Transformers are essential components in nearly all areas where electricity is generated, transmitted, distributed, or consumed. Their main function—adjusting voltage levels—enables the safe and efficient use of electric power. By understanding their common applications, we can better appreciate the critical role transformers play in modern infrastructure and daily life.

How Are Transformers Used in Power Plants and Transmission Networks?

Electricity generation and delivery is a complex, multi-stage process that involves massive voltage changes across different grid levels. In this system, transformers are essential components, enabling efficient long-distance transmission and seamless voltage coordination between generation, transmission, and distribution networks. Without transformers, the grid would suffer from massive power losses, voltage instability, and incompatible voltage levels across regions. This article explains how transformers are used in power plants and transmission networks, highlighting their roles, types, and impact on grid efficiency and reliability.

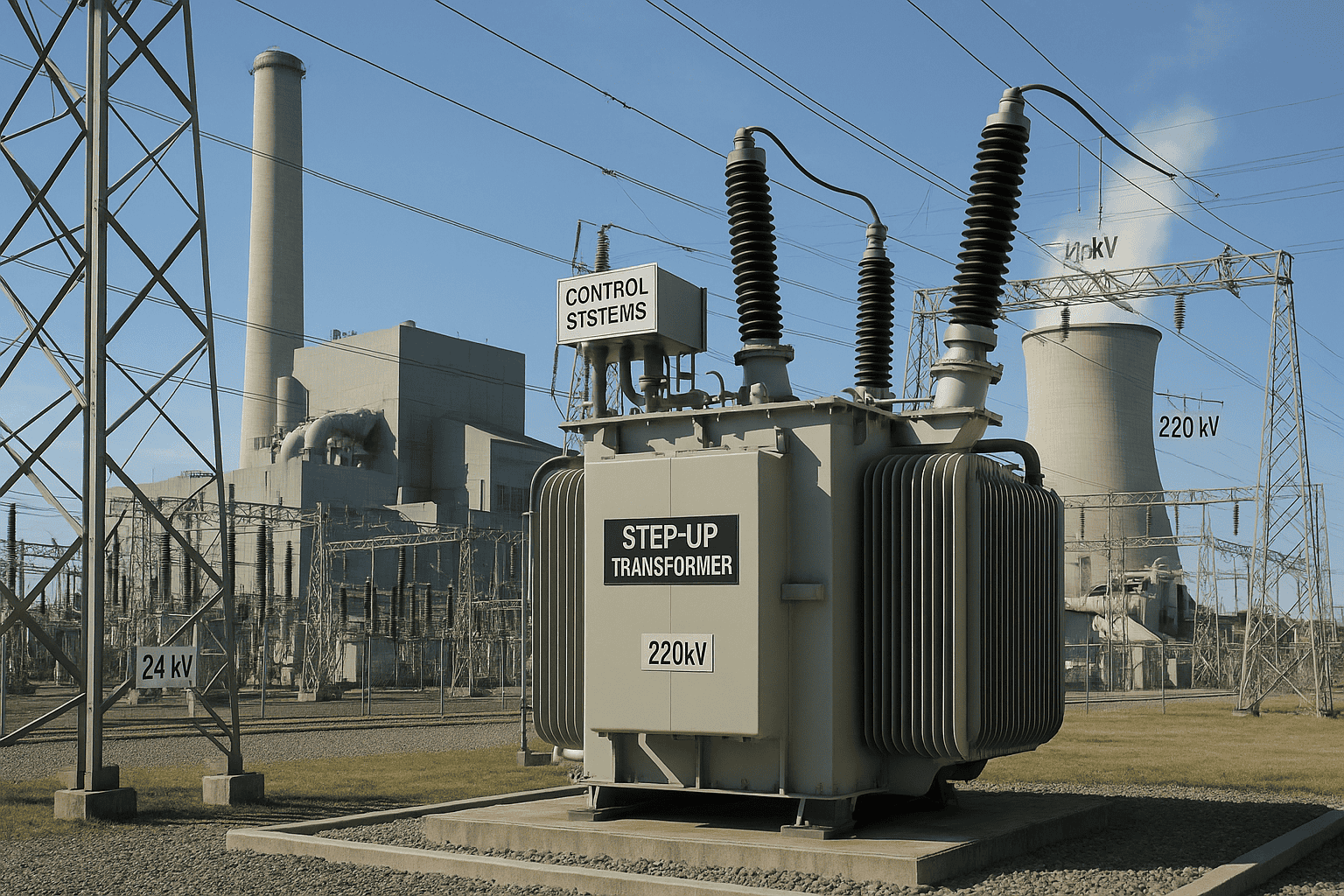

Transformers are used in power plants to step up the voltage from generator output levels (typically 11–25kV) to high-voltage transmission levels (132–765kV), enabling long-distance energy transport with minimal losses. In transmission networks, transformers interconnect grids of different voltage levels, balance power flow between regions, and step down voltage for sub-transmission and distribution.

These transformer systems are strategically placed to ensure energy is transmitted efficiently, safely, and with full system coordination.

Transformers step up voltage at power plants and step down voltage in transmission networks to ensure efficient energy delivery.True

Voltage must be increased for long-distance transmission to reduce losses, and then decreased for safe use by consumers.

Transmission networks operate without transformers since energy flows directly from generation to end-users.False

Transformers are critical for adapting voltage levels, managing grid interconnection, and enabling safe, loss-reduced power delivery.

1. Generator Step-Up Transformers (GSUs) at Power Plants

| Location | Between generator terminal and power station switchyard |

|---|---|

| Function | Steps up generator voltage (11–25kV) to transmission level (132–765kV) |

| Transformer Type | Three-phase oil-immersed transformer, typically with on-load tap changer (OLTC) |

| Output Voltage Levels | 132kV, 220kV, 400kV, or 765kV depending on grid tier |

GSUs allow bulk power from turbines to enter the transmission grid efficiently, reducing I²R losses by minimizing current flow.

2. Interconnecting Transformers in Transmission Networks

| Location | At major substations connecting different voltage levels |

|---|---|

| Function | Enables grid segments (e.g. 400kV ↔ 220kV ↔ 132kV) to exchange power |

| Transformer Type | Two-winding or autotransformer (common for high MVA capacity) |

| Role | Grid balancing, load sharing, reactive power support |

These transformers provide voltage coordination, region-to-region power transfer, and fault isolation between network zones.

3. Reactive Power Management and Voltage Control

| Special Transformer Use | Purpose |

|---|---|

| Shunt Reactors | Absorb reactive power and control overvoltage |

| Phase-Shifting Transformers | Manage power flow direction and magnitude |

| Booster Transformers | Correct voltage drops along long transmission lines |

These are vital for grid stability, especially in high-load corridors and inter-country connections.

4. Step-Down Transformers for Sub-Transmission Entry

| Installed At | Receiving substations or regional load centers |

|---|---|

| Function | Converts 220/132kV transmission voltage to 66/33/11kV levels |

| Transformer Type | Oil-immersed or gas-insulated power transformers |

| Application | Supplies voltage suitable for large commercial and utility feeders |

These transformers ensure grid power is adapted for local distribution and industrial use.

Summary Table: Transformer Use Across Power Infrastructure

| Stage | Voltage Conversion | Transformer Type | Primary Function |

|---|---|---|---|

| Power Plant | 11–25kV → 132–765kV | Generator Step-Up Transformer | Feed power into transmission system |

| Grid Interconnection | 132kV ↔ 220kV ↔ 400kV | Auto or Two-Winding Transformer | Inter-region power exchange and balancing |

| Transmission Corridor | Maintain 400kV | Phase-Shifting, Shunt or Booster | Manage flow and stability |

| Sub-Transmission Entry | 400/220/132kV → 66/33/11kV | Step-Down Transformer | Prepares power for regional distribution |

| Local Distribution | 11kV → 400/230V | Pole-Mounted Transformer | Delivers usable power to homes and businesses |

Key Design Features of Power Plant and Transmission Transformers

| Feature | Purpose |

|---|---|

| OLTC (On-Load Tap Changer) | Maintain voltage stability under load variation |

| High-Grade Insulation System | Withstand high temperatures and electromagnetic stress |

| Cooling System (ONAN/ONAF) | Control oil and winding temperature under load |

| Buchholz Relay | Detect internal faults in oil-immersed transformers |

| Gas Monitoring and Sensors | Enable predictive maintenance in smart grid environments |

These features ensure high reliability, essential for 24/7 power plant and transmission operation.

Case Study: Hydro Power Plant Transmission Integration

| System Segment | Voltage Level | Transformer Role |

|---|---|---|

| Generator Terminal | 13.8kV | GSU steps up to 220kV |

| Switchyard Output | 220kV | Transmitted to regional substation over 40km |

| Receiving Substation | 220kV → 33kV | Step-down transformer for local grid entry |

| Local Distribution | 33kV → 400V/230V | Final step-down for city and rural consumers |

This structure is standard in many hydro, thermal, and gas-fired generation systems globally.

What Is the Role of Transformers in Residential Power Supply?

Electricity from the national grid cannot be supplied directly to households due to dangerously high voltages and system incompatibility. If 11kV or 33kV power lines were connected directly to homes, it would cause appliance damage, fire hazards, and electrical shock risks. To bridge the gap between transmission voltages and safe, usable levels, transformers are deployed at the final step of power distribution. These units are compact, reliable, and designed to safely convert medium-voltage electricity to the 230V supply used in residences. This article explains the key role of transformers in residential power supply systems.

Transformers in residential power supply systems step down medium-voltage electricity (typically 11kV or 33kV) from distribution lines to low-voltage levels (230V or 400V), enabling safe and stable electricity delivery to homes. They also regulate voltage, isolate circuits for safety, and protect against overloads and faults, ensuring reliable energy use for lighting, appliances, and electronics.

Without these transformers, electrical systems in residential areas would be unstable, hazardous, and incompatible with everyday electrical devices.

Residential transformers step down medium-voltage electricity from distribution networks to 230V for household use.True

This voltage reduction ensures electrical safety and compatibility with domestic appliances and wiring standards.

Homes can be powered directly from 11kV or 33kV lines without transformers.False

Direct high-voltage connections are unsafe and would destroy household electronics and create severe fire risks.

How Electricity Reaches Your Home – The Role of the Residential Transformer

| Step | Voltage Level | Component Involved |

|---|---|---|

| Substation Output | 33kV or 11kV | Primary distribution feeder |

| Local Transformer (Pole/Pad) | 11kV → 400V/230V | Step-down transformer (oil-immersed or dry) |

| Service Line to Home | 230V single-phase | Underground or overhead service drop |

| Household Load | 230V or 400V (3-phase) | Domestic wiring and circuit breakers |

This flow ensures safe and reliable electricity for residential neighborhoods.

Common Types of Residential Transformers

| Type | Installation Location | Typical Power Range | Advantages |

|---|---|---|---|

| Pole-Mounted | On utility poles (rural, suburban) | 10–100 kVA | Easy to install, accessible, low-cost |

| Pad-Mounted | On sidewalks (urban areas) | 100–315 kVA | Tamper-proof, compact, quiet |

| Vault/Underground | Inside buildings or utility vaults | 25–250 kVA | Aesthetically integrated, space-saving |

These transformers are designed to be weather-resistant, oil-cooled or air-cooled, and equipped with basic protection features like fuses and lightning arresters.

Key Functions in Residential Power Supply

1. Voltage Step-Down

- Converts dangerous 11,000 or 33,000 volts to 230V single-phase or 400V three-phase

- Compatible with household loads: TVs, fridges, washing machines, lighting, etc.

2. Circuit Isolation

- Prevents grid disturbances (e.g., surges or harmonics) from reaching homes

- Protects domestic wiring and appliances

3. Voltage Stability

- Maintains regulated voltage output under varying load conditions

- Prevents under-voltage (brownouts) and over-voltage that damage devices

4. Safety and Fault Protection

- Includes grounding, lightning protection, and surge arresters

- Prevents faults from traveling up the line to affect broader network

Technical Specifications Example

| Parameter | Typical Value for Residential Transformer |

|---|---|

| Rated Capacity | 25kVA, 50kVA, 100kVA, 200kVA |

| Primary Voltage | 11kV or 33kV |

| Secondary Voltage | 400V (3-phase) / 230V (single-phase) |

| Frequency | 50Hz / 60Hz |

| Cooling Type | ONAN (Oil Natural Air Natural) or Dry-Type |

| Impedance | 4% to 6% |

| Efficiency | ≥ 98% at full load |

These units are often factory-tested per IEC 60076 or ANSI C57 standards.

Maintenance and Lifespan Considerations

| Activity | Frequency | Purpose |

|---|---|---|

| Oil Level and Condition Check | Annually | Prevent insulation breakdown |

| Insulation Resistance Test | Every 2–5 years | Verify winding integrity |

| Visual Inspection | Quarterly | Look for leaks, corrosion, or damage |

| Thermographic Survey | As needed | Identify hot spots or overload risks |

With proper maintenance, residential transformers typically last 25–35 years.

Summary Table: Role of Residential Transformers

| Function | Benefit to End Users |

|---|---|

| Voltage step-down | Safe and usable power for all household appliances |

| Isolation and safety | Protection from external faults and electrical noise |

| Load handling | Balances supply for multiple homes or apartment blocks |

| System reliability | Ensures continuous, disturbance-free operation |

Residential transformers are strategic assets in every distribution network, ensuring your lights stay on and your appliances stay protected.

Why Are Transformers Important in Industrial Manufacturing?

Industrial manufacturing plants consume large quantities of electrical energy to power machinery, automation systems, lighting, HVAC, and process equipment. However, the electricity supplied by utilities is typically at high or medium voltages, which cannot be directly used by most industrial devices. If the voltage is too high, it risks damaging equipment or causing operational hazards. This is why transformers are indispensable in every manufacturing facility—they adapt incoming power to the exact voltage, phase, and capacity needed for efficient, safe, and continuous operation. In this article, we explore why transformers are so important in industrial manufacturing.

Transformers are important in industrial manufacturing because they convert high-voltage supply power into usable voltage levels (such as 400V or 230V), enable stable operation of heavy machinery, isolate sensitive control systems from electrical noise, and ensure safety and energy efficiency throughout production processes. They are essential for powering motors, drives, lighting, automation systems, and critical production lines.

Without properly selected and installed transformers, modern industrial facilities would suffer from equipment failures, inefficiencies, and unsafe working conditions.

Transformers are critical in industrial manufacturing because they convert high-voltage utility power into usable levels for machinery and equipment.True

Industrial systems require stable and specific voltage levels that transformers provide, ensuring safe and efficient operation.

Transformers are only necessary in residential and commercial applications, not in industrial manufacturing.False

Industrial manufacturing depends on customized transformer systems to handle high loads, varied voltages, and sensitive control systems.

Key Roles of Transformers in Manufacturing Facilities

| Transformer Function | Manufacturing Benefit |

|---|---|

| Voltage Step-Down | Converts 33kV or 11kV utility input to 400V or 230V for plant operations |

| Equipment Compatibility | Supplies exact voltage levels needed by motors, drives, and automation |

| Circuit Isolation | Prevents faults and harmonics from affecting sensitive electronics |

| Load Distribution | Balances electrical loads across departments or production zones |

| Safety Assurance | Provides earthing and protects against overvoltage and surges |

Transformers are typically deployed at the facility’s incoming power room, feeding main switchboards, motor control centers (MCCs), and subpanels.

Typical Voltage Flow in Industrial Manufacturing

| Power Stage | Voltage Level | Transformer Used |

|---|---|---|

| Utility Feeder | 11kV or 33kV | Oil-immersed step-down transformer |

| Main Distribution Panel | 400V or 415V | Dry-type transformer (indoor use) |

| Control & Instrument Panels | 230V / 110V / 24V | Isolation transformer or control transformer |

| Large Motors / Drives | 400V or 690V | K-rated transformer or custom design |

A medium-sized plant may use multiple transformers to segment loads for production lines, utilities, and sensitive electronics.

Types of Transformers Used in Manufacturing

| Transformer Type | Application | Advantages |

|---|---|---|

| Oil-Immersed Transformer | Outdoor or high-capacity areas | High efficiency, excellent cooling for continuous duty |

| Dry-Type Transformer | Indoor, low-maintenance applications | Fire-resistant, suitable for clean environments |

| Isolation Transformer | CNC machines, PLC systems, test benches | Eliminates ground loops, protects against surges |

| Auto-Transformer | Motor starting, HVAC units | Compact, economical for voltage regulation |

| K-Rated Transformer | Harmonic-rich environments (VFDs, IT loads) | Handles non-linear currents without overheating |

Each transformer must be selected based on load profile, environment, harmonics, and safety classification.

Transformer Use Case: CNC Machining Facility

| System Component | Transformer Role |

|---|---|

| Main Utility Input (11kV) | Step-down to 400V for machinery |

| Machine Control Panels | Isolated 230V or 110V for logic circuits |

| Servo Drive Cabinets | Stabilized voltage using K-rated dry-type transformers |

| Emergency Power Feed | Generator to plant via bypass transformer |

Transformers enable consistent spindle control, axis movement accuracy, and EMI-free operation.

Energy Efficiency and Power Quality

Transformers also contribute to power factor correction and energy conservation:

| Efficiency Feature | Impact |

|---|---|

| High-grade core laminations | Reduces no-load losses |

| Low-leakage impedance | Improves voltage stability under variable loads |

| OLTC (on-load tap changer) | Adjusts voltage in real time to match equipment needs |

| Harmonic filtering | Minimizes distortion from variable frequency drives (VFDs) |

Efficient transformers can lower electricity bills and extend equipment life by reducing wear from voltage fluctuations.

Safety and Compliance in Industrial Environments

| Standard / Requirement | Transformer Role |

|---|---|

| IEC 60076 / ANSI C57.12 | Ensures voltage regulation and insulation durability |

| IEEE 519 (harmonics) | Requires transformers that tolerate harmonic distortion |

| NFPA 70E / OSHA | Mandates fault isolation and grounding systems |

Transformers in industrial environments are also designed with fire protection, thermal sensors, and protective relays to comply with safety regulations.

How Do Transformers Support Commercial Buildings and Urban Infrastructure?

Cities and commercial districts rely on complex and continuous electricity supply to power lighting, elevators, HVAC, office systems, public transit, and communication networks. However, the high voltage supplied by utilities is not directly usable for buildings or public systems. Transformers bridge this voltage gap, enabling reliable and efficient energy distribution across skyscrapers, malls, transit systems, and city blocks. In this article, we explore how transformers support commercial buildings and urban infrastructure and why they are vital for modern urban living.

Transformers support commercial and urban infrastructure by stepping down medium-voltage electricity (typically 11kV or 33kV) to low-voltage levels (400V/230V), suitable for lighting, HVAC, elevators, office equipment, and smart city systems. They ensure stable voltage, enable building-scale power distribution, provide electrical isolation, and integrate with smart metering and automation platforms.

Without transformers, cities would be unable to run safely or efficiently, and commercial properties would experience voltage instability and energy loss.

Transformers in commercial buildings step down high-voltage supply to levels suitable for safe and reliable power use.True

These transformers convert medium-voltage input to usable 400V/230V output for lighting, HVAC, and building systems.

Urban infrastructure can operate without transformers since city grids already supply usable voltage directly.False

Utility grids distribute power at high voltages, requiring on-site transformers to step down electricity before it enters buildings and infrastructure systems.

Where Transformers Are Used in Commercial and Urban Settings

| Application Area | Transformer Role | Voltage Conversion |

|---|---|---|

| Office Towers & Hotels | Supplies building systems and tenant loads | 11kV → 400V |

| Shopping Malls | Feeds escalators, HVAC, lighting, shops, and signage | 33kV → 400/230V |

| Urban Street Lighting | Powers public lighting circuits | 11kV → 230V |

| Underground Transit (Metro) | Traction and station power distribution | 33kV → 750V DC (via rectifiers) |

| Public Infrastructure (Parks, Schools, Hospitals) | Powers lighting, equipment, and campus facilities | 11kV → 400V/230V |

Transformers are typically installed in basement substations, utility rooms, pad-mounted units, or underground vaults in urban zones.

Common Types of Transformers in Urban Environments

| Transformer Type | Use Case | Key Characteristics |

|---|---|---|

| Dry-Type Transformer | Office buildings, commercial malls | Fire-safe, low-maintenance, compact for indoor spaces |

| Pad-Mounted Transformer | Outdoor plazas, schools, shopping areas | Tamper-resistant, sealed, weatherproof |

| Oil-Immersed Transformer | Larger public buildings or infrastructure | High capacity, efficient, suitable for heavy loads |

| Isolation Transformer | Hospitals, data centers, telecoms | Prevents ground loops and protects sensitive equipment |

Each transformer is selected based on load size, location constraints, fire risk, and maintenance preferences.

Functional Benefits to Commercial and Urban Infrastructure

1. Voltage Adaptation

- Converts medium-voltage utility feed to 400V three-phase or 230V single-phase

- Enables safe, standardized voltage for lights, computers, elevators, and more

2. Load Segmentation and Management

- Allows zonal distribution (e.g., floor-by-floor, tenant-by-tenant)

- Integrates with building energy management systems (BEMS)

3. Electrical Isolation and Protection

- Prevents grid surges from affecting building electronics

- Provides galvanic isolation and balanced load feeding

4. Efficiency and Energy Saving

- Low-loss designs (≤2% losses)

- Supports smart monitoring for real-time load optimization

Sample Layout: Transformer in a Commercial High-Rise

| Component | Purpose | Voltage Level |

|---|---|---|

| Utility Feeder | Incoming medium voltage | 11kV or 33kV |

| Main Step-Down Transformer | Central transformer in basement | 11kV → 400V |

| Floor Distribution Panels | Floor-wise segmentation of power | 400V |

| Tenant Load Centers | Local circuit boards for lighting, sockets | 230V |

| UPS & Generator Interfaces | Backup systems linked via bypass transformers | 400V |

This system ensures that each building system—elevators, HVAC, security—is powered safely and separately.

Compliance and Safety Features

| Feature | Importance |

|---|---|

| Fire-Retardant Design | Mandatory for indoor transformers in commercial buildings |

| Temperature Sensors & Fans | Prevent overheating and optimize load response |

| Arc Fault and Surge Protection | Safeguard against lightning and short circuits |

| Smart Meter Integration | Enables load monitoring, demand prediction, and energy audits |

Urban transformers must meet IEC 60076, ISO 9001, and local fire/electrical codes for safety and reliability.

Contribution to Smart City Infrastructure

| Smart System | Transformer Role |

|---|---|

| Smart Lighting | Provides stable voltage to control nodes and LED fixtures |

| EV Charging Infrastructure | Steps down power to 400V or 230V stations with surge control |

| Communication Hubs | Isolated power for routers, base stations, and IT systems |

| District Energy Systems | Powers chillers, pumps, and distribution valves |

Modern transformers are now IoT-integrated, allowing remote monitoring, performance diagnostics, and maintenance alerts.

Where Are Transformers Used in Renewable Energy Systems Like Solar and Wind?

Solar panels and wind turbines generate electricity from natural resources, but their raw output cannot be directly used by the grid or end-users. These systems produce power at low voltages, often in variable conditions. To connect this power efficiently and safely to medium-voltage or high-voltage transmission networks, transformers are deployed at several stages of a renewable energy system. Their placement is critical for both energy efficiency and grid compatibility. This article explores where transformers are used in renewable energy systems like solar and wind, and why their roles are essential for clean energy deployment.

Transformers are used in renewable energy systems at the inverter or generator output (to step up low voltage), at collector substations (to aggregate and raise medium voltage to grid levels), and at grid interconnection points. In solar farms, transformers step up inverter AC output, while in wind farms, they step up turbine AC output. These transformers enable efficient, compliant, and reliable energy export to the utility grid.

They ensure power is transmitted at the right voltage level, minimizing losses and stabilizing flow from intermittent sources.

Transformers in solar and wind energy systems step up low voltage generation to medium and high voltages for grid integration.True

Solar panels and wind turbines generate power at low voltages (400–690V), requiring transformers to step it up to 11kV–33kV and eventually 132kV+ for grid use.

Solar and wind farms can connect directly to the power grid without using transformers.False

Grid voltage requirements cannot be met directly by generation output, making transformers essential for compliance and system safety.

Key Locations of Transformers in Solar and Wind Energy Systems

| System Location | Transformer Type | Voltage Conversion | Function |

|---|---|---|---|

| At Inverter Output (Solar) | Pad-mounted step-up transformer | 400V → 11kV or 33kV | Converts inverter AC output to medium voltage |

| At Turbine Base (Wind) | Generator step-up transformer | 690V → 11kV or 33kV | Converts turbine-generated AC to collection voltage |

| Collector Substation | Power transformer | 33kV → 132kV or 220kV | Aggregates power from multiple feeders |

| Grid Interconnection Point | Grid-tie transformer | 132/220kV → grid busbar | Ensures grid-compliant voltage and phase connection |

| Battery Integration (Optional) | BESS transformer | Variable ↔ 11kV or 33kV | Balances and connects energy storage systems |

Transformers are the voltage interface at each critical energy transition point in the renewable chain.

Transformer Applications in Solar Power Systems

| Component | Voltage Output/Input | Transformer Role |

|---|---|---|

| Solar PV Panels | DC | Inverters convert to 400V–690V AC |

| Inverter Output Transformer | 400V–690V → 11kV/33kV | Stepping up to feeder line voltage |

| Feeder Lines | 11kV–33kV | Transfer power to substation |

| Collector Substation | 33kV → 132kV or 220kV | Step up for transmission-level export |

Solar transformers must tolerate frequent load cycling, high ambient temperatures, and harmonics from inverters.

Transformer Applications in Wind Energy Systems

| Component | Voltage Output/Input | Transformer Role |

|---|---|---|

| Wind Turbine Generator | 690V (AC) | Local transformer steps up to 11kV or 33kV |

| Base/Pad Transformer | 690V → 33kV | Often integrated into nacelle or near turbine base |

| Feeder Collector Lines | 33kV | Connect multiple turbines to central substation |

| Wind Farm Substation | 33kV → 132kV / 220kV | Main step-up for regional transmission line connection |

Offshore and remote wind farms use sealed, compact transformers for reliability in harsh conditions.

Renewable Collector Substation Design

| Function | Transformer Type | Typical Capacity | Output Voltage |

|---|---|---|---|

| Aggregates multiple feeders | Power transformer | 10–200 MVA | 132kV, 220kV, or 400kV |

| Enables grid interconnection | High-voltage step-up | Grid code-compliant | Matches regional transmission level |

| Supports SCADA and protection | Smart transformer design | Remote monitoring capable | Integrated with IEDs |

These substations are the final voltage interface before utility grid integration.

Smart Grid and Renewable Transformer Features

| Feature | Purpose |

|---|---|

| OLTC (On-load tap changer) | Maintains voltage during output fluctuations |

| High Efficiency Cores | Reduces losses during peak solar or wind generation |

| Smart Sensors & SCADA | Enables monitoring, fault detection, and remote control |

| Low Impedance Design | Supports rapid response to generation changes |

These transformers are built to handle non-linear loads and fluctuating input from intermittent renewable sources.

What Critical Applications Rely on Transformers, Such as Hospitals and Data Centers?

In critical environments like hospitals and data centers, electrical continuity, stability, and safety are non-negotiable. A split-second voltage drop or surge can result in life-threatening medical equipment failure or catastrophic data loss. Transformers in these settings are not just used for voltage conversion—they serve as strategic power quality, isolation, and redundancy devices. They allow these essential services to function without interruption, even under grid instability or power failure conditions. This article explores which critical applications depend on transformers, with a focus on hospitals, data centers, and other mission-critical infrastructures.

Critical applications like hospitals, data centers, airports, and command centers rely on transformers to ensure continuous power delivery, voltage regulation, electrical isolation, and compatibility with emergency and backup systems. Transformers in these settings manage safe voltage levels for sensitive equipment, work alongside UPS and generators, and provide redundancy to maintain power even during faults or maintenance.

These transformers are custom-engineered to meet rigorous standards for performance, safety, and failover reliability.

Transformers are essential in hospitals and data centers to provide safe, stable, and isolated power for critical systems.True

They regulate voltage, prevent electrical noise, and integrate with UPS and backup systems to guarantee uninterrupted operation.

Transformers are not necessary in facilities with uninterrupted power supply (UPS) systems.False

UPS systems work in conjunction with transformers, not independently—they rely on transformers for voltage conversion, isolation, and load compatibility.

Critical Applications That Rely on Transformers

| Facility Type | Transformer Function | Typical Power Ratings |

|---|---|---|

| Hospitals | Isolation, voltage step-down, and continuity for life-support equipment | 100kVA – 2,500kVA |

| Data Centers | Power conditioning, harmonics handling, and UPS integration | 500kVA – 5,000kVA+ |

| Airports | Lighting systems, radar, air control tower systems | 250kVA – 3,000kVA |

| Emergency Services HQ | Critical communication and dispatch infrastructure | 100kVA – 1,000kVA |

| Defense and Security Systems | Redundant power for surveillance, server farms, and secure comms | 500kVA – 4,000kVA |

| Telecom Base Stations | Clean isolated power for equipment racks and battery backup | 50kVA – 500kVA |

These facilities use custom transformer designs, including isolation, shielding, fire-rated dry types, and low-impedance windings for ultra-reliable power.

Hospital Power Architecture with Transformers

| Zone | Transformer Use | Voltage Conversion |

|---|---|---|

| Main Grid Feed | Step-down transformer for general hospital systems | 11kV or 33kV → 400V |

| Operating Theaters | Isolation transformers to prevent shock hazards | 400V → 230V (isolated) |

| ICU & Medical Imaging | Shielded transformers to prevent EMI interference | 400V → 230V |

| Emergency Generator Interface | Matching transformer for standby system input | 400V / 480V → 400V |

| UPS and Monitoring Systems | K-rated isolation transformers for clean, harmonic-free power | 400V ↔ 400V |

According to IEC 60364-7-710, all medical locations must be powered through isolated transformers to ensure patient safety.

Data Center Power System with Transformers

| Power Flow Stage | Transformer Role | Typical Transformer Type |

|---|---|---|

| Utility Service Entry | Step-down for facility input | Oil-immersed or dry-type |

| UPS Integration | Voltage conditioning and bypass load path | K-rated or isolation transformer |

| Server Rack Panels | Voltage matching and surge protection | Low-noise, shielded dry-type |

| Backup Generator Interface | Ensures match and transition during switchover | Matching transformer |

| Cooling Systems | Dedicated transformers for HVAC and chillers | Dry-type or pad-mounted units |

Tier III and Tier IV data centers require N+1 or 2N redundancy, meaning multiple transformers feed identical systems for uninterrupted uptime.

Special Features in Critical Transformers

| Feature | Purpose |

|---|---|

| K-Rating (K4–K20) | Supports non-linear harmonic-rich IT and UPS loads |

| Electrostatic Shielding | Prevents high-frequency noise and EMI transfer |

| Low Impedance Design | Maintains voltage regulation under fluctuating loads |

| BMS / SCADA Integration | Enables real-time monitoring of transformer temperature, load, oil, etc. |

| Fire-Resistant Insulation | Critical for indoor and public-access transformer areas |

In hospitals, low-voltage isolation transformers also support high reliability in nurse call systems, MRI suites, and sterilization zones.

Compliance and Standards for Critical Applications

| Standard | Applies To | Requirement |

|---|---|---|

| IEC 60364-7-710 | Medical Electrical Systems | Isolated power, leakage monitoring |

| TIA-942 / Uptime Tier Certs | Data Center Design | Redundant transformer systems with predictable uptime |

| NEC Article 517 | Health Care Facilities (USA) | Isolation transformers required for life safety |

| ISO 13485 | Medical Device Safety | Stable voltage with no transient interference |

| IEEE 1100 (Emerald Book) | Sensitive Electronics Facilities | K-rated and shielded transformers for critical IT applications |

Conclusion

Transformers are commonly used across the power grid, from high-voltage transmission lines to low-voltage applications in homes and devices. They are the silent enablers behind reliable electricity, whether it's powering a factory, charging your phone, or running a life-saving machine in a hospital. As energy systems evolve, transformers will continue to be a cornerstone of electrical innovation and safety.

FAQ

Q1: What are transformers commonly used in?

A1: Transformers are commonly used in systems that require voltage conversion, energy distribution, or electrical isolation. Major applications include:

Power grids (generation, transmission, distribution)

Industrial plants

Commercial and residential buildings

Electronic devices

Renewable energy systems

Railways and public infrastructure

Q2: How are transformers used in the power sector?

A2: In the power sector, transformers are used to:

Step up voltage at generation stations for transmission

Step down voltage at substations for distribution

Manage voltage levels across long-distance power lines

Enable grid interconnections and stability

Q3: What role do transformers play in industries?

A3: In industrial applications, transformers:

Power heavy machinery

Distribute power within plants

Provide custom voltage levels

Support automation and control systems

Enhance electrical safety through isolation

Q4: How are transformers used in homes and businesses?

A4: Common household and commercial uses include:

Utility distribution transformers to deliver 120/240V

Doorbell and thermostat transformers

Chargers and adapters for phones and laptops

Power supplies in TVs, routers, and other electronics

Q5: Are transformers used in modern technology and renewable energy?

A5: Yes, transformers are key in:

Solar and wind energy systems to match grid voltage

Electric vehicle charging stations

Smart grids with real-time voltage regulation

Medical and telecom equipment requiring precise, stable power

References

"Common Transformer Applications Explained" – https://www.transformertech.com/common-transformer-uses

"Where Are Transformers Commonly Used?" – https://www.electrical4u.com/common-uses-of-transformers

"Understanding Transformer Applications in Daily Life" – https://www.powermag.com/transformer-usage-guide

"Industry-Wide Applications of Electrical Transformers" – https://www.energycentral.com/c/ee/transformers-in-industry

"Smart Grid and Renewable Transformer Use Cases" – https://www.smartgridnews.com/transformer-application-overview

"ResearchGate: Global Transformer Deployment Study" – https://www.researchgate.net/transformer-applications

"PowerGrid: Real-World Transformer Integration" – https://www.powergrid.com/transformer-use-cases

"ScienceDirect: Transformer Role in Power and Tech Systems" – https://www.sciencedirect.com/common-transformer-applications