As power systems evolve and electrical demand increases, existing transformers may no longer meet performance, efficiency, or capacity requirements. Upgrading transformers—rather than fully replacing them—can be a cost-effective way to improve system reliability, extend equipment life, and adapt to new grid conditions. This article explores the possibilities, methods, and considerations involved in transformer upgrades.

What Does It Mean to Upgrade a Transformer?

As power demands grow and systems modernize, relying on legacy transformers without reevaluation leads to major risks—overloads, efficiency losses, overheating, and regulatory non-compliance. A transformer designed for yesterday's needs may not support today’s grid complexity or future expansion. That's where transformer upgrades come in. But upgrading doesn't always mean replacing the whole unit—it's about improving capability, reliability, and lifespan through targeted interventions. This article breaks down what it really means to upgrade a transformer, the key methods involved, and when it’s the right choice.

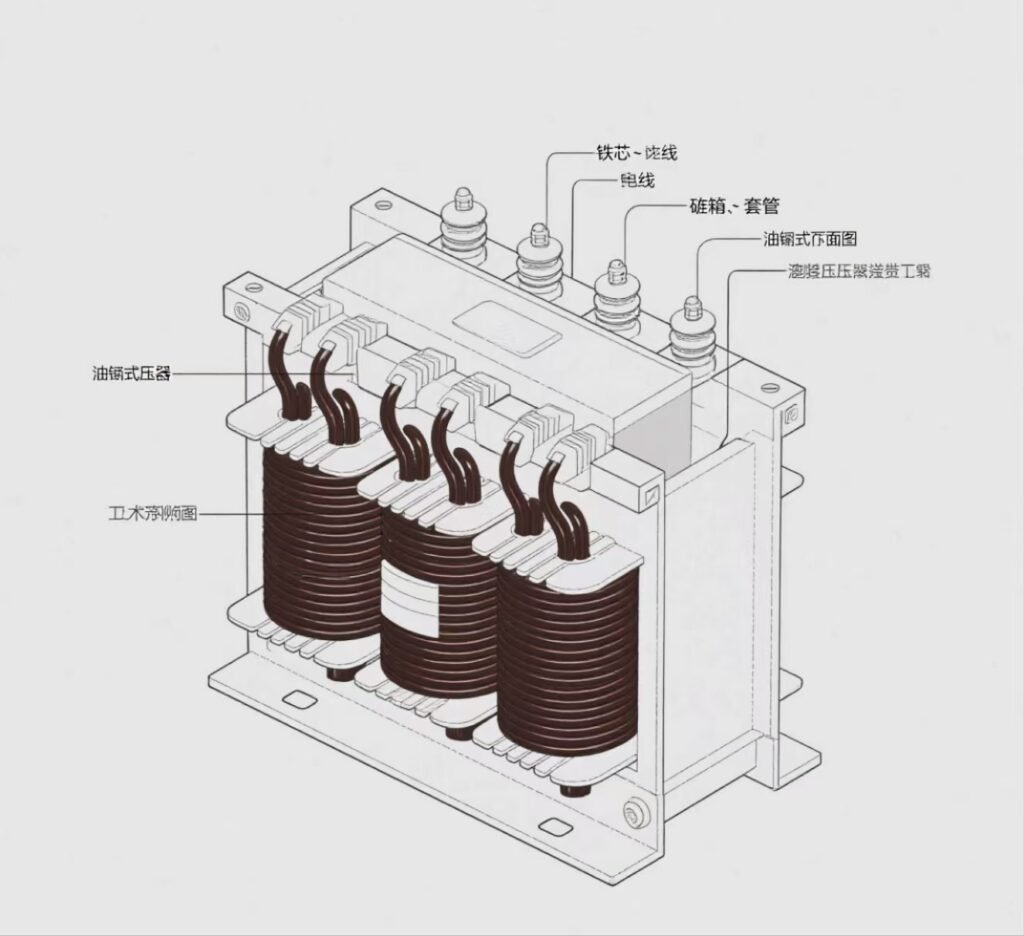

Upgrading a transformer refers to the process of enhancing its performance, capacity, safety, or monitoring capabilities through modifications such as increasing kVA rating, improving insulation, upgrading cooling systems, rewinding coils, retrofitting protection relays, or adding IoT-based condition monitoring. It is a cost-effective alternative to full replacement and ensures the transformer meets current and future operational demands.

Understanding upgrade options helps asset managers, engineers, and operators decide when to invest in enhancement versus total replacement—especially when facing rising energy demands or regulatory constraints.

Transformer upgrades always require complete replacement of the unit.False

Many upgrades can be performed without full replacement, such as coil rewinding, cooling enhancement, or protection relay retrofitting, which extend life and increase performance without new unit installation.

Why Upgrade a Transformer Instead of Replacing It?

| Reason for Upgrade | Benefit |

|---|---|

| Capacity Mismatch | Boost kVA/MVA rating to meet increased load |

| Thermal Overload Issues | Improve cooling system or derate rise class |

| Efficiency Improvements | Reduce load losses with better winding material or core steel |

| Monitoring Deficiency | Add sensors for temperature, gas analysis, partial discharge detection |

| Protection Gaps | Install advanced relays and circuit breakers for fault detection |

| Environmental Compliance | Replace mineral oil with eco-friendly esters, reduce noise emissions |

| Aging Components | Rewind coils, replace insulation, and extend operational life |

Upgrading allows continued use of existing infrastructure (like housing, cable runs, and foundations), saving costs while delivering performance gains.

Types of Transformer Upgrades

1. Power Capacity Upgrade (KVA/MVA Enhancement)

- Method: Rewind coils with heavier gauge conductor; increase core cross-section if feasible.

- Result: 10–30% higher output rating.

- Application: Where load growth has outpaced transformer’s original design.

| Pre-Upgrade Rating | Post-Upgrade Rating | Method Applied |

|---|---|---|

| 1,000 kVA | 1,300 kVA | Rewound with larger conductor |

| 2 MVA | 2.4 MVA | Core steel optimization |

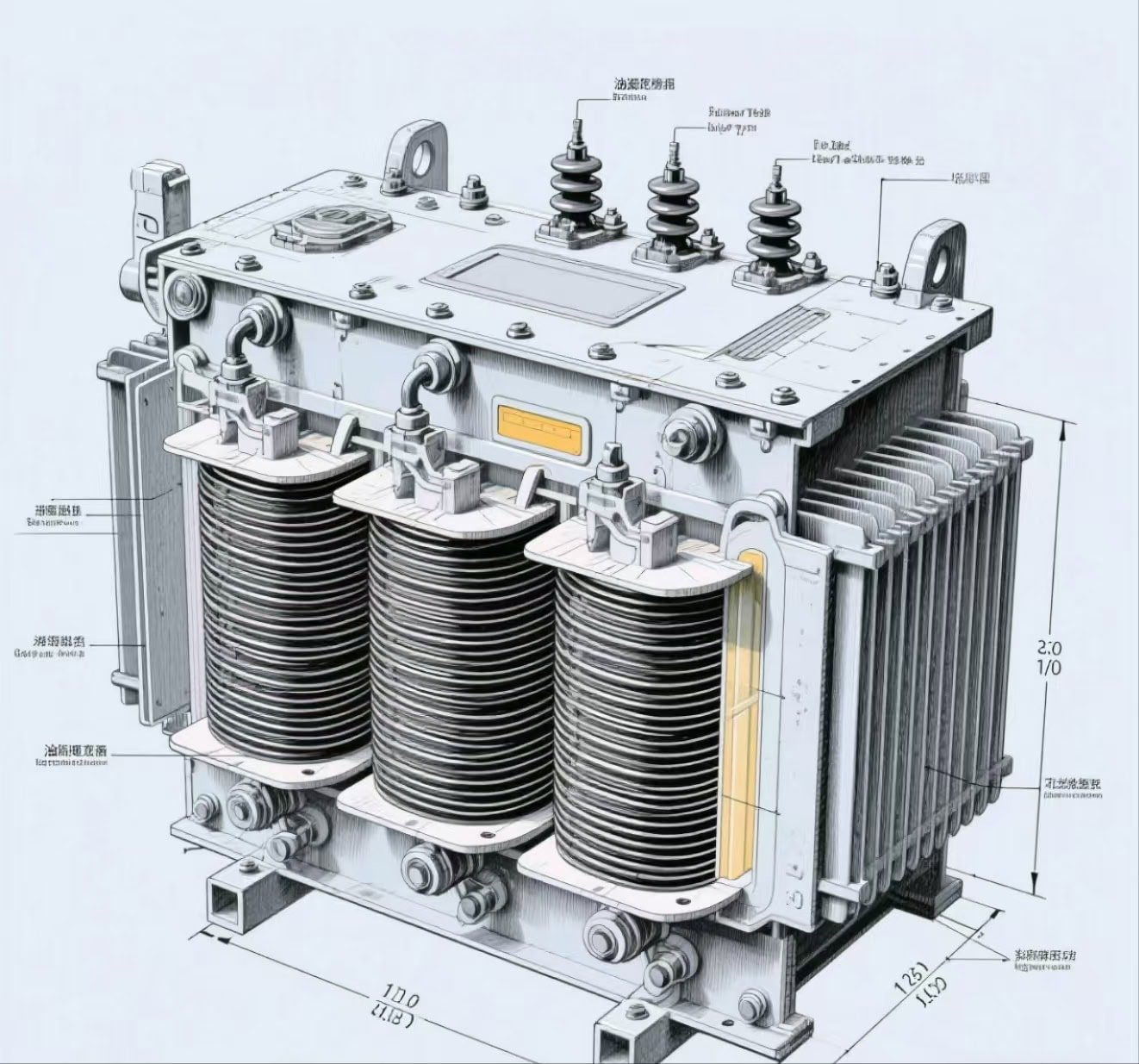

2. Cooling System Upgrades

Types:

- Add or replace cooling fans (ONAN to ONAF).

- Install oil pumps for forced circulation (OFAF).

- Introduce dry-type air blowers (AF).

- Benefit: Reduces temperature rise → enables load increase.

- Monitoring Add-on: Oil temperature gauges, WTI, fan control logic.

Adding forced cooling to a transformer can allow a higher loading capacity without rewinding.True

Improved cooling reduces thermal stress, allowing transformers to carry more current while staying within temperature limits.

3. Insulation and Rewinding Upgrade

- Purpose: Restore dielectric strength and reduce risk of flashover or breakdown.

Actions:

- Replace aged insulation with higher-temperature class materials (e.g., Class F to H).

- Rewind primary/secondary coils with new copper or aluminum.

- Vacuum pressure impregnation for dry types.

Rewinding Benefits:

| Before Upgrade | After Upgrade |

|---|---|

| Insulation Class B | Insulation Class F or H |

| Old varnish coating | Modern epoxy resin or Nomex-based layering |

| Degraded copper | High-conductivity copper windings |

4. Protection and Safety Retrofit

Components to Upgrade:

- Overcurrent and differential relays

- Buchholz relay and PRD (oil-filled)

- Temperature alarms and auto-trip logic

- Arc flash mitigation kits

Digital Integration:

- Connect relays to SCADA/PLC

- Add alarm annunciators

- Install trip interlocks for fire suppression systems

Sample Protection Retrofit Diagram:

| Device | Function |

|---|---|

| 87T Differential Relay | Detects winding faults |

| 49 Thermal Relay | Trips on excessive winding temp |

| 63 Buchholz Relay | Trips on gas formation in oil |

| IoT RTD Sensors | Provides real-time thermal data |

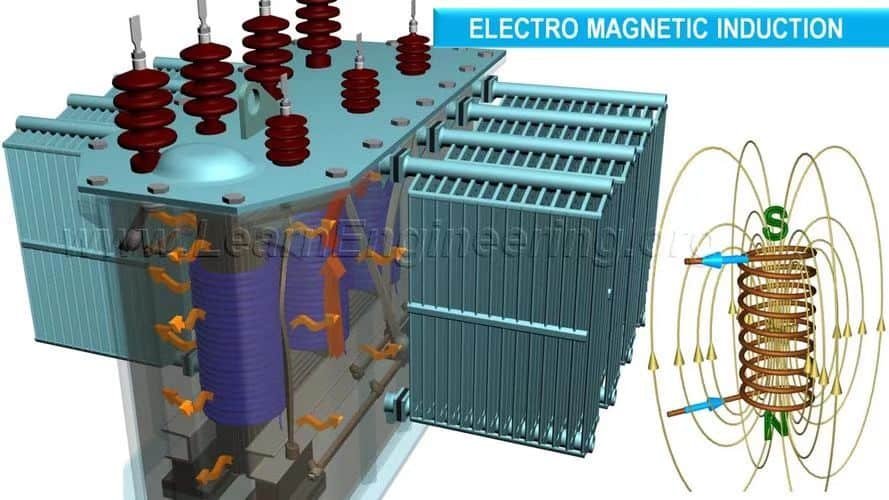

5. Smart Monitoring Integration

Transformers upgraded with digital sensors and monitoring platforms transition into smart assets capable of predictive maintenance.

| Feature | Function |

|---|---|

| DGA Monitor | Detects arcing, overheating, and incipient faults |

| Partial Discharge Sensor | Identifies insulation degradation early |

| Online RTD Sensors | Track hot-spot temperatures continuously |

| IoT Gateway & Analytics | Sends data to cloud for remote monitoring |

SCADA-Compatible Upgrades:

- Add Modbus/IEC 61850 gateways

- Integrate alarms and thermal data into existing dashboards

When Should You Consider Upgrading a Transformer?

| Condition | Recommendation |

|---|---|

| Load has increased by >10% | Upgrade to handle additional capacity |

| Unit is 15–25 years old | Evaluate rewinding, insulation replacement |

| Excessive thermal alarms | Add or upgrade cooling system |

| Protection trips too often | Modernize relay and protection systems |

| Regulatory compliance failed | Retrofit to meet new fire/environmental standards |

| No digital monitoring in place | Install smart sensors and alert systems |

A transformer with stable temperature and load never requires upgrading.False

Even if load and temperature appear stable, insulation ages, regulations change, and better efficiency becomes viable through upgrades. Preventive upgrades increase reliability and system readiness.

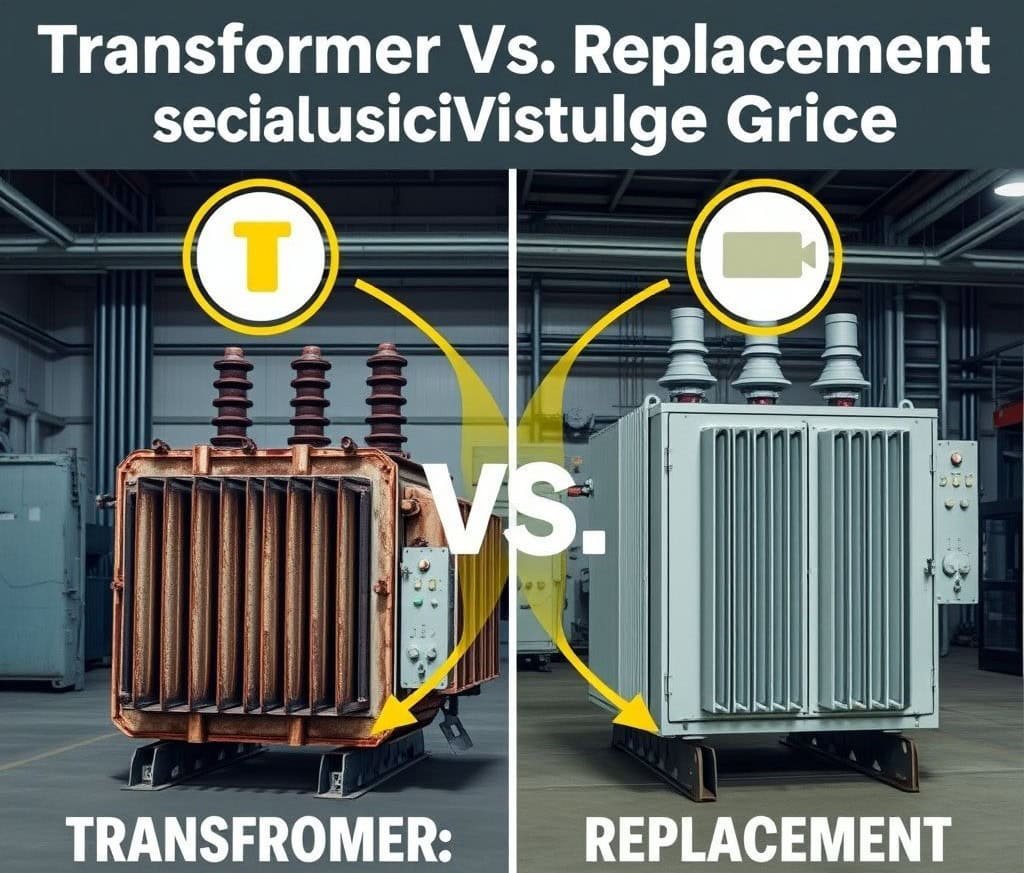

Upgrade vs. Replace: Cost and ROI Comparison

| Action | Typical Cost (USD) | Downtime | Asset Life Extension | ROI Period |

|---|---|---|---|---|

| Full Replacement | \$25,000–\$200,000+ | 1–2 weeks | 25–35 years | 10+ years |

| Coil Rewinding | \$7,000–\$35,000 | 5–10 days | 10–15 years | 3–5 years |

| Cooling System Add-on | \$3,000–\$12,000 | 1–2 days | +20–30% capacity | 2–3 years |

| Smart Sensor Upgrade | \$2,500–\$10,000 | <1 day (retrofit) | Enhanced diagnostics | Immediate |

Which Components Can Be Upgraded in a Transformer?

As transformers age or operate under increasing loads, upgrading individual components becomes a practical alternative to full replacement. However, many operators and engineers don’t realize just how many internal and external transformer components can be upgraded to improve performance, reliability, efficiency, or digital monitoring capability. Whether you’re looking to increase power rating, extend service life, or enhance safety, a component-specific upgrade strategy delivers significant value. This article details which transformer components are upgradeable, how upgrades are implemented, and what benefits each upgrade brings.

Upgradable transformer components include windings, insulation systems, cooling assemblies, bushings, tap changers, protection relays, digital sensors, control panels, conservators, and monitoring systems. These upgrades improve power handling, thermal stability, fault detection, and asset management, often with minimal downtime and without full transformer replacement.

Upgrades are highly customizable and scalable, allowing asset managers to target only the components that need improvement. Let’s explore the key upgradeable components, their functions, and technical upgrade options.

All transformer components are fixed at the time of manufacture and cannot be upgraded later.False

Many transformer components—including windings, cooling systems, relays, and monitoring units—are modular and can be upgraded or replaced during maintenance without full unit replacement.

List of Key Upgradeable Transformer Components

| Component Category | Specific Components That Can Be Upgraded |

|---|---|

| Electrical Core/Winding | HV/LV Windings, Insulation System, Magnetic Core (limited) |

| Cooling System | Fans, Oil Pumps, Radiators, Dry Air Blowers |

| Protection & Control | Relays, Breakers, Trip Logic, Buchholz Relay, Pressure Relief Devices |

| Tap Changing System | On-load and Off-load Tap Changers, Drive Motors, Control Interfaces |

| Monitoring Instruments | Temperature Sensors, Oil Level Gauges, Gas Detectors, SCADA Gateways |

| External Accessories | Bushings, Cable Boxes, Conservator Tank, Breather Units |

1. HV and LV Windings

What Can Be Upgraded?

- Rewinding with heavier conductors for higher current capacity

- Replacing degraded insulation (e.g., paper to Nomex, varnish to epoxy)

- Upgrading insulation class from Class B to F or H

Benefits:

- Increased power rating (10–30%)

- Reduced hot-spot temperatures

- Extended service life by 10–15 years

| Pre-Upgrade | Post-Upgrade |

|---|---|

| Copper with Class B ins. | Copper with Class F + VPI varnish |

| Paper insulation | Epoxy or resin-bonded laminate |

2. Cooling Assembly

Upgradeable Parts:

| Component | Upgrade Option |

|---|---|

| Cooling Fans | Add or replace with higher-capacity units (AF/ONAF) |

| Oil Pumps (OFAF) | Install for forced circulation in large units |

| Radiator Modules | Add fin surface area or replace clogged fins |

| Dry Air Blowers | Improve cooling in dry-type units |

| Automatic Controls | Install programmable fan logic and thermal feedback |

Benefits:

- Enhanced thermal management

- Higher load capacity without overheating

- Optimized energy usage with automatic control logic

Cooling fans on transformers can only be installed during manufacturing.False

Cooling fans can be added later as retrofit upgrades to oil-filled or dry-type transformers to increase thermal performance and allow higher loading.

3. Protection and Relay Systems

Replace or Add:

- Modern microprocessor-based relays (replace electromechanical types)

- Differential protection relays (87T) for internal faults

- Overcurrent relays with thermal memory

- Surge protection devices and lightning arrestors

- Buchholz relay and pressure relief device (for oil-filled units)

Benefits:

- Improved fault detection and trip accuracy

- Integration with SCADA or automation systems

- Increased operator safety and faster fault isolation

| Old Device | Upgrade Option |

|---|---|

| Electromechanical OCR | Digital OCR with time-delay and event logging |

| No internal fault protection | Add 87T relay and gas detection logic |

4. Tap Changer Assembly

Upgrade Paths:

- Replace manual tap changers with on-load tap changers (OLTC)

- Upgrade drive motor, gear mechanism, and selector switch

- Install electronic tap changer controllers with digital HMI

Benefits:

- Remote voltage regulation

- Load balancing without shutdown

- Reduced arcing and improved contact life

| Tap Range Before | Tap Range After |

|---|---|

| ±2 steps manual | ±9 steps automatic with feedback |

| No controller | Touchscreen tap position control |

5. Monitoring and Smart Systems

Add or Retrofit:

- Winding temperature indicators (WTI)

- Top oil temperature gauges

- Dissolved Gas Analysis (DGA) units

- Partial discharge monitors

- IoT gateways (Modbus, IEC 61850)

- SCADA-compatible data loggers and alarms

Benefits:

- Enables predictive maintenance

- Detects early signs of insulation failure or arcing

- Real-time asset health tracking

Adding modern monitoring sensors can reduce transformer failure rates.True

Real-time condition monitoring helps detect thermal, electrical, and dielectric stress early, allowing timely maintenance and fault prevention.

6. External Hardware & Accessories

Upgrade Options:

| Part | Upgrade Description |

|---|---|

| Bushings (HV/LV) | Replace cracked or outdated porcelain with composite |

| Conservator Tank | Retrofit with bladder-type tank for oil-air separation |

| Breather Unit | Install self-regenerating silica gel or oil seal type |

| Terminal Boxes | Replace or expand for new cable sizes or insulation |

| Labels and Nameplates | Update for compliance and traceability |

Benefits:

- Enhanced mechanical reliability

- Reduced oil contamination from moisture

- Better integration with modern cable and safety standards

Case Study Snapshot: Industrial Transformer Upgrade

| Upgrade Area | Action Taken | Result |

|---|---|---|

| Windings & Insulation | Rewound with Class H epoxy-coated copper | Rating increased from 1.6 to 2 MVA |

| Cooling System | Added 4 axial fans, temp-based ONAF logic | Load rise by 25% without overheating |

| Protection Relay | Installed 87T differential and WTI alarms | Improved fault detection and trip time |

| Monitoring | Online DGA and RTD system added | Enabled predictive maintenance |

| Tap Changer | Upgraded to motor-driven OLTC | Enabled real-time voltage adjustment |

What Are the Benefits and Limitations of Upgrading a Transformer?

Many organizations are drawn to transformer upgrades as a cost-saving alternative to full replacement—but upgrades are not a one-size-fits-all solution. When done correctly, upgrading can extend a transformer's life, enhance its performance, and reduce long-term risk. But when misunderstood or poorly planned, it may fail to deliver ROI, especially for units near end-of-life. Therefore, it’s crucial to understand both the advantages and limitations of transformer upgrading before deciding on the right course of action.

Upgrading a transformer offers benefits such as extended service life, improved capacity, enhanced monitoring, and lower cost compared to replacement. However, limitations include physical design constraints, age-related material fatigue, thermal derating, and diminishing returns on severely aged units. A technical and economic evaluation must be conducted to ensure the upgrade justifies the investment.

Whether you're considering a winding replacement, smart monitoring integration, or a full thermal management retrofit, knowing the trade-offs will help you make the best decision for performance, safety, and budget.

Transformer upgrades always result in the same performance as a new unit.False

While upgrades can significantly enhance functionality, they may not restore a transformer to ‘as-new’ condition due to core aging and insulation wear that cannot be fully reversed.

Key Benefits of Transformer Upgrading

1. Extended Operational Life

- Upgrade Actions: Rewinding, insulation replacement, bushing upgrades

- Result: Adds 10–20 years of operational life, depending on condition

- Use Case: Industrial or utility-grade transformers over 10 years old but structurally sound

| Component Upgraded | Life Extension Estimate |

|---|---|

| Windings | 10–15 years |

| Insulation System | 8–12 years |

| Cooling Enhancement | 5–10 years |

2. Cost Savings Compared to Replacement

- Upgrading typically costs 30–60% less than new transformer installation

Avoids:

- Site demolition or structural retrofit

- Permits and regulatory delays

- Downtime due to long lead times for new units

| Scenario | Replacement Cost | Upgrade Cost (Est.) | Savings |

|---|---|---|---|

| 1 MVA oil-filled unit | $50,000 | $22,000–$28,000 | ~45% |

| 2.5 MVA dry-type | $85,000 | $35,000–$48,000 | ~50–60% |

Transformer upgrades are typically more cost-effective than full replacement, especially for mid-life units.True

For transformers that are mechanically sound and not nearing end-of-life, targeted upgrades can restore performance at a fraction of the cost of a new unit.

3. Improved Performance and Load Handling

Common Enhancements:

- Cooling fans or pumps (ONAN → ONAF)

- Larger conductor windings for increased current

- Tap changer automation

Effect: 10–30% more load capacity without overheating

| Feature | Before Upgrade | After Upgrade |

|---|---|---|

| Load Handling (kVA) | 1,000 kVA | 1,200–1,300 kVA |

| Cooling Class | ONAN | ONAF or OFAF |

| Tap Changing | Manual | Automatic (OLTC) |

4. Enhanced Monitoring and Predictive Maintenance

Upgrades enable digital transformation of legacy units

Add IoT sensors for:

- Winding temperature

- Dissolved gas analysis (DGA)

- Partial discharge

- Load profiling

Integrates with SCADA or cloud dashboards

| Monitoring Parameter | Added Sensor | Benefit |

|---|---|---|

| Oil/Gas Formation | Online DGA Monitor | Detect incipient faults early |

| Hot Spot Detection | Fiber optic RTDs | Prevent thermal overload |

| Overload Trends | Digital ammeters + loggers | Optimize energy usage |

5. Environmental and Regulatory Compliance

- Switch to biodegradable oil (natural ester) to meet eco-standards

- Reduce fire risk in indoor or marine settings with dry-type conversion

- Noise abatement via enclosure redesign or silent fan upgrades

Upgraded transformers can help meet updated environmental or fire safety codes.True

Upgrading insulation materials, switching to eco-friendly oil, or using dry-type replacements enhances safety and ensures compliance with modern standards.

Limitations of Transformer Upgrades

1. Core and Structural Constraints

- Transformer cores are not usually replaced during upgrades

Aged cores may:

- Increase no-load losses

- Limit capacity boost

- Generate more heat or noise

| Core Age | Limitation |

|---|---|

| >25 years | Higher iron loss, audible hum |

| Laminated steel | May not support higher flux density |

| Rigid frame design | Restricts space for larger windings |

2. Thermal and Insulation Derating

- Repeated thermal cycles cause insulation aging

- Upgrading windings doesn’t always restore original dielectric strength

- Dry-type units in humid environments may not regain full rating even after insulation replacement

| Original Temp Class | Current Capability After Upgrade |

|---|---|

| Class H (180°C) | Often derated to Class F or B |

| Class F (155°C) | May retain rating if core is intact |

3. Diminishing ROI for End-of-Life Units

If core and tank show signs of:

- Corrosion

- Gas formation

- Frequent tripping

- Internal arcing

…it may be more cost-effective to replace than to upgrade

| Transformer Condition | Upgrade Worth It? | Recommendation |

|---|---|---|

| Mid-life, minor faults | ✅ Yes | Proceed with modular upgrades |

| Aging, multi-fault record | ❌ No | Plan for new unit replacement |

A transformer with internal arcing and gas formation is a good candidate for upgrading.False

Such units often suffer from irreversible core damage or insulation breakdown, making replacement a safer and more economical choice.

4. Logistical and Downtime Constraints

Rewinding and structural upgrades require:

- Factory handling or on-site disassembly

- 3–15 days of system downtime

- In critical power systems, bypass transformers or gensets must be arranged

| Upgrade Type | Typical Downtime |

|---|---|

| Digital monitoring | <1 day (hot-swap) |

| Coil rewinding | 5–10 days |

| Core optimization | Not typically feasible |

| Cooling system add-on | 1–2 days |

5. Warranty & Standardization Gaps

- Upgraded transformers may lose their original OEM warranty

Mixing old and new components can create standard compliance gaps

- Example: IEC 60076-22 requires full type testing for major modifications

- Custom upgrades may not match nameplate unless re-certified

Summary Comparison: Benefits vs. Limitations

| Aspect | Benefits | Limitations |

|---|---|---|

| Cost Efficiency | 30–60% cheaper than replacement | May not justify cost on heavily aged units |

| Performance Boost | Up to 30% more capacity | Capped by core limits and insulation aging |

| Lifecycle Extension | Adds 10–20 years of useful life | Not always possible beyond 30+ years |

| Downtime | Faster than replacement | Still requires shutdown for coil upgrades |

| Monitoring & Compliance | Enables smart features, meets new standards | May need re-certification for major changes |

When Is It Better to Upgrade vs. Replace a Transformer?

Deciding whether to upgrade or replace a transformer is a critical choice with direct impacts on safety, performance, cost, and downtime. Many organizations struggle with this decision, especially when budgets are tight and downtime is unacceptable. Delaying a necessary replacement can lead to catastrophic failures, while replacing a transformer that could be cost-effectively upgraded wastes capital and resources. To avoid both extremes, this guide provides a clear, engineering-based approach to determine when to upgrade and when full replacement is the smarter option.

Upgrading is better when the transformer’s core and structure are intact, faults are manageable, and performance gaps can be fixed with modular enhancements. Replacement is better when insulation has deteriorated beyond repair, core losses are high, or repeated failures indicate end-of-life. The decision must weigh asset age, load growth, risk, downtime tolerance, and long-term ROI.

Knowing when to stop maintaining and start replacing is the hallmark of strategic asset management. This article outlines the technical, financial, and operational considerations that define the right decision.

Transformer upgrades are always more cost-effective than replacements.False

While upgrades often save costs for mid-life transformers, replacement may be more economical and reliable when core aging, dielectric degradation, or repeated failures are present.

Quick Decision Table: Upgrade or Replace?

| Condition | Upgrade | Replace |

|---|---|---|

| Age < 20 years, no major failures | ✅ Yes | |

| Insulation or winding degradation present | ✅ Possible | ❌ Only if minor |

| Frequent trips, gas formation, or internal arcing | ✅ Yes | |

| Load increase < 25% needed | ✅ Yes | |

| Load increase > 40% needed | ❌ Limited | ✅ Yes |

| Core losses high or audible hum increasing | ✅ Yes | |

| Requires IoT/digital monitoring | ✅ Yes | |

| Fire safety upgrade required | ✅ Yes | |

| Asset age > 30 years, no core upgrade possible | ✅ Yes | |

| Budget limits full replacement | ✅ Yes | ❌ Delayed |

When to Upgrade a Transformer

1. Transformer Core Is Structurally Sound

- No significant rust, noise, or lamination degradation

- No repeated Buchholz trips or internal fault records

- Magnetic flux density still within design limits

✅ Upgrade insulation, windings, cooling, or monitoring

2. Load Growth Is Moderate and Predictable

- Existing transformer is overloaded by 10–25%

- You need time to phase in full capacity

- You can temporarily derate load and rely on fan/pump upgrades

✅ Add cooling (ONAN → ONAF), rewind for higher current, automate tap changers

3. You Need Enhanced Monitoring or Compliance

- Want to integrate with SCADA or cloud monitoring

- Require DGA sensors, PD detection, or RTDs

- Complying with fire code via dry-type conversion

✅ Install smart sensors, modern relays, new bushings, or flameproof enclosures

Transformer upgrades can help meet fire and environmental safety standards.True

By upgrading to dry-type transformers, retrofitting fire-rated enclosures, or using eco-friendly ester oils, transformers can comply with updated codes.

4. Budget Is Tight and Downtime Must Be Minimized

- Upgrade can be completed in 2–10 days

- Transformer base, cabling, and civil works remain intact

- Limited funding restricts purchase of new equipment

✅ Choose modular upgrades with minimal disruption

When to Replace a Transformer

1. Repeated Internal Faults or Arcing Detected

- Gassing events (confirmed by DGA)

- Faulted insulation causing carbon tracking

- Flashovers, excessive vibration, or abnormal noise

❌ Upgrading becomes risky and unreliable

✅ Install new unit with modern core, insulation, and protection

2. Asset Age Exceeds 25–30 Years with High Wear

- Core steel aging leads to higher no-load loss

- Oil contamination beyond purification (sludging, acidity)

- Thermal degradation of insulation irreversible

🛑 Upgrading windings won’t resolve core inefficiency

✅ New transformer provides full lifecycle ROI and warranty

3. Transformer Capacity Is Too Low for Future Demand

- Load projections exceed 30–40% of nameplate rating

- Upgrades cannot accommodate higher voltages/currents

- Existing frame or core is too small to accept larger coils

✅ Select a new transformer sized for future scalability

4. Compliance Cannot Be Achieved by Upgrade Alone

- National grid codes require full type-tested units

- Short-circuit withstand capacity must be increased

- Arc-flash mitigation requires full redesign

✅ Replace to meet safety, performance, and regulatory needs

Transformer replacements are required when insulation life, core integrity, and cooling systems have all deteriorated beyond recovery.True

When the three major subsystems—electrical (insulation), magnetic (core), and thermal (cooling)—are degraded, replacing the transformer ensures safety and performance.

Technical Comparison: Upgrade vs Replace

| Parameter | Upgrade | Replace |

|---|---|---|

| Cost | 30–60% of new transformer | 100% + installation + permits |

| Lead Time | 5–15 days (modular) | 3–6 months (custom units) |

| Downtime | 1–10 days | 5–14 days |

| Asset Life Extension | 10–20 years | 25–35 years |

| Risk Mitigation | Moderate (if core is aged) | High (reset to factory standard) |

| Monitoring/Automation | Easily added | Fully built-in |

| Warranty | None unless re-certified | Full OEM warranty |

| ROI Payback Time | 1–3 years (depending on scope) | 6–10 years (long-term asset) |

Example Scenarios

✅ UPGRADE:

- A 1.5 MVA dry-type transformer, 12 years old, operating at 85% load with no internal faults, is upgraded with Class H insulation, cooling fans, and RTD sensors to support an expected 15% load increase over 5 years.

✅ REPLACE:

- A 20 MVA oil-filled unit from 1992 with sludged oil, repeated Buchholz trips, and elevated hydrogen in DGA, is replaced with a modern ester-oil unit with integrated SCADA and arc-flash shielding.

Conclusion

Yes, transformers can be upgraded—especially when the goal is to extend service life, improve efficiency, or meet evolving operational demands without the high cost of full replacement. By selectively upgrading components like cooling systems, tap changers, or protection devices, utilities and industries can enhance performance while minimizing disruption and investment. A thorough condition assessment is essential to determine whether an upgrade or a full replacement is the best path forward.

FAQ

Q1: Can existing transformers be upgraded instead of replaced?

A1: Yes, many transformers can be upgraded or retrofitted to enhance performance, extend service life, and meet modern standards—without full replacement. Common upgrades include:

Cooling system improvements

On-load tap changer (OLTC) modernization

Insulation upgrades

Digital monitoring system integration

This is especially viable when the core and tank are structurally sound, and budget or downtime constraints exist.

Q2: What are typical transformer upgrade options?

A2: Upgrades can include:

Retrofitting with smart sensors and IoT monitoring systems

Replacing old bushings with higher-rated or composite models

Upgrading cooling systems (e.g., from ONAN to ONAF)

Installing modern OLTCs or motor-drive units

Rewinding coils with better conductor or insulation materials

Each option aims to enhance reliability, energy efficiency, and grid compatibility.

Q3: What are the benefits of upgrading a transformer?

A3: Benefits include:

Extended service life (by 10–20 years in some cases)

Improved energy efficiency through reduced losses

Better voltage regulation and load handling

Compliance with newer safety or environmental standards

Avoidance of costly replacements and long lead times

Upgrades are particularly beneficial in aging grids or industrial facilities.

Q4: How do you assess whether a transformer is a good candidate for upgrade?

A4: Before upgrading, conduct a comprehensive condition assessment:

Dissolved Gas Analysis (DGA)

Insulation resistance and winding resistance tests

Thermal imaging and partial discharge scans

Mechanical integrity check (core, tank, supports)

If the structure is solid and core losses are acceptable, an upgrade is often a cost-effective alternative to replacement.

Q5: Are there standards or guidelines for transformer upgrades?

A5: Yes, upgrades must follow applicable standards such as:

IEEE C57.140 – Guide for Evaluation and Reconditioning of Liquid-Immersed Transformers

IEC 60076-7 – Loading Guide for Oil-Immersed Power Transformers

OEM-specific retrofit guidelines

Additionally, utility and grid operator specifications may define upgrade scope, especially for critical infrastructure.

References

IEEE C57.140-2006: Transformer Life Extension Guide

https://standards.ieee.org/standard/C57_140-2006.html

Electrical4U: Transformer Upgrades and Retrofits

https://www.electrical4u.com/retrofitting-transformers/

Doble Engineering: Asset Life Extension Planning

https://www.doble.com/solutions/transformer-upgrade-and-modernization/

ScienceDirect: Cost-Benefit Analysis of Transformer Retrofits

https://www.sciencedirect.com/science/article/pii/S235248471930115X

NREL: Strategies for Transformer Life Extension

https://www.nrel.gov/docs/fy21osti/transformer-upgrade-strategies.pdf