Polychlorinated biphenyls (PCBs) were once widely used as insulating fluids in electrical equipment due to their stability and fire-resistant properties. However, PCBs are now banned worldwide because of their toxicity, persistence in the environment, and severe health risks. Modern transformer designs, especially dry type transformers, have completely eliminated the use of PCBs. This article explores whether dry type transformers contain PCBs and explains the reasons behind their environmental safety.

What Are PCBs and Why Were They Used in Transformers?

In the mid-20th century, transformers and other electrical equipment often relied on specialized insulating liquids to prevent overheating, suppress fires, and ensure safe operation under high voltages. One of the most widely used insulating fluids was PCBs (polychlorinated biphenyls). At the time, PCBs seemed ideal because they were chemically stable, non-flammable, and excellent electrical insulators. However, these same properties later revealed serious environmental and health hazards, leading to worldwide bans and strict regulations.

PCBs (polychlorinated biphenyls) are synthetic chemical compounds once used in transformers as insulating and cooling fluids because of their high thermal stability, non-flammability, and dielectric properties. They were widely adopted from the 1930s to the 1970s but later banned due to their toxicity, persistence in the environment, and health risks including cancer and immune system damage.

PCBs are still legally used in new transformers.False

Since the late 1970s and 1980s, PCBs have been banned or severely restricted worldwide due to environmental persistence and health hazards. Modern transformers use mineral oil, synthetic esters, or dry-type designs instead.

1. Properties That Made PCBs Attractive

- Excellent Dielectric Strength → Allowed safe operation under high voltages.

- High Thermal Stability → Withstood temperatures >250°C without breaking down.

- Non-Flammability → Provided safety in urban and industrial applications.

- Chemical Inertness → Did not react with metals or insulating materials.

- Long Service Life → Low maintenance requirements compared to alternatives.

2. Timeline of PCB Use in Transformers

| Period | Usage of PCBs | Key Notes |

|---|---|---|

| 1930s–1950s | Widespread adoption | Seen as revolutionary for electrical safety. |

| 1960s | Peak usage | Hundreds of thousands of transformers used PCB fluids. |

| 1970s | First environmental concerns | Studies linked PCBs to wildlife and human health issues. |

| Late 1970s–1980s | Phase-out and bans | US (TSCA 1979), EU, Japan, and others banned production. |

| Present | Only in legacy equipment | Old units are being phased out and safely disposed. |

3. Health and Environmental Hazards

- Bioaccumulation: PCBs persist in soil, water, and living organisms.

- Toxicity: Linked to cancer, liver damage, reproductive and immune disorders.

- Environmental Persistence: Half-life in the environment is decades or more.

- Disposal Risk: Leaks from old transformers contaminate soil and groundwater.

4. Alternatives to PCBs

- Mineral Oil → Widely used, though flammable.

- Silicone Fluids → Non-flammable, higher cost.

- Natural and Synthetic Esters → Biodegradable, high fire point.

- Dry-Type Transformers → No liquid insulation needed, safer for indoor use.

What Are the Health and Environmental Risks of PCBs in Transformers?

When polychlorinated biphenyls (PCBs) were first introduced as transformer insulating fluids, their non-flammability and chemical stability were seen as revolutionary. However, these same properties made them extremely persistent pollutants. Once released, PCBs spread through soil, water, and the food chain, creating long-term contamination. For humans, exposure—even at low concentrations—has been associated with serious health impacts, while environmental systems face decades of disruption due to their resistance to natural breakdown.

PCBs in transformers pose significant health and environmental risks because they are toxic, bioaccumulative, and persistent. Human exposure is linked to cancer, immune suppression, liver damage, and developmental disorders, while environmental impacts include contamination of soil and water, accumulation in the food chain, and long-lasting ecosystem damage.

PCBs naturally degrade in a few months after leakage.False

PCBs are highly stable, resist natural degradation, and can persist in the environment for decades, making cleanup extremely challenging.

1. Health Risks of PCB Exposure

| Health Effect | Description | Exposure Pathways |

|---|---|---|

| Carcinogenicity | Classified as a probable human carcinogen by IARC and EPA. | Occupational exposure, contaminated food. |

| Immune System Damage | Reduces immune response and increases susceptibility to infections. | Airborne vapors, ingestion. |

| Reproductive & Developmental Effects | Associated with birth defects, low birth weight, and developmental delays. | Maternal transfer, contaminated fish/meat. |

| Neurological Impacts | Linked to learning and memory issues, especially in children. | Prenatal exposure, ingestion. |

| Liver & Endocrine Disruption | Causes liver toxicity and hormone interference. | Inhalation, ingestion, dermal contact. |

2. Environmental Risks of PCBs

- Soil Contamination → PCBs bind strongly to soil particles and persist for decades.

- Water Pollution → Slowly leach into groundwater and rivers, contaminating drinking sources.

- Bioaccumulation → Concentrate in fish, birds, and mammals, moving up the food chain.

- Ecological Damage → Affect reproduction in wildlife (e.g., fish, seals, and birds).

- Persistence → Half-life in sediments and soils can exceed 20–50 years.

3. Case Study – PCB Legacy Pollution

- Hudson River, USA: Decades of PCB discharge led to widespread fish contamination, forcing fishing bans that remain in place.

- Baltic Sea: Marine ecosystems still show PCB traces long after bans.

- Urban Substations: Leaks from old PCB transformers continue to create localized hotspots of soil and groundwater pollution.

4. Why PCB Risks Are Hard to Mitigate

- Non-Biodegradable: PCBs resist bacterial and chemical breakdown.

- Long-Range Transport: Found in Arctic wildlife far from industrial sources.

- Costly Remediation: Soil excavation, incineration, or chemical treatment required.

- Regulatory Burden: Owners of PCB-containing transformers face strict compliance, labeling, and disposal requirements.

Why Do Dry Type Transformers Not Contain PCBs?

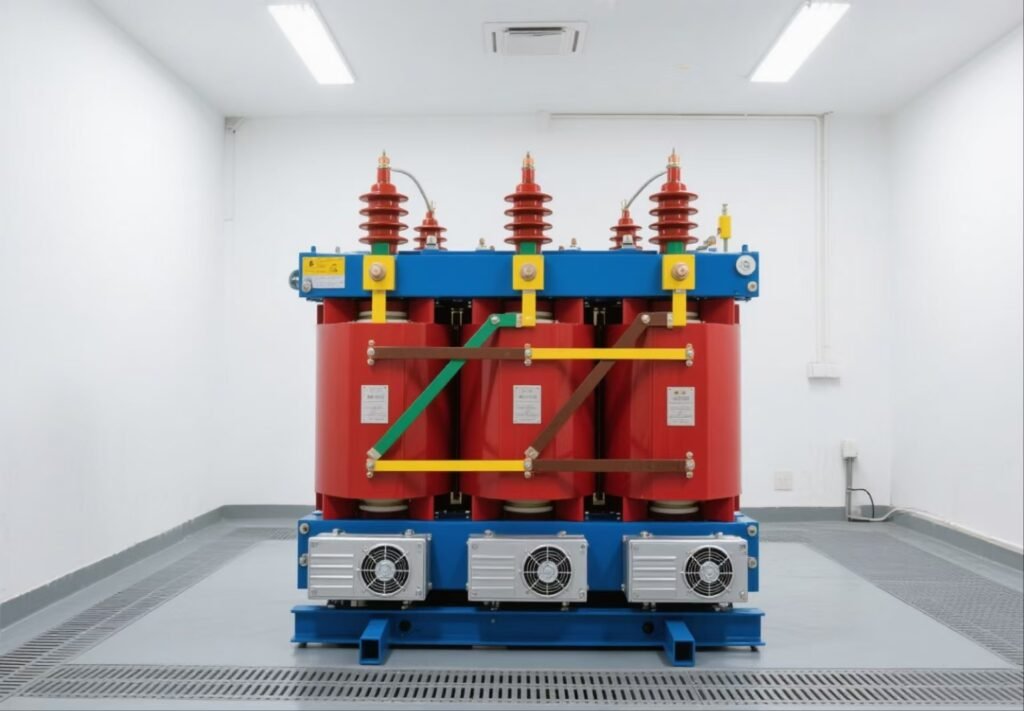

Historically, polychlorinated biphenyls (PCBs) were used in some oil-filled transformers because of their non-flammability and insulating strength. However, PCBs became infamous for their toxicity, bioaccumulation, and environmental persistence, leading to strict bans worldwide. In contrast, dry type transformers were engineered without any liquid insulation, meaning they have no need for PCB fluids. Their insulation relies on resin, varnish, or air, eliminating the pollution and fire risks associated with oil-filled PCB transformers.

Dry type transformers do not contain PCBs because they use solid insulation (epoxy resin, cast resin, or varnish) and air for cooling instead of liquid insulating fluids. Since PCBs were exclusively used as insulating and cooling oils, the absence of liquids in dry type transformers makes the presence of PCBs impossible.

Dry type transformers may contain PCBs in their insulation materials.False

PCBs were only ever used in liquid insulating oils, not in the solid epoxy or resin systems of dry type transformers. Therefore, dry type transformers are inherently PCB-free.

1. Key Design Differences That Eliminate PCBs

| Feature | Oil-Filled Transformers (Historical PCB Use) | Dry Type Transformers (PCB-Free) |

|---|---|---|

| Insulation Medium | Mineral oil, silicone oil, or historically PCB oil | Epoxy resin, varnish, or cast resin |

| Cooling Method | Oil circulation (ONAN, ONAF, etc.) | Air natural (AN) or air forced (AF) |

| PCB Risk | High (if built before 1980s) | None – no liquid used |

| Fire Hazard | Reduced with PCB oil, but environmental cost | Low fire risk without liquid insulation |

| Applications | Outdoor substations, high-voltage | Indoor buildings, commercial, sensitive facilities |

2. Why Dry Type Transformers Are Naturally PCB-Free

- No liquid required → Cooling relies on airflow and heat dissipation.

- Solid insulation → Windings encapsulated in resin or varnish, no oil presence.

- Inherent fire safety → No combustible or toxic liquid fuels inside.

- Environmental compliance → Meets modern green building and safety standards.

3. Benefits of PCB-Free Dry Type Transformers

- Safety: No risk of oil leaks, fire, or PCB contamination.

- Environmental Protection: Fully compliant with PCB bans and eco-regulations.

- Low Maintenance: No need for oil sampling, leak checks, or PCB monitoring.

- Indoor Compatibility: Preferred for hospitals, schools, data centers, and high-rises.

What Are the Insulation and Cooling Methods in Dry Type Transformers?

Unlike oil-filled transformers that rely on liquid insulation and cooling, dry type transformers use a combination of solid insulation materials and air circulation to ensure safe and reliable operation. This design eliminates the risks of oil leaks, PCB contamination, and fire hazards, making them suitable for indoor and sensitive environments. Understanding their insulation and cooling systems is crucial for selecting the right transformer for specific applications.

Dry type transformers use epoxy resin, cast resin, or varnish for insulation and rely on natural air (AN) or forced air (AF) systems for cooling. Solid insulation protects the windings from electrical stress and environmental factors, while air circulation removes heat generated during load operation, ensuring reliable and safe performance without oils or PCBs.

Dry type transformers require liquid insulation for proper cooling.False

Dry type transformers use solid insulation materials and air circulation for cooling, eliminating the need for oil or liquid-based systems.

1. Insulation Methods in Dry Type Transformers

| Insulation Method | Description | Advantages | Common Applications |

|---|---|---|---|

| Vacuum Pressure Impregnated (VPI) | Windings impregnated with varnish under vacuum and pressure | Good electrical strength, moisture resistance, economical | Commercial buildings, general indoor use |

| Vacuum Pressure Encapsulated (VPE) | Thicker resin layers applied for stronger protection | Enhanced moisture resistance, better thermal performance | Marine, mining, humid environments |

| Cast Resin (CRT) | Windings completely encapsulated in epoxy resin mold | High dielectric strength, mechanical rigidity, fire resistance | Data centers, hospitals, high-rise buildings |

2. Cooling Methods in Dry Type Transformers

| Cooling Method | Abbreviation | Description | Typical Rating Range |

|---|---|---|---|

| Air Natural | AN | Heat dissipated naturally through air circulation | Up to ~2.5 MVA |

| Air Forced | AF | Fans increase airflow to boost cooling capacity | Up to ~10 MVA |

| Air Natural / Air Forced Combination | AN/AF | Operates naturally at normal load, fans switch on at overload | Flexible indoor and industrial applications |

3. How Insulation and Cooling Work Together

- Insulation system: Protects windings from high voltage stress and prevents short circuits.

- Cooling system: Removes resistive (I²R) and core losses converted into heat during operation.

- Synergy: A robust insulation system ensures safety, while efficient cooling extends transformer lifespan and improves load handling.

4. Design Considerations for Engineers

- Load profile: Higher loads may require forced air cooling.

- Environment: High humidity favors cast resin or VPE insulation.

- Fire safety: Cast resin types are preferred in public infrastructure due to fire resistance.

- Maintenance: AN types are simplest, but AF systems require fan monitoring and occasional replacement.

What Are the Environmental and Safety Advantages of PCB-Free Transformers?

For decades, polychlorinated biphenyls (PCBs) were used in liquid-filled transformers for their insulating and fire-resistant properties. However, they were later found to be toxic, persistent in the environment, and harmful to human health. Regulations worldwide now prohibit their use. The modern shift to PCB-free transformers—particularly dry type designs—brings clear environmental and safety advantages, which are especially critical in urban, industrial, and public infrastructure applications.

PCB-free transformers eliminate the risks of toxic leaks, soil and water contamination, and long-term bioaccumulation, while also improving fire safety, compliance with environmental regulations, and suitability for indoor installations. Their solid insulation and air cooling systems make them inherently safer for people and the environment compared to historical PCB-filled units.

PCB-free transformers can still leak toxic fluids harmful to the environment.False

Dry type PCB-free transformers do not use liquid insulation, eliminating the possibility of PCB leaks or contamination.

1. Environmental Advantages of PCB-Free Transformers

| Factor | PCB-Containing Transformers | PCB-Free Transformers |

|---|---|---|

| Soil & Water Impact | High contamination risk due to oil leaks | No risk of PCB leaks—resin or air insulation |

| Waste Disposal | Hazardous, requires special treatment | Non-hazardous disposal, lower cost |

| Bioaccumulation | Persistent organic pollutant, harmful to ecosystems | None—materials are stable and safe |

| Green Standards | Non-compliant with modern environmental laws | Fully compliant with RoHS, REACH, green building codes |

2. Safety Advantages of PCB-Free Transformers

- Reduced Fire Risk: Solid insulation and air cooling eliminate combustible oil.

- Non-Toxic Operation: No risk of inhalation or exposure to harmful chemicals.

- Indoor Compatibility: Safe for hospitals, schools, data centers, and high-rises.

- Simplified Maintenance: No oil sampling or PCB testing required.

- Worker Safety: Technicians are not exposed to hazardous PCB residues.

3. Compliance and Regulations

- Global bans: The Stockholm Convention and EPA regulations prohibit PCB use.

- Building standards: LEED and BREEAM certifications encourage PCB-free equipment.

- Insurance: Facilities with PCB-free transformers often receive lower fire and liability premiums.

4. Long-Term Benefits

- Sustainability: PCB-free transformers align with corporate environmental goals.

- Lifecycle Savings: Lower waste management and insurance costs.

- Future-Proofing: Meets all current and anticipated safety and environmental regulations.

How Do PCB-Free Transformers Ensure Compliance with International Standards and Regulations?

As global industries phase out PCB-containing equipment due to their toxicity, PCB-free transformers are designed and manufactured to comply with stringent international safety, environmental, and performance standards. These regulations not only ensure equipment safety but also protect people, ecosystems, and infrastructure. For operators, compliance guarantees trust, reduces liability, and secures long-term operational approval.

PCB-free transformers comply with major international standards such as IEC, IEEE, and ANSI for performance and testing, as well as environmental regulations under RoHS, REACH, and the Stockholm Convention, which strictly prohibit PCB use. This ensures safe operation, environmental protection, and legal conformity across industries worldwide.

PCB-free transformers are not regulated by international standards.False

PCB-free transformers must meet international standards like IEC, IEEE, ANSI for design and testing, and comply with environmental laws banning PCBs.

1. Core International Standards

| Standard Body | Standard Scope | Relevance for PCB-Free Transformers |

|---|---|---|

| IEC (International Electrotechnical Commission) | IEC 60076 series on power transformers, covering insulation, testing, losses, cooling | Defines global benchmarks for safety and performance |

| IEEE (Institute of Electrical and Electronics Engineers) | IEEE C57 standards on dry type and liquid-filled transformers | Widely applied in North America for transformer design/testing |

| ANSI (American National Standards Institute) | ANSI standards align with IEEE but ensure U.S. regulatory compliance | Ensures product acceptance in U.S. installations |

| ISO (International Organization for Standardization) | ISO 14001 for environmental management, ISO 9001 for quality systems | Ensures sustainable and certified manufacturing |

2. Environmental and Chemical Safety Regulations

- Stockholm Convention (2001): Global treaty eliminating persistent organic pollutants (POPs) including PCBs.

- EPA (U.S.) & EU REACH: Strict rules against PCB use, handling, and disposal.

- RoHS (Restriction of Hazardous Substances): Restricts harmful substances in electrical equipment.

- WEEE (Waste Electrical and Electronic Equipment Directive): Ensures environmentally responsible disposal.

3. Compliance Advantages of PCB-Free Transformers

- Guaranteed legality: Avoids penalties and restrictions from banned substances.

- International acceptance: Standard-compliant transformers can be exported globally.

- Reduced liability: Eliminates contamination risks associated with PCB leaks.

- Future-proofing: Meets both present and anticipated stricter environmental rules.

4. Practical Impacts for Users and Operators

- Certifications: Transformers carry nameplate labels indicating IEC/IEEE compliance.

- Procurement: Easier approval for public tenders and green building projects.

- Insurance: Lower fire and environmental risk premiums.

- Audits: Simplifies environmental and safety audits by proving non-use of banned PCBs.

Conclusion

Dry type transformers do not contain PCBs, as they use solid insulation systems like epoxy resin or Nomex and are cooled by air rather than oil. This design eliminates the risk of PCB contamination, making them safer for people, property, and the environment. With international regulations strictly prohibiting PCB use, dry type transformers provide a modern, eco-friendly, and compliant solution for commercial, industrial, and critical infrastructure applications.

FAQ

Q1: Do dry type transformers contain PCBs?

No, dry type transformers do not contain PCBs (polychlorinated biphenyls). Unlike older oil-filled transformers, which historically used PCB-based insulating fluids, dry type transformers rely on solid insulation and air cooling, making them completely PCB-free.

Q2: Why were PCBs used in transformers before?

PCBs were once used in oil-filled transformers due to their excellent insulating and fire-resistant properties. However, they were later banned globally because of their toxic, carcinogenic, and non-biodegradable nature, which posed severe health and environmental risks.

Q3: Are dry type transformers safer for the environment?

Yes, dry type transformers are safer because they use no oil or PCB-based fluids. This eliminates the risk of soil and water contamination, making them environmentally friendly and suitable for indoor use in sensitive locations like hospitals and schools.

Q4: How are PCBs regulated in transformers today?

Most countries follow strict international regulations such as the Stockholm Convention and EPA bans that prohibit the manufacture and use of PCBs. Modern transformers, especially dry type units, are designed to comply fully with these regulations.

Q5: What makes dry type transformers a preferred eco-friendly choice?

Their PCB-free design, absence of oil, low fire risk, and minimal maintenance requirements make dry type transformers a sustainable choice for commercial, industrial, and data center applications.

References

U.S. Environmental Protection Agency (EPA) - PCB Regulations: https://www.epa.gov/pcbs

Stockholm Convention on Persistent Organic Pollutants - https://www.stockholmconvention.org

IEEE - Transformer Insulation and PCB Phase-Out: https://ieeexplore.ieee.org

NEMA - Dry Type Transformer Standards: https://www.nema.org

Electrical4U - Dry Type Transformer and PCB Safety: https://www.electrical4u.com

EEP - PCB-Free Transformer Advantages: https://electrical-engineering-portal.com

All About Circuits - PCB-Free Transformer Technology: https://www.allaboutcircuits.com