Transformer efficiency is influenced by multiple real-world operating conditions. Among them, harmonics, power quality issues, and load variation are critical factors that can increase losses, reduce lifespan, and compromise performance. By framing these topics as key questions, we can better understand how each factor impacts transformer efficiency and what solutions are available.

How Do Harmonics Increase Transformer Losses and Heating?

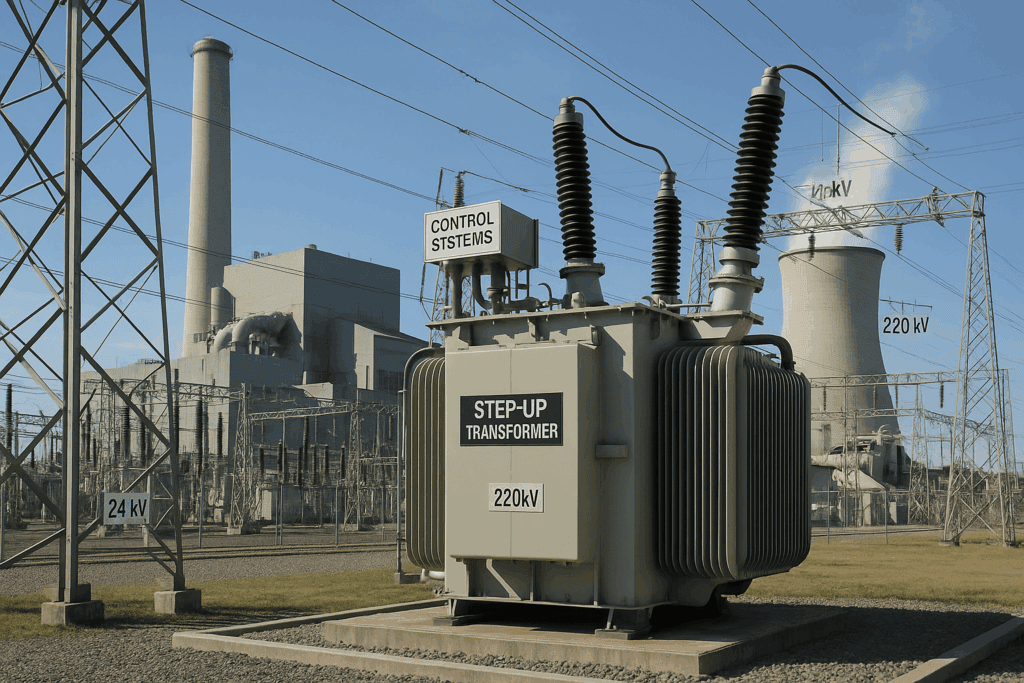

In modern power systems, transformers are expected to handle not just sinusoidal currents but also complex waveforms created by nonlinear loads. Computers, variable frequency drives, LED lighting, and industrial converters introduce harmonics into the grid—currents at integer multiples of the fundamental frequency. The consequence is excessive heating, reduced efficiency, insulation stress, and even premature transformer failure. If ignored, harmonics shorten service life, increase energy costs, and compromise reliability. The solution lies in understanding how harmonics affect transformer losses and ensuring proper design, derating, or mitigation.

Harmonics increase transformer losses and heating by raising eddy current and hysteresis losses in the core, amplifying I²R (copper) losses in windings, and creating stray flux that causes localized hot spots. Non-sinusoidal currents from harmonics produce excessive neutral currents and additional heating in structural components. As a result, transformers under harmonic-rich loads run hotter, age faster, and require derating or harmonic mitigation to maintain safe operation.

For industries, utilities, and data centers, managing harmonics is no longer optional—it is essential for protecting valuable transformer assets and ensuring stable, efficient operation.

Harmonics do not significantly affect transformer heating.False

Harmonics amplify core and winding losses, causing excess heat and accelerated insulation aging.

Transformers in harmonic-rich environments must be derated to prevent overheating.True

IEEE and IEC standards recommend transformer derating when harmonic distortion is present to ensure thermal safety.

Mechanisms of Harmonic-Induced Losses in Transformers

When harmonic currents flow through a transformer, multiple loss components increase:

Copper Losses (I²R):

- Harmonic currents increase RMS current, raising winding resistance losses.

- Higher order harmonics (5th, 7th, etc.) add significantly to total heating.

Core Losses (Hysteresis & Eddy Current):

- Non-sinusoidal voltages distort magnetic flux.

- Eddy current losses rise with frequency (proportional to f²), meaning higher harmonics cause disproportionately more heat.

Stray & Structural Losses:

- Stray flux induced by harmonic currents heats tank walls, clamps, and structural parts.

- Triplen harmonics (3rd, 9th, 15th) accumulate in the neutral of three-phase systems, creating additional losses.

Dielectric Stress & Hot Spots:

- Uneven heating accelerates insulation degradation.

- Leads to early failure compared to sinusoidal operation.

Quantitative Impact of Harmonics on Transformer Losses

| Harmonic Order | Relative Frequency (Hz in 50Hz System) | Effect on Losses | Typical Source |

|---|---|---|---|

| 3rd Harmonic | 150 Hz | Neutral current buildup, heating | Lighting, UPS |

| 5th Harmonic | 250 Hz | High eddy current losses | Variable drives |

| 7th Harmonic | 350 Hz | Core distortion, added heating | Converters |

| 9th+ Harmonics | 450 Hz+ | Severe stray losses, dielectric stress | Arc furnaces |

Below is an example comparison of transformer losses under harmonic loading:

| Condition | No-Load Losses (kW) | Load Losses (kW) | Hot-Spot Temperature Rise (°C) | Expected Life (Years) |

|---|---|---|---|---|

| Pure Sinusoidal Load | 2.5 | 12 | +55 | 30–35 |

| 15% THD (Total Harmonic Distortion) | 2.5 | 18 | +75 | 20–25 |

| 30% THD | 2.5 | 26 | +95 | 10–15 |

The data shows how even moderate harmonic distortion drastically accelerates thermal stress and shortens lifespan.

Case Study: Data Center Transformers

A global data center operator observed frequent overheating alarms on 2000 kVA distribution transformers, despite operating below rated load. Analysis revealed a total harmonic distortion (THD) of 22% due to servers, UPS systems, and LED lighting. The transformer’s winding losses nearly doubled, leading to 20°C higher hot-spot temperatures. The operator installed K-rated transformers (designed for harmonic-rich environments) and harmonic filters. Post-mitigation, winding temperatures normalized, and failure risks reduced significantly.

What Role Does Power Quality Play in Transformer Efficiency?

Transformers are designed to operate most efficiently under near-ideal power conditions: balanced three-phase sinusoidal voltages and currents with minimal distortion. However, real-world systems often suffer from poor power quality issues such as voltage fluctuations, harmonics, unbalanced loads, and reactive power. These conditions increase losses, accelerate insulation aging, and reduce transformer lifespan. For utilities and industries, this translates into higher energy costs, more frequent failures, and expensive downtime. The solution is to understand the relationship between power quality and transformer efficiency, then apply corrective measures to ensure stable and reliable operation.

Power quality directly impacts transformer efficiency by influencing copper losses, core losses, stray flux heating, and thermal aging. Issues such as harmonics, voltage unbalance, and reactive power increase RMS currents and distortion, leading to overheating and reduced efficiency. Maintaining high power quality minimizes transformer losses, extends insulation life, lowers operating costs, and enhances overall system reliability.

This means customers should not only focus on transformer design and materials but also evaluate the quality of the power feeding their equipment. Even the most efficient transformer cannot perform optimally if the supplied power is distorted or unstable.

Power quality issues have little impact on transformer efficiency.False

Poor power quality increases transformer heating and losses, reducing efficiency and service life.

Correcting power quality problems can extend transformer lifespan by decades.True

Better power quality reduces thermal stress and insulation breakdown, delaying aging.

Key Power Quality Factors Affecting Transformer Efficiency

Several aspects of power quality directly influence transformer performance:

| Power Quality Issue | Effect on Transformers | Example |

|---|---|---|

| Harmonics (THD) | Increases eddy current and copper losses; overheating | Data centers, VFD-driven motors |

| Voltage Unbalance | Causes uneven winding heating, efficiency loss | Three-phase motors on unbalanced supply |

| Voltage Fluctuations | Frequent magnetizing inrush, increased losses | Weak grids, rural substations |

| Reactive Power (Low PF) | Increases RMS current, higher copper losses | Industrial plants with inductive loads |

| Transients & Surges | Stresses insulation, premature breakdown | Switching events, lightning |

Quantitative Impact of Power Quality on Efficiency

| Condition | Transformer Efficiency (%) | Hot-Spot Rise (°C) | Expected Life (Years) |

|---|---|---|---|

| Ideal Power Quality | 99.1 | +55 | 30–35 |

| 10% Voltage Unbalance | 97.8 | +70 | 20–25 |

| 20% Total Harmonic Distortion | 96.5 | +80 | 15–20 |

| Low Power Factor (0.8 lagging) | 95.9 | +85 | 12–18 |

| Frequent Voltage Surges/Transients | 95.0 | +90 | <15 |

This shows how poor power quality steadily erodes both efficiency and service life.

Case Study: Industrial Plant with High Harmonics

An industrial plant operating multiple variable frequency drives (VFDs) observed that their distribution transformers were running hotter than expected despite operating at only 70% rated load. Power quality analysis revealed 25% total harmonic distortion (THD), which doubled the winding losses and increased stray flux heating. By installing passive harmonic filters and replacing standard transformers with K-rated harmonic-resistant units, efficiency improved by 2.2% and insulation hot-spot temperatures decreased by 15°C, extending service life by nearly a decade.

The Link Between Power Quality and Lifecycle Costs

A transformer’s purchase price is only a fraction of its total cost of ownership (TCO). Poor power quality increases annual energy losses, accelerates aging, and forces premature replacements. In contrast, good power quality means lower losses, less maintenance, and extended life. Investing in power quality monitoring and correction systems (filters, power factor correction, balanced loading) directly reduces lifecycle costs while improving grid reliability.

How Does Load Variation Affect No-Load and Load Losses in Power Transformers?

In power transformers, losses are inevitable, but their behavior depends heavily on how the transformer is loaded. Some customers mistakenly assume that transformer losses only occur when the transformer is under load. In reality, no-load losses occur whenever the transformer is energized, regardless of load, while load losses depend on the amount and quality of load current. When load variation is not considered during design or operation, transformers can operate inefficiently, overheat, or age prematurely—causing financial losses and reduced service life. The solution is to understand how load variations affect both no-load and load losses, then optimize operation accordingly.

Load variation affects transformer losses by keeping no-load (core) losses constant regardless of load, while load (copper and stray) losses increase proportionally to the square of the load current. At light loads, no-load losses dominate efficiency, while at heavy loads, load losses dominate. This means transformer efficiency varies with load, peaking at the “optimal loading point” where no-load and load losses are balanced.

For customers, this understanding is crucial in specifying, selecting, and operating transformers for maximum efficiency and reliability.

Transformer losses remain constant regardless of load.False

No-load losses remain constant, but load losses rise with the square of the current, making total losses dependent on load variation.

Transformer efficiency is highest when load losses equal no-load losses.True

The point where load and no-load losses are balanced is known as the optimal efficiency point.

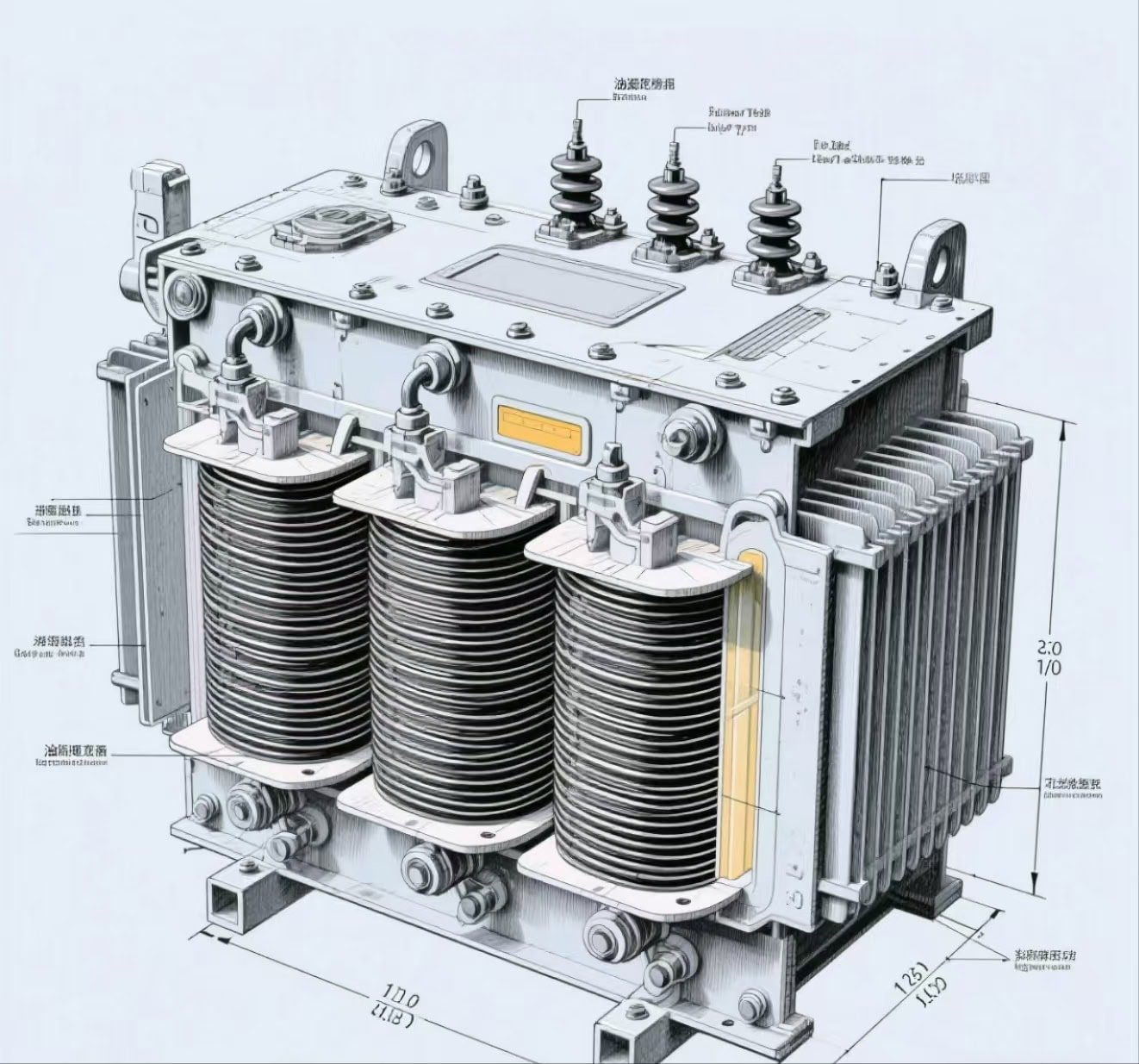

No-Load vs Load Losses: The Basics

No-Load Losses (Core Losses):

- Caused by magnetizing current and core magnetization.

- Include hysteresis and eddy current losses.

- Constant whenever the transformer is energized, independent of load.

Load Losses (Copper + Stray Losses):

- Caused by winding resistance (I²R losses), leakage flux, and stray eddies in structural parts.

- Increase with square of load current (∝ I²).

- Strongly affected by load variation and power quality (harmonics).

Load Variation and Transformer Efficiency

The efficiency of a transformer is defined as:

\eta = \frac{P{out}}{P{out} + P_{loss}}

Where:

- $P{loss} = P{no-load} + P_{load}$

- $P_{load} \propto I^2$

This means:

- At low loads, no-load losses dominate → lower efficiency.

- At high loads, load losses dominate → overheating risk.

- At the optimum load point, efficiency peaks.

Comparative Data: Loss Distribution at Different Loads

| Load Level (% of Rated) | No-Load Losses (kW) | Load Losses (kW) | Total Losses (kW) | Efficiency (%) |

|---|---|---|---|---|

| 25% | 2.5 | 1.9 | 4.4 | 96.8 |

| 50% | 2.5 | 7.5 | 10.0 | 97.8 |

| 75% | 2.5 | 16.9 | 19.4 | 98.1 |

| 100% | 2.5 | 30.0 | 32.5 | 97.6 |

| 125% (Overload) | 2.5 | 46.9 | 49.4 | 96.1 |

The table shows that efficiency peaks around 70–80% loading—where load losses balance with no-load losses.

Case Study: Utility Distribution Transformers

A utility operating 500 kVA distribution transformers in rural areas observed poor efficiency because load levels averaged below 30% most of the year. Since no-load losses dominated at light loads, transformers were burning unnecessary energy. By replacing oversized units with right-sized transformers optimized for actual load profiles, the utility reduced annual energy losses by 18% and improved voltage stability.

Why Load Variation Matters

- Underloading: High percentage of energy wasted as constant core losses.

- Overloading: Excess copper losses, overheating, insulation aging, and reduced life.

- Fluctuating Loads: Frequent efficiency swings, requiring careful monitoring and sometimes demand-side load management.

At What Loading Levels Is Transformer Efficiency Highest?

When operating a transformer, one of the biggest challenges is ensuring that it runs at its most efficient point. Many customers assume that efficiency is highest when a transformer is fully loaded, but this is not true. Transformers have two categories of losses: no-load losses, which remain constant, and load losses, which rise with the square of the current. If a transformer is loaded too lightly, no-load losses dominate; if overloaded, copper losses increase rapidly. The solution is to identify the optimal loading point, where efficiency reaches its maximum.

Transformer efficiency is highest at the loading level where no-load (core) losses equal load (copper) losses. This typically occurs at 60%–80% of rated capacity, depending on the transformer’s design. At this balance point, total losses are minimized, hot-spot temperature rise is controlled, and efficiency peaks.

For utilities, industries, and renewable projects, knowing this operating point is essential to avoid wasting energy and to extend transformer life.

Transformer efficiency is highest at 100% rated load.False

Load losses rise with the square of current, so full-load operation often reduces efficiency compared to the optimal balance point.

The maximum efficiency of a transformer occurs when load losses equal no-load losses.True

This is the fundamental principle of transformer efficiency, supported by IEC and IEEE standards.

Transformer Loss Mechanism and Load Dependence

No-Load Losses (Core Losses):

- Caused by hysteresis and eddy currents in the magnetic core.

- Independent of load; constant as long as transformer is energized.

Load Losses (Copper + Stray Losses):

- Proportional to current squared (I²R).

- Increase rapidly with higher load.

Thus, transformer efficiency varies with load, peaking at the maximum efficiency point (MEP) when:

\text{No-Load Losses} = \text{Load Losses}

Example Efficiency Variation with Load

| Load Level (% of Rated) | No-Load Losses (kW) | Load Losses (kW) | Total Losses (kW) | Efficiency (%) |

|---|---|---|---|---|

| 25% | 2.5 | 1.9 | 4.4 | 96.8 |

| 50% | 2.5 | 7.5 | 10.0 | 97.8 |

| 75% | 2.5 | 16.9 | 19.4 | 98.1 |

| 100% | 2.5 | 30.0 | 32.5 | 97.6 |

| 125% (Overload) | 2.5 | 46.9 | 49.4 | 96.1 |

From this table, we see efficiency peaks around 70–80% loading, where no-load and load losses are balanced.

Case Study: Urban vs Rural Distribution Transformers

- Urban Grid: Transformers in urban networks often operate at 70–90% loading due to high, stable demand. These units usually run near their maximum efficiency point.

- Rural Grid: Transformers in rural areas often operate below 30% loading. Here, constant no-load losses dominate, leading to poor efficiency. Utilities that downsized or right-sized transformers for actual demand achieved up to 20% annual energy savings.

Why the Maximum Efficiency Point Matters

- Energy Cost Savings: Lower losses reduce operating costs.

- Extended Service Life: Avoids overheating from excessive load losses.

- Grid Stability: Higher efficiency means less wasted energy, improving overall system reliability.

- Environmental Benefit: Reduced losses mean lower CO₂ emissions for utilities.

How Do Design, Material Quality, Environmental Conditions, Load Variation, Power Quality, and Harmonics Impact Transformer Lifespan and Reliability?

Transformers are long-life assets, often expected to run reliably for 25–40 years. However, real-world conditions—ranging from poor material quality, design flaws, harsh environments, load fluctuations, power quality issues, and harmonics—can significantly shorten their lifespan. Failures lead to costly outages, downtime, safety hazards, and expensive replacements. The solution is to understand how these factors influence transformer health and reliability, and to ensure proper design, operation, and maintenance from the beginning.

Transformer lifespan and reliability are directly influenced by design accuracy, material quality, environmental and operating conditions, load variation, power quality, and harmonics. Poor design or low-grade materials accelerate insulation aging, harsh environments cause corrosion and overheating, fluctuating or harmonic-rich loads increase losses, and poor power quality shortens service life. When optimized, these factors ensure stable operation, long lifespan, and high reliability; when neglected, they cause premature failures and high lifecycle costs.

This makes it essential for utilities, industries, and renewable operators to consider all influencing factors holistically, rather than focusing only on transformer nameplate ratings.

Transformer lifespan is determined only by design and not by environmental or operational factors.False

Environmental, load, and power quality conditions significantly accelerate or delay insulation aging, directly impacting lifespan.

High-quality materials and optimized design extend transformer reliability by decades.True

Premium insulation, copper, and core steel reduce losses, slow degradation, and increase service life.

1. Role of Design and Material Quality

- Impact on Lifespan: High-quality design ensures correct flux distribution, mechanical stability, and cooling efficiency. Materials like grain-oriented silicon steel and oxygen-free copper reduce losses, while thermally upgraded insulation delays aging.

- Failure Risk if Neglected: Poor-grade insulation breaks down under heat and moisture, inferior steel cores raise no-load losses, and weak mechanical structures fail during short-circuits.

| Factor | Good Practice Outcome | Poor Practice Outcome |

|---|---|---|

| Core Steel | Low hysteresis → lower heating → 35+ years | High losses → overheating → <20 years |

| Winding Conductor | Oxygen-free copper → stable resistance | Impure copper → hot-spots, failures |

| Insulation | Thermally upgraded paper/oil → slow aging | Low-grade → fast breakdown |

2. Environmental and Operating Conditions

- Impact on Lifespan: Ambient temperature, humidity, dust, altitude, and corrosive atmosphere affect insulation aging, oil degradation, and cooling performance.

- Failure Risk if Neglected: Tropical climates accelerate moisture ingress; deserts cause overheating and dust blockage; coastal regions promote corrosion.

| Environment | Average Service Life (Years) | Failure Risk |

|---|---|---|

| Controlled Indoor | 35–40 | Very Low |

| Tropical High Humidity | 20–25 | High (moisture breakdown) |

| Desert Heat & Dust | 15–20 | High (cooling blockage) |

| Coastal/Industrial Zone | 18–22 | Medium-High (corrosion) |

3. Load Variation

- Impact on Lifespan: No-load losses are constant, while load losses rise with the square of load current. Operating near the optimal load point (60–80%) ensures best efficiency and lowest thermal stress.

- Failure Risk if Neglected: Chronic overloading accelerates thermal aging and hot-spot formation, while chronic underloading wastes energy through constant core losses.

4. Power Quality Issues

- Impact on Lifespan: Voltage unbalance, poor power factor, and surges increase current flow, heating, and insulation stress.

- Failure Risk if Neglected: Even transformers operating within load ratings fail early if subjected to poor power quality conditions.

5. Harmonics

- Impact on Lifespan: Harmonic currents (3rd, 5th, 7th, etc.) amplify copper and stray losses, generate hot spots, and stress insulation.

- Failure Risk if Neglected: High THD (Total Harmonic Distortion) environments can cut lifespan in half if K-rated or harmonic-mitigating measures are not applied.

| Harmonic Level (THD) | Hot-Spot Rise (°C) | Life Expectancy (Years) |

|---|---|---|

| <5% (Normal) | +55 | 30–35 |

| 15% | +75 | 18–22 |

| 30% | +95 | 10–15 |

Case Study: Utility Fleet Analysis

A European utility conducted a fleet study and found that transformers operating in clean indoor substations lasted over 35 years, while those in coastal, high-humidity outdoor locations averaged only 20 years. Units serving data centers with high harmonic loads showed insulation aging 40% faster than expected. After introducing harmonic filters, improved cooling, and corrosion-resistant designs, failure rates dropped by 60% across the fleet.

What Strategies Can Improve Transformer Efficiency Under Real Conditions?

Transformers are designed for high efficiency, often above 98%, but real operating conditions such as fluctuating loads, harmonics, poor power quality, and harsh environments reduce their actual performance. The result is higher energy losses, accelerated aging, rising operating costs, and reduced reliability. The solution lies in applying practical efficiency-improvement strategies that consider both design and operating realities to maximize performance, extend lifespan, and cut lifecycle costs.

The most effective strategies to improve transformer efficiency under real conditions include optimizing load management (operating near 60–80% capacity), using high-quality materials and advanced designs, implementing proper cooling systems, reducing harmonics with filters or K-rated transformers, maintaining good power quality, and applying predictive monitoring and maintenance. Together, these strategies minimize losses, reduce overheating, and extend service life.

These methods are widely applied in utilities, industrial plants, and renewable power projects where reliability and energy efficiency are critical.

Transformer efficiency is fixed at the time of manufacture and cannot be improved during operation.False

Efficiency can be improved during operation through load management, cooling optimization, and harmonic mitigation strategies.

Operating a transformer at 60–80% of its rated load achieves the best balance between no-load and load losses, maximizing efficiency.True

At this loading level, core and copper losses are balanced, reducing total losses.

1. Optimized Load Management

- Principle: Efficiency peaks when load losses equal no-load losses (typically 60–80% loading).

- Strategy: Right-size transformers for demand, avoid chronic underloading, and prevent prolonged overloads.

- Implementation: Utilities conduct load profiling and demand forecasting, while industries may deploy multiple parallel units to match variable demand.

| Load Level (% of Rated) | Efficiency Trend | Risk if Sustained |

|---|---|---|

| <30% | Low (core losses dominate) | Energy waste |

| 60–80% | Highest efficiency | Optimal zone |

| >100% | Efficiency drops (copper losses dominate) | Accelerated aging |

2. High-Quality Design and Materials

- Principle: Better materials reduce intrinsic losses.

- Strategy: Use grain-oriented silicon steel for low hysteresis, oxygen-free copper windings, and thermally upgraded insulation.

- Implementation: Manufacturers optimize lamination thickness and adopt amorphous core materials for ultra-low no-load losses.

3. Advanced Cooling Techniques

- Principle: Heat accelerates insulation aging and increases resistance, raising copper losses.

- Strategy: Employ ONAN/ONAF/ODAF cooling systems, forced oil or air circulation, and advanced radiators.

- Implementation: Smart cooling systems that activate under peak load prevent hot-spot overheating.

4. Harmonic Mitigation

- Principle: Harmonics increase I²R losses, eddy currents, and stray flux heating.

- Strategy: Use harmonic filters, K-rated transformers, or derating factors in harmonic-rich environments (e.g., data centers).

- Implementation: Install active filters or phase-shifting transformers to suppress distortion.

| Harmonic Distortion (THD %) | Loss Increase (%) | Recommended Action |

|---|---|---|

| <5% | Normal | Standard design ok |

| 10–15% | +10–20% losses | K-rated transformer |

| 20–30% | +25–40% losses | Active harmonic filters |

5. Power Quality Improvement

- Principle: Voltage imbalance and low power factor increase current and losses.

- Strategy: Apply automatic voltage regulators, capacitor banks, and surge protection.

- Implementation: Smart grid monitoring ensures voltage stability and corrective response.

6. Predictive Monitoring and Maintenance

- Principle: Efficiency drops when faults (moisture ingress, winding displacement, cooling failure) remain undetected.

- Strategy: Use dissolved gas analysis (DGA), infrared thermal scanning, and IoT-based monitoring.

- Implementation: Predictive analytics allows condition-based maintenance instead of reactive repairs.

Case Study: Industrial Plant Efficiency Upgrade

An automotive manufacturing plant replaced old 1 MVA distribution transformers with amorphous core units, installed harmonic filters on drives, and applied predictive monitoring. Results:

- Loss reduction: 17%

- Annual savings: 110 MWh

- Extended life expectancy: +12 years

Conclusion

Harmonics, power quality issues, and load variation directly influence transformer performance by increasing electrical and thermal stress. These factors not only reduce efficiency but can also shorten service life if left unmanaged. However, with proper design considerations, harmonic filtering, power factor correction, and optimized loading practices, operators can maintain high efficiency and extend the lifespan of transformers, ensuring both reliability and sustainability in power systems.

FAQ

Q1: How do harmonics affect transformer efficiency?

Harmonics from non-linear loads (like VFDs, UPS systems, or LED lighting) create additional eddy currents and stray losses in transformer windings and cores. This results in higher heating, reduced efficiency, and shortened insulation life. To counteract this, K-rated transformers or harmonic filters are often used.

Q2: How does poor power quality impact transformers?

Poor power quality—such as voltage sags, swells, flicker, and unbalance—stresses transformer insulation and windings. Repeated exposure causes overheating, increased energy losses, and premature aging. In extreme cases, it may trigger protection systems or lead to unexpected shutdowns.

Q3: How does load variation influence transformer efficiency?

Transformers are most efficient between 60% and 80% of rated load. Operating at very low loads wastes energy since core losses remain constant, while overloading increases copper losses and heating, significantly lowering efficiency and lifespan.

Q4: Can harmonics and load variation cause transformer derating?

Yes. Transformers exposed to heavy harmonic distortion or fluctuating loads may need to be derated (operated below their rated capacity) to avoid overheating and insulation damage. Manufacturers often provide derating guidelines for non-linear loads.

Q5: How can transformer efficiency be protected from these issues?

Use K-rated or harmonic mitigating transformers for harmonic-heavy environments.

Install power quality monitoring systems to detect voltage disturbances.

Maintain transformers within their rated load range.

Implement active or passive filters to reduce harmonic impact.

Ensure proper cooling and regular maintenance to manage additional heating.

References

IEEE Std C57.110 – Transformer Application for Non-Sinusoidal Load Currents: https://ieeexplore.ieee.org

IEC 60076 – Transformer Loading and Power Quality Standards: https://webstore.iec.ch

NEMA – Power Quality and Transformer Guidelines: https://www.nema.org

Electrical4U – Effect of Harmonics on Transformer Efficiency: https://www.electrical4u.com

EEP – How Power Quality Affects Transformer Performance: https://electrical-engineering-portal.com

All About Circuits – Harmonics and Transformers Explained: https://www.allaboutcircuits.com

Energy.gov – Power Quality and Energy Efficiency: https://www.energy.gov