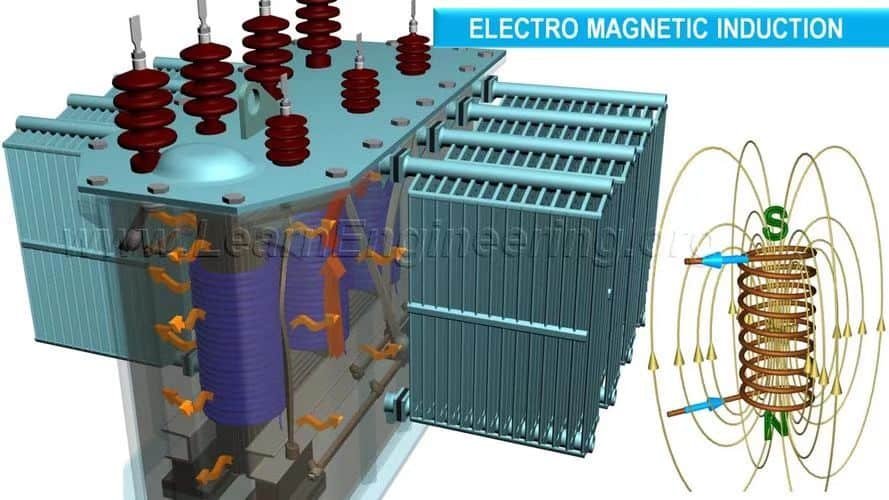

Power transformers are critical components in modern power systems, enabling efficient voltage conversion for generation, transmission, and distribution. Understanding their functionality, classification, and application is essential for engineers, utility operators, and decision-makers in the energy sector. This guide provides key insights into how power transformers work, their design flexibility, failure modes, and selection criteria to support safe and efficient electrical infrastructure planning.

What Are the Available Voltage and Power Capacity Ranges for Power Transformers?

Electric power systems rely heavily on the selection of correctly rated transformers. Choosing the appropriate voltage and power capacity range is essential for maintaining efficiency, safety, and compatibility in the grid or facility. Failure to do so can result in voltage drops, overheating, or even catastrophic system failure. From small distribution networks to high-voltage transmission lines, every application demands a transformer that fits specific operational limits. This article addresses the full spectrum of available transformer voltage and power ratings, their technical implications, and how they apply across different industries.

Power transformers are available in a wide range of voltage ratings, typically from 11 kV up to 765 kV, and power capacities from 500 kVA to over 1,000 MVA. These ranges determine where a transformer fits in the power grid—from substation step-up transformers to large-scale grid interconnectors. Selection depends on application, load demand, transmission distance, and national grid codes.

Understanding these ranges helps electrical planners and engineers design resilient and efficient systems. Whether for utility-scale transmission or large industrial plants, voltage and capacity ratings determine the transformer's insulation needs, physical size, load endurance, and cost. Let’s explore these ratings in-depth.

Power transformers are limited to a maximum of 33kV.False

Power transformers are designed for high and extra-high voltage applications, typically starting above 33kV and going up to 765kV or more in some national grids.

🔌 Voltage Rating Categories for Power Transformers

Voltage rating determines how much electric potential the transformer can handle safely and efficiently. This influences insulation, BIL (Basic Insulation Level), and arc clearance.

Voltage Classification Table

| Voltage Class | Voltage Range (Typical) | Application |

|---|---|---|

| Medium Voltage (MV) | 1 kV – 35 kV | Distribution, industrial service |

| High Voltage (HV) | 35 kV – 220 kV | Substations, regional transmission |

| Extra High Voltage (EHV) | 220 kV – 400 kV | Inter-regional transmission |

| Ultra High Voltage (UHV) | >400 kV (e.g., 500kV–765kV) | Cross-country transmission and bulk power |

Voltage Rating Examples

| Transformer Type | Primary Voltage | Secondary Voltage | Use Case |

|---|---|---|---|

| Industrial Substation | 132 kV | 11 kV | Steel plants, manufacturing |

| Grid Step-Up Transformer | 22 kV | 400 kV | Power plant to grid connection |

| Regional Step-Down | 220 kV | 33 kV | Regional distribution interface |

| Distribution Transformer | 33 kV | 415 V | City or suburban areas |

⚡ Power Capacity Ranges (kVA / MVA)

Power capacity, rated in kVA (kilovolt-amperes) or MVA (megavolt-amperes), defines how much load a transformer can carry continuously without overheating.

Typical Power Rating Spectrum

| Category | Power Capacity | Typical Use Case |

|---|---|---|

| Distribution Transformer | 50 kVA – 2.5 MVA | Local power delivery (residential, schools) |

| Small Power Transformer | 2.5 MVA – 25 MVA | Medium industry, small substations |

| Medium Power Transformer | 25 MVA – 100 MVA | Substations, hospitals, data centers |

| Large Power Transformer | 100 MVA – 400 MVA | Regional transmission |

| Extra Large (GSU/Grid) | 400 MVA – 1,200+ MVA | Power plants, interconnection transformers |

Design Note:

Larger MVA units require more robust cooling (OFAF, OFWF), complex insulation schemes, and more advanced protection devices.

📊 Comprehensive Rating Chart

Power Capacity vs Voltage Classification

| Voltage Class | kVA/MVA Rating Range | Application Type |

|---|---|---|

| MV (≤ 35 kV) | 50 kVA – 5 MVA | Distribution, urban supply |

| HV (66 kV – 220 kV) | 5 MVA – 250 MVA | Substations, transmission support |

| EHV (220 kV – 400 kV) | 250 MVA – 600 MVA | Grid interconnectors, regional tie-lines |

| UHV (500 kV – 765 kV+) | 500 MVA – 1,200+ MVA | Bulk transmission, national grid backbones |

Voltage/Power Design Matrix

| Rated Voltage (kV) | Possible Power Range (MVA) | Transformer Type |

|---|---|---|

| 11/0.415 | 0.05 – 2.5 | Distribution Transformer |

| 66/11 | 2.5 – 20 | Step-down Substation Transformer |

| 132/33 | 10 – 60 | Regional Distribution Transformer |

| 220/66 or 220/132 | 60 – 200 | High Voltage Power Transformer |

| 400/220 | 200 – 500 | Grid Tie Transformer |

| 765/400 | 500 – 1,200+ | Ultra-High Voltage GSU Transformer |

🔍 Technical Design Considerations by Rating

Insulation Level (BIL)

Higher voltage requires thicker insulation and longer creepage distances to prevent breakdown.Cooling Mechanism

High-capacity units need forced oil and forced air (OFAF), or even water-cooled designs (ODWF).Protection Requirements

Protection relays vary with MVA rating: higher ratings demand differential protection, Buchholz relays, and pressure relief devices.Physical Size & Weight

- A 2.5 MVA 33/11kV transformer weighs \~4 tons

- A 500 MVA 400/220kV transformer weighs >200 tons

🏗️ Real-World Application Example

Case Study: 500 MVA, 400/220 kV GSU Transformer in a Hydroelectric Plant

- Voltage Rating: 400 kV (HV side), 22 kV (generator side)

- Power Rating: 500 MVA

- Cooling: OFAF with 2-stage fans

- Weight: Approx. 250,000 kg

- Installed Location: Remote mountainous region in Southeast Asia

- Outcome: Enabled 200+ km power delivery with <2.5% losses

Can Power Transformers Be Customized for Specific Impedance, Tap Range, or Cooling Types?

When deploying a power transformer into a grid or industrial network, “off-the-shelf” specifications rarely match unique performance, safety, or regulatory demands. Choosing a standard unit without tuning key operational parameters such as impedance, tap range, or cooling method can result in load imbalances, voltage instability, or costly overheating. Fortunately, modern power transformer design allows full customization of these critical features to suit exact system requirements. This article explores how custom impedance, tap changers, and cooling methods are engineered into transformers for optimal operation.

Yes, power transformers can be fully customized to meet specific impedance, tap range, and cooling method requirements. These parameters directly affect system protection, voltage regulation, and thermal performance. Impedance is adjusted to manage fault current and load sharing; tap range tuning enables voltage flexibility; and cooling types such as ONAN, ONAF, or OFWF are selected based on ambient conditions and load profiles.

Customizing these features ensures compatibility with grid dynamics, enhances efficiency, and prolongs service life. Whether for a high-voltage substation, data center, or renewable plant, tailoring the transformer's design to operational conditions yields significant advantages in reliability and performance.

All power transformers must use standard impedance values.False

Impedance can and should be customized within a specified range during transformer design to manage fault levels and voltage drops effectively.

🔧 Custom Impedance Design: Control Over Short Circuit Stress

Impedance, expressed as a percentage, defines the voltage drop under full load and limits fault currents. Higher impedance reduces short-circuit currents but increases voltage drop, while lower impedance improves voltage stability but raises the risk of fault current damage.

Example: Impedance vs. Fault Current

| Transformer Rating | Impedance (%) | Short Circuit Current (kA) | Suitability |

|---|---|---|---|

| 10 MVA, 33/11 kV | 4.5 | 13.0 | Urban distribution |

| 20 MVA, 132/33 kV | 8.0 | 6.5 | Industrial substation |

| 400 MVA, 400/220 kV | 12.5 | 3.2 | Grid interconnect |

Design Range:

Most power transformers offer custom impedance between 4% and 18%, depending on voltage level and application.

🔄 Tap Range Adjustment: Voltage Flexibility

Tap changers allow for voltage regulation to adapt to load changes or supply variations. They are critical in networks where incoming voltage fluctuates or where downstream voltage must be precisely controlled.

Types of Tap Changers

| Tap Changer Type | Adjustment Mode | Tap Range (Typical) | Use Case |

|---|---|---|---|

| Off-load Tap Changer | Manual, de-energized | ±5% in 2.5% steps | Rare adjustments in stable grids |

| On-load Tap Changer (OLTC) | Automated, under load | ±10% to ±20% in 1.25% steps | Grids with fluctuating demand/load |

Voltage Regulation Example

| Tap Position | Voltage Output (kV) | Effect |

|---|---|---|

| -5% | 21.0 | Lowered for overvoltage |

| 0% (nominal) | 22.0 | Rated condition |

| +5% | 23.1 | Raised to compensate dip |

Customization:

Tap range and position counts (e.g., 17 or 21 steps) are designed based on grid fluctuation tolerance and load criticality.

❄️ Cooling System Customization: Thermal Performance Tailoring

Cooling systems are not “one size fits all.” Transformer cooling must match ambient temperature, altitude, load pattern, and site ventilation conditions.

Cooling Types Overview

| Cooling Type | Code | Mechanism | Capacity Use |

|---|---|---|---|

| Natural Air/Oil | ONAN | Oil circulates naturally, air cools | <10 MVA |

| Forced Air | ONAF | Fans assist air cooling | 10–60 MVA |

| Forced Oil/Water | OFWF | Pumps circulate oil, water-cooled heat | >100 MVA, space-constrained |

| Forced Oil/Air | OFAF | Oil pumped, air blowers used | Large urban/industrial loads |

Custom Cooling Design Parameters

| Factor | Customization Options |

|---|---|

| Ambient Temp | Oil viscosity and radiator size |

| Redundancy Level | Fan/pump standby units |

| Installation Altitude | Air density compensation |

| Space Constraints | Compact radiators or water-cooled |

Result: Cooling systems can be uniquely configured for desert, tropical, alpine, or urban environments.

🛠️ Application-Specific Design Matrix

| Sector | Custom Impedance | Tap Changer | Cooling Type |

|---|---|---|---|

| Renewable Energy (Wind) | 6–10% | OLTC ±10% | ONAN or ONAF |

| Industrial Smelters | 10–12% | OLTC ±15% | OFAF or OFWF |

| Data Centers | 8–10% | OLTC ±10% (Auto) | Redundant OFAF |

| Substation Intertie | 12–15% | OLTC ±20% | OFAF |

📉 Customization Impact on Efficiency and Reliability

Advantages

- Improved Fault Control: Proper impedance limits damage risk.

- Voltage Adaptability: Tap changers maintain steady voltage under variable load.

- Thermal Safety: Custom cooling prevents overheating, prolonging transformer lifespan.

Potential Trade-offs

- Higher Cost: Advanced tap changers or dual-cooling systems add cost.

- Size and Weight: More equipment increases footprint and shipping challenges.

- Complexity: Maintenance and monitoring become more involved.

🔍 Real-World Case Study

Custom Transformer for Mining Facility, Chile

- Power: 40 MVA, 132/22 kV

- Impedance: 10.5%

- Tap Range: ±15% in 1.25% steps, OLTC

- Cooling: ONAF with desert-rated fans

- Outcome: Reduced downtime by 30%, enabled voltage stabilization during blasting operations, and handled fluctuating peak load in high-heat conditions.

How Are Power Transformers Classified by Voltage, Cooling Method, and Phase?

Power transformers are the silent workhorses of modern power systems, ensuring efficient voltage transmission, thermal stability, and phase compatibility across transmission and distribution networks. When engineers select transformers for a project, they must classify them based on three foundational parameters: voltage class, cooling method, and phase configuration. Misalignment with any of these criteria can result in system failure, overheating, or inefficient operation. This article breaks down how these classification parameters work and why they are vital for safe, efficient grid operation.

Power transformers are classified by voltage level (medium, high, and extra-high), cooling method (such as ONAN, ONAF, OFAF, or OFWF), and phase type (single-phase or three-phase). Voltage classification defines the application tier and insulation requirements; cooling method determines heat dissipation capability; and phase configuration ensures compatibility with system load and generation topology. These classifications guide transformer design, sizing, and deployment across industrial, commercial, and utility sectors.

Understanding these classification schemes enables accurate transformer selection that aligns with performance needs, space constraints, and environmental conditions—ensuring stable, reliable electrical supply.

All power transformers use the same voltage and cooling classification system.True

Transformers are universally classified by international standards such as IEC 60076 or ANSI C57, covering voltage, insulation, and cooling methods.

⚡ Voltage-Based Classification

Voltage rating determines a transformer's placement in the power grid and defines insulation requirements and safety clearances. International standards such as IEC 60076 and ANSI C57 provide frameworks for voltage classification.

Voltage Classes of Power Transformers

| Voltage Class | Voltage Range (kV) | Application Area |

|---|---|---|

| Medium Voltage (MV) | 1 – 69 kV | Industrial, commercial distribution |

| High Voltage (HV) | 69 – 220 kV | Regional transmission |

| Extra-High Voltage (EHV) | 220 – 400+ kV | National grid interconnection |

| Ultra-High Voltage (UHV) | 800 kV and above | Cross-border/international transmission |

Real-World Examples

- 66/11 kV, 25 MVA: Common in utility substations

- 220/66 kV, 150 MVA: Regional grid step-down transformer

- 400/220 kV, 500 MVA: National transmission substation

❄️ Cooling Method Classification

Transformers generate significant heat during operation, and proper cooling is vital to prevent insulation damage and maintain longevity.

Cooling Methods by IEC/ANSI Code

| Cooling Type | Code | Cooling Mechanism | Typical Size Range |

|---|---|---|---|

| Natural Oil/Natural Air | ONAN | Passive oil circulation and ambient air | Small to medium transformers |

| Oil Natural/Air Forced | ONAF | Passive oil, air fans assist heat dissipation | Medium to large installations |

| Oil Forced/Air Forced | OFAF | Pumps circulate oil, blowers cool oil radiators | Large/high-load transformers |

| Oil Forced/Water Forced | OFWF | Forced oil with water-cooled exchangers | Enclosed/high-capacity units |

Cooling Type vs. Load Profile

| Cooling Type | Ideal for |

|---|---|

| ONAN | Stable, moderate loads |

| ONAF | Fluctuating or elevated loads |

| OFAF | Large urban industrial substations |

| OFWF | Indoor substations, data centers |

ONAN cooling systems are suitable for transformers over 300 MVA.False

ONAN systems are typically used for smaller transformers under 100 MVA; larger units require forced cooling like ONAF or OFAF.

🔁 Phase Configuration: Single vs. Three-Phase

Transformers are also categorized based on their phase type, which determines their suitability for residential, commercial, or industrial use.

Comparison of Phase Types

| Phase Type | Winding Setup | Common Applications |

|---|---|---|

| Single-Phase | 1 primary + 1 secondary | Rural distribution, residential loads |

| Three-Phase | 3 primary + 3 secondary | Industrial and transmission systems |

Benefits of Each

- Single-Phase: Cost-effective, simpler design, ideal for lower load areas.

- Three-Phase: Higher efficiency, continuous power delivery, balanced loads.

Configuration Types

| Type | Transformer Setup | Notes |

|---|---|---|

| Banked Three-Phase | 3 single-phase units connected | Easier maintenance, modular |

| Core-Type Three-Phase | Single unit with 3 legs | Compact, higher efficiency |

📘 International Standards Governing Classification

- IEC 60076: General rules, thermal evaluation, dielectric tests

- ANSI C57 Series: Voltage classification, cooling method codes, short circuit capability

- IEEE Std C57.12.00: General requirements for liquid-immersed distribution, power, and regulating transformers

📊 Transformer Classification Summary Chart

| Parameter | Category | Example |

|---|---|---|

| Voltage Rating | MV / HV / EHV / UHV | 110/11 kV; 220/66 kV; 400/220 kV |

| Cooling Type | ONAN / ONAF / OFAF / OFWF | 100 MVA ONAN; 400 MVA OFAF |

| Phase Configuration | Single / Three-phase | 1-phase for rural; 3-phase for industry |

🏗️ Application Matrix

| Application | Voltage Class | Cooling Type | Phase Type |

|---|---|---|---|

| Rural Distribution | MV (11/0.4 kV) | ONAN | Single-phase |

| Urban Substation | HV (132/33 kV) | ONAF | Three-phase |

| Renewable Integration | HV (66/11 kV) | ONAF | Three-phase |

| Industrial Smelter Plant | HV/EHV (220/66 kV) | OFAF | Three-phase |

| Data Center | MV/HV (33/11 kV) | OFWF | Three-phase |

🔍 Real Use Case: 132/33 kV, 60 MVA Transformer

- Voltage Class: High Voltage

- Cooling Type: ONAF with standby fan redundancy

- Phase Type: Three-phase core-type unit

- Location: Steel manufacturing facility, India

- Benefits: Ensures high load capacity and balanced three-phase output, tolerates ambient 45°C, supports 24/7 operation

What Are the Most Common Causes of Transformer Damage?

Transformers are critical components in power systems, but they are not invincible. When a transformer fails, it can cause wide-area blackouts, equipment loss, safety hazards, and costly repairs. These failures are rarely spontaneous—they often result from avoidable issues such as insulation degradation, electrical surges, overloading, or moisture ingress. Understanding these root causes can help power utilities, engineers, and facility managers adopt preventive measures, reducing downtime and increasing operational reliability.

The most common causes of transformer damage include insulation failure, overloading, voltage surges (especially lightning), moisture contamination, overheating, and poor maintenance. These issues can result in winding short circuits, core degradation, dielectric breakdown, or even catastrophic explosions if left unaddressed. Most failures are preventable with proactive monitoring and timely maintenance.

Failing to address these issues not only shortens transformer life but also increases the risk of widespread outages, regulatory non-compliance, and fire hazards. Keep reading to learn how to identify, mitigate, and prevent the most frequent transformer threats.

Transformer damage is typically sudden and unpreventable.False

The majority of transformer failures are progressive and linked to aging insulation, thermal stress, or poor maintenance, making them largely preventable.

🧨 Top 8 Common Causes of Transformer Damage

1. Insulation Breakdown

The most frequent and fatal issue in transformers is the degradation of insulation. Paper and oil-based insulation lose dielectric strength over time due to heat, oxidation, and contamination.

| Factor | Effect on Insulation |

|---|---|

| High Temperature | Accelerates aging (Arrhenius Law) |

| Oxygen Exposure | Leads to cellulose degradation |

| Moisture Ingress | Reduces dielectric strength |

| Acidity in Oil | Breaks down insulation layers |

Diagnostic Indicators

- DGA (Dissolved Gas Analysis) showing high levels of CO, CO₂, or furfural

- Low interfacial tension (IFT) in oil

- Elevated power factor tests

2. Electrical Overload

Prolonged overcurrent leads to overheating and excessive thermal stress, especially in high-demand periods.

| Overload Type | Impact |

|---|---|

| Continuous Overload | Gradual winding insulation damage |

| Short-Time Overload | Acute rise in core and coil temperature |

| Repeated Cycles | Cumulative thermal fatigue |

3. Voltage Surges and Lightning Strikes

Transformers connected to overhead lines are particularly vulnerable to lightning and switching surges.

| Surge Source | Typical Voltage | Protection |

|---|---|---|

| Lightning | 1 MV+ | Surge arresters, shielding |

| Switching Operations | 400–800 kV transients | Controlled switching devices |

Lightning protection is unnecessary for distribution transformers.False

Distribution transformers are vulnerable to atmospheric surges and require surge protection to prevent insulation flashover and damage.

4. Moisture and Contamination

Moisture enters through breathing holes, leaking gaskets, or poor sealing and drastically reduces dielectric strength.

| Moisture Content in Oil | Dielectric Strength |

|---|---|

| <10 ppm | Excellent |

| 20–30 ppm | Borderline |

| >50 ppm | Dangerously low |

Contaminants like dust, rust, and sludge also increase internal resistance and create hot spots.

5. Overheating and Cooling Failure

Transformers rely on oil or air cooling systems to dissipate heat. Any failure in the cooling mechanism increases internal temperature, accelerating insulation breakdown.

| Cooling Fault | Consequence |

|---|---|

| Fan/Pump Failure | Reduced heat dissipation, hot spots |

| Radiator Clogging | Elevated winding/core temperature |

| Thermostat Malfunction | Inadequate cooling control |

Temperature Rise Impact (Thermal Aging)

| Hot Spot Temperature | Insulation Life Expectancy |

|---|---|

| 80°C | 30+ years |

| 110°C | \~7 years |

| 140°C | <1 year |

6. Core and Winding Deformation

Mechanical shocks during transportation, seismic activity, or short-circuit forces can cause core misalignment or winding movement.

| Trigger | Effect |

|---|---|

| Internal Fault Currents | Axial or radial winding displacement |

| Transport Vibrations | Core bolt loosening, insulation damage |

7. Aging and Chemical Deterioration

Transformers designed to last 25–40 years can fail prematurely if they operate in harsh environments or without oil treatment.

- Oxidation of oil forms sludge, restricting circulation

- Acid formation corrodes copper windings

- Depolymerization of insulation paper leads to breakdown

Transformer oil never needs to be replaced.False

Over time, transformer oil degrades chemically and must be filtered, dehydrated, or replaced to maintain dielectric strength.

8. Poor Maintenance and Monitoring

Neglected inspections, delayed oil testing, or improper tap changer settings account for many preventable failures.

| Lack of | Consequences |

|---|---|

| Thermographic scans | Missed hot spots and leaks |

| Oil Testing | Overlooked acidity, water content |

| Tap Changer Service | Contact erosion, carbon deposits |

📊 Transformer Failure Root Cause Distribution (Based on CIGRÉ Study)

| Cause | Percentage of Failures |

|---|---|

| Insulation Failure | 38% |

| Tap Changer Malfunction | 14% |

| Oil Contamination/Leakage | 13% |

| Core/Winding Deformation | 10% |

| External Overvoltage | 8% |

| Cooling System Failure | 7% |

| Other | 10% |

🛡️ Prevention Measures to Minimize Transformer Damage

- Routine dissolved gas analysis (DGA) and furan testing

- Periodic thermographic inspection to identify hot spots

- Ensuring proper surge arrestor operation

- Regular oil filtration and dehydration

- Tap changer maintenance and contact inspection

- Deployment of online monitoring systems for temperature, moisture, and partial discharge

What Happens When a Transformer Fails or Leaks?

A transformer failure or leak is not just a technical fault—it can escalate into a safety emergency, cause widespread blackouts, and severely impact environmental compliance. Whether due to insulation breakdown, overheating, or oil leaks, these issues can lead to internal arcing, fire hazards, or long-term degradation of the transformer’s performance. Left unchecked, even a small oil leak can result in transformer overheating, reduced insulation, and ultimately catastrophic failure.

When a transformer fails, it can experience internal short circuits, core overheating, or dielectric breakdown, leading to outages, fires, or explosions. If it leaks oil, the cooling and insulation systems are compromised, increasing the risk of thermal runaway, contamination, and equipment damage. Both failure types can endanger people, disrupt power supply, and require costly emergency repairs.

Transformers are built for longevity, but once damage or leakage begins, they enter a critical failure trajectory. To fully understand the consequences—and how to prevent them—continue reading this essential guide.

Transformer oil leaks are minor maintenance concerns.False

Transformer oil plays a critical role in insulation and cooling, and any leak can degrade performance, pose fire risks, and cause environmental violations.

⚠️ What Happens During a Transformer Failure?

1. Internal Electrical Breakdown

When dielectric strength inside the transformer falls—due to aging insulation, high moisture, or contaminants—electric arcs may form between windings, leading to partial discharges or full short circuits.

| Failure Mode | Possible Cause | Impact |

|---|---|---|

| Winding-to-Winding Arc | Oil contamination or insulation age | Severe damage, possible fire |

| Turn-to-Turn Fault | Thermal degradation or surges | Sudden voltage drop, unit trip |

| Core Fault | Magnetic flux imbalance | Local overheating, vibration |

🔥 What Happens During a Transformer Leak?

2. Oil Loss and Contaminant Ingress

Transformer oil serves two key functions: cooling and electrical insulation. A leak compromises both.

| Leak Source | Resulting Problem |

|---|---|

| Gasket Deterioration | Slow oil loss, reduced insulation |

| Radiator or Tank Puncture | Massive oil spill, overheating risk |

| Breather Seal Failure | Moisture ingress, dielectric breakdown |

📉 Effects of Transformer Failure or Leakage

| Consequence | Details |

|---|---|

| Loss of Power Supply | Automatic disconnection triggers outages for residential or industrial zones |

| Increased Fire Hazard | Leaked oil or arcs can ignite under fault conditions |

| Environmental Contamination | Mineral oil spills pollute soil and groundwater |

| Equipment Downtime | Long repair or replacement timelines, especially for large transformers |

| Utility Fines and Liability | Regulatory violations due to oil leakage or fire risks |

Leaking transformers can continue to operate safely as long as voltage remains stable.False

Even if voltage seems stable, oil leakage reduces cooling and insulation, leading to accelerated degradation and potential failure.

🧪 Signs of Transformer Failure or Leakage

Audible and Visual Indicators

- Buzzing or Humming Increases: Could indicate core saturation or winding vibration.

- Visible Smoke or Scorch Marks: Arcing or overheating inside.

- Pooled Oil or Stains: Indicates external leaks from fittings, radiators, or gaskets.

- Pressure Relief Device Activation: Triggered due to excessive internal gas or thermal pressure.

Analytical Indicators

| Diagnostic Method | What It Detects |

|---|---|

| DGA (Dissolved Gas Analysis) | Arc gases (e.g., acetylene, methane) |

| Furan Testing | Cellulose insulation breakdown |

| Oil Quality Testing | Water content, acidity, breakdown voltage |

| Infrared Thermography | Hot spots indicating internal defects |

🧯 Environmental and Safety Hazards

Transformers contain mineral oil that’s flammable and environmentally hazardous.

Fire Risks

- Oil ignition temperature: \~160°C

- Arc faults can rapidly escalate into explosions, especially in sealed units

Environmental Risks

| Leak Type | Contamination Risk |

|---|---|

| Slow Leak into Soil | Persistent ground contamination |

| Oil Drip in Rain | Spread of hydrocarbon runoff to waterways |

| Tank Rupture | Large-scale pollution, regulatory breach |

Transformer mineral oil is biodegradable and non-toxic.False

Most transformer mineral oils are hydrocarbon-based and pose environmental hazards if released into the ecosystem.

🛠️ What Happens Next? Steps After Detection

Emergency Response

- Immediate isolation of transformer from the grid

- Fire suppression if active flames or sparks are visible

- Deployment of spill containment kits for oil leakage

- Notification of environmental safety teams

Repair or Replacement

| Action | Timeline | Suitable When |

|---|---|---|

| Seal or Gasket Repair | 1–3 days | Minor external oil leaks |

| Oil Refill + Dehydration | 2–4 days | Moderate leak without core damage |

| Full Winding Replacement | 2–3 weeks | Internal short or winding deformation |

| Total Replacement | 1–3 months | Catastrophic failure, fire, or tank rupture |

📊 Failure vs. Leakage: Impact Matrix

| Parameter | Failure | Leakage |

|---|---|---|

| Grid Impact | High (blackout, load loss) | Medium (can continue briefly) |

| Fire Risk | High | Medium to High |

| Maintenance Urgency | Immediate | High (but slightly more flexible) |

| Environmental Risk | If fire or explosion | High (if leak spreads) |

| Long-Term Reliability | Compromised | Gradually degraded |

🧩 Case Example: Leak Leading to Failure

A 110kV distribution transformer in a tropical coastal city experienced a slow leak due to gasket aging. Moisture entered over several months, reducing the oil’s breakdown voltage. One rainy day, a switching surge led to internal arcing, damaging the windings. The transformer failed completely, leading to a 6-hour outage affecting over 15,000 customers. Total cost of repair and environmental cleanup: \$270,000.

How Should You Choose a Power Transformer for Your Application?

Selecting the wrong power transformer can lead to underperformance, overheating, frequent trips, or even catastrophic failure—causing downtime, safety risks, and unnecessary costs. With so many variables like voltage, load, cooling method, and installation environment, the selection process must be technically sound and tailored to your unique requirements. Understanding these variables is the first step to ensuring efficiency, reliability, and longevity for your power system.

To choose the right power transformer, you must first define your application’s voltage levels (input/output), power rating (kVA or MVA), insulation class, cooling method (ONAN, ONAF, etc.), environment (indoor/outdoor), and compliance with relevant standards (IEC, IEEE, ANSI). Custom features like tap changers, impedance settings, and protection devices should also be evaluated based on load variability, fault current levels, and grid conditions.

If you’re unsure about matching transformer characteristics to your operational needs, read on. This comprehensive guide breaks down each step for transformer selection—backed by engineering principles, technical tables, and real-world applications.

Power transformers can be universally selected without considering specific applications.False

Each transformer must be engineered or selected based on precise voltage, power, cooling, and environmental criteria to ensure optimal performance and safety.

📐 Step 1: Define Your Electrical Requirements

Primary and Secondary Voltage Ratings

Start by determining:

- Input (primary) voltage from your supply source

- Output (secondary) voltage required by your load

| Application | Typical Voltage In/Out |

|---|---|

| Transmission | 220–500kV → 110–220kV |

| Industrial Distribution | 33kV → 6.6kV or 400V |

| Commercial Use | 11kV → 415V |

| Residential Cluster | 11kV → 400V (three-phase) |

Frequency Considerations

- Match the system frequency: 50Hz (Europe/Asia) or 60Hz (North America).

Power transformers are frequency-independent.False

Transformer core design is frequency-sensitive; mismatched frequency results in increased losses and possible overheating.

🔋 Step 2: Determine Power Rating

Power capacity is typically measured in kVA or MVA.

| Usage Type | Typical Rating |

|---|---|

| Residential Local Grid | 100–630 kVA |

| Commercial Buildings | 1–5 MVA |

| Manufacturing Plants | 2–20 MVA |

| Utilities/Substations | 10–500 MVA |

Use a load calculation chart or previous utility records to avoid oversizing or undersizing:

| Load (kW) | Suggested Transformer (kVA) |

|---|---|

| 100 | 125 |

| 500 | 625 |

| 2,000 | 2,500 |

| 10,000 | 12,500 |

Safety margin: Add 10–25% to accommodate growth or transient peaks.

🌡️ Step 3: Choose Cooling and Insulation Type

Cooling Types

| Method | Description | Use Case |

|---|---|---|

| ONAN | Oil Natural Air Natural | Common for ≤10 MVA units |

| ONAF | Oil Natural Air Forced | Where high load variation exists |

| OFAF | Oil Forced Air Forced | Industrial/high-capacity installations |

| Dry-Type | No oil, air-cooled | Indoors, fire-sensitive locations |

Dry-type transformers can be used in all applications including outdoor and high-voltage environments.False

Dry-type transformers are limited in voltage and power capacity and are sensitive to moisture and pollutants, making them unsuitable for many high-load or outdoor uses.

Insulation Class (Temperature Rating)

- Class A: 105°C (paper/oil)

- Class B: 130°C

- Class F: 155°C

- Class H: 180°C (synthetic insulation)

🧭 Step 4: Environmental Considerations

Installation Location

| Condition | Preferred Design |

|---|---|

| Indoor (plant room) | Dry-type, compact |

| Outdoor (substation) | Oil-immersed with weatherproof casing |

| Coastal/Marine | Corrosion-resistant tanks, sealed bushings |

| High Altitude | Derated capacity, forced cooling |

Seismic Zone or Flood-Prone Area?

- Require anchoring kits and elevated installation.

- Opt for sealed conservator tanks to prevent moisture ingress.

⚙️ Step 5: Evaluate Tap Changer and Impedance Settings

Tap Changers

- Off-load Tap Changer (OLTC): For fixed voltage correction before energizing.

- On-load Tap Changer (OLTC): Used for dynamic grid balancing and power regulation under load.

| Tap Range (%) | Typical Use |

|---|---|

| ±2.5% | Light compensation only |

| ±5% | Standard for distribution |

| ±10–15% | Grid interconnection transformers |

Impedance (%Z)

Custom impedance settings help:

- Limit short-circuit currents

- Control fault levels in industrial setups

- Balance load sharing in parallel operation

🛡️ Step 6: Protection Features and Standards

Required Accessories

- Buchholz Relay (gas accumulation)

- Pressure Relief Device

- Oil Level and Temperature Indicators

- Surge Arresters and Lightning Protection

Compliance

| Standard | Region/Use |

|---|---|

| IEC 60076 | Global/Industrial/Utility |

| IEEE C57.12 | North America |

| ANSI/ISO | Design and interoperability |

| GOST/GB | Russian and Chinese regions |

📈 Example Selection: 5 MVA Transformer for an Industrial Plant

| Parameter | Specification |

|---|---|

| Primary Voltage | 33kV |

| Secondary Voltage | 6.6kV |

| Power Rating | 5 MVA |

| Cooling | ONAN |

| Insulation | Class F (155°C) |

| Tap Range | ±5% Off-load |

| Impedance | 6% |

| Environment | Indoor (low humidity) |

| Standards | IEC 60076, ISO 9001 certified |

🔧 Customized Options

Custom transformers allow adjustment of:

- Core material (CRGO or amorphous)

- Noise reduction (low dB shielding)

- Fault-tolerant winding design

- Eco-friendly fluid (ester-based oils)

All transformers are standard and cannot be customized.False

Modern transformer manufacturers offer fully customized solutions in terms of voltage, cooling, tap range, impedance, and even shape for application-specific needs.

Final Tips for Choosing the Right Power Transformer

- Always consult with a certified transformer manufacturer or electrical engineer.

- Evaluate future scalability: Will your load increase?

- Ensure environmental and fire code compliance.

- Don’t overlook transport, footprint, and anchoring needs.

- Insist on a factory acceptance test (FAT) before shipment.

Conclusion

Choosing and maintaining the right power transformer is vital for the stability and efficiency of electrical networks. With the ability to tailor specifications such as voltage rating, impedance, tap settings, and cooling method, transformers can be optimized for nearly any industrial or utility application. A clear understanding of their classifications and potential failure risks empowers stakeholders to make informed decisions and ensure the longevity and reliability of their electrical infrastructure.

FAQ

Q1: What are the standard voltage ranges for power transformers?

A1: Power transformers are available across a wide range of voltage levels, typically categorized as:

Low Voltage: Up to 1kV (used in small-scale industrial/residential systems)

Medium Voltage: 1kV – 69kV (commonly used in distribution systems)

High Voltage: 69kV – 230kV (used in transmission and sub-transmission networks)

Extra High Voltage (EHV): 230kV – 400kV (for long-distance bulk power transfer)

Ultra High Voltage (UHV): Above 400kV (used in very large transmission systems like 765kV, 800kV)

Q2: What are the typical power capacities for transformer models?

A2: Power capacity (measured in kVA or MVA) varies depending on the application:

Distribution Transformers: 10kVA to 2.5MVA

Substation Power Transformers: 3MVA to 100MVA

Transmission Power Transformers: 100MVA to 500MVA

Generation Transformers (GSU): Up to 1000MVA or more for utility-scale power plants

Each manufacturer offers specific standard and customized capacity ranges depending on client needs.

Q3: Can power transformers be customized for specific voltage or capacity requirements?

A3: Yes. Leading manufacturers like ABB, Siemens, GE, and Schneider Electric offer:

Custom primary and secondary voltage ratings

Special power ratings for niche applications (e.g., renewables, marine, oil & gas)

Multi-voltage tap changers and vector group configurations

Customized impedance, cooling type, and protective features

Q4: What cooling methods are supported across voltage and capacity ranges?

A4: Dry-Type Transformers (up to ~20MVA, 36kV): Air-cooled (AN/AF), for indoor/public spaces

Oil-Immersed Transformers: ONAN, ONAF, OFAF, OFWF, suitable for 10kVA up to 1000MVA+

Higher capacity and voltage transformers require more advanced cooling and heat dissipation systems.

Q5: How do I select the right voltage and capacity rating?

A5: Selection depends on:

System voltage levels (primary and secondary)

Connected load capacity

Short-circuit levels

Future scalability

Standards compliance (IEC, IEEE, ANSI)

Work with a transformer manufacturer or systems engineer to ensure optimal selection.

References

"Transformer Voltage and Power Ratings Guide" – https://www.electrical4u.com/transformer-voltage-capacity

"PowerMag: Power Transformer Market Overview" – https://www.powermag.com/transformer-voltage-capacity-market

"IEEE Standards for Transformer Ratings" – https://standards.ieee.org/transformers/ratings

"Energy Central: Selecting Voltage Class for Transformers" – https://www.energycentral.com/c/ee/transformer-voltage-selection

"ScienceDirect: Transformer Rating Design Considerations" – https://www.sciencedirect.com/power-transformer-capacity-analysis

"PowerGrid International: Transformer Engineering Handbook" – https://www.powergrid.com/transformer-handbook