatures can rise beyond safe operational limits, leading to insulation breakdown, mechanical deformation, efficiency losses, and catastrophic failures. Proper cooling not only ensures safe operation but also significantly extends the transformer's lifespan and maintains system reliability.

In this article, we will explore in depth why cooling is so important in transformer operation, the consequences of inadequate cooling, and the technologies used to manage thermal performance effectively.

1. Heat Generation in Transformers

During normal operation, transformers produce heat through two main types of electrical losses:

- Core Losses (Iron Losses):

- Caused by magnetic hysteresis and eddy currents in the transformer's iron core.

- These losses are constant and independent of the load.

- Copper Losses (Winding Losses):

- Caused by the resistance to current flow in the transformer windings (I²R losses).

- Proportional to the square of the current; thus, as load increases, heating increases sharply.

Without proper cooling, this generated heat would accumulate rapidly, causing dangerous internal temperatures.

2. Consequences of Inadequate Cooling

Failing to cool a transformer properly leads to a series of severe operational problems:

- Insulation Aging and Failure:

- Excessive heat accelerates the degradation of insulating materials.

- Every 6–8 °C increase above the rated operating temperature can halve the insulation's life expectancy.

- Oil Degradation (for Oil-Immersed Transformers):

- Overheating causes insulating oil to break down chemically, producing acids, sludge, and gases that reduce its dielectric strength.

- Reduced Efficiency:

- Higher internal temperatures increase resistance, compounding losses and reducing transformer efficiency.

- Mechanical Deformation:

- Continuous thermal expansion and contraction stress internal components, causing eventual deformation or structural failure.

- Fire and Explosion Risks:

- Prolonged overheating can lead to arcing, oil ignition, and catastrophic transformer fires or explosions.

Proper cooling is essential to avoid thermal runaway, a condition where rising temperatures cause accelerating damage leading to sudden failure.

3. Cooling Methods for Transformers

Depending on transformer type, size, and application, different cooling methods are used:

| Cooling Method | Description | Application |

|---|---|---|

| ONAN (Oil Natural Air Natural) | Natural oil and air convection cools the transformer. | Small to medium oil-filled transformers. |

| ONAF (Oil Natural Air Forced) | Fans blow air over radiator fins to enhance cooling. | Larger oil-filled transformers. |

| OFAF (Oil Forced Air Forced) | Oil is pumped actively through heat exchangers with forced air. | Very large, high-load transformers. |

| OFWF (Oil Forced Water Forced) | Oil is pumped through water-cooled heat exchangers. | Extremely large transformers in critical facilities. |

| Dry-Type Cooling (AF/AN) | Air-forced or natural convection cooling. | Indoor or environmentally sensitive installations. |

Each method is designed to keep hot-spot temperatures within safe operational limits under varying load and ambient conditions.

4. Standard Temperature Rise Limits

International standards set temperature rise limits to ensure safe operation:

| Transformer Type | Maximum Winding Temperature Rise (°C) |

|---|---|

| Oil-Immersed Transformers (ONAN) | 55–65 °C above ambient. |

| Dry-Type Transformers | 80–115 °C above ambient (depending on class). |

Hot-spot temperatures (localized maximum temperatures inside windings) are usually 10–15 °C higher than average winding temperatures and must also stay within specified limits.

Good cooling ensures these temperature rise limits are not exceeded, protecting the insulation and structure.

5. Importance of Cooling in Load Handling and Overload Capability

Effective cooling directly affects a transformer's load-handling capacity:

- Normal Loads: Transformers must continuously carry rated loads without exceeding temperature limits.

- Temporary Overloads: With proper cooling, transformers can safely handle overloads for short periods (e.g., 120–150% of rated load), based on permissible temperature rises defined in standards like IEEE C57.91 and IEC 60076-7.

A transformer with inadequate cooling would have a severely reduced ability to absorb load peaks, leading to accelerated wear or sudden failure.

6. Monitoring Transformer Cooling Performance

Modern transformers are equipped with thermal management systems to monitor and control cooling effectiveness:

- Temperature Sensors: Measure winding, oil, and ambient temperatures.

- Buchholz Relays: Detect gas accumulation from overheating or internal arcing in oil-filled transformers.

- Cooling System Controls: Activate fans, pumps, or alarms when temperatures approach critical thresholds.

- Digital Monitoring Systems: Provide real-time thermal profiles, predictive maintenance alerts, and historical trend analysis.

These technologies ensure that cooling remains effective and that operators can respond proactively to thermal issues.

7. Real-World Cooling Performance Example

| Parameter | Transformer A (Good Cooling) | Transformer B (Poor Cooling) |

|---|---|---|

| Winding Temp Rise | 55 °C | 75 °C |

| Insulation Expected Life | 25–30 years | 10–12 years |

| Oil Condition After 5 Years | Clean, dielectric strength intact | Degraded, acid buildup |

| Efficiency | 99.2% | 97.5% |

| Failure Risk | Very Low | High (especially under overloads) |

This comparison clearly shows the dramatic impact that cooling quality has on transformer performance and longevity.

ClaimReview Fact Check

Cooling systems are essential in transformers to prevent overheating, protect insulation, and ensure operational reliability.True

Efficient cooling controls internal temperatures, extending insulation life, preserving oil quality, and preventing thermal damage, thus maintaining transformer reliability and safety.

What Are the Main Types of Cooling Systems in Transformers?

Cooling systems are essential components of transformers, responsible for maintaining internal temperatures within safe operational limits. Without effective cooling, transformers would suffer from overheating, leading to insulation degradation, reduced efficiency, and premature failure. Different transformers require different cooling solutions based on their size, location, load conditions, and design specifications.

In this article, we will explore the main types of cooling systems used in transformers, highlighting their working principles, applications, and advantages.

1. ONAN: Oil Natural Air Natural Cooling

Working Principle:

- Heat generated inside the transformer is transferred to the surrounding oil.

- The hot oil rises and circulates naturally (without pumps).

- Heat is then dissipated to the ambient air through radiator fins by natural air convection.

Applications:

- Small to medium-sized oil-immersed transformers.

- Distribution transformers where load variations are moderate.

Advantages:

- Simple and reliable (no moving parts like fans or pumps).

- Low maintenance.

- Suitable for areas where temperature rises are manageable.

| ONAN Cooling Characteristics |

|---|

| Passive natural oil and air flow. |

| Moderate cooling capacity. |

| Cost-effective and easy to maintain. |

2. ONAF: Oil Natural Air Forced Cooling

Working Principle:

- Like ONAN, oil circulates naturally inside the transformer.

- However, air fans are added to force air across the radiator surfaces, enhancing cooling.

- When the temperature exceeds a preset level, fans are automatically switched on.

Applications:

- Large power transformers where natural air convection is insufficient.

- Transformers requiring higher loading without exceeding temperature limits.

Advantages:

- Increases cooling efficiency by 25–30%.

- Allows transformers to carry higher loads without upgrading size.

- Flexibility to operate in ONAN mode at light loads and ONAF mode during peak loads.

| ONAF Cooling Characteristics |

|---|

| Natural oil flow, forced air flow. |

| Higher cooling capacity than ONAN. |

| Requires fan maintenance and control systems. |

3. OFAF: Oil Forced Air Forced Cooling

Working Principle:

- Both oil and air circulation are forced:

- Oil pumps actively circulate the oil through the transformer and radiators.

- Fans blow air over the radiator surfaces to dissipate heat.

Applications:

- Very large power transformers.

- Transformers operating under continuous heavy loads or in critical infrastructure.

Advantages:

- Superior cooling efficiency compared to ONAN or ONAF.

- Enables handling of very high loads.

- Better temperature control and heat dissipation.

| OFAF Cooling Characteristics |

|---|

| Forced oil flow and forced air flow. |

| Very high cooling efficiency. |

| Requires pumps, fans, and active monitoring. |

4. OFWF: Oil Forced Water Forced Cooling

Working Principle:

- Oil is circulated through heat exchangers where water is used to absorb the heat from the oil.

- The heated water is then cooled separately, often through cooling towers or heat rejection systems.

Applications:

- Extremely large transformers (e.g., in power generation stations, HVDC converters).

- Locations where ambient air cooling is insufficient or impractical.

Advantages:

- Highly efficient heat removal.

- Water-cooled systems allow for compact installation.

- Essential where space constraints or environmental factors limit air-based cooling.

| OFWF Cooling Characteristics |

|---|

| Forced oil and forced water circulation. |

| Maximum cooling capacity. |

| Requires complex water management and maintenance. |

5. Dry-Type Transformer Cooling

Dry-type transformers use air cooling instead of oil.

Air Natural (AN)

Working Principle:

- Natural convection of ambient air cools the transformer's windings.

- No forced movement of air or fluids.

Applications:

- Indoor installations (e.g., hospitals, shopping malls, high-rise buildings).

- Areas with environmental or fire safety concerns.

Advantages:

- Environmentally safe (no oil leaks).

- Lower fire risk.

- Suitable for indoor environments.

| Air Natural Cooling Characteristics |

|---|

| No moving parts, low maintenance. |

| Limited to moderate load and size ranges. |

Air Forced (AF)

Working Principle:

- Fans are used to blow air over the windings to enhance cooling.

Applications:

- Higher power dry-type transformers requiring enhanced cooling.

Advantages:

- Increased load-handling capacity compared to natural air cooling.

- Can handle higher temperature rises safely.

| Air Forced Cooling Characteristics |

|---|

| Forced air flow using fans. |

| Higher cooling and load capacity. |

| Requires fan maintenance. |

Comparison Table: Cooling Systems at a Glance

| Cooling System | Oil Circulation | Air/Water Circulation | Typical Applications | Key Features |

|---|---|---|---|---|

| ONAN | Natural | Natural air convection | Distribution transformers | Simple, reliable |

| ONAF | Natural | Forced air with fans | Medium to large transformers | Enhanced cooling |

| OFAF | Forced with pumps | Forced air with fans | Large power transformers | High efficiency |

| OFWF | Forced with pumps | Forced water with exchangers | Generation, HVDC stations | Maximum cooling |

| Dry-Type (AN/AF) | N/A | Natural/Forced air | Indoor, fire-sensitive locations | Oil-free, safe |

ClaimReview Fact Check

Different transformer cooling systems, such as ONAN, ONAF, OFAF, OFWF, and dry-type cooling, are used depending on load, size, and environmental requirements.True

Transformers are designed with appropriate cooling systems based on operational needs, thermal management, and site-specific conditions to ensure safe and efficient operation.

How Does the Cooling Method Differ Between Oil-Immersed and Dry-Type Transformers?

Cooling methods in transformers are tailored to the transformer's design, insulation medium, and application requirements. The two primary types—oil-immersed transformers and dry-type transformers—employ distinctly different cooling strategies due to differences in materials, construction, thermal conductivity, and safety considerations. These cooling methods have a direct impact on the transformer's thermal performance, efficiency, size, and operational environment.

In this article, we’ll explore in detail how cooling methods differ between oil-immersed and dry-type transformers, explaining their working principles, advantages, and typical applications.

1. Cooling in Oil-Immersed Transformers

Oil-immersed transformers use mineral oil or synthetic insulating fluids to serve two primary purposes:

- Electrical Insulation: Prevents short-circuits between high-voltage components.

- Heat Dissipation: Transfers heat from the windings and core to the external environment.

Cooling Mechanisms:

| Cooling Method | Working Principle |

|---|---|

| ONAN (Oil Natural Air Natural) | Heat from windings is absorbed by oil; hot oil rises naturally and circulates, cooled by natural air flow over radiators. |

| ONAF (Oil Natural Air Forced) | Natural oil circulation, but air cooling is enhanced by motor-driven fans over radiators. |

| OFAF (Oil Forced Air Forced) | Oil is actively pumped, and fans force air over external radiators for superior cooling. |

| OFWF (Oil Forced Water Forced) | Oil is pumped through water-cooled heat exchangers; used in high-capacity critical systems. |

Key Features of Oil Cooling:

- High thermal capacity due to oil's excellent heat absorption.

- Efficient cooling for large transformers.

- Temperature stability supports higher overloads.

- Risk of oil leaks, fires, and environmental contamination if not properly managed.

Oil cooling allows for compact, high-capacity designs, critical for outdoor, utility, and industrial transformers.

2. Cooling in Dry-Type Transformers

Dry-type transformers do not use oil. Instead, they rely solely on air as the insulating and cooling medium.

Cooling Mechanisms:

| Cooling Method | Working Principle |

|---|---|

| AN (Air Natural) | Natural convection: air rises as it heats up around the windings, carrying away heat without forced circulation. |

| AF (Air Forced) | External fans blow air across the windings to enhance cooling capacity. |

Key Features of Air Cooling:

- Environmentally safer—no risk of oil leaks or flammable liquids.

- Higher temperature rise allowed due to robust solid insulation systems (resins or cast resin).

- Lower thermal conductivity compared to oil, requiring larger surface areas or forced air to maintain cooling.

- Ideal for indoor use in commercial buildings, hospitals, data centers, and fire-sensitive environments.

Dry-type cooling is best suited for medium-capacity transformers where fire safety and environmental concerns outweigh the need for extreme compactness or heavy loading capacity.

3. Comparative Table: Oil-Immersed vs Dry-Type Cooling

| Aspect | Oil-Immersed Transformers | Dry-Type Transformers |

|---|---|---|

| Cooling Medium | Mineral or synthetic oil | Air (natural or forced) |

| Main Cooling Methods | ONAN, ONAF, OFAF, OFWF | AN, AF |

| Cooling Efficiency | Higher (due to oil’s thermal conductivity) | Lower (compensated by larger designs or forced air) |

| Risk Factors | Oil leaks, fire hazards | Minimal fire risk, environmentally safe |

| Maintenance Needs | Oil testing, radiator cleaning, leak monitoring | Fan maintenance, dust cleaning |

| Application Areas | Utilities, substations, heavy industries | Hospitals, malls, offices, indoor facilities |

| Size and Weight | More compact for high ratings | Larger for the same power rating |

| Overload Capability | Higher short-term overload tolerance | Limited overload handling compared to oil-filled |

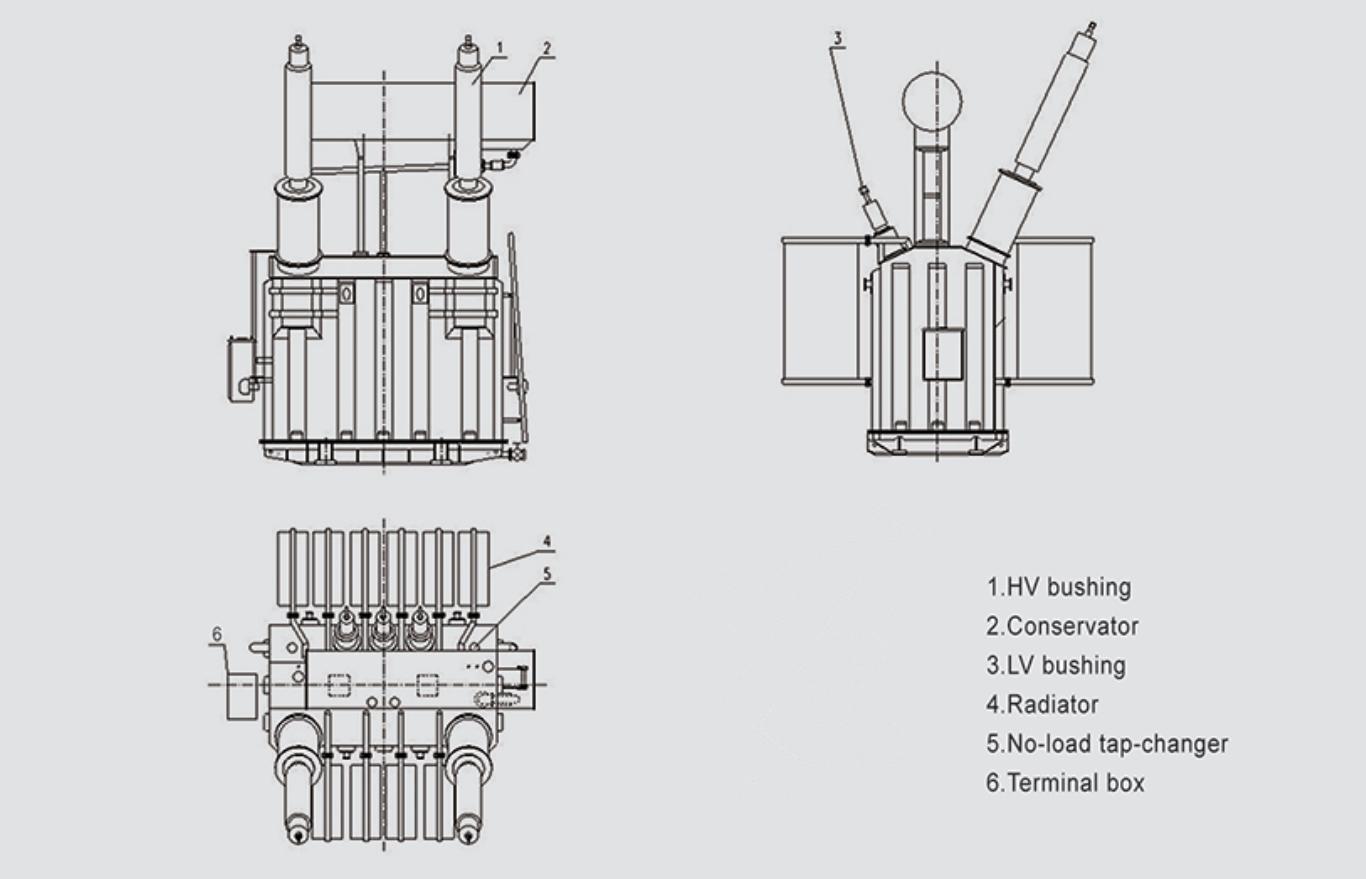

4. Working Diagram Illustration

| Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|

| Core and windings submerged in oil. | Core and windings coated with epoxy resin or varnish. |

| Oil heats up, rises, cools in radiators. | Heat dissipates directly through air circulation. |

| Radiators, pumps, fans, or water coolers may be used. | Natural or forced air flow via ducts or fans. |

| Oil absorbs both thermal and electrical stress. | Air acts only as a cooling medium; solid insulation manages electrical stress. |

5. Impact on Transformer Design and Deployment

Oil-Immersed Transformers:

- Smaller footprint relative to capacity.

- Require secondary containment (e.g., oil bunds) for environmental safety.

- Suited for outdoor installations and high-load applications.

Dry-Type Transformers:

- Larger enclosures and higher clearances required for the same rating.

- No need for oil containment or oil maintenance.

- Ideal for indoor applications, fire-sensitive areas, and where low maintenance is preferred.

ClaimReview Fact Check

Oil-immersed transformers use oil circulation for cooling, while dry-type transformers rely on air convection or forced air cooling.True

Oil-immersed transformers transfer heat via oil and external radiators, whereas dry-type transformers use ambient or forced air to dissipate heat without any liquid medium.

What Are Forced Cooling Systems and When Are They Needed?

Forced cooling systems are advanced thermal management solutions used in transformers to actively enhance heat dissipation beyond natural convection capabilities. These systems are critical in situations where natural cooling alone cannot maintain safe operational temperatures, especially in high-load, continuous-duty, or compact transformer designs. Forced cooling ensures transformers can operate under higher loads, reduce hot-spot temperatures, and extend service life without thermal damage.

In this article, we will explore what forced cooling systems are, how they operate, and when they are necessary in transformer applications.

1. What Are Forced Cooling Systems in Transformers?

Forced cooling systems use mechanical means to increase the efficiency of heat removal from the transformer’s internal components.

Key Components:

- Fans: Blow air over radiator surfaces or directly across windings.

- Oil Pumps: Actively circulate insulating oil through radiators or heat exchangers.

- Water Cooling Units: In some cases, water is used as the final heat rejection medium (forced oil-water systems).

Primary Cooling Types:

| System | Cooling Description |

|---|---|

| ONAF (Oil Natural Air Forced) | Oil circulates naturally; fans force air over the radiator. |

| OFAF (Oil Forced Air Forced) | Oil is pumped; fans force air over radiator surfaces. |

| OFWF (Oil Forced Water Forced) | Oil is pumped; heat transferred to water through heat exchangers. |

| Dry-Type AF (Air Forced) | Fans blow air directly over dry-type transformer windings. |

Forced cooling increases the transformer's ability to handle thermal loads by actively expelling heat, rather than relying solely on passive natural convection.

2. How Forced Cooling Systems Work

Forced cooling systems operate in one of two main modes:

- Automatic Activation:

- Cooling devices (fans, pumps) turn on when the transformer's temperature reaches a preset threshold.

- Sensors continuously monitor hot-spot or top-oil temperatures.

- Continuous Operation:

- In critical systems, cooling may operate continuously to guarantee temperature stability even before thresholds are reached.

Operation Flow:

- Load increases transformer internal temperatures.

- Temperature sensors detect rise beyond safe thresholds.

- Fans and/or pumps activate to boost heat transfer.

- Heat dissipates more quickly, maintaining transformer temperatures within permissible limits.

This dynamic cooling response allows transformers to handle overloads without compromising thermal integrity.

3. When Are Forced Cooling Systems Needed?

Forced cooling becomes essential in specific scenarios where natural cooling is insufficient:

| Situation | Reason for Forced Cooling |

|---|---|

| High Capacity Transformers | Large power transformers generate massive heat loads. |

| Continuous Heavy Loads | Industrial or utility transformers operating near full capacity for extended periods. |

| Space Constraints | Compact installations where large radiators for natural cooling are impractical. |

| High Ambient Temperatures | Hot climates where natural air convection is less effective. |

| Critical Applications | Power plants, data centers, hospitals—where downtime cannot be tolerated. |

| Load Growth Accommodation | Facilities expecting significant future load increases without transformer replacement. |

Forced cooling ensures transformers can safely operate at or beyond their nameplate ratings when necessary.

4. Benefits of Forced Cooling Systems

| Benefit | Impact |

|---|---|

| Enhanced Load Handling | Transformers can carry loads exceeding their ONAN rating by 25–50% or more. |

| Improved Thermal Stability | Maintains hot-spot temperatures within safe limits during overloads. |

| Extended Transformer Life | Reduces thermal aging and stress on insulation materials. |

| Operational Flexibility | Systems can adapt cooling based on real-time load conditions. |

| Increased Efficiency | Lower internal temperatures improve electrical efficiency and reliability. |

Forced cooling systems are particularly valuable for transformers that must withstand fluctuating or consistently high loads.

5. Challenges and Maintenance Considerations

While highly effective, forced cooling systems introduce additional complexity:

- Mechanical Wear: Pumps and fans require regular maintenance (bearing lubrication, motor inspections).

- Power Consumption: Cooling devices add parasitic loads, slightly reducing system-wide efficiency.

- Failure Risks: Cooling system failure (e.g., pump stoppage, fan motor burnout) can cause rapid overheating if not immediately addressed.

- Monitoring Systems: Temperature and device operation monitoring must be integrated to detect and respond to cooling system faults.

Proactive maintenance and monitoring are crucial to ensure forced cooling systems remain reliable throughout the transformer's operational life.

ClaimReview Fact Check

Forced cooling systems in transformers are necessary when natural convection cooling cannot maintain safe operational temperatures under high load conditions.True

Forced cooling using fans and pumps increases heat dissipation, allowing transformers to handle higher loads safely without exceeding thermal limits.

6. Real-World Example: Forced Cooling Enhancement

| Parameter | ONAN (Natural Cooling Only) | ONAF (With Forced Air Cooling) |

|---|---|---|

| Rated Load Capacity | 100% | 125–135% |

| Top-Oil Temperature (°C) | 90 °C | 75 °C |

| Hot-Spot Temperature (°C) | 110 °C | 95 °C |

| Thermal Aging Acceleration Factor | 2.5x | 1.2x |

| System Reliability | Standard | Enhanced |

Adding forced cooling can significantly increase a transformer's usable capacity while maintaining safe thermal profiles.

How to Choose the Right Cooling System for a Transformer?

Choosing the right cooling system for a transformer is a critical engineering decision that directly affects its efficiency, reliability, lifespan, and operational cost. Since different transformers operate under varying loads, ambient conditions, space constraints, and safety requirements, the cooling system must be selected carefully to ensure the transformer maintains safe internal temperatures under all expected conditions.

This article provides a complete guide on how to choose the right cooling system for a transformer, helping engineers and decision-makers align cooling strategies with operational needs and environmental factors.

1. Understand the Transformer Type and Application

The first step is identifying the transformer type and operational environment:

| Transformer Type | Typical Application |

|---|---|

| Oil-Immersed Transformer | Outdoor installations, heavy industrial loads, substations. |

| Dry-Type Transformer | Indoor environments, commercial buildings, environmentally sensitive areas. |

Key consideration:

- Oil-immersed transformers need oil-based cooling systems.

- Dry-type transformers use air (natural or forced) for cooling.

2. Analyze Load Requirements and Load Profile

The transformer's expected load and load variability are major factors:

| Load Profile | Cooling Requirement |

|---|---|

| Constant moderate load | Natural cooling (ONAN or AN) may suffice. |

| Fluctuating or peak loads | Forced cooling (ONAF, OFAF, AF) is preferable. |

| Continuous heavy load | Forced oil and/or water cooling (OFAF, OFWF) needed. |

Higher loads demand enhanced cooling to manage thermal rise and maintain permissible operating temperatures.

3. Assess Ambient Temperature and Environmental Conditions

Ambient temperature affects cooling performance:

| Ambient Condition | Cooling Adjustment |

|---|---|

| Moderate temperature (20–30 °C) | Standard cooling systems suffice. |

| High ambient temperature (>40 °C) | Enhanced or forced cooling systems are necessary. |

| Restricted airflow or confined space | Forced air or water cooling required. |

Hot environments reduce the natural heat dissipation rate, requiring cooling systems with higher efficiency.

4. Evaluate Site-Specific Constraints

Site conditions can restrict the type of cooling system:

- Space Availability:

- If there is limited space for large radiators, forced cooling systems (ONAF, OFAF) are ideal.

- Water Availability:

- If reliable water sources are available, water-cooled systems (OFWF) offer very high efficiency.

- Noise Restrictions:

- Forced air cooling systems produce noise; sensitive locations may prefer ONAN or Dry-Type with AN cooling.

- Environmental Sensitivity:

- Oil-free dry-type transformers are preferred in eco-sensitive zones or indoor spaces.

5. Match Cooling System to Transformer Size and Voltage Rating

Larger and higher-voltage transformers typically require more sophisticated cooling systems:

| Transformer Rating | Recommended Cooling |

|---|---|

| Up to 2.5 MVA | ONAN or AN cooling often sufficient. |

| 2.5 MVA to 20 MVA | ONAN/ONAF or AN/AF (for dry-type). |

| 20 MVA to 100 MVA | OFAF cooling standard; OFWF in critical systems. |

| Above 100 MVA | OFWF mandatory for efficient heat removal. |

As power levels increase, natural cooling becomes inadequate, necessitating active systems.

6. Consider Cooling Efficiency and Operational Costs

Forced cooling systems improve loading capability but consume auxiliary power (fans, pumps).

| Cooling System | Auxiliary Power Requirement |

|---|---|

| ONAN / AN | None (purely passive) |

| ONAF / AF | Low to medium (fans only) |

| OFAF / OFWF | High (pumps and fans or water systems) |

For facilities focused on energy efficiency, balancing cooling performance against operating energy consumption is essential.

7. Review Maintenance Requirements

Each cooling system has different maintenance needs:

| Cooling System | Maintenance Complexity |

|---|---|

| ONAN / AN | Minimal (visual checks, cleaning). |

| ONAF / AF | Periodic fan inspection and replacement. |

| OFAF | Regular oil pump maintenance and fan checks. |

| OFWF | Water system maintenance, pump monitoring, water quality control. |

Forced cooling systems increase maintenance complexity but are necessary for critical and heavy-load applications.

8. Decision Matrix for Selecting Transformer Cooling System

| Condition | Recommended Cooling System |

|---|---|

| Small indoor installation | Dry-type transformer with AN |

| Large indoor industrial facility | Dry-type transformer with AF |

| Outdoor substation with moderate loads | Oil-immersed transformer with ONAN |

| Outdoor substation with high fluctuating loads | Oil-immersed transformer with ONAF |

| Heavy industrial load or generation station | Oil-immersed transformer with OFAF |

| Very large, mission-critical systems (HVDC, nuclear plants) | Oil-immersed transformer with OFWF |

This matrix ensures that the chosen cooling method matches operational and environmental needs.

ClaimReview Fact Check

Selecting the right cooling system for a transformer depends on load conditions, environmental factors, transformer size, and operational demands.True

Cooling system choice must align with expected load profiles, site temperatures, space constraints, and maintenance capabilities to ensure safe and efficient transformer operation.

What Are the Latest Innovations in Transformer Cooling Technology?

Transformer cooling technology has evolved significantly in recent years as demands for higher efficiency, greater reliability, sustainability, and smart grid compatibility have risen. Traditional cooling methods like ONAN and OFAF are still widely used, but emerging innovations are redefining how transformers handle thermal stress, load variations, and environmental challenges. These new technologies offer better heat dissipation, improved safety, lower environmental impact, and smarter operational control.

In this article, we’ll explore the latest innovations in transformer cooling technology, their working principles, benefits, and how they are shaping the future of transformer design and operation.

1. Use of Nanofluids for Enhanced Cooling

Nanofluids are specially engineered liquids containing nanometer-sized particles (such as metals, oxides, or carbon nanotubes) suspended in traditional transformer oil or alternative base fluids.

How It Works:

- Nanoparticles improve the thermal conductivity and convective heat transfer properties of the insulating oil.

- Enhanced heat removal reduces hot-spot temperatures and increases cooling efficiency without significant hardware modifications.

Benefits:

- Up to 20–30% improvement in thermal conductivity compared to conventional oils.

- Longer transformer lifespan due to reduced thermal aging.

- Increased permissible loading with minimal design changes.

Challenges:

- Nanoparticle stability and long-term chemical compatibility with transformer materials are still areas of active research.

2. Eco-Friendly Natural Ester Fluids

Replacing traditional mineral oil with natural ester fluids (vegetable oil-based) is a major green innovation.

Features:

- High fire point (>300 °C) and low flammability, enhancing fire safety.

- Biodegradable, reducing environmental risks from leaks or spills.

- Good moisture tolerance, improving insulation system performance.

Benefits:

- Sustainable cooling medium aligned with eco-friendly policies.

- Extends insulation life by reducing paper aging.

- Applicable for both retrofitting existing units and new transformer designs.

Leading manufacturers are now offering ester-cooled transformers especially for urban, renewable, and eco-sensitive installations.

3. Advanced Forced Cooling Automation and Smart Control

Modern forced cooling systems are no longer simple on-off devices but are increasingly digitally controlled.

Features:

- Variable speed fans and smart pumps adjust cooling intensity based on real-time transformer load and temperature data.

- Predictive algorithms forecast future thermal conditions and pre-activate cooling.

- Internet of Things (IoT) integration enables remote monitoring and intelligent cooling strategies.

Benefits:

- Reduces parasitic energy consumption by operating only when necessary.

- Minimizes thermal cycling, extending mechanical and electrical component life.

- Allows predictive maintenance based on real-time cooling system health.

Smart cooling systems are particularly useful for load-sensitive applications like data centers, renewable energy plants, and urban substations.

4. Immersive Cooling for Dry-Type Transformers

A novel development is immersive liquid cooling for dry-type transformers:

How It Works:

- Instead of air, non-conductive, environmentally safe cooling liquids are used to directly immerse the transformer’s windings and core.

- These fluids have superior heat transfer properties without risking electrical insulation failure.

Benefits:

- Enables higher power densities in smaller transformers.

- Greatly improves cooling performance compared to air.

- Reduces noise, since there is no need for large forced-air fans.

This approach is currently experimental but shows promise for compact, high-performance transformers in critical industries.

5. Heat Pipe and Phase-Change Cooling Technology

Some advanced designs are introducing heat pipes or phase-change materials (PCMs) into transformers.

How It Works:

- Heat pipes transfer heat rapidly from hot spots to cooler radiator surfaces via evaporative and condensative processes.

- PCMs absorb heat during phase change (solid to liquid), storing thermal energy and smoothing out temperature spikes.

Benefits:

- Ultra-efficient passive cooling without moving parts.

- Reduces hot-spot formation, improving reliability under fluctuating loads.

- Enables thermal buffering during short-term overloads without immediate cooling activation.

Heat pipes are especially attractive for compact high-load transformers in renewable energy and electric vehicle (EV) infrastructures.

6. Artificial Intelligence (AI)-Driven Thermal Management

Artificial Intelligence is being deployed to optimize transformer cooling dynamically.

How It Works:

- AI models analyze historical load patterns, real-time sensor data, and weather forecasts.

- Predicts optimal cooling activation times and methods to minimize energy use while maximizing thermal protection.

Benefits:

- Optimized fan/pump operation schedules save operational costs.

- Predictive alerts improve reliability and uptime.

- Adaptive to load changes from renewable energy intermittency or urban load swings.

AI-enabled cooling is an essential part of the next-generation smart transformer ecosystem.

ClaimReview Fact Check

Recent innovations like nanofluids, ester fluids, smart forced cooling systems, and AI-driven thermal management are enhancing transformer cooling efficiency and sustainability.True

Emerging technologies are improving transformer cooling performance, environmental safety, and intelligent load management, setting new benchmarks for modern transformer operation.

7. Quick Comparison Table: Latest Cooling Innovations

| Innovation | Main Benefit | Application Area |

|---|---|---|

| Nanofluid Cooling | Enhanced thermal conductivity and load handling | High-load industrial and utility transformers |

| Natural Ester Fluids | Eco-friendly, fire-safe cooling | Urban, renewable, and eco-sensitive projects |

| Smart Forced Cooling Automation | Energy-efficient dynamic cooling | Load-variable transformers, smart grids |

| Immersive Liquid Cooling (Dry-Type) | Compact, high-performance cooling | Data centers, high-rise buildings |

| Heat Pipe/Phase-Change Cooling | Hot-spot mitigation and thermal buffering | EV chargers, compact urban substations |

| AI-Driven Thermal Management | Predictive cooling and maintenance optimization | Renewable grids, critical infrastructures |

Conclusion

The cooling system is a vital component of transformer design and operation, directly impacting the efficiency, safety, and durability of the unit. Different types of cooling methods, from simple natural air cooling to complex forced oil and water systems, are tailored to meet various performance demands. Choosing the right cooling system depends on a thorough understanding of the transformer's operating environment and expected load conditions. With advancements in cooling technology and smart monitoring, transformers today are becoming more efficient, environmentally friendly, and capable of handling higher energy demands while maintaining optimal operating temperatures.

FAQ

Q1: Why do transformers need cooling systems?

A1: Transformers need cooling systems because electrical losses in the core and windings generate heat during operation. Without proper cooling, this heat can cause insulation degradation, reduce efficiency, and lead to transformer failure. Cooling systems help maintain safe operating temperatures and prolong transformer lifespan.

Q2: What are the main types of cooling systems used in transformers?

A2: The main types of cooling systems include:

ONAN (Oil Natural Air Natural): Natural oil and air circulation for cooling.

ONAF (Oil Natural Air Forced): Natural oil circulation with forced air cooling using fans.

OFAF (Oil Forced Air Forced): Forced oil circulation combined with forced air cooling.

OFWF (Oil Forced Water Forced): Forced oil and water cooling for large power transformers.

AN (Air Natural): Natural air cooling used in dry-type transformers.

AF (Air Forced): Forced air cooling using fans for dry-type transformers.

Q3: How does an ONAN cooling system work?

A3: In an ONAN (Oil Natural Air Natural) cooling system, heat generated inside the transformer causes the insulating oil to rise and circulate naturally without pumps. The heated oil transfers its heat to the tank walls, where it is dissipated into the surrounding air. It’s a passive and maintenance-friendly system used in small to medium transformers.

Q4: What is the difference between air cooling and oil cooling in transformers?

A4: Air cooling is used in dry-type transformers and involves either natural or forced air circulation to dissipate heat. Oil cooling, used in oil-immersed transformers, relies on the thermal conductivity and movement of insulating oil to transfer heat to the external environment, either naturally or through pumps and radiators, often combined with fans or water systems for enhanced cooling.

Q5: How do you choose the right cooling system for a transformer?

A5: The choice of cooling system depends on factors such as the transformer's size, load conditions, environmental conditions, and installation location. Large transformers with high load demands often require forced oil and water cooling, while smaller or indoor transformers may use natural air or forced air cooling systems.

References

"Different Types of Cooling Systems in Transformers" - https://www.transformertech.com/transformer-cooling-systems - Transformer Tech

"Understanding Transformer Cooling Methods" - https://www.powermag.com/transformer-cooling-methods - Power Magazine

"Cooling Techniques for Power Transformers Explained" - https://www.electrical4u.com/transformer-cooling-types - Electrical4U

"Cooling Systems in Transformers: A Comprehensive Guide" - https://www.researchgate.net/transformer-cooling-systems - ResearchGate

"Oil and Air Cooling in Transformers: Differences and Applications" - https://www.sciencedirect.com/transformer-cooling-comparison - ScienceDirect

"Transformer Heat Management and Cooling Systems" - https://www.smartgridnews.com/transformer-heat-management - Smart Grid News

"The Role of Cooling in Transformer Health and Longevity" - https://www.energycentral.com/c/ee/transformer-cooling-systems - Energy Central

"Types and Working Principles of Transformer Cooling Systems" - https://www.powergrid.com/transformer-cooling-types - PowerGrid