With growing concerns over the environmental impact of electrical infrastructure, dry-type transformers are gaining popularity as a more eco-friendly alternative to traditional oil-immersed transformers. Unlike oil-filled transformers, dry-type transformers do not rely on petroleum-based oils, making them inherently safer and more environmentally sustainable. These transformers offer a variety of environmental benefits, ranging from reducing the risk of oil spills to minimizing waste and promoting energy efficiency.

In this article, we will explore the environmental benefits of dry-type transformers and why they are increasingly being favored in modern electrical systems.

What is a Dry-Type Transformer?

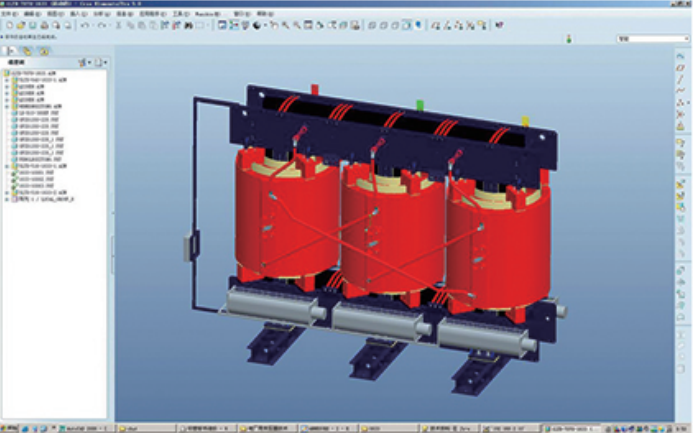

In the world of electrical distribution, transformers are essential components that transfer electrical energy between circuits. However, not all transformers are the same. One of the most commonly used types is the dry-type transformer, which stands out for its unique design, reliability, and safety advantages.

A dry-type transformer is a transformer that utilizes air for cooling instead of liquid like oil. This makes it ideal for environments where fire risk needs to be minimized, as it eliminates the risk of oil leaks or spills. In this article, we’ll explore what dry-type transformers are, how they work, their benefits, and their applications.

What is a Dry-Type Transformer?

A dry-type transformer is an electrical transformer that uses air as the coolant to dissipate the heat generated during operation. Unlike oil-filled transformers, which use mineral oil or other liquids for cooling, dry-type transformers rely on solid insulation materials, such as epoxy resin, polyester, and paper, to insulate the windings and prevent electrical faults.

These transformers are commonly used in both low-voltage and medium-voltage applications, where safety and reliability are paramount. They can be designed in a variety of shapes, including pad-mounted or vault-mounted, to meet specific installation requirements.

How Does a Dry-Type Transformer Work?

Dry-type transformers operate on the same principles as traditional oil-filled transformers but rely on air for cooling. The core and windings of the transformer are made of conductive materials (usually copper or aluminum), and the magnetic field induces a voltage in the secondary winding. The transformer steps up or steps down the voltage based on the turns ratio between the primary and secondary windings.

To ensure that the transformer does not overheat, solid insulation materials are used to isolate the windings, and the transformer relies on air circulation to dissipate the heat generated by the electrical currents. The absence of oil in these transformers makes them an ideal choice for use in indoor settings, such as commercial buildings or public spaces.

Key Features of Dry-Type Transformers

- Air-cooled: Dry-type transformers use air as a cooling medium, making them safer and more environmentally friendly compared to oil-filled transformers.

- Solid Insulation: The windings are insulated with materials like epoxy resin, polyester, or paper, which provide excellent dielectric strength and heat resistance.

- Compact Design: These transformers are often more compact and lighter than oil-filled transformers due to the absence of oil and the use of efficient materials.

- Low Maintenance: Since there is no oil to monitor or replace, dry-type transformers generally require less maintenance.

- Environmentally Friendly: The lack of oil in dry-type transformers means that there are no risks of oil leaks or contamination, making them a more sustainable option.

- Safety: Dry-type transformers eliminate the fire hazard associated with oil-filled transformers, making them a safer option in critical areas like hospitals, schools, and commercial buildings.

Benefits of Dry-Type Transformers

1. Safety

One of the biggest advantages of dry-type transformers is their increased safety. Without the use of oil, the risk of fire or toxic chemical spills is minimized. Dry-type transformers are ideal for environments where safety is a top priority, including:

- Indoors: Buildings such as hospitals, offices, and schools, where fire risk must be minimized.

- Highly populated areas: Where a fire or leak could endanger many people.

In addition, dry-type transformers do not have the environmental concerns associated with oil-filled units, such as contamination of nearby land or water sources in case of leakage.

2. Environmental Friendliness

Since dry-type transformers don’t use oil, they are considered environmentally friendly. The absence of oil means there’s no risk of oil leaks, which could cause environmental pollution. This makes dry-type transformers an ideal choice in sensitive areas such as near water bodies or in urban environments.

Furthermore, their design typically allows for recyclable materials to be used in manufacturing, reducing environmental impact.

3. Lower Maintenance Costs

Dry-type transformers are designed with fewer components and have a simpler construction compared to their oil-filled counterparts. As a result, they tend to have lower maintenance requirements. The absence of oil means there is no need for regular oil checks, oil changes, or treatment. This leads to a reduction in ongoing maintenance costs.

Additionally, solid insulation in dry-type transformers does not degrade over time as quickly as oil insulation, meaning they can operate for longer without needing major servicing.

4. Compact and Space-Efficient

Due to the lack of an oil reservoir, dry-type transformers tend to have a more compact design, which allows for space-saving installations. This is particularly advantageous in urban environments where available space for transformers may be limited. Their smaller size also reduces the overall weight, making them easier to install and transport.

5. Versatility in Installation

Dry-type transformers are versatile in terms of installation. They are often used in places where oil-filled transformers cannot be installed due to space, fire, or environmental concerns. Dry-type transformers can be:

- Installed indoors

- Placed in high-altitude locations (as they don’t require an external cooling system)

- Mounted in places where high safety standards are required

They also perform well at higher altitudes, where the lack of oxygen could affect the performance of oil-filled transformers.

6. Energy Efficiency

Although dry-type transformers may have slightly lower efficiency compared to oil-filled transformers due to their cooling method, modern dry-type transformers are designed to be highly efficient. Advances in solid insulation and air-cooling technology have improved their energy conversion efficiency, making them a reliable and effective choice for various applications.

7. Low Noise Levels

Dry-type transformers tend to operate with lower noise levels compared to oil-filled transformers. This is because there is no liquid involved, which can cause vibrations and produce sound. As a result, dry-type transformers are well-suited for installation in noise-sensitive environments such as hospitals, schools, and offices.

Applications of Dry-Type Transformers

Dry-type transformers are widely used in a variety of applications, including:

- Commercial Buildings: For powering lighting, HVAC, and other equipment where oil leaks are a concern.

- Industrial Plants: To step down high voltages for machinery and equipment that operate on lower voltages.

- Power Distribution: In urban areas where the environmental impact of oil-filled transformers needs to be minimized.

- Renewable Energy Systems: For integrating solar power and wind power into the grid.

- High-Altitude Areas: Where the cooling properties of oil-filled transformers would be less efficient.

Dry-type transformers are also a common choice for smart grids and electric vehicle charging stations, where sustainability, safety, and space-saving designs are crucial.

How Do Dry-Type Transformers Contribute to Environmental Safety?

Dry-type transformers are becoming an increasingly popular choice in electrical distribution systems due to their numerous advantages, particularly when it comes to environmental safety. Unlike traditional oil-filled transformers, dry-type transformers do not use liquid insulation, which significantly reduces their environmental impact. In this article, we’ll explore how dry-type transformers contribute to environmental safety and why they are considered an eco-friendly alternative.

What Makes Dry-Type Transformers Environmentally Safe?

Dry-type transformers are designed with the aim of minimizing environmental risks while delivering the same level of performance as oil-filled transformers. Here's how:

1. Elimination of Oil and Hazardous Liquids

Traditional oil-filled transformers rely on mineral oil or other flammable liquids for cooling and insulation. These oils, while effective for cooling, pose a serious environmental risk due to their flammability and potential for leakage. In the event of a leak, the oil can contaminate nearby soil, water, and ecosystems.

On the other hand, dry-type transformers eliminate the need for oil. They use air as the cooling medium, and solid insulation materials, such as epoxy resin, polyester, or paper. This absence of oil greatly reduces the environmental risks associated with oil spills, fires, and chemical contamination, making dry-type transformers a safer choice for installations in urban or sensitive environments.

2. Reduced Fire Hazard

Oil-filled transformers, if exposed to extreme conditions, can ignite or cause fires due to the combustible nature of the oil inside. A transformer fire not only endangers human life but also leads to toxic emissions, environmental damage, and significant financial loss.

Since dry-type transformers do not contain flammable oils, the fire hazard is greatly reduced. They are especially suitable for indoor installations in places where the risk of fire needs to be minimized, such as:

- Hospitals

- Schools

- Residential buildings

- Data centers

Dry-type transformers meet stringent safety standards and are recognized for their ability to function in high-temperature environments without risking a fire.

3. Lower Risk of Contaminating Waterways

In oil-filled transformers, if the transformer were to suffer a fault or damage, the oil inside may leak, potentially contaminating surrounding waterways, rivers, or lakes. Oil spills not only cause direct harm to aquatic life but also pose long-term challenges in terms of cleanup.

Dry-type transformers completely eliminate this risk. With no oil to leak, there is no threat to water systems or nearby ecosystems, making them a more eco-friendly option for use in environmentally sensitive areas, such as near water bodies or wetlands.

4. No Toxic Chemical Waste

Some oil-filled transformers use oils that contain toxic chemicals like polychlorinated biphenyls (PCBs), which are environmentally harmful and potentially carcinogenic. PCBs were used in older transformers but have since been banned due to their severe environmental and health effects.

Since dry-type transformers do not use oil, they avoid the use of toxic chemicals. They are made with non-toxic materials and are safer for both the environment and human health. In fact, most modern dry-type transformers use non-toxic, recyclable insulation materials, further reducing their environmental footprint.

5. Energy Efficiency and Reduced Carbon Footprint

Dry-type transformers tend to be more energy-efficient than oil-filled transformers because they require less maintenance and can be designed with advanced materials to minimize energy losses. With low energy losses, dry-type transformers contribute to reduced power consumption and ultimately help in lowering the carbon footprint of the overall electrical grid.

Additionally, many dry-type transformers are designed for use in renewable energy systems, such as solar power and wind farms, where their environmental safety and energy efficiency further support sustainability goals.

6. Sustainable Manufacturing and Disposal

Another aspect that makes dry-type transformers eco-friendly is their design for sustainability. The materials used in dry-type transformers, such as epoxy resins, polyesters, and paper, are often recyclable and environmentally safe.

At the end of their lifecycle, dry-type transformers can be recycled more easily than oil-filled units. The absence of oil and toxic substances makes their disposal less hazardous, and the materials used in manufacturing are often more easily repurposed in a closed-loop recycling system.

7. Contribution to Smart Grid Initiatives

Dry-type transformers play a significant role in the development of smart grids. Smart grids are designed to improve the efficiency and reliability of the electrical distribution system by integrating digital technologies. These systems rely on sensors, remote monitoring, and data analytics to enhance performance and sustainability.

As part of a smart grid system, dry-type transformers can be integrated with remote monitoring systems to track real-time performance and predict maintenance needs. This helps reduce unnecessary repairs and downtime, leading to lower emissions and a more sustainable energy infrastructure.

Benefits of Dry-Type Transformers for Environmental Safety

| Benefit | Environmental Impact |

|---|---|

| No Oil Usage | Eliminates risk of oil spills and environmental contamination. |

| Lower Fire Hazard | Reduces risk of fires in indoor and high-risk environments. |

| No Toxic Chemicals | Avoids the use of harmful chemicals like PCBs and reduces health risks. |

| Energy Efficiency | Helps reduce carbon footprint and supports sustainability goals. |

| Recyclable Materials | Uses recyclable and eco-friendly materials, contributing to circular economy. |

Applications Where Dry-Type Transformers Excel in Environmental Safety

Dry-type transformers are ideal for urban areas, environmentally sensitive locations, and fire-sensitive installations. Some common areas of application include:

- Indoor use in residential buildings: Where fire and oil spill risks must be minimized.

- Substations in urban environments: Where space is limited, and safety is crucial.

- Renewable energy systems: For sustainable energy production with minimal environmental impact.

- Data centers and industrial applications: Where cooling efficiency and minimal maintenance are required.

What Role Does Reduced Use of Hazardous Materials Play in Environmental Sustainability?

The reduction of hazardous materials in manufacturing, energy production, and industrial applications plays a critical role in environmental sustainability. By limiting the use of toxic substances, we can significantly minimize pollution, health risks, and ecological damage, while also fostering a more sustainable and responsible economy.

This article explores the various ways in which reducing hazardous material usage contributes to sustainability, along with the benefits for industries, ecosystems, and future generations.

Why Reducing Hazardous Materials is Crucial for Sustainability

Hazardous materials—such as toxic chemicals, heavy metals, volatile organic compounds (VOCs), and persistent organic pollutants (POPs)—pose serious threats to the environment and human health. The long-term accumulation of these materials leads to issues such as soil and water contamination, air pollution, and biodiversity loss.

By adopting safer alternatives and implementing green chemistry, industries can significantly reduce their environmental footprint while ensuring compliance with global sustainability goals such as the United Nations Sustainable Development Goals (SDGs).

1. Protecting Soil and Water Quality

One of the most immediate benefits of reducing hazardous materials is the prevention of soil and water contamination. Industrial waste containing chemicals like lead, mercury, and polychlorinated biphenyls (PCBs) can seep into groundwater, affecting drinking water sources and agricultural productivity.

Key Benefits:

- Prevents toxic leaching into rivers, lakes, and underground water reservoirs.

- Reduces the need for expensive water treatment and soil remediation efforts.

- Supports clean agriculture by minimizing harmful chemical residues in crops.

2. Improving Air Quality and Reducing Greenhouse Gas Emissions

Many hazardous materials used in industrial processes release toxic gases into the atmosphere, contributing to air pollution and climate change. Chemicals like sulfur dioxide (SO₂), nitrogen oxides (NOₓ), and VOCs are major contributors to acid rain, smog formation, and respiratory diseases.

By switching to eco-friendly alternatives, such as water-based solvents instead of VOC-heavy industrial cleaners, industries can significantly improve air quality while reducing their carbon footprint.

Case Study:

A shift from oil-based to dry-type transformers eliminates the risk of oil spills and reduces emissions from oil-based insulation burning, promoting cleaner air and lower environmental impact.

3. Enhancing Human Health and Workplace Safety

Many hazardous substances pose serious health risks to workers and surrounding communities. Exposure to chemicals like benzene, asbestos, and formaldehyde is linked to conditions such as cancer, neurological disorders, and respiratory illnesses.

Industries that adopt non-toxic and low-emission materials benefit from:

- Safer working conditions, reducing occupational health hazards.

- Lower healthcare costs associated with chronic exposure to hazardous substances.

- Compliance with international health and safety regulations such as OSHA (Occupational Safety and Health Administration) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals).

4. Encouraging Sustainable Manufacturing Practices

The shift toward hazard-free materials encourages industries to adopt sustainable production methods. This includes:

- Green chemistry innovations that minimize toxic waste.

- Biodegradable alternatives to hazardous chemicals.

- Closed-loop manufacturing, where materials are recycled and reused instead of being disposed of as hazardous waste.

Example:

In the electronics industry, manufacturers are increasingly phasing out lead-based soldering and switching to lead-free alternatives, reducing toxic electronic waste (e-waste) and making devices more environmentally friendly.

5. Supporting Circular Economy and Waste Reduction

A circular economy aims to reduce waste and maximize resource efficiency by promoting recycling, reuse, and sustainable disposal. Hazardous materials disrupt this cycle because they require special disposal methods, increasing environmental costs.

By replacing hazardous materials with non-toxic alternatives, industries can:

- Increase recyclability of products and materials.

- Reduce hazardous waste generation.

- Lower disposal costs and regulatory fines.

Key Statistic:

According to the World Economic Forum, transitioning to a circular economy could reduce global waste production by 90% while driving economic growth.

6. Reducing Ecological Damage and Protecting Biodiversity

Hazardous materials released into the environment have devastating effects on wildlife and ecosystems. Heavy metals like cadmium and arsenic accumulate in the food chain, leading to toxic effects in marine life, birds, and terrestrial animals.

By reducing hazardous material use, we can:

- Prevent bioaccumulation of toxic substances in ecosystems.

- Protect endangered species and maintain biodiversity.

- Promote eco-friendly products that do not harm wildlife.

Example:

The ban on DDT pesticides has helped restore populations of birds like bald eagles and peregrine falcons, which were once on the brink of extinction due to chemical poisoning.

7. Strengthening Global Sustainability Goals

Governments and industries worldwide are increasingly aligning with global sustainability initiatives, such as:

- The Paris Agreement, which aims to limit global warming.

- The European Green Deal, which promotes a toxic-free environment.

- The UN Sustainable Development Goals (SDGs), particularly Goal 12: Responsible Consumption and Production.

By reducing hazardous materials, companies enhance their corporate social responsibility (CSR) and contribute to a greener, more sustainable economy.

How Industries Can Transition to Safer Alternatives

Transitioning to low-impact materials requires investment in research, innovation, and regulatory compliance. Here are some strategies industries can adopt:

| Sustainable Strategy | Impact on Environmental Safety |

|---|---|

| Using biodegradable materials | Reduces non-decomposable hazardous waste. |

| Implementing green chemistry | Minimizes toxic emissions and hazardous byproducts. |

| Developing non-toxic coatings and solvents | Lowers exposure risks for workers and surrounding ecosystems. |

| Switching to dry-type transformers | Eliminates oil spills, fire hazards, and chemical contamination. |

| Promoting eco-friendly packaging | Reduces plastic pollution and chemical leaching. |

How Do Dry-Type Transformers Promote Energy Efficiency?

Dry-type transformers are increasingly being used in various applications due to their energy-efficient design and operational benefits. Unlike traditional oil-filled transformers, which rely on liquid insulation, dry-type transformers use air or solid insulation to ensure safe and efficient energy transfer. Their unique characteristics not only make them safer but also contribute significantly to energy savings. This article delves into the ways dry-type transformers promote energy efficiency, and why they are becoming a go-to choice for many industries striving to reduce energy loss.

What Makes Dry-Type Transformers Energy Efficient?

Dry-type transformers are constructed to minimize energy losses through both reduced core losses and lower operating temperatures. Their design eliminates the need for oil, and they are often placed in ventilated, cooled spaces, which ensures that they operate at a higher efficiency compared to their oil-immersed counterparts.

1. Reduced Energy Loss

The most significant energy loss in any transformer occurs due to core losses (also called iron losses) and winding losses (also known as copper losses). Dry-type transformers are designed with materials and construction techniques that reduce these losses.

Core Loss Reduction: Dry-type transformers use high-grade silicon steel or amorphous steel in their cores, which are engineered to have low hysteresis and eddy current losses. This results in less energy being lost as heat.

Winding Loss Reduction: The winding is constructed using high-quality copper or aluminum, ensuring low resistance and thus reducing energy losses through heat generation.

The absence of oil in dry-type transformers also ensures that no additional energy is required for cooling or circulation, which further enhances their overall efficiency.

2. Improved Heat Dissipation

One of the challenges for transformers is maintaining an optimal operating temperature. Overheating can lead to increased losses and reduced lifespan.

Dry-type transformers are often equipped with natural ventilation systems that allow air to flow freely around the transformer, promoting effective heat dissipation. This prevents the transformer from overheating, ensuring it operates at a more stable temperature.

Since there is no oil to absorb heat, dry-type transformers are better suited for high-temperature environments and can handle larger variations in ambient temperatures without compromising efficiency.

3. No Energy Loss from Cooling Systems

Oil-filled transformers require energy-consuming cooling systems to circulate the oil and maintain the right temperature levels. These cooling systems can add a significant amount of energy consumption, especially in large or high-capacity transformers.

In contrast, dry-type transformers rely on natural cooling, often enhanced by external fans or heat sinks, which do not require additional energy inputs for cooling, saving energy over time.

4. Increased Load Efficiency

Dry-type transformers are more efficient under light loads because they operate with lower core losses compared to their oil-filled counterparts. When the transformer is not fully loaded, core losses in oil-filled transformers can be more significant due to the oil’s slow circulation rate and the fact that oil doesn't cool as efficiently as air.

- The reduced core loss in dry-type transformers means they can operate with higher efficiency even when supplying partial loads. This is a significant advantage in areas where transformers are often underutilized.

5. Compact and Modular Design

The design of dry-type transformers is often compact and modular, which allows them to be placed closer to end-users and reduces the need for long-distance power transmission.

- Transmission losses are reduced because energy does not have to travel as far, decreasing overall energy waste.

- Dry-type transformers can be used in a distributed generation model, where energy is generated and transformed close to where it is used, further enhancing overall system efficiency.

6. Lower Maintenance Costs Lead to Long-Term Savings

Dry-type transformers generally require less maintenance than oil-filled transformers because they do not have oil to leak or degrade. The reduction in maintenance costs leads to long-term operational savings, which can be invested back into improving energy efficiency in other areas.

- The absence of oil also reduces the risk of fire hazards, meaning that dry-type transformers are often safer and less costly to maintain.

7. Contribution to Sustainable Energy Practices

Dry-type transformers support sustainable energy practices by eliminating the need for hazardous materials like oil, which can leak or contaminate the environment if not handled properly. They are more environmentally friendly due to:

- The absence of oil disposal concerns.

- Lower energy consumption and reduced carbon footprints.

- Reduced risks associated with fire hazards and chemical leaks.

Energy Efficiency Comparison: Dry-Type vs. Oil-Filled Transformers

| Transformer Type | Core Losses | Winding Losses | Cooling Requirements | Maintenance | Energy Efficiency |

|---|---|---|---|---|---|

| Dry-Type Transformer | Low | Low | Natural or fan-assisted | Low | High |

| Oil-Filled Transformer | Moderate to High | High | Oil circulation system | Higher | Moderate to Low |

This table summarizes the primary differences in energy efficiency between dry-type and oil-filled transformers. As seen, dry-type transformers generally outperform oil-filled ones in terms of both energy efficiency and maintenance.

Real-World Example: Applications of Dry-Type Transformers

Dry-type transformers are commonly used in areas where environmental concerns and space limitations are significant, such as:

- Indoor spaces like commercial buildings and data centers, where they can efficiently serve electrical needs without the risk of oil leaks.

- Renewable energy systems, including solar and wind power facilities, where clean and reliable transformers are necessary for converting electrical energy with minimal loss.

- Industrial facilities where high efficiency and reduced maintenance are key factors in maximizing operational performance.

How Do Dry-Type Transformers Enhance Recycling and Waste Management?

Dry-type transformers are known for their energy efficiency and environmental safety. But one of the most compelling reasons they are becoming more popular, especially in green energy and eco-conscious sectors, is their positive impact on recycling and waste management. Unlike oil-filled transformers, which can pose challenges in terms of waste disposal and environmental risks, dry-type transformers contribute significantly to reducing the environmental footprint and improving the sustainability of electrical systems. In this article, we will explore how dry-type transformers enhance recycling and waste management efforts, making them an important choice for industries focused on environmental responsibility.

1. Elimination of Hazardous Oil Waste

One of the most significant environmental advantages of dry-type transformers is the absence of oil. Traditional oil-filled transformers use mineral oil or synthetic oils as insulation and cooling agents. These oils can be toxic, flammable, and difficult to dispose of properly. They can leak or spill, potentially contaminating the soil, water, and air, posing a serious environmental risk. In addition, the disposal of used transformer oil can be complex and costly, involving specialized recycling procedures.

In contrast, dry-type transformers use solid insulation materials such as epoxy resin, polyester, or paper, which eliminate the need for oil. The absence of oil reduces the potential for harmful waste products, making dry-type transformers significantly safer for the environment. As a result, dry-type transformers contribute to better waste management practices, as they do not require disposal of large volumes of used oil or complicated oil recycling processes.

2. Materials are More Recyclable

Another major benefit of dry-type transformers in terms of waste management is the recyclability of their materials. The primary insulation materials used in dry-type transformers, such as epoxy resin, polyester, and paper-based materials, are more easily recyclable compared to the oil and metal components found in traditional transformers.

Epoxy resin, commonly used as a solid insulation material in dry-type transformers, is durable, heat-resistant, and environmentally friendly. When the transformer reaches the end of its life, the epoxy resin can be broken down and recycled, reducing the overall waste generated by transformer disposal.

Polyester and paper-based insulation materials can be easily separated and recycled through conventional waste management systems, unlike oils or oil-contaminated materials that require specialized handling.

Dry-type transformers, therefore, contribute to the recycling economy by ensuring that most of their components can be recycled or repurposed, leading to less waste and reduced environmental impact.

3. Reduced Need for Hazardous Chemical Waste Disposal

Oil-filled transformers often require the use of hazardous chemicals during maintenance and repairs. These chemicals can lead to toxic waste that needs to be carefully handled and disposed of. For example, oil treatments or chemical additives can accumulate in the oil over time, making disposal procedures more complicated.

Dry-type transformers, however, eliminate the need for chemical additives or hazardous treatments during operation, reducing the potential for chemical waste generation. They use air or solid insulation materials, which are inherently safer and more environmentally friendly, minimizing the risks associated with chemical waste disposal.

4. Eco-Friendly Design and Manufacturing

The materials used in the manufacturing of dry-type transformers are selected not only for their electrical properties but also for their sustainability. Manufacturers often prioritize eco-friendly sourcing and low-impact production processes when creating dry-type transformers.

For instance:

- Recycled materials such as recycled copper and aluminum are commonly used in the construction of dry-type transformers, reducing the need for virgin resources.

- The manufacturing processes for dry-type transformers tend to have a lower carbon footprint compared to those used for oil-filled transformers, as there are no extensive steps required to process or handle oil.

By supporting the use of recycled materials and promoting sustainable production methods, dry-type transformers contribute to reducing the environmental impact of transformer manufacturing.

5. Lower Risk of Environmental Contamination

Dry-type transformers pose a significantly lower risk of environmental contamination due to their lack of oil. Oil-filled transformers, especially in the event of a malfunction or natural disaster, can spill their oil, leading to contamination of waterways, soil, and air. These incidents require costly cleanup operations, which can involve hazardous waste management.

Since dry-type transformers do not contain oil, they present a minimal risk of contamination and the need for expensive cleanup, which not only reduces environmental hazards but also reduces the overall cost of disposal when the transformer reaches the end of its useful life.

6. Longer Lifespan Reduces Frequency of Disposal

The design and construction of dry-type transformers help ensure a longer operational lifespan, often leading to fewer replacements over time. This extended lifespan reduces the frequency at which transformers must be disposed of, further reducing waste generation.

In addition, dry-type transformers are more reliable, requiring less frequent maintenance, which in turn reduces the need for component replacement. By enhancing the durability of the transformer, the overall energy cost of replacing and disposing of old transformers is minimized, contributing to long-term sustainability.

7. Reduced Fire Risk and Hazardous Materials

Traditional oil-filled transformers carry an inherent risk of fire hazards due to the flammability of the oil. This risk not only endangers the safety of personnel and equipment but can also cause significant environmental damage during fire incidents.

Dry-type transformers, on the other hand, are designed to be fire-resistant, reducing the potential for such hazards. The use of solid insulation and the absence of flammable liquids ensures that dry-type transformers have a significantly lower risk of causing fires, thus contributing to overall safer and more eco-friendly transformer operation.

8. End-of-Life Recycling of Transformers

When a dry-type transformer reaches the end of its life, the recycling process is more straightforward and less energy-intensive than that of oil-filled transformers. The disassembly of dry-type transformers involves the separation of copper windings, steel cores, and solid insulation materials, all of which are recyclable through established waste management systems.

- Copper and aluminum windings are valuable materials that can be easily recycled into new products, reducing the need for mining and extracting virgin metals.

- The steel cores can also be recycled, with minimal energy required to repurpose the metal for new manufacturing processes.

What Are the Benefits of Dry-Type Transformers in Urban and Sensitive Environments?

Dry-type transformers are becoming an increasingly popular choice for urban areas and sensitive environments, where safety, environmental impact, and space limitations are top priorities. Unlike oil-filled transformers, which can pose risks of oil spills and are less adaptable to confined spaces, dry-type transformers offer distinct advantages in these settings. In this article, we will explore the numerous benefits of dry-type transformers in urban and sensitive environments, particularly in terms of safety, environmental impact, space-saving design, and reliability.

1. Zero Risk of Oil Spills and Contamination

In urban environments, the potential for environmental contamination is a significant concern. Oil-filled transformers, which use mineral oil or other synthetic oils as cooling agents, can pose a risk of oil leakage or spills due to aging, accidents, or natural disasters like floods. Such incidents can lead to the contamination of waterways, soil, and air, causing significant environmental damage.

Dry-type transformers, in contrast, do not use oil or flammable liquids for cooling, making them an ideal choice for sensitive environments like residential areas, commercial buildings, and parks. By eliminating the risk of oil spills, dry-type transformers ensure that urban spaces remain safe and free from contamination. This characteristic is particularly critical in locations where ecosystems, wildlife, or clean water sources need protection.

2. Enhanced Safety in Crowded or High-Traffic Areas

Urban environments are often densely populated, with a high concentration of residential buildings, businesses, and public spaces. In these areas, safety is a primary concern, and electrical equipment must be designed to prevent hazards such as fires, electrical shocks, or explosions.

Dry-type transformers offer enhanced safety due to their solid insulation materials and fire-resistant design. They do not contain flammable oils, which significantly reduces the likelihood of fire hazards. Additionally, solid insulation materials like epoxy resin or polyester are highly resistant to high temperatures and electrical faults, ensuring that dry-type transformers can operate safely even in densely populated urban settings.

In the case of malfunction or overload, dry-type transformers are less likely to pose a risk to surrounding areas, as they are self-extinguishing and do not rely on volatile cooling fluids. This makes them an ideal solution for areas with high foot traffic or where public safety is a concern.

3. Compact and Space-Saving Design

Urban environments are often characterized by limited space for infrastructure, and many areas have to contend with space constraints when it comes to installing electrical equipment. Dry-type transformers are inherently more compact than traditional oil-filled transformers, making them a better fit for areas with limited space.

Their smaller footprint allows dry-type transformers to be installed in confined spaces, such as buildings, underground vaults, or small utility rooms. This space-saving capability makes them especially suited for cities where land is scarce and efficient use of available space is critical. Furthermore, dry-type transformers are often designed for indoor installation, which can be beneficial in densely populated or urbanized locations where outdoor installation is not always feasible.

4. Environmentally Friendly and Sustainable

As cities continue to grow and the need for sustainable energy solutions increases, urban planners and building managers are placing more emphasis on eco-friendly infrastructure. Dry-type transformers offer several environmental benefits, making them an excellent choice for green building projects, smart grids, and sustainable cities.

- Oil-free design: As mentioned earlier, dry-type transformers do not contain oils, which means they do not need to be disposed of or recycled. This reduces the environmental impact associated with the disposal of hazardous oils in traditional transformers.

- Use of recyclable materials: Dry-type transformers are often made from recyclable components such as copper, aluminum, and solid insulation materials, which makes them easier to recycle at the end of their operational life.

- Energy efficiency: Dry-type transformers are typically more energy-efficient than their oil-filled counterparts, which can result in lower carbon emissions and energy consumption in urban grids.

For environmentally conscious cities and communities, dry-type transformers provide a sustainable option that aligns with green energy goals and reduces the overall environmental impact of power distribution systems.

5. Low Maintenance and Reduced Downtime

Urban infrastructure requires reliable systems with minimal downtime, as interruptions in power supply can have serious consequences on businesses, hospitals, and public services. Dry-type transformers have a low-maintenance design compared to oil-filled transformers, which require regular oil checks, filtration, and maintenance of cooling systems.

Since dry-type transformers operate without oil, there are fewer components to monitor and maintain. This reduces maintenance costs, increases reliability, and ensures that power supply systems remain operational with fewer interruptions. The low-maintenance nature of dry-type transformers makes them an excellent choice for urban areas where operational efficiency and reliability are paramount.

6. Adaptable to Smart Grid Technologies

As urban areas evolve and smart grids become more prevalent, transformers must be able to integrate seamlessly into intelligent power networks. Dry-type transformers are well-suited for smart grid applications because they can easily be outfitted with smart sensors and remote monitoring systems that allow operators to monitor transformer performance in real-time.

- Real-time data collection enables operators to track parameters such as temperature, load, and voltage, allowing for predictive maintenance and the prevention of potential failures.

- Remote monitoring and control systems improve the efficiency and reliability of the transformer network, ensuring that the urban power supply remains uninterrupted.

Dry-type transformers can be seamlessly integrated into smart grid infrastructure, making them an important component of future urban power systems that prioritize automation, efficiency, and sustainability.

7. Ideal for Sensitive or Eco-Conscious Areas

Sensitive environments such as nature reserves, ecological parks, or areas near protected wildlife require electrical equipment that does not pose a risk to the ecosystem. Dry-type transformers are an excellent choice for these sensitive environments because they are environmentally safe, non-toxic, and fire-resistant.

By eliminating the need for flammable oils, dry-type transformers provide a low-risk solution for power distribution in sensitive ecological zones. Furthermore, their recyclable components and energy-efficient design contribute to the overall environmental protection of these areas.

8. Noise Reduction in Urban Areas

Noise pollution is a significant concern in urban settings, and the electrical equipment used in these environments must be designed to minimize noise emissions. Dry-type transformers are generally quieter than oil-filled transformers because they do not use cooling fans or pumps that can generate noise.

This makes them an excellent choice for urban areas where noise pollution can affect the quality of life for residents. Their quiet operation is particularly beneficial in residential areas or places where people live or work in close proximity to electrical infrastructure.

Conclusion

Dry-type transformers offer several environmental benefits that make them an attractive option in both industrial and urban electrical grids. By eliminating the need for oil, they reduce the risk of oil spills, which can cause significant environmental damage. They also minimize the use of hazardous materials and are easier to recycle, reducing their environmental footprint at the end of their life cycle.

In addition, dry-type transformers often have better energy efficiency, which helps in reducing the overall carbon footprint of the power distribution system. With their ability to operate without the need for cooling oils, they also help reduce energy consumption, contributing to a greener, more sustainable grid.

Given these advantages, dry-type transformers are ideal for sensitive environments such as urban areas, schools, hospitals, and residential zones, where safety and environmental concerns are critical. As the push for greener technologies grows, dry-type transformers will continue to play a vital role in helping utilities meet their sustainability goals and improve the environmental footprint of electrical infrastructure.

FAQ

Q1: How do dry-type transformers reduce environmental risks?

A1: Dry-type transformers eliminate the risk of oil spills, which are a common environmental concern with oil-filled transformers. Since dry-type transformers use solid insulation materials, they prevent contamination of soil and water, making them a safer choice for the environment.

Q2: Are dry-type transformers more energy-efficient than oil-filled transformers?

A2: Yes, dry-type transformers are generally more energy-efficient because they have better heat dissipation properties due to their design and lack of oil. This reduces the likelihood of energy losses, leading to a more sustainable power distribution system and lower carbon emissions.

Q3: How do dry-type transformers contribute to a greener energy future?

A3: Dry-type transformers support greener energy systems by being free of harmful oils and chemicals. They also require less maintenance and have a longer lifespan, reducing waste and the need for frequent replacements. Their efficiency and sustainability make them ideal for environmentally conscious power distribution systems.

Q4: What are the maintenance advantages of dry-type transformers for the environment?

A4: Dry-type transformers require less maintenance compared to oil-filled transformers, which reduces the need for hazardous waste disposal, like used oils. This lower maintenance requirement means fewer resources are consumed, and less environmental damage occurs from transformer upkeep.

Q5: How does the use of dry-type transformers align with sustainability goals?

A5: Dry-type transformers are an environmentally friendly choice for achieving sustainability goals. Their oil-free design reduces the risk of pollution, their energy efficiency contributes to reduced greenhouse gas emissions, and their longer lifespan helps minimize electronic waste and resource consumption.

References

"Environmental Impact of Dry-Type Transformers" - https://www.energycentral.com/c/ee/environmental-impact-dry-type-transformers - Energy Central

"How Dry-Type Transformers Support Eco-Friendly Power Distribution" - https://www.transformertech.com/dry-type-transformers - Transformer Tech

"Sustainable Power Solutions: The Benefits of Dry-Type Transformers" - https://www.sciencedirect.com/topics/engineering/dry-type-transformers - ScienceDirect

"Green Energy and Dry-Type Transformers: A Perfect Match" - https://www.powergrid.com/green-transformers - PowerGrid

"The Role of Dry-Type Transformers in Reducing Environmental Impact" - https://www.researchgate.net/green-transformers - ResearchGate

"Reducing Carbon Footprint with Dry-Type Transformers" - https://www.powermag.com/reduce-carbon-footprint-dry-type - Power Magazine

"Eco-Friendly Benefits of Dry-Type Transformers" - https://www.electrical4u.com/dry-type-transformer-benefits - Electrical4U

"The Green Benefits of Choosing Dry-Type Transformers" - https://www.smartgridnews.com/green-transformers - Smart Grid News