Dry type transformers are widely used in modern power distribution systems where safety, reliability, and eco-friendliness are essential. Unlike oil-immersed transformers, they rely on air for cooling and insulation. The cooling method plays a critical role in their performance, and the two most common classifications are AN (Air Natural) and AF (Air Forced). Understanding the difference between AN and AF cooling helps engineers, operators, and buyers choose the right transformer for their specific application.

What Is a Dry Type Transformer?

Transformers are critical to reliable power distribution, but not all environments are suitable for oil-filled units due to fire risk, leakage concerns, or maintenance demands. In commercial buildings, underground facilities, and sensitive installations, these risks can lead to safety hazards, regulatory complications, and costly downtime. To address these challenges, dry type transformers offer a safe, efficient, and low-maintenance alternative, making them the preferred solution where fire safety and environmental protection are priorities.

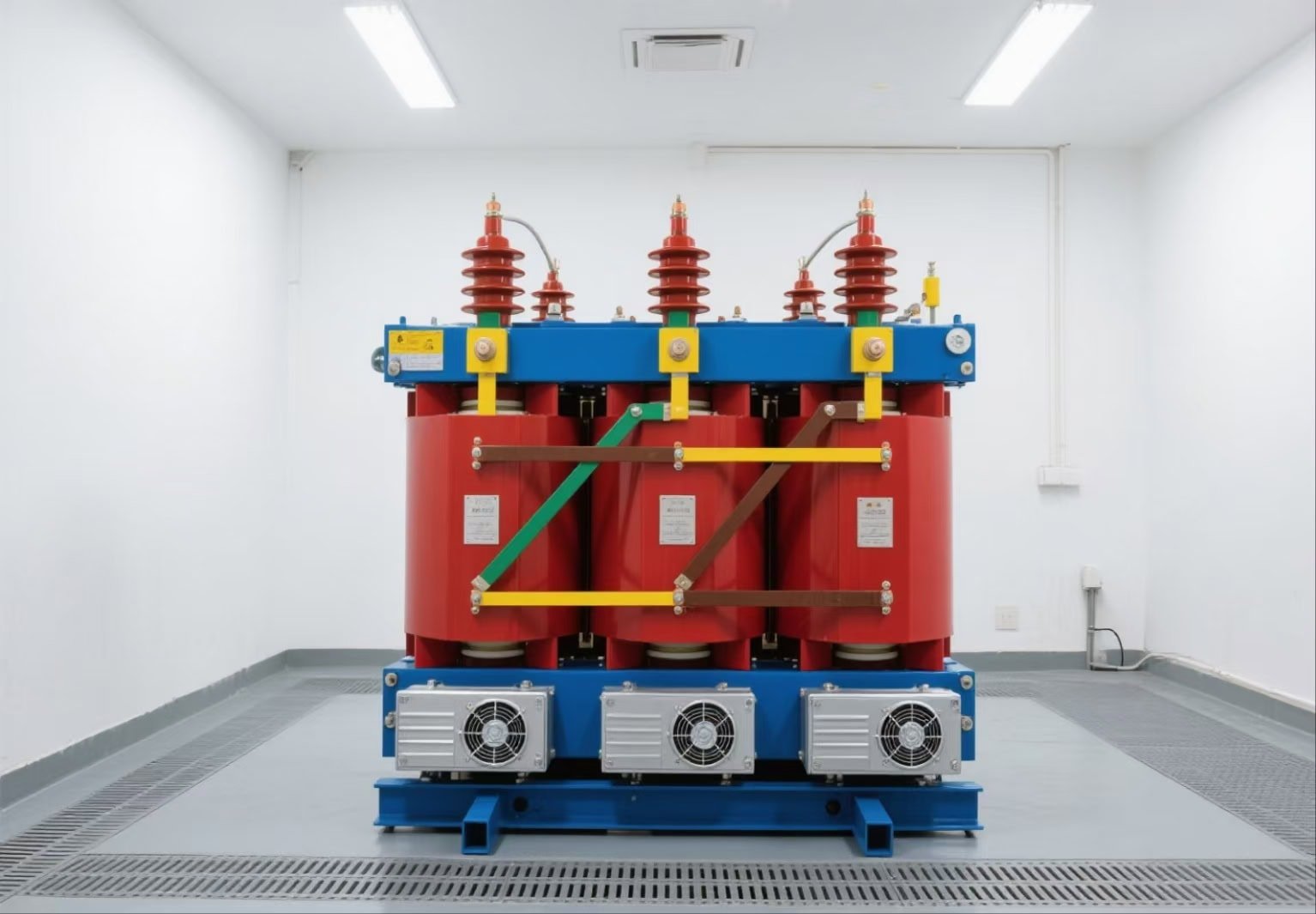

A dry type transformer is a transformer that uses solid insulation and air for cooling instead of liquid insulating oil. Its windings are typically cast in epoxy resin or varnish, making it fire-resistant, environmentally safe, and suitable for indoor or confined-space applications.

Dry type transformers use oil for insulation and cooling.False

Unlike oil-immersed transformers, dry type units rely on solid insulation systems (epoxy, varnish) and air cooling, eliminating oil completely.

Construction Features

Dry type transformers differ from oil-filled types in design and insulation:

- Core and Windings – Copper or aluminum windings are insulated with varnish or epoxy resin.

- Insulation System – Either Vacuum Pressure Impregnated (VPI) varnish or Cast Resin epoxy.

- Cooling Medium – Ambient air, sometimes forced with fans.

- Enclosure Options – Open, ventilated, or fully enclosed for dust/moisture protection.

| Type | Insulation Method | Cooling | Application |

|---|---|---|---|

| VPI (Vacuum Pressure Impregnated) | Polyester/epoxy varnish | Natural/forced air | General-purpose indoors |

| Cast Resin | Epoxy resin cast coils | Natural/forced air | Harsh or high-moisture environments |

Key Advantages

- Fire Safety – No oil means minimal fire/explosion risk.

- Low Maintenance – No oil monitoring, testing, or disposal needed.

- Environmentally Friendly – No risk of oil leakage or PCB contamination.

- Indoor Suitability – Compact, safe, and often compliant with building codes.

- Durability – Resistant to moisture, chemicals, and mechanical stress.

Limitations

- Higher Initial Cost – More expensive than oil-immersed units of the same rating.

- Lower Capacity Range – Typically used up to 20–30 MVA, not for very large power stations.

- Ventilation Needs – Must have good airflow for cooling.

- Noise – Can be noisier than oil-filled counterparts.

Applications

- Commercial buildings and high-rises

- Underground substations and tunnels

- Hospitals, schools, and public infrastructure

- Data centers and IT facilities

- Offshore and marine environments (with special enclosures)

- Renewable energy plants (solar/wind inverters, distribution)

Understanding Cooling Methods in Dry Type Transformers

Transformers generate heat during operation, and without proper cooling, this heat can degrade insulation, shorten service life, or even cause failures. In oil-immersed transformers, oil acts as both an insulator and coolant. However, in dry type transformers, cooling relies entirely on air circulation and solid insulation, making it critical to understand the available cooling methods. Choosing the right system ensures longer lifespan, safer operation, and compliance with performance standards.

Dry type transformer cooling methods refer to the techniques used to dissipate heat from the windings and core, primarily through natural or forced air circulation. The most common classifications are AN (Air Natural), AF (Air Forced), and hybrid combinations, each providing different cooling efficiency levels depending on load conditions and installation environment.

Dry type transformers use liquid cooling systems similar to oil-filled transformers.False

Dry type transformers rely solely on air-based cooling methods such as natural convection or forced air with fans. No liquids are used.

Types of Cooling Methods in Dry Type Transformers

1. AN (Air Natural)

- Cooling occurs by natural convection of air around the transformer.

- Suitable for normal load conditions in well-ventilated areas.

- Simplest, most reliable, and requires no auxiliary equipment.

2. AF (Air Forced)

- Uses fans or blowers to increase airflow and improve heat dissipation.

- Allows the transformer to handle higher loads without overheating.

- Requires power supply for fans and additional maintenance.

3. ANAF (Air Natural + Air Forced)

- Transformer operates on natural air cooling at normal load.

- Fans switch on automatically during overload conditions.

- Balances efficiency and reliability, commonly used in critical applications.

4. Hybrid Systems with Filters or Ducts

- Advanced designs may include air ducts, dust filters, or climate-controlled enclosures.

- Applied in harsh environments (e.g., underground, marine, or dusty industrial sites).

Comparison of Cooling Methods

| Cooling Method | Heat Removal Mechanism | Capacity Range | Advantages | Limitations |

|---|---|---|---|---|

| AN (Air Natural) | Natural convection airflow | Low to medium ratings | No moving parts, low cost, reliable | Limited cooling capacity |

| AF (Air Forced) | Fans/blowers push air | Medium to high ratings | Higher load capacity, compact design | Fan failure risk, maintenance |

| ANAF | Combination (auto fans) | Medium to high ratings | Efficient under varying load conditions | Requires control system |

| Hybrid (Ducted/Filtered) | Directed/filtered airflow | All ranges | Suitable for harsh or enclosed environments | Higher installation cost |

Key Design Considerations

- Ambient Temperature – Cooling efficiency depends heavily on the installation environment.

- Ventilation Space – Adequate clearance around transformer is essential.

- Load Profile – Transformers serving fluctuating or peak loads benefit from forced cooling.

- Redundancy Needs – Critical facilities often install fan monitoring or backup systems.

- Noise Levels – Forced cooling can increase operational noise.

What Does AN (Air Natural) Mean in Dry Type Transformers?

Transformers generate heat during operation due to electrical and magnetic losses. Without efficient cooling, this heat can damage insulation and reduce lifespan. For dry type transformers, one of the simplest and most widely used cooling methods is AN (Air Natural). It provides safe, reliable operation while keeping design complexity and costs low.

AN (Air Natural) cooling means the transformer relies entirely on natural air circulation around its core and windings for heat dissipation. No fans, pumps, or external cooling devices are involved. Heat rises naturally from the windings and is transferred into the surrounding air through convection and radiation. This method is suitable for normal load conditions and environments with adequate ventilation.

AN cooling in transformers uses fans to blow air across the windings.False

Air Natural cooling works solely by natural convection of air without the aid of fans or blowers.

How AN Cooling Works

- Electrical losses in the core and windings produce heat.

- This heat warms the transformer surface.

- Warm air rises naturally, while cooler surrounding air flows in to replace it.

- The cycle continues, providing a passive cooling system.

Advantages of AN Cooling

- High reliability – no moving parts that can fail.

- Low maintenance – no fans, filters, or mechanical devices.

- Quiet operation – no fan noise, ideal for indoor installations.

- Cost-effective – simple design, reduced operational expenses.

- Environmentally friendly – uses only natural airflow.

Limitations of AN Cooling

- Restricted load capacity – effective only under rated or moderate loading.

- Dependent on ambient conditions – poor ventilation reduces cooling efficiency.

- Not ideal for confined or high-temperature environments.

Comparison: AN vs. AF Cooling

| Feature | AN (Air Natural) | AF (Air Forced) |

|---|---|---|

| Cooling mechanism | Natural air convection | Fans or blowers push air |

| Complexity | Simple, no moving parts | Requires fans, control system |

| Load handling capacity | Normal load only | Higher loads, overload handling |

| Maintenance | Minimal | Requires periodic fan servicing |

| Noise | Very quiet | Moderate noise from fans |

What Does AF (Air Forced) Mean in Dry Type Transformers?

Transformers generate heat during operation, and if this heat is not effectively removed, insulation damage and reduced lifespan can occur. While AN (Air Natural) cooling relies only on natural convection, AF (Air Forced) cooling provides an enhanced method to manage higher loads and hotter environments.

AF (Air Forced) cooling means that external fans or blowers are installed to force air circulation across the transformer’s core and windings, improving heat dissipation. This allows the transformer to handle higher loads, reduce hot spots, and operate more safely in confined or high-temperature spaces compared to AN cooling.

AF cooling in transformers depends entirely on natural convection.False

Unlike AN cooling, AF cooling actively uses fans or blowers to move air across the transformer windings and core.

How AF Cooling Works

- Heat generated in windings and core rises to the transformer’s surface.

- Fans or blowers push cool air directly onto windings and core surfaces.

- Forced airflow accelerates heat transfer, lowering operating temperature.

- Cooling efficiency is much greater than natural convection alone.

Advantages of AF Cooling

- Increased load capacity – enables transformers to run above natural cooling ratings.

- Extended lifespan – keeps insulation within safe thermal limits.

- Compact installations – suitable for confined or underground areas with limited ventilation.

- Better thermal stability – reduces risk of overheating under variable loads.

Limitations of AF Cooling

- Higher maintenance – fans require servicing, bearings may wear.

- Noise generation – added sound from fan motors.

- Dependency on power supply – if fans fail, cooling efficiency drops.

- Extra cost – initial investment and ongoing electricity for fans.

Comparison: AN vs. AF Cooling

| Feature | AN (Air Natural) | AF (Air Forced) |

|---|---|---|

| Cooling mechanism | Natural air convection | Fans/blowers push air |

| Load capacity | Rated load only | Rated + increased load |

| Maintenance | Minimal | Regular fan inspection/repairs |

| Noise | Silent | Moderate (fan noise) |

| Cost | Lower | Higher (fans, controls, energy use) |

AN vs. AF: Key Differences in Performance and Application in Dry Type Transformers

When selecting a dry type transformer, cooling method is a critical factor that directly affects reliability, capacity, cost, and maintenance needs. Two common cooling systems are AN (Air Natural) and AF (Air Forced), each suited to different environments and performance demands. Choosing the wrong system can result in overheating, shortened transformer lifespan, or unnecessary cost increases.

AN (Air Natural) cooling relies on natural convection of ambient air, making it simple, maintenance-free, and cost-efficient. AF (Air Forced) cooling uses fans or blowers to actively push air across transformer windings and core, enabling higher load capacity and improved thermal performance but at the expense of higher maintenance, noise, and dependency on auxiliary systems.

AF cooling allows transformers to operate at higher loads than AN cooling.True

Forced air circulation improves heat dissipation, enabling transformers to carry additional load without exceeding thermal limits.

Key Differences Between AN and AF Cooling

| Feature | AN (Air Natural) | AF (Air Forced) |

|---|---|---|

| Cooling mechanism | Passive natural air convection | Active fans/blowers push air |

| Load capacity | Rated load only (base rating) | Base rating + enhanced load capacity |

| Temperature control | Ambient-dependent, less precise | More controlled, reduces hot spots |

| Reliability | Very high (no moving parts) | Lower (fans add risk of failure) |

| Maintenance requirements | Minimal | Regular fan/bearing checks, possible replacements |

| Noise level | Virtually silent | Moderate to high (fan operation) |

| Cost | Lower upfront and operating cost | Higher initial cost + ongoing energy consumption |

| Typical applications | Offices, schools, light commercial, small loads | Industrial plants, underground substations, data centers, renewable energy plants |

Performance Considerations

- AN Cooling: Best for installations with stable loads, ample space, and environments where low noise and minimal maintenance are priorities.

- AF Cooling: Essential where load variability, high ambient temperatures, or confined spaces make natural convection insufficient.

Application Scenarios

- AN Transformers: Office buildings, hospitals, residential complexes, educational institutions.

- AF Transformers: High-rise basements, tunnels, industrial manufacturing lines, data centers, and renewable substations.

What Are the Practical Applications of AN and AF Dry Type Transformers?

When planning transformer installations, choosing between AN (Air Natural) and AF (Air Forced) cooling systems depends not only on electrical specifications but also on where and how the transformer will operate. Each cooling type has distinct suitability based on load characteristics, safety requirements, noise constraints, and environmental conditions. Selecting the wrong system may lead to overheating, wasted energy, or unnecessary costs.

AN-cooled transformers are commonly applied in environments with stable loads, low noise requirements, and minimal maintenance access. AF-cooled transformers are preferred in demanding environments with fluctuating or high loads, restricted ventilation, or elevated thermal stress, where active cooling is necessary to maintain safe operation.

AN cooling is more suitable for light commercial applications than AF cooling.True

Air Natural systems provide silent, maintenance-free cooling that aligns with the needs of offices, schools, and residential complexes.

Practical Applications of AN Transformers (Air Natural)

AN-cooled dry type transformers are widely installed in applications where simplicity, reliability, and quiet operation are critical:

- Schools and Universities – Safe, silent operation with minimal maintenance.

- Hospitals and Clinics – Low noise and zero oil-based fire risk.

- Commercial Buildings – Shopping malls, offices, and hotels requiring compact, reliable solutions.

- Residential Complexes – Indoor basement installations without ventilation fans.

- Renewable Energy (small-scale) – Rooftop solar or small wind installations where loads are predictable.

Practical Applications of AF Transformers (Air Forced)

AF-cooled dry type transformers are ideal in environments where load density is high and ventilation is limited:

- Data Centers – High load density requires precise thermal control.

- Industrial Plants – Manufacturing lines, steel mills, and chemical plants with fluctuating loads.

- Underground Substations – Basements, tunnels, and confined spaces with poor air circulation.

- Renewable Energy (utility-scale) – Wind farms and solar plants with load variability and higher ambient temperatures.

- Mining and Offshore Platforms – Harsh, confined environments needing compact but high-capacity solutions.

Comparison Table: AN vs. AF Applications

| Application Area | AN (Air Natural) | AF (Air Forced) |

|---|---|---|

| Educational Institutions | ✓ Ideal (quiet, safe) | ✗ Not required unless load is very high |

| Healthcare Facilities | ✓ Silent, maintenance-free | ✗ Rarely used due to fan noise |

| Commercial/Residential | ✓ Reliable for stable loads | ✗ Usually unnecessary |

| Industrial Plants | ✗ Limited capacity | ✓ Handles high/variable loads |

| Data Centers | ✗ Not precise enough | ✓ Supports high density, continuous load |

| Underground/Tunnel Systems | ✗ Poor heat dissipation | ✓ Required for safe thermal control |

| Utility-Scale Renewables | ✗ Capacity limits | ✓ Ensures efficiency at scale |

Conclusion

A dry type transformer AN/AF refers to its cooling classification. AN (Air Natural) transformers rely solely on natural airflow, making them suitable for standard loads and environments with good ventilation. AF (Air Forced) transformers, on the other hand, use fans to push air through the windings, significantly increasing cooling efficiency and allowing the unit to handle higher loads. In practice, many dry type transformers are dual-rated (e.g., 1000 kVA AN / 1500 kVA AF), giving operators flexibility in managing demand. Choosing between AN and AF depends on the application, load requirements, and environmental conditions.

FAQ

Q1: What is a dry type transformer with AF cooling?

A dry type transformer with AF cooling (Air Forced) uses external fans to blow air across its windings and core for improved heat dissipation. Unlike oil-filled units, dry type transformers rely only on air circulation, and forced ventilation enhances their load-handling capability.

Q2: How does AF cooling differ from AN cooling?

AN (Air Natural): Relies on natural air circulation without fans, suitable for normal loads.

AF (Air Forced): Uses fans to provide additional airflow, enabling the transformer to handle higher loads or operate at cooler temperatures.

Q3: What are the advantages of AF cooling in dry type transformers?

AF cooling increases load capacity, reduces overheating risk, and extends transformer life. It is especially useful in enclosed spaces like data centers, commercial buildings, or industrial plants where heat buildup can compromise reliability.

Q4: Where are AF cooled dry type transformers commonly used?

They are widely used in commercial buildings, hospitals, data centers, and industrial facilities, where safety, low maintenance, and efficient cooling are critical. AF cooling ensures stable operation in high-demand environments.

Q5: Are there any drawbacks to AF cooled dry type transformers?

Yes, drawbacks include dependency on fan operation, which requires regular maintenance, additional power consumption for fans, and potential noise. If the fans fail, the transformer automatically derates to its AN capacity to prevent overheating.

References

IEEE Std C57.12.01 – Dry Type Transformer Standards: https://ieeexplore.ieee.org

IEC 60076-11 – Dry Type Transformer Cooling Methods: https://webstore.iec.ch

NEMA – Dry Type Transformer Guidelines: https://www.nema.org

Electrical4U – Dry Type Transformer Cooling Explained: https://www.electrical4u.com

EEP – Cooling Methods of Dry Type Transformers: https://electrical-engineering-portal.com

All About Circuits – Transformer Cooling Types: https://www.allaboutcircuits.com

Engineering Toolbox – Transformer Cooling Data: https://www.engineeringtoolbox.com