Selecting the right power transformer is crucial for ensuring the safety, efficiency, and reliability of an electrical system. A mismatch in transformer specifications can lead to operational inefficiencies, increased losses, or even equipment failure. Each project—whether it's for an industrial facility, substation, or renewable energy plant—has unique technical and environmental demands. This guide outlines the key factors that influence transformer selection and helps project engineers and procurement teams make informed decisions.

What Are the Voltage and Power Requirements for Power Transformers?

When specifying or selecting a power transformer, voltage and power ratings are the first and most critical design parameters. These determine not only the transformer’s physical size and winding structure, but also how it integrates into the electrical grid, substation, or industrial system it supports.

Voltage requirements define the transformer’s high-voltage (HV) and low-voltage (LV) sides, while power rating (in kVA or MVA) determines the maximum load the transformer can carry continuously under rated conditions. Frequency, phase, impedance, and tap range are additional key specifications. These ratings must match the upstream and downstream grid or plant design.

Improperly specified voltage or power ratings can lead to overloading, short-circuit risk, or failure to synchronize with the grid.

Voltage and power ratings are flexible and can be adjusted after transformer installation.False

Voltage and power ratings are fixed at the design and manufacturing stage and must be precisely specified in advance to match the system requirements.

🔌 Key Voltage Specifications

| Voltage Parameter | Description | Example (IEC/IEEE standard) |

|---|---|---|

| Primary (HV) Voltage | Rated input side voltage (e.g., from grid or generator) | 132 kV, 66 kV, 33 kV |

| Secondary (LV) Voltage | Output side voltage (e.g., to distribution or load) | 11 kV, 6.6 kV, 400 V |

| Tap Voltage Range | Adjustability range for voltage regulation | ±5% in 16 steps (OLTC/DETC) |

| Rated Frequency | AC frequency for which transformer is optimized | 50 Hz or 60 Hz |

| Basic Insulation Level (BIL) | Surge withstand capacity for lightning or switching overvoltage | 250–1050 kV (depending on HV level) |

⚡ Power Rating Specifications

| Power Parameter | Description | Example Value |

|---|---|---|

| Rated Power (S) | Continuous apparent power the transformer can handle (kVA or MVA) | 1.25 MVA, 10 MVA, 100 MVA |

| Cooling Class (ONAN/ONAF) | Determines output rating with/without forced cooling | 10 MVA ONAN / 12.5 MVA ONAF |

| Impedance (%) | Internal voltage drop under load; affects fault current & protection | 6.25%, 8%, 10% |

| Duty Cycle | Load profile (e.g., continuous, cyclic, overload) | 100% rated, 150% overload for 2h |

| Thermal Limit | Peak loading condition (hot spot temperature, aging factor) | 140 °C hot spot; aging rate <1.0 |

📊 Example Transformer Ratings (Medium Voltage)

| Parameter | Typical Distribution Transformer | Typical Power Transformer |

|---|---|---|

| Power (kVA/MVA) | 250 kVA – 5 MVA | 10 MVA – 250 MVA |

| HV Voltage | 11 kV, 22 kV, 33 kV | 66 kV, 132 kV, 220 kV |

| LV Voltage | 400 V, 6.6 kV, 11 kV | 11 kV, 33 kV |

| Frequency | 50 Hz or 60 Hz | 50 Hz or 60 Hz |

| Tap Range | ±5% (±2×2.5% DETC) | ±10% in 17 steps (OLTC) |

| Impedance | 4%–6% | 8%–12% |

🧠 Key Considerations When Specifying Voltage & Power

- Grid Compatibility: Match HV rating to transmission or substation bus

- Load Demand: Select MVA rating based on peak and continuous load (plus 10–20% margin)

- Short Circuit Calculations: Use impedance to size protection relays and fuses

- Transformer Location: Indoor, outdoor, urban, or coastal affects insulation and BIL

- Cooling Needs: Higher ratings may require ONAF or ODAF cooling for thermal stability

🛠️ How to Specify Correct Ratings in a Purchase Order

| Specification Category | Required Details for PO or Data Sheet |

|---|---|

| HV/LV Voltage | Nominal + rated withstand voltages |

| Rated Power | In MVA with cooling class definition (e.g., ONAN/ONAF) |

| Impedance | % at rated power and temperature |

| Tap Range & Method | % range, number of steps, OLTC or DETC |

| Frequency | 50 Hz (Europe, Asia) or 60 Hz (Americas, parts of Asia) |

💬 Expert Note

“Incorrect voltage rating or tap range is one of the most common causes of site commissioning delay. If the transformer can’t match grid voltage or handle expected loads, the entire substation may fail to energize safely.”

— Senior Design Engineer, Transformer OEM

How Do Load Characteristics Affect Transformer Choice?

Choosing the right power transformer is not just about voltage and MVA—it's about understanding the nature of the electrical load it will serve. Load characteristics such as duty cycle, peak demands, harmonic content, unbalanced loading, and load variability all influence how the transformer should be rated, cooled, protected, and monitored.

Load characteristics affect transformer choice by determining the required power rating, cooling class, impedance, thermal design, and insulation aging tolerance. Steady loads allow for optimized core loss designs, while cyclic or harmonic-rich loads require transformers with enhanced thermal margin, higher overload capacity, derated losses, or special materials to handle non-sinusoidal currents.

A mismatch between transformer design and load behavior leads to overheating, premature aging, inefficiency, or failure during peak load conditions.

Transformer selection is based only on voltage and not on the type of load.False

Transformer choice must consider the electrical load's nature—cyclic, harmonic-rich, intermittent, or unbalanced—to ensure correct sizing, thermal stability, and lifespan.

🔌 Key Load Characteristics That Influence Transformer Design

| Load Characteristic | Description | Impact on Transformer Selection |

|---|---|---|

| Load Type | Steady (e.g., lighting), cyclic (e.g., motors), fluctuating (e.g., arc furnaces) | Affects cooling class and overload rating |

| Duty Cycle | % of time at or near full load (continuous, peak, idle) | Determines whether transformer can operate ONAN or needs ONAF |

| Peak Demand | Maximum expected load, including startup inrush or contingency | Requires overload margin or dynamic capacity rating |

| Harmonic Content (THD) | Distortion caused by non-linear loads (drives, inverters) | May need K-rated or low-loss core with reduced eddy current paths |

| Unbalance | Unequal load on phases (common in rural, industrial grids) | Impacts winding configuration and core saturation limits |

| Inrush Current Behavior | Sudden surges from motor or transformer energization | Influences protection coordination and core design |

📊 Transformer Design Adjustments for Load Types

| Load Profile | Recommended Transformer Features |

|---|---|

| Steady Load (100%) | Standard ONAN transformer with optimized core loss |

| Cyclic Load (50–150%) | ONAF/ODAF with thermal sensors and dynamic overload margin |

| Harmonic Load (THD >5%) | Low-flux density core, derated capacity, copper shields |

| Motor Start Load | Core designed for inrush tolerance, reinforced tap changers |

| Intermittent Peak Load | Designed for high peak short duration, oversized radiators |

| Unbalanced Load | Zig-zag or delta tertiary winding for neutral stability |

🧠 Factors to Consider When Matching Transformer to Load

| Factor | Questions to Ask |

|---|---|

| Rated Power vs Actual Load | What’s the max expected load vs average? Add 10–25% design margin |

| Load Curve | How does load vary over 24 hours? Any night dips or morning spikes? |

| Harmonics Origin | Is the load driven by VFDs, UPS, or arc furnaces? |

| Load Growth | Will demand increase in 5–10 years? Add capacity for expansion |

| Overload Tolerance | Should the transformer handle 120–150% for limited hours? |

🔍 Load Type vs Transformer Cooling & Design Chart

| Load Characteristic | Cooling Requirement | Typical Transformer Choice |

|---|---|---|

| Constant Full Load | ONAN | Core-optimized 2-winding transformer |

| 50%–150% Cyclic Load | ONAN/ONAF | Forced cooling with RTDs and alarms |

| High Harmonic Load | ONAN or ONAF + Derating | K-rated or custom harmonic-duty units |

| Frequent Switching | ONAN with sturdy OLTC | Regulating transformer with high MCBF |

| Short Peak Bursts | ONAN or OFAF with margin | Thermal-buffered windings, copper bias |

🛠️ Real-World Example

A wind farm step-up transformer initially failed thermal compliance due to load variability and inverter harmonics. The replacement unit featured low-loss core steel, upgraded ONAF cooling, and derated impedance, resulting in compliant thermal performance with extended overload endurance.

📋 How to Document Load for Transformer Sizing

| Load Data to Provide | Purpose |

|---|---|

| 24-hour load profile (kW/MW) | Analyzes load cycle for overload tolerance |

| Harmonic spectrum (%) | Identifies design needs for THD compatibility |

| Start-up/inrush curves | Checks magnetizing surge handling and saturation risks |

| Fault level data (kA, sec) | Helps set transformer impedance and protection margins |

| Expansion forecast (5–10 years) | Adds sizing headroom for growth |

What Environmental and Installation Conditions Must Be Considered for Power Transformers?

Power transformers are high-value, long-life assets, and their reliability depends not only on their internal design, but also on the external conditions where they are installed. Harsh climates, corrosive environments, seismic activity, and even urban noise restrictions can dramatically influence transformer design, cooling choice, enclosure type, and protection features.

Environmental and installation conditions such as ambient temperature, humidity, altitude, pollution level, seismic risk, salinity, access for maintenance, indoor/outdoor location, and fire safety must be considered when designing or selecting a transformer. These factors affect cooling capacity, insulation life, mechanical design, and installation logistics.

Ignoring these site-specific conditions can lead to premature aging, loss of efficiency, and costly operational failures.

Transformers are universally applicable and environmental conditions don't affect their design or performance.False

Transformers must be engineered or selected based on environmental and installation conditions to ensure reliability, efficiency, and lifespan in specific field applications.

🌡️ Key Environmental Conditions That Influence Transformer Design

| Condition | Impact on Transformer | Typical Design Adaptation |

|---|---|---|

| Ambient Temperature | Affects thermal loading and oil expansion | Derating for >40 °C or heating for <–20 °C |

| Humidity / Rain | Risk of condensation and insulation breakdown | Use of anti-condensation heaters or sealed tank |

| Altitude (>1000 m) | Reduces air cooling and dielectric strength | Voltage derating or oil pressure adjustment |

| Dust & Pollution | Accelerates surface tracking, cooling blockage | Higher creepage bushings, IP-rated enclosures |

| Salinity / Marine Air | Corrosion of steel parts and connectors | Stainless hardware, epoxy coatings, zinc primers |

| Seismic Zone | Risk of mechanical displacement or tank damage | Seismic base design, tank stiffeners |

| Wind & Flooding Risk | Overturn or submersion risk in natural disasters | Elevated plinths, anchoring kits |

🏗️ Installation Condition Categories

| Location Type | Considerations | Typical Measures |

|---|---|---|

| Outdoor Substation | Rain, UV, vandalism, open air cooling | Weatherproof canopy, radiators with guards |

| Indoor Room | Space constraints, temperature buildup, fire code compliance | Dry-type units, forced ventilation, fire dampers |

| Basement Vault | Flood risk, access difficulty | Oil sump, oil-immersed flameproof units |

| Rooftop / High-Rise | Vibration, wind, weight restrictions | Dry-type or compact pad-mounted transformer |

| Mining / Tunnels | Dust, vibration, confined air | Dust-sealed enclosures, high IP rating |

| Nuclear / Hazardous | Explosion-proof, low fault risk tolerance | ATEX-certified designs, arc-resistant cabinets |

📊 Environmental Classifications per IEC/IEEE

| IEC/IEEE Code | Description | Design Implication |

|---|---|---|

| IEC Pollution Level IV | Very heavy industrial pollution | High creepage distance, composite bushings |

| IEEE C57 GSU Transformer | Generator step-up near turbines | High flux core, air-filtered enclosures |

| IEC Climate Class C3 | Harsh outdoor climates | UV/storm-resistant coatings, tropical insulation |

| Seismic Zone 4 | High earthquake potential | Reinforced base and oil conservator |

🧠 Installation Design Questions to Answer

| Key Question | Why It Matters |

|---|---|

| What is the max/min ambient temperature? | Determines cooling type and thermal aging margin |

| Will it be exposed to dust, sand, or salt? | Drives enclosure IP rating and corrosion resistance |

| Is the site in a seismic or flood-prone zone? | Requires structural anchoring and base elevation |

| Is it for indoor, underground, or rooftop use? | Determines size, heat dissipation, and safety compliance |

| Is regular access for maintenance available? | Affects layout of control cubicles and inspection ports |

🛠️ Installation Accessories Based on Environment

| Environment Condition | Accessory / Design Feature |

|---|---|

| High Dust / Sand | Mesh-protected radiators, pressurized cabinets |

| Cold Climate | Oil heaters, thermal insulation, cold-start OLTCs |

| Coastal / Salt Fog | Epoxy bushings, marine paint system, zinc-rich primer |

| Indoor Hazardous Area | Fire suppression ports, zero-leak oil tanks |

| Remote Mountain Site | Hermetically sealed tank, no conservator design |

🧾 Field Example: Coastal Substation Installation

A 20 MVA, 132/33 kV transformer installed within 2 km of the sea was specified with:

- Polymer composite bushings to resist salt tracking

- Epoxy-coated radiator fins and stainless hardware

- Breather with silica gel and oil trap

- IP55 control box and anti-condensation heater

The result was over 10 years of uninterrupted service despite corrosive air and high humidity.

What Cooling Method Is Appropriate for the Project?

Transformer reliability and lifespan depend heavily on effective heat dissipation. Power transformers generate internal heat through copper (load) and core (no-load) losses. Selecting the right cooling method ensures safe operation, prevents thermal aging, and supports rated power output under real operating conditions.

The appropriate cooling method for a project depends on the transformer’s power rating, load profile, environmental conditions, and installation space. Common cooling methods include ONAN (oil natural air natural), ONAF (oil natural air forced), OFAF (oil forced air forced), and dry-type air cooling. Each method is suited to different project scales, cooling demands, and site constraints.

Selecting the wrong cooling method can lead to overheating, derating, or even thermal failure in peak load conditions.

All transformers can use the same cooling method regardless of rating or environment.False

Cooling methods must match the transformer's power level, site conditions, and load profile to ensure thermal performance and lifespan.

❄️ Overview of Transformer Cooling Methods

| Cooling Code | Full Form | Description |

|---|---|---|

| ONAN | Oil Natural Air Natural | Passive cooling via convection in oil and ambient air; silent and efficient |

| ONAF | Oil Natural Air Forced | Fans blow air across radiators to improve cooling |

| OFAF | Oil Forced Air Forced | Oil pumped through heat exchangers and air blown by fans |

| ODAF | Oil Directed Air Forced | Directional oil flow improves winding cooling |

| AN/AF | Air Natural / Air Forced (Dry) | Used in dry-type transformers; ventilated or fan-assisted |

| OW | Oil-to-Water Cooling | For indoor or marine use; water cooled via heat exchangers |

🧪 Selection Guide: Matching Cooling to Project Type

| Project Type | Recommended Cooling Method | Why It Fits |

|---|---|---|

| <5 MVA Indoor Load Center | AN or AF (Dry-type) | No oil risk, compact footprint |

| 5–20 MVA Outdoor Utility | ONAN or ONAF | Balanced cost and reliability |

| >20 MVA Urban Substation | ONAF or OFAF | Handles high loads, requires active cooling |

| 50–100 MVA Transmission | OFAF or ODAF | Maintains temperature under sustained grid load |

| Renewable Step-Up Plant | ONAF with redundancy | Variable loads require dynamic cooling |

| Marine/Nuclear Facility | OW (oil-water) | Enclosed spaces need fluid-cooled, explosion-proof design |

📊 Cooling Capacity Comparison

| Cooling Method | Typical Cooling Boost (%) | Typical Transformer Rating (MVA) | Maintenance Complexity |

|---|---|---|---|

| ONAN | Base capacity | 1–15 MVA | Low |

| ONAF | +25–40% | 10–40 MVA | Medium (fan checks) |

| OFAF | +50–100% | 30–100+ MVA | High (pump + fan) |

| ODAF | +100–150% | >100 MVA | Very high |

| AN (Dry) | Base rating | <5 MVA | Low |

| AF (Dry) | +25–50% | <10 MVA | Medium (fan only) |

🧠 Considerations for Cooling Method Selection

| Factor | Influence on Cooling Choice |

|---|---|

| Power Rating | Higher power needs active oil cooling (OFAF/ODAF) |

| Ambient Temperature | Hot climates may require ONAF instead of ONAN |

| Noise Constraints | ONAN or dry-type AN used in noise-sensitive areas |

| Maintenance Capability | Remote or unmanned sites prefer ONAN or dry-type |

| Fire Risk / Indoor Use | Dry-type or sealed oil units preferred |

| Voltage Level | High-voltage transformers (>132 kV) often require OFAF/ODAF |

🛠️ Installation Design Implications

| Cooling Method | Design Consideration |

|---|---|

| ONAN | Requires natural airflow and ambient space |

| ONAF | Needs power supply and space for fans |

| OFAF/ODAF | Includes oil pumps, thermal relays, redundancy systems |

| Dry-Type | Requires clear air ducts, dust filters, low humidity |

| OW | Water source, plumbing, and cooling towers required |

💬 Engineering Insight

“For a 66/11 kV transformer operating in a desert climate, we had to switch from ONAN to ONAF with dual fan groups. This kept top-oil temperature below 60 °C under peak solar load.”

— Utility Design Lead, Middle East

What Are the Efficiency and Loss Performance Requirements for Power Transformers?

In large-scale power and utility projects, efficiency isn’t a bonus—it’s a core requirement. Power transformers run continuously for decades, so even small inefficiencies translate into huge long-term energy costs. Regulatory standards such as IEC 60076-20, DOE 10 CFR Part 431, and EU EcoDesign Tier 2 enforce strict thresholds on allowable energy losses.

Transformer efficiency and loss performance requirements are defined by a combination of no-load loss (core loss), load loss (copper loss), total loss at 50%–100% load, and overall efficiency benchmarks. These are influenced by the transformer’s MVA rating, application (distribution or power), cooling method, and local energy regulations.

Selecting a transformer that meets or exceeds these standards ensures lower operating costs, regulatory compliance, and improved grid sustainability.

Transformer efficiency is not regulated and is up to the supplier.False

Efficiency and loss limits for transformers are governed by international standards and energy policies such as IEC 60076, DOE, and EU EcoDesign regulations.

🔋 Understanding Transformer Losses

| Loss Type | Occurs When? | Cause | Affected By |

|---|---|---|---|

| No-Load Loss (P₀) | Energized but no load connected | Magnetic hysteresis & eddy currents in core | Core material, flux density |

| Load Loss (Pᵏ) | When load current flows | I²R losses in windings | Conductor size, temperature |

| Stray Losses | Under load | Leakage flux-induced eddies | Design geometry, tank proximity |

| Dielectric Losses | Constant | Capacitive current and insulation | Minimal—important at HV only |

🧮 Efficiency Formula & Rating

- Efficiency (η) = Output Power / (Output Power + Total Losses)

- Measured at 50%–100% rated load, with 75 °C reference winding temperature

| Transformer Rating | Target Efficiency (50%–100% Load) |

|---|---|

| ≤2.5 MVA (Distribution) | 98.5–99.2% |

| 5–20 MVA (Substation) | 99.2–99.5% |

| >50 MVA (Power Level) | 99.5–99.7% |

📋 Key Global Standards & Their Loss Requirements

| Standard | Governs | Typical Application |

|---|---|---|

| IEC 60076-20 | Energy performance limits | Worldwide (Europe, Asia, Middle East) |

| DOE 10 CFR Part 431 | Minimum energy performance standards | USA only |

| EU EcoDesign Tier 2 | Enforced loss caps post 2021 | Europe, IEC countries |

| BIS IS 1180 | India transformer efficiency ratings | 11 kV/22 kV/33 kV class distribution |

📊 Typical Loss Benchmarks (11 kV Class Transformers)

| Rating (kVA) | No-Load Loss (W) | Load Loss at 75°C (W) | Max Total Loss (W) | Efficiency (@50% Load) |

|---|---|---|---|---|

| 500 kVA | ≤800 | ≤5,300 | ≤6,100 | ~98.9% |

| 1000 kVA | ≤1,100 | ≤8,100 | ≤9,200 | ~99.0% |

| 1600 kVA | ≤1,500 | ≤11,800 | ≤13,300 | ~99.1% |

| 2500 kVA | ≤2,000 | ≤16,000 | ≤18,000 | ~99.2% |

🛠️ Design Measures to Meet Efficiency Targets

| Strategy | Effect |

|---|---|

| Use CRGO core steel | Reduces hysteresis and eddy losses in core |

| Opt for larger conductor cross-section | Lowers winding resistance and copper losses |

| Design lower flux density | Reduces core saturation and magnetic losses |

| Use circular winding geometry | Minimizes leakage flux and hot spots |

| Employ active cooling (ONAF/OFAF) | Allows safe operation at high load with reduced losses |

💡 Transformer Efficiency vs Load Chart

| Load Level (% of Rated) | Efficiency (%) – Typical 5 MVA Unit |

|---|---|

| 25% | ~98.5% |

| 50% | ~99.0% |

| 75% | ~99.2% |

| 100% | ~99.3% |

Efficiency drops at low load due to fixed core losses dominating total loss profile.

🧠 How to Specify Efficiency in a Tender or RFP

| Specification Field | Entry Example |

|---|---|

| Rated Efficiency @ 75 °C | ≥99.2% @ full load |

| Max No-Load Loss | ≤1,200 W |

| Max Load Loss @ 75 °C | ≤7,800 W |

| Test Standard | IEC 60076-1 / DOE 10 CFR Part 431 |

| Load Factor for Evaluation | 0.7 or site-specific curve |

💬 Case Example

In a 33/11 kV substation in Europe, transformers rated at 1600 kVA were selected with a total loss of 12,800 W, yielding a 10-year energy savings of over \$85,000 compared to lower-efficiency models. The project met EU Tier 2 compliance and improved grid loading performance.

What Standards and Certifications Must the Transformer Comply With?

Power transformers must adhere to a rigorous framework of international, regional, and application-specific standards to ensure they are safe, reliable, efficient, and suitable for the grid or installation environment. These standards cover everything from design and performance to safety, testing, environmental compliance, and product certification.

Transformers must comply with global standards such as IEC 60076 (international), IEEE C57 (North America), ISO 9001/14001 (management), CE (Europe), BIS (India), UL (North America), and local grid codes. Certification ensures conformance in performance, safety, insulation coordination, loss limits, and environmental compatibility.

Failure to comply with these standards may result in customs rejection, refusal to energize by utilities, invalidated warranties, or non-qualification in competitive bids.

Transformers can be manufactured and installed without meeting any formal standards.False

Transformers must meet international and national electrical, safety, and quality standards to be eligible for procurement, installation, and energization.

📘 Primary International Standards

| Standard Group | Region of Influence | Scope Covered |

|---|---|---|

| IEC 60076 Series | Global (Europe, Asia, MENA) | Design, losses, insulation, testing, noise, eco-performance |

| IEEE C57 Series | USA, Canada, South America | Equivalent of IEC, adapted for North American grid behavior |

| ANSI C57 | USA | North American adoption of IEEE for testing and ratings |

| ISO 9001 / 14001 | Global | Quality management and environmental systems for manufacturing |

✅ Certification Marks & What They Mean

| Mark | Certification Body | Significance |

|---|---|---|

| CE | EU Conformity Assessment | Confirms safety, EMC, and environmental compliance for Europe |

| UL / cUL | Underwriters Laboratories | Safety certification for North America and Canada |

| BIS | Bureau of Indian Standards | Mandatory for transformers sold in India |

| EAC (Eurasian) | Russia, Belarus, Kazakhstan | Customs union product conformity |

| UKCA | United Kingdom | Post-Brexit UK compliance label |

🔧 Common IEC Standards in Transformer Projects

| IEC Standard | Title & Scope |

|---|---|

| IEC 60076-1 | General Requirements & Ratings |

| IEC 60076-2 | Temperature Rise |

| IEC 60076-3 | Insulation Levels and Dielectric Tests |

| IEC 60076-5 | Ability to Withstand Short Circuit |

| IEC 60076-7 | Loading Guide Based on Thermal Aging |

| IEC 60076-10 | Determination of Sound Level |

| IEC 60076-11 | Dry-Type Transformers |

| IEC 60076-20 | Energy Efficiency and EcoDesign Loss Limits |

🛠️ IEEE / ANSI Standards for North American Projects

| Standard Code | Title |

|---|---|

| IEEE C57.12.00 | General Requirements for Liquid-Immersed Transformers |

| IEEE C57.12.90 | Testing Procedures for Transformers |

| IEEE C57.91 | Loading Guide for Mineral-Oil Immersed Transformers |

| ANSI C57.12.01 | Dry-Type General-Purpose Transformers |

| IEEE C57.110 | Harmonic Load Guidelines |

📋 Compliance in Tender Specifications

| Tender Requirement | Example Compliance Entry |

|---|---|

| Applicable Standard | IEC 60076-1, 60076-3, 60076-5 |

| Test Certificate Reference | Type test per IEC 60076-3, FAT report attached |

| Quality System Certification | Manufacturer ISO 9001:2015, ISO 14001:2015 certified |

| CE Compliance | CE declaration attached, harmonized standards listed |

| BIS Number (India) | ISI mark and BIS license no. for distribution transformers |

🌍 Country-Specific Mandates

| Country/Region | Required Certifications |

|---|---|

| USA / Canada | UL Listed / cUL Recognized, IEEE-tested |

| Europe | CE Mark, EcoDesign Tier 2 (Post-2021) |

| India | BIS Certification for <2500 kVA transformers |

| Middle East (GCC) | IEC-compliant with DEWA/SEC/KAHRAMAA utility approval |

| Africa | SABS (South Africa), IEC/ISO conformance elsewhere |

💬 Engineer's Insight

“In one project, the transformer met IEC specs but lacked CE marking—this delayed EU site energization by three weeks. Now we require suppliers to deliver third-party CE declarations upfront.”

— Procurement Manager, European EPC

Conclusion

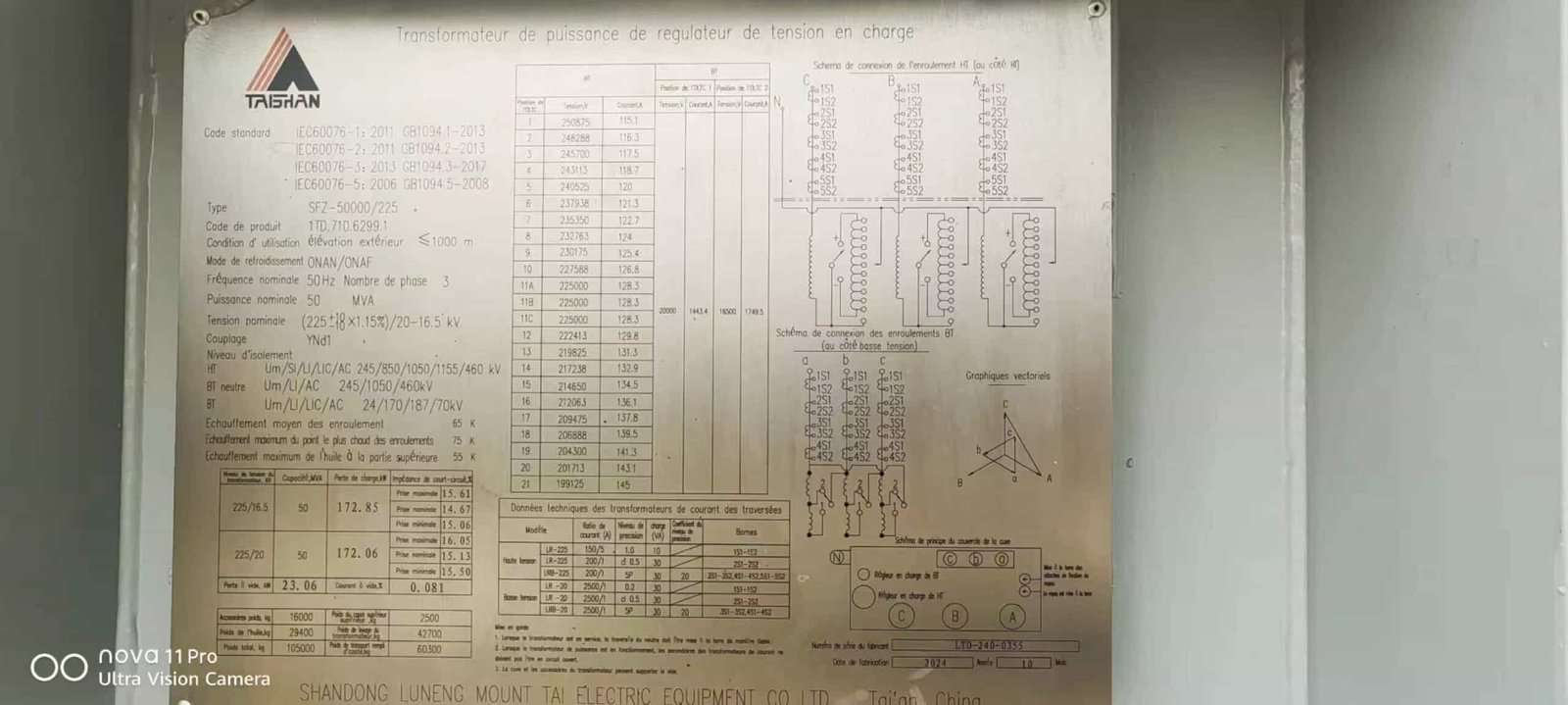

The selection of a power transformer is a multifaceted decision that balances electrical performance, site conditions, regulatory compliance, and economic feasibility. By thoroughly evaluating voltage needs, load profile, environmental conditions, and applicable standards, project stakeholders can choose a transformer that delivers long-term reliability and optimal performance. Partnering with an experienced manufacturer like Luneng Taishan Transformer ensures that each unit is customized to meet the exact demands of the project while maintaining the highest quality standards.

FAQ

Q1: What are the primary factors in selecting a power transformer?

A1: Key selection factors include:

Primary and secondary voltage ratings

Power capacity (kVA or MVA) based on load demand

Frequency (typically 50Hz or 60Hz)

Cooling method (ONAN, ONAF, dry-type, etc.)

Impedance and voltage regulation

Installation location (indoor/outdoor, altitude, temperature)

Compliance with standards (IEC, IEEE, ANSI)

Q2: How do voltage levels affect transformer selection?

A2: The transformer's voltage rating must match the supply and load system:

High-voltage side connects to the grid or generation source

Low-voltage side feeds the distribution or industrial load

Transformer windings, insulation, and bushing design are all impacted by voltage class.

Q3: Why is transformer capacity important?

A3: Transformer capacity (kVA/MVA) determines:

The maximum load it can handle continuously

Overload tolerance and future scalability

Undersized units may overheat, while oversized ones result in higher capital and no-load losses. Capacity should be calculated with load factor, diversity factor, and future growth in mind.

Q4: What role does cooling method play in transformer selection?

A4: The cooling system affects:

Heat dissipation efficiency

Installation environment suitability (e.g., indoor vs. outdoor)

Maintenance needs

Oil-immersed transformers (ONAN/ONAF) are common in high-power applications, while dry-type units are safer for confined or fire-prone areas.

Q5: What environmental and regulatory factors are considered?

A5: Selection must consider:

Ambient temperature and altitude (affects cooling and derating)

Seismic or marine environments (impact structural design)

Noise level restrictions

Local electrical codes and utility interconnection requirements

Also, transformer design should meet energy efficiency mandates like DOE, IEC Tier 2, or EU EcoDesign.

References

"Transformer Selection Guide" – https://www.electrical4u.com/how-to-choose-transformer

"IEEE: Guidelines for Transformer Sizing and Application" – https://ieeexplore.ieee.org/document/8237559

"Hitachi Energy: Transformer Selection Criteria" – https://www.hitachienergy.com/products/transformers/selection

"DOE Transformer Efficiency Standards" – https://www.energy.gov/eere/buildings/distribution-transformer-efficiency-standards

"PowerMag: Key Design Considerations for Transformer Projects" – https://www.powermag.com/transformer-design-criteria

"Energy Central: Factors That Influence Transformer Procurement" – https://www.energycentral.com/c/ee/transformer-selection-factors