Energy efficiency has become a defining benchmark in modern transformer design, influencing purchasing decisions, regulatory requirements, and long-term operational strategy. Dry-type transformers, known for their safety, environmental compatibility, and low maintenance, are increasingly evaluated not only for reliability but for their ability to reduce losses and operating costs. This article examines how their energy-efficiency compares with traditional oil-immersed transformers and other transformer types, highlighting both their strengths and practical limitations within real-world applications.

What Metrics Are Used to Evaluate Energy Efficiency in Transformers?

Evaluating transformer energy efficiency relies on a set of technical metrics that quantify how effectively the unit converts electrical power while minimizing losses. These metrics allow engineers, utilities, and procurement teams to determine long-term operating costs, performance stability, and compliance with modern energy-efficiency standards. Because transformers operate continuously for decades, even small differences in efficiency have large impacts on lifetime cost and environmental sustainability.

The most important metrics focus on losses—both fixed and variable—along with standardized efficiency values and regulatory performance classes. Understanding these indicators enables buyers to compare different transformer types, core materials, cooling methods, and design options more accurately.

No-Load (Core) Losses

No-load losses represent the energy consumed simply by energizing the transformer, even when it carries no load. They are primarily caused by magnetization of the core, hysteresis, and eddy currents. These losses remain nearly constant and are heavily influenced by core material choice, lamination thickness, and manufacturing precision.

Lower no-load losses are especially valuable in systems where transformers stay energized 24/7—such as distribution networks, solar farms, hospitals, and commercial buildings.

Load (Copper) Losses

Load losses occur only when current flows through the windings. They rise with load according to the square of the current (I²R), meaning they increase rapidly under heavy demand. Load losses include resistive heating, stray losses, and additional thermal effects.

This metric is critical for high-duty applications like industrial processes, EV charging networks, and data centers where transformers often operate near full load.

Total Losses at Rated Load

Total losses combine no-load and load losses to show the overall power dissipation under specified loading conditions. This provides a direct measure of operating efficiency and helps compare transformer models based on expected utilization patterns.

A transformer optimized for low total losses provides:

- Lower energy consumption

- Reduced heat generation

- Longer insulation life

- Lower lifetime operating costs

Efficiency at Specified Load Levels

Efficiency is often expressed at specific load points:

- 50% load efficiency

- 75% load efficiency

- 100% (full-load) efficiency

Different applications prioritize different load points. For example:

- Renewable energy systems may require high partial-load efficiency.

- Industrial plants demand strong full-load performance.

Evaluating efficiency at multiple load levels ensures proper alignment with real-world operating scenarios.

Energy Efficiency Performance Classes

Industry standards define minimum efficiency requirements and maximum allowable losses. Common frameworks include:

- IEC 60076-20 Transformer Efficiency Classes

- European EcoDesign Tier 1 & Tier 2 limits

- DOE 2016 requirements (North America)

- NEMA TP-1 / NEMA Premium guidelines

These classes allow buyers to compare transformers using universal benchmarks and ensure compliance with regional regulations.

Load Factor and Loss Evaluation Factor (A-Factor)

The load factor indicates the average load relative to rated capacity over time.

The A-Factor (loss evaluation factor) converts losses into monetary terms, showing how important each type of loss is in the specific application.

Utilities often use these factors to determine whether a low-loss transformer will provide enough long-term savings to justify a higher initial price.

Temperature Rise and Hot-Spot Performance

Although not a direct efficiency metric, temperature rise strongly correlates with energy losses. Lower-loss transformers run cooler, which improves service life and reduces thermal stress on insulation systems.

Hot-spot temperature metrics include:

- Winding hot-spot temperature

- Top-oil or top-air temperature

- Maximum temperature rise limits

Better thermal performance usually indicates higher efficiency and greater reliability.

Power Factor and Harmonic Performance

In environments with nonlinear loads, like data centers or industrial plants, harmonics increase losses and reduce effective efficiency.

Metrics such as:

- Total Harmonic Distortion (THD)

- K-Factor ratings

help quantify how well a transformer handles harmonic-rich loads without excessive heat or efficiency degradation.

How Do Dry-Type Transformers Minimize Core and Load Losses?

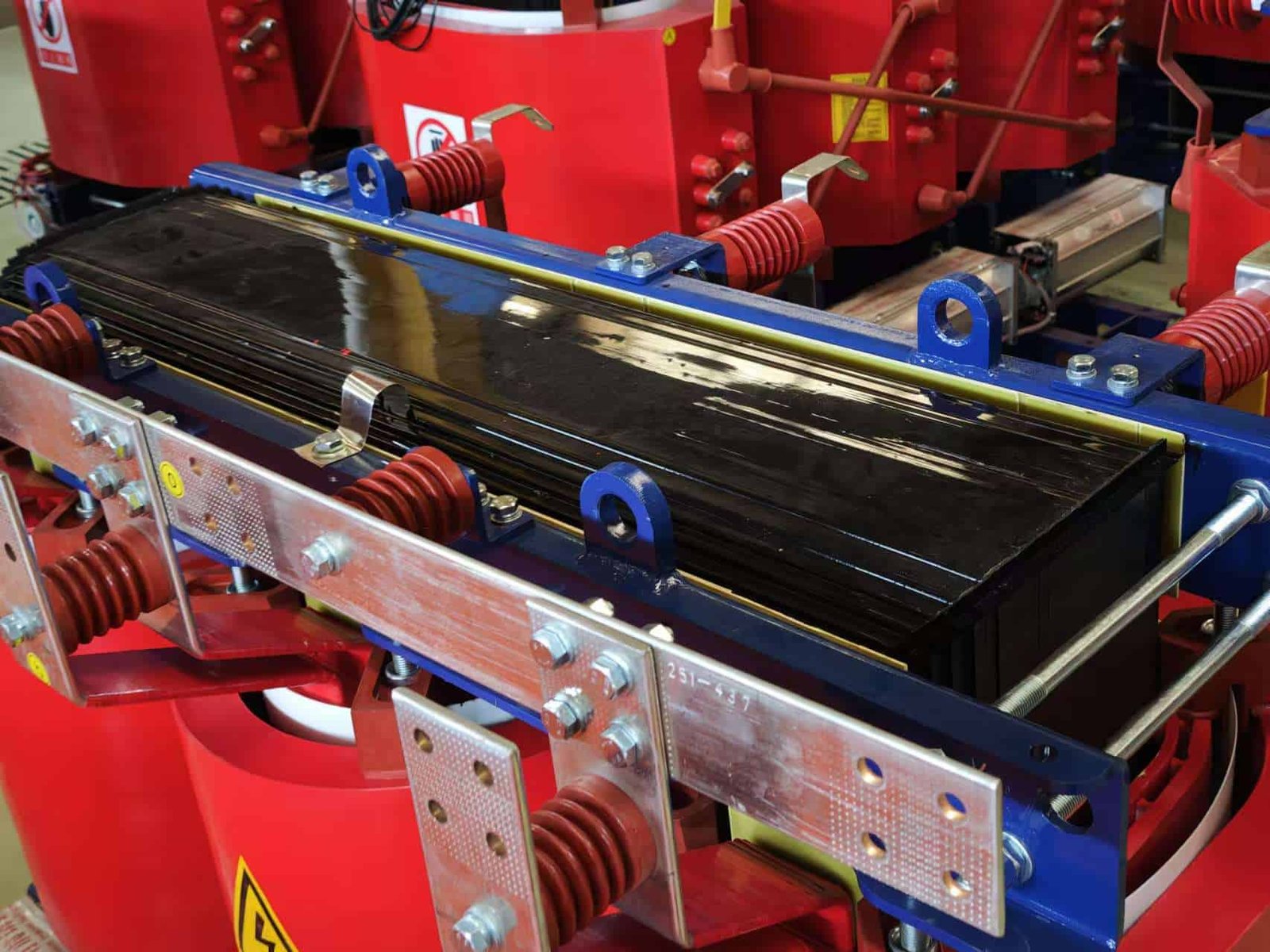

Dry-type transformers are engineered to deliver high electrical efficiency while maintaining excellent thermal and environmental performance. Because they operate without insulating oil, their design depends heavily on advanced core materials, optimized winding geometry, and enhanced cooling techniques to reduce both core losses (no-load losses) and load losses (copper and stray-load losses). Minimizing these two loss categories is central to achieving energy efficiency, lowering heat generation, improving reliability, and meeting modern efficiency regulations such as DOE, EcoDesign, and IEC performance classes. Manufacturers employ a combination of material science, electromagnetic design, and thermal engineering to ensure that dry-type transformers maintain low losses across a wide range of operating conditions.

Reducing Core Losses Through Advanced Magnetic Materials

Core losses in dry-type transformers mainly arise from hysteresis and eddy currents. To address this, modern dry-type transformers use high-grade magnetic materials that provide superior magnetic permeability and reduced core excitation requirements. Amorphous metal cores are increasingly replacing traditional grain-oriented silicon steel (CRGO) in energy-focused applications because the irregular atomic structure of amorphous metals significantly reduces hysteresis losses. Likewise, thinner laminations, laser-scribed grain orientation, and precision stacking further suppress eddy currents by shortening the conductive path for circulating currents. These improvements not only lower the no-load loss but also reduce the temperature rise of the transformer, increasing insulation life and overall reliability. The combination of high-quality magnetic steel and precise manufacturing tolerances ensures minimal magnetizing power consumption and optimal flux distribution through the core.

Optimized Winding Designs for Lower Load Losses

Load losses stem from the electrical resistance of the windings as well as additional stray-load losses caused by leakage flux and mechanical geometry. To minimize resistive losses, dry-type transformers often employ highly conductive copper or aluminum windings with increased cross-sectional area, especially in high-duty cycles or harmonic-rich environments. Foil windings and continuously transposed conductor (CTC) designs help achieve uniform current distribution and suppress circulating currents that otherwise increase resistive losses. Additionally, optimized winding placement reduces leakage reactance, lowering stray losses and improving voltage regulation. Using high-precision CNC winding equipment ensures tight, consistent winding patterns that reduce resistance variations and limit hotspots, thereby lowering overall I²R losses during operation.

Minimizing Stray Losses Through Electromagnetic Optimization

Stray losses arise from leakage flux penetrating structural components such as clamping plates, coil supports, or metal enclosures. Dry-type transformers address this by optimizing magnetic circuit geometry and designing flux shields from low-loss, non-magnetic materials such as fiberglass laminate or composite barriers. Finite element analysis (FEA) is widely used to simulate flux distribution and identify areas where stray fields could increase local heating. By adjusting core-leg spacing, channel geometry, and winding-to-core alignment, designers achieve a more confined magnetic path, reducing parasitic losses. These optimizations also help prevent localized overheating, which is especially important since dry-type units depend on natural or forced-air cooling rather than oil circulation.

Reducing Losses Through Enhanced Cooling Systems

Although cooling does not directly eliminate losses, effective thermal management lowers winding resistance and improves overall efficiency. Dry-type transformers typically use natural air (AN/AA) or forced-air cooling (AF/FA). Modern designs integrate large ventilation ducts, resin systems with high thermal conductivity, and external air channels to maximize heat dissipation. Lower operating temperatures reduce I²R resistance in the windings and prevent thermal aging of insulation, which indirectly sustains low losses throughout the transformer's lifetime. Some high-capacity dry-type transformers now use advanced materials like nanofilled epoxy or high-thermal-conductivity resins to reduce thermal impedance between winding layers, further lowering temperature rise and improving load-loss performance.

Using High-Efficiency Core Shapes and Joint Designs

Core geometry also influences losses. Step-lap joint construction reduces localized flux concentrations at core joints, providing smoother magnetic transitions. This significantly lowers both eddy current and hysteresis losses. Additionally, 3-limb and 5-limb core configurations are optimized based on application needs, balancing magnetic efficiency and mechanical stability. Improved clamping systems maintain optimal pressure distribution on the core to reduce gaps, ensuring uniform flux and minimizing localized heating or vibration. These design details contribute significantly to achieving low no-load losses in dry-type models.

Mitigating Harmonic-Induced Losses in Modern Applications

Nonlinear loads such as EV chargers, data centers, and variable-speed drives produce harmonics that increase transformer losses. Dry-type transformers address this challenge through K-factor rated windings, reinforced insulation, and magnetic steel selections tailored to high-frequency behavior. Additional shielding and optimized winding geometry reduce stray flux that would otherwise amplify harmonic losses. This is critical for maintaining low losses in modern grid environments where harmonic levels continue to rise.

How Do Dry-Type Transformers Compare to Oil-Immersed Units in Efficiency?

Dry-type and oil-immersed transformers both play critical roles in modern electrical systems, but they achieve efficiency through fundamentally different mechanisms. Their comparative performance is shaped by thermal behavior, magnetic core performance, load conditions, insulation aging, cooling effectiveness, and the electrical environment in which they operate. Understanding how these factors interact reveals why each technology excels in different applications and capacity ranges.

Core Loss Efficiency Differences

Core losses (no-load losses) are dominated by hysteresis and eddy currents in the magnetic core. Because these losses occur whenever the transformer is energized, they heavily influence long-term energy consumption.

Oil-immersed transformers typically achieve lower core losses because the oil bath maintains a more uniform and lower operating temperature. Cooler steel operates with reduced magnetizing power, and the oil environment helps suppress localized heating that can increase core losses over time.

Dry-type transformers, however, have benefited significantly from modern engineering. The use of amorphous metal cores, laser-scribing, step-lap construction, and improved assembly precision has narrowed the gap. In medium-voltage ranges, especially below ~5 MVA, dry-type transformers can deliver core-loss performance that is nearly equal to oil-immersed units. However, at very high capacities, oil-immersed designs still outperform due to superior thermal stability.

Summary:

- Low/medium power: losses are nearly equal

- High power: oil-immersed maintains lower core losses

- Efficiency gap is narrowing due to advanced core materials

Load Loss Performance Under Real Operating Conditions

Load losses (I²R losses in windings + stray losses) scale directly with current. These losses depend heavily on temperature, because copper resistance increases as windings heat up.

Oil-immersed transformers excel here. Circulating oil removes heat efficiently, keeping winding temperatures lower. This results in:

- Lower copper resistance

- Lower I²R losses

- Better performance under overload or high-duty cycles

Dry-type transformers, cooled by air or forced ventilation, experience naturally higher winding temperatures under full load. Even with high-conductivity copper, foil-wound coils, and optimized airflow channels, dry units typically exhibit higher load losses at high load factors.

However, dry-type units often outperform oil-immersed units in applications with:

- Light or moderate loading

- Short duty cycles

- Harmonic-rich environments

Because their mechanical structure is more resilient, losses do not rise as dramatically in nonlinear or pulsed-load systems.

Summary:

- Heavy load = oil-immersed more efficient

- Partial load = dry-type can equal or surpass

- Harmonics = dry-type more stable and predictable

Cooling Method Efficiency Impact

Cooling mechanisms define the temperature ceiling, and temperature governs losses.

Oil-Immersed Cooling (ONAN/ONAF/ODAF)

- Superior heat transfer

- Natural convection reduces hotspots

- Lower average winding temperatures

- Supports higher-capacity transformers efficiently

This is why oil-filled units dominate high-voltage and high-MVA categories.

Dry-Type Cooling (AN/AF/ANAF)

- Air is less effective than oil

- Heat removal relies on engineered airflow paths

- Newer resin systems improve thermal conductivity

- Forced-air designs significantly enhance performance

Advanced dry-type models with epoxy cast resin and multi-channel ventilation have closed the gap—but still cannot match oil-immersed thermal performance at large capacities.

Efficiency at Different Power Levels

The efficiency comparison is strongly dependent on transformer size.

| Power Range | Dry-Type Efficiency | Oil-Immersed Efficiency | Winner |

|---|---|---|---|

| ≤ 1 MVA | High | Very High | Nearly equal |

| 1 – 5 MVA | High | Very High | Slight oil advantage |

| 5 – 20 MVA | Moderate–High | Excellent | Oil-immersed |

| 20+ MVA | Limited availability | Excellent | Oil-immersed (only practical option) |

Dry-type models simply do not scale economically or thermally in the highest ranges, which makes high-voltage systems inherently dominated by oil-filled designs.

Harmonics, Partial-Load Behavior, and Real Efficiency

Modern electrical environments involve nonlinear loads:

EV chargers, VFDs, UPS systems, PV inverters.

Dry-type transformers often provide better real-world efficiency because:

- Resin-cast coils have better mechanical rigidity

- Lower susceptibility to stray flux heating

- Performance degrades less under harmonics

Oil-immersed units can achieve very high theoretical efficiency, but harmonics and uneven loading can increase losses sharply.

Aging and Long-Term Efficiency Stability

Efficiency changes over a transformer’s life. As insulation ages, internal heat increases, and losses rise.

Oil-immersed units age primarily due to:

- Oil oxidation

- Water content changes

- Sludge formation

- Paper-cellulose deterioration

If oil is not maintained properly, efficiency gradually declines.

Dry-type transformers age differently:

- No oil → no oxidation/sludge

- Cast resin systems maintain dielectric strength longer

- Heat cycling slightly accelerates resin micro-cracking but does not significantly raise losses

In many indoor/controlled environments, dry-type efficiency remains more stable over decades.

Regulatory Standards and Measured Efficiency

Efficiency is not evaluated informally—it is standardized under:

- IEC 60076

- IEC 60076-11 (dry-type)

- DOE 2016/2023 efficiency rules

- EU EcoDesign Tier 1 & Tier 2 requirements

- EN 50588-1

Across regions, standards reflect one major trend:

At equivalent kVA ratings, oil-immersed transformers usually achieve slightly higher mandated minimum efficiency.

Dry-type minimum efficiency levels are slightly lower, but the gap narrows each year due to improvements in materials and thermal design.

Final Comparison Summary

| Aspect | Dry-Type | Oil-Immersed | Efficiency Winner |

|---|---|---|---|

| Core loss | Low–Moderate | Very low | Oil-immersed |

| Load loss | Moderate | Very low | Oil-immersed |

| Partial-load efficiency | Very good | Good | Dry-type |

| Overload behavior | Limited | Excellent | Oil-immersed |

| Harmonic environments | Strong | Moderate | Dry-type |

| Long-term stability | Very good | Good with maintenance | Dry-type (unless poorly ventilated) |

| High-voltage performance | Limited | Excellent | Oil-immersed |

How Do Cooling Methods Influence Overall Energy Performance?

Cooling methods play a decisive role in transformer energy performance because temperature directly affects winding resistance, insulation aging, core magnetization behavior, and long-term load capability. Whether the transformer relies on air, forced air, natural oil circulation, or directed oil flow, its cooling system determines how efficiently electrical and magnetic losses are dissipated. This thermal environment controls the stability of load losses (I²R), the behavior of stray losses, and the transformer’s ability to maintain high efficiency across different load profiles, ambient conditions, and duty cycles. As a result, cooling design is not just a mechanical detail; it is a major electrical performance variable that shapes both operational efficiency and lifecycle cost.

Cooling Class and Its Relationship to Temperature, Losses, and Efficiency

The relationship between cooling and efficiency begins with temperature. Every rise of 10°C in winding temperature increases copper’s electrical resistance by approximately 4%. This means poorer cooling causes higher real-time load losses. Oil-immersed transformers, with their circulating oil and strong thermal conductivity, effectively keep winding temperatures low. This results in lower copper losses and higher energy performance under continuous or heavy loading.

Dry-type transformers, cooled by air (AN) or forced air (AF/ANAF), inherently operate at higher temperatures. Even with optimized airflow channels, thermally conductive resin, and modern insulation systems, coil temperature remains higher than in oil-filled units. This higher temperature raises copper resistance during operation, which leads to higher I²R losses—particularly at high load factors or in demanding industrial applications.

Thus, cooling class determines:

- Winding temperature

- Copper resistance

- Magnitude of load losses

- Hotspot behavior

- Ability to sustain overload

- Long-term performance stability

This is why cooling is not a secondary specification; it fundamentally shapes energy efficiency.

Air-Cooled vs. Oil-Cooled Systems: Comparative Thermal Efficiency

Air and oil behave differently as heat transfer mediums.

- Air is a weak conductor, requiring engineered geometry and forced circulation to achieve adequate cooling.

- Oil conducts and transports heat much more effectively through natural or forced convection.

Oil-immersed cooling systems (ONAN, ONAF, OFAF) maintain stable temperatures even at high loads. This consistency reduces thermal cycling, minimizes insulation stress, and preserves low-loss operation over decades. Forced-air dry-type systems can perform well but usually exhibit greater temperature variability, which can raise losses during heavy-duty cycles.

Air-cooled transformers excel in environments where safety, fire resistance, or indoor installation matters, but they are not designed to match the thermal efficiency of oil circulation under high electrical stress.

Impact of Cooling on Overload Capability and Real-World Efficiency

In high-load, long-duration scenarios—industrial plants, utility substations, EV charging hubs—oil-filled transformers maintain efficiency because their cooling systems can handle overload cycles with minimal temperature escalation.

Cooling method determines real-world efficiency in the following ways:

- Limited cooling headroom → dry-type units experience rising resistance and higher load losses

- Strong thermal buffer → oil-immersed transformers maintain stable losses under repetitive loading cycles

- Air systems show higher sensitivity to ambient temperature

- Oil systems maintain performance even in hot climates due to superior heat dispersion

This is why utility networks and high-power renewable-energy systems rely heavily on oil-filled designs.

Influence of Cooling on Core Loss Stability

Core losses primarily depend on magnetization properties and steel quality, but cooling still influences them. As core temperature rises:

- Magnetic hysteresis increases

- Eddy current losses rise

- Localized hotspots distort flux patterns

Oil baths suppress these effects through uniform thermal distribution, preventing localized overheating. Dry-type designs, especially resin-cast, may develop thermal gradients that slightly increase magnetizing losses during prolonged operation.

Thus, oil cooling naturally preserves lower core-loss stability over life.

Harmonic Environments and Cooling Performance

In harmonic-rich systems (data centers, EV chargers, VFDs), stray losses and eddy-current heating increase dramatically.

Cooling must therefore manage:

- Additional heating in conductors

- Higher induction in structural parts

- Hotspots created by harmonic distortion

Dry-type transformers often perform better structurally under harmonics because their resin-encapsulated windings resist vibration and mechanical stress. However, from a thermal efficiency standpoint, oil-filled units still dissipate harmonic-induced heating more effectively.

This means dry-type may be more robust mechanically, but oil-immersed is usually more efficient thermally under harmonics.

Cooling Method and Long-Term Energy Performance

Cooling strongly influences aging, which then influences long-term energy performance.

Oil-immersed units age through oil oxidation and cellulose degradation but maintain stable electrical losses for much of their lifespan when properly maintained. Their temperatures remain low, which preserves conductivity and keeps losses close to original specifications.

Dry-type units age through resin brittleness and micro-cracking. Higher coil temperatures accelerate this process, which can slightly increase losses over decades. Ventilation quality and ambient temperature play critical roles; poor environments degrade efficiency faster.

Cooling stability = long-term efficiency stability.

Environmental Conditions and Their Impact on Cooling Efficiency

Cooling method determines how external conditions affect performance:

- High altitude reduces air density → significantly weaker dry-type cooling

- Coastal or humid environments complicate ventilation paths → dry-type heats faster

- Hot climates strain air-cooled units more severely

- Oil systems maintain strong thermal performance regardless of ambient air conditions

Because cooling defines the thermal envelope, transformers with poor cooling adaptability suffer disproportionately in harsh environmental conditions.

Where Do Dry-Type Transformers Offer the Best Efficiency Advantages?

Dry-type transformers provide meaningful efficiency advantages in specific environments where thermal behavior, load characteristics, and installation conditions align with their inherent design strengths. While oil-immersed transformers generally lead in absolute thermal efficiency for high-capacity applications, dry-type units outperform, or at least equal, oil-filled models in several important low- and medium-voltage scenarios—especially where safety, partial-load stability, harmonic tolerance, or environmental constraints dominate. Their resin-cast or VPI windings, combined with advanced ventilation channels and low-loss magnetic cores, allow them to deliver high real-world efficiency under operating conditions that typically challenge oil-based systems.

High Partial-Load Conditions and Light-Duty Cycles

Dry-type transformers show some of their strongest efficiency benefits under partial-load operation. Because their load losses scale more predictably with temperature and they experience less thermal inertia than oil-filled units, they maintain stable performance in applications where loads fluctuate throughout the day. Schools, office buildings, commercial complexes, and public facilities often operate at 20–60% load, and dry-type transformers maintain high efficiency across this entire band.

At light load, differences in copper resistance are less critical, allowing the dry type’s low core-loss designs—especially those using amorphous metal—to perform extremely well. Oil-filled models may be optimized for full-load efficiency, but their no-load advantages narrow when utilization levels remain low for long periods.

Indoor Installations With Limited Ventilation Requirements

Dry-type transformers often deliver superior real-world efficiency in indoor applications where oil-filled units require additional protective infrastructure. Oil-filled transformers need fire barriers, containment pits, forced ventilation, and sometimes cooling ductwork. These auxiliary systems consume energy or impose design constraints that reduce the effective operating efficiency of the entire installation.

Dry-type transformers eliminate the need for:

- Fire suppression systems tied to transformer cooling

- Oil containment basins

- Mechanical ventilation designed for hazardous environments

- Cooling auxiliaries associated with oil circulation

Because they operate with air cooling and non-flammable insulation, installation-related overhead is significantly reduced, which indirectly boosts overall system efficiency.

Environments With Harmonics, Nonlinear Loads, and Frequent Switching

Modern electrical systems increasingly depend on power electronics—VFDs, UPS systems, data center servers, EV charging modules, and solar inverters. These introduce harmonics and transient currents that generate additional stray and eddy-current losses.

Dry-type transformers offer important efficiency advantages in such environments due to:

- Better mechanical rigidity of resin-cast windings

- Lower risk of oil circulation heating under harmonics

- Reduced sensitivity to localized flux distortion

- More stable losses under distorted waveforms

Because harmonics create uneven heating patterns, the air-cooled, rigid winding structure of dry-type transformers maintains more predictable thermal behavior compared to oil-filled systems, whose oil circulation may not remove localized harmonic hotspots as effectively.

Applications with Tight Thermal Constraints but Moderate Power Ratings

In moderate capacities—typically below 5 MVA—dry-type transformers can match or exceed the overall efficiency of oil-immersed models because of precision winding construction, compact magnetic paths, and thermally conductive resin. Their simpler thermal pathways reduce internal hotspots, and temperature rise is distributed evenly when the units operate below maximum loading.

Examples include:

- Hospitals

- Universities

- Public infrastructure

- High-rise buildings

- Airports

- Commercial centers

In such installations, dry-type transformers often maintain efficiency advantages due to stability, reduced auxiliary equipment, and consistent thermal performance under intermittent loads.

Facilities Where Maintenance and Downtime Affect Effective Efficiency

Dry-type transformers require near-zero routine maintenance. Oil-filled units, by contrast, require periodic:

- Oil sampling

- Dissolved gas analysis

- Moisture monitoring

- Filtration and regeneration

- Containment inspections

Even if the transformer itself is efficient, maintenance interruptions reduce the effective operational efficiency of the entire system. Dry-type transformers avoid maintenance-related downtime, which in some facilities—especially data centers, manufacturing plants, and transportation hubs—translates directly into higher operational productivity and reduced lifecycle losses.

Harsh or Contaminated Environments That Challenge Oil-Filled Cooling Systems

Dry-type transformers handle harsh conditions where oil-filled units suffer cooling inefficiencies or accelerated aging. Dust, moisture, corrosive gases, and humidity degrade oil faster than they affect resin-encapsulated or VPI windings. Poor oil quality increases internal losses and reduces insulation performance over time.

Dry-type models remain efficient in:

- Mining sites

- Chemical plants

- Coastal regions

- Tunnel installations

- Offshore environments (with proper enclosures)

Because airflow cooling can be isolated or ducted easily, thermal performance remains stable even in challenging atmospheres.

Conclusion

Dry-type transformers have evolved to deliver high levels of energy efficiency, often matching or approaching the performance of modern oil-immersed units—especially in low- and medium-voltage distribution applications. Their low no-load losses, advanced insulation systems, and optimized cooling designs make them a strong choice where safety, environmental performance, and lifecycle cost are priorities. However, oil-immersed transformers still retain an edge in ultra-high-capacity or transmission-level efficiency due to superior thermal conductivity and cooling characteristics. As manufacturing technologies continue to advance, dry-type transformers are closing this gap, positioning themselves as an increasingly efficient solution for a wide range of modern power systems.

FAQ

Q1: What are the latest technology trends in dry type transformers?

Dry type transformer technology is evolving rapidly as industries demand better safety, efficiency, and environmental performance. One major trend is the adoption of smart sensors and digital monitoring, allowing operators to track temperature, humidity, partial discharge, and load conditions in real time. This shift reduces downtime through predictive maintenance and extends transformer life. Another key development is the use of high-performance insulation materials such as epoxy resin with nanotechnology additives, improving thermal conductivity and mechanical strength. Manufacturers are also introducing higher efficiency core designs, such as amorphous metal cores and low-loss silicon steel, to meet increasingly strict energy regulations.

Additionally, the industry is embracing compact and modular designs, enabling easier installation in space-constrained environments like data centers and metro stations. Improved cooling systems—such as advanced natural-air (AN) and forced-air (AF) designs—allow for higher load capacity without compromising reliability. Fire-resistant materials, low-smoke resins, and eco-safe insulation are gaining adoption, particularly in commercial and public infrastructure projects. Overall, the technological direction focuses on enhanced safety, digitization, energy efficiency, and sustainable materials.

Q2: Why is market demand for dry type transformers increasing globally?

Global demand is rising due to the expansion of industries that require safe, eco-friendly, and indoor-suitable transformers. Sectors such as data centers, renewable energy, commercial buildings, metro systems, and offshore platforms increasingly depend on dry type transformers for their fire safety and low maintenance advantages. Government regulations pushing for reduced environmental impact and safer equipment in public areas further accelerate adoption.

The renewable energy boom—especially solar and wind—also contributes to demand. Dry type transformers are preferred in wind turbine towers, solar farms, and battery energy storage systems due to their moisture resistance and minimal maintenance requirements. Additionally, electrification of infrastructure in developing countries, rising urbanization, and strict environmental standards in developed markets are all major growth drivers. As industries move toward greener solutions, dry type transformers are becoming a top choice worldwide.

Q3: How are digital features shaping the dry type transformer market?

Digitization is transforming how dry type transformers are managed and maintained. Embedded IoT sensors, real-time temperature monitoring, partial discharge detection, and smart load management help operators make data-driven decisions. Predictive analytics can detect potential failures before they occur, reducing costly outages and improving operational reliability. Digital twins—virtual models of physical transformers—allow engineers to simulate performance under different load conditions, aiding in design optimization and maintenance planning.

Remote monitoring is particularly valuable in renewable energy installations and large industrial facilities where equipment is dispersed or hard to reach. As smart grids expand, utilities increasingly demand digitally enabled transformers that support automation and grid integration. The integration of cloud-based monitoring platforms further strengthens this trend, contributing to sustained market growth.

Q4: What industries are driving technological innovation in dry type transformers?

Key industries influencing innovation include:

Data centers, which require high-efficiency, low-noise, high-reliability transformer designs

Renewable energy, which pushes demand for compact, moisture-resistant, and vibration-resistant units

Railway and metro systems, which need fire-safe, durable transformers for underground and enclosed spaces

Commercial buildings, where safety, noise reduction, and efficiency standards continue to tighten

Manufacturing plants, which seek higher load capacities and better heat management

These sectors demand performance improvements such as better thermal design, lower losses, wider voltage ranges, and enhanced safety—all of which influence technological advancements.

Q5: What future trends are expected for dry type transformers?

The future points toward greater efficiency, smarter monitoring, and more environmentally sustainable materials. Nanocomposite insulation, low-loss amorphous cores, and advanced cooling systems are expected to become standard. Growing interest in smart energy management will push manufacturers to integrate more IoT and AI-based monitoring solutions. Additionally, stricter regulations and carbon reduction policies will continue to favor dry type transformers over oil-filled alternatives in many applications.

Market forecasts indicate strong growth, especially in Asia-Pacific, Europe, and North America. Rapid urbanization, renewable energy expansion, and rising concerns over fire safety will continue to drive demand. Over the next decade, dry type transformers are expected to play a crucial role in smart grids, microgrids, electric transportation infrastructure, and high-reliability industrial environments.

References

IEC 60076-11 – Dry Type Transformers — https://www.iec.ch

IEEE Transformer Technology Innovations — https://ieeexplore.ieee.org

Schneider Electric MV Transformer Developments — https://www.se.com

MarketsandMarkets – Dry Type Transformer Market Report — https://www.marketsandmarkets.com

Global Market Insights – Dry Type Transformer Trends — https://www.gminsights.com

International Energy Agency – Grid & Renewable Expansion Reports — https://www.iea.org

Statista – Transformer Market Growth Data — https://www.statista.com