Power transformers are the backbone of the electrical power system. Their primary role is to transfer electrical energy between circuits while adjusting voltage levels as needed. Whether stepping up voltage for efficient transmission or stepping it down for safe distribution and usage, the main purpose of power transformers is vital to the stability, efficiency, and scalability of power networks across the globe.

What Does a Power Transformer Do in an Electrical Grid?

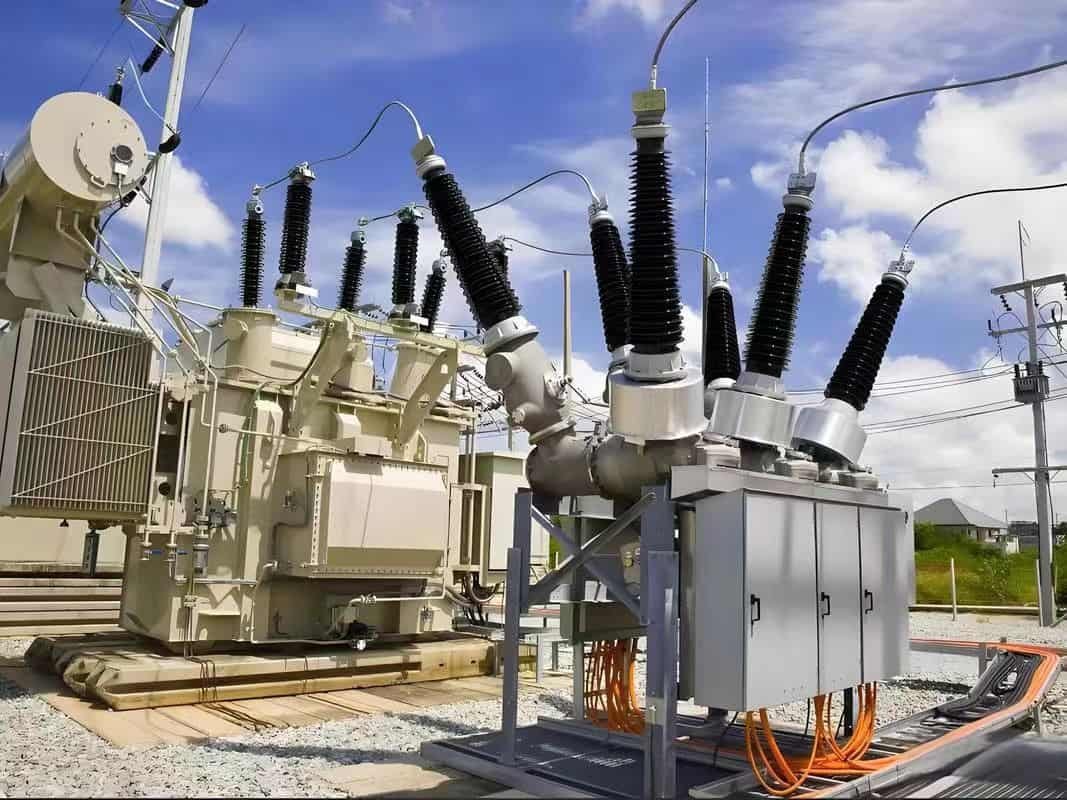

Electricity doesn't travel from power plants to your home or factory in the same form. It must be transformed across several voltage levels to enable safe, efficient, and reliable delivery. This transformation is made possible by the power transformer—a core component of every electrical grid. These large, high-capacity transformers are the workhorses of energy infrastructure, performing voltage conversion at every critical point in the grid to ensure minimal losses, stable voltages, and optimal load distribution. In this article, we explain what a power transformer does in the electrical grid and why it’s absolutely essential to grid function.

A power transformer in an electrical grid changes voltage levels between different sections of the grid—stepping up voltage at power plants for efficient long-distance transmission and stepping down voltage at substations for safe local distribution. It enables efficient energy flow, reduces losses, stabilizes voltage, and supports grid interconnection and load management.

From generation to consumption, power transformers maintain grid performance, reliability, and safety.

Power transformers step up and step down voltage levels in the electrical grid to enable efficient energy transmission and safe usage.True

High voltage reduces current and losses during transmission, while step-down transformers ensure voltage is appropriate for homes and businesses.

Power transformers are only needed in power plants and are not used elsewhere in the grid.False

Power transformers are used throughout the grid—at generation, transmission substations, distribution substations, and industrial entry points.

Where Power Transformers Operate in the Grid

| Grid Stage | Transformer Role | Voltage Conversion |

|---|---|---|

| Power Generation Plant | Step-up for transmission | 11–25kV → 132–765kV |

| Transmission Substation | Grid voltage level interconnection | 765kV ↔ 400kV ↔ 220kV ↔ 132kV |

| Receiving Substation | Step-down for regional distribution | 132kV → 33kV / 11kV |

| Industrial or Urban Feeder | Final step-down for consumption | 33kV / 11kV → 400V / 230V |

Power transformers are strategically placed at voltage transition points to adapt energy for the next stage of delivery.

Primary Functions of Power Transformers

1. Voltage Transformation

- Step-up at generation to reduce current and transmission loss

- Step-down at substations for safe end-user voltage levels

2. Grid Interconnection

- Connect different voltage levels and regional power systems

- Balance load flow between zones and utilities

3. System Efficiency

- Lower current at higher voltages reduces I²R losses

- Enables long-distance transmission with minimal infrastructure cost

4. Voltage Regulation

- Maintains stable voltage under variable load conditions using OLTC (on-load tap changers)

5. Protection and Isolation

- Isolates faulted grid sections

- Prevents faults from cascading across the system

Transformer Ratings in Grid Applications

| Grid Tier | Typical Voltage | Transformer Capacity | Application |

|---|---|---|---|

| Ultra-High Voltage (UHV) | 400–765kV | 250–1,200 MVA | Interregional transmission |

| High Voltage (HV) | 132–220kV | 100–500 MVA | Regional transmission and substation |

| Medium Voltage (MV) | 11–66kV | 10–100 MVA | Subtransmission and industrial feeders |

| Low Voltage (LV) | 230V / 400V | ≤10 MVA | Local and residential distribution |

Transformer design depends on voltage level, power flow, grid configuration, and environmental factors.

Technical Features of Grid Power Transformers

| Feature | Purpose |

|---|---|

| Oil-Immersed Cooling (ONAF/ONAN) | Dissipates heat from high loads |

| OLTC (On-Load Tap Changer) | Adjusts voltage dynamically under load conditions |

| Bushings and Surge Arresters | Protect against lightning and switching surges |

| Smart Sensors (IoT Enabled) | Enable monitoring of temperature, load, and insulation |

| Buchholz Relay & Gas Monitor | Detect internal faults or oil degradation early |

Modern transformers are digitally integrated into SCADA and smart grid systems, allowing real-time diagnostics and remote control.

Grid Stability Support Functions

| Function | Role of Transformer |

|---|---|

| Voltage Control | Prevents sags and surges under load fluctuation |

| Reactive Power Compensation | Supports power factor and reduces VAR-related losses |

| Frequency Synchronization | Allows different generation sources to operate in-phase |

| Load Sharing | Ensures multiple feeders are balanced across regional grids |

In complex grids, power transformers enable stability and resilience during peak demand and fault conditions.

Visual Example: Grid with Transformer Placement

| Grid Component | Voltage Flow | Transformer Role |

|---|---|---|

| Thermal Plant Generator | 13.8kV | Step-up to 400kV |

| Transmission Line | 400kV over 200 km | Carries power with low loss |

| Regional Substation | 400kV → 220kV | Interconnection transformer |

| City Substation | 220kV → 33kV | Step-down for local feeders |

| Residential Transformer | 11kV → 230V | Pole or pad-mounted for household supply |

This structured use of transformers ensures voltage is optimized for each part of the journey.

Why Is Voltage Conversion Important in Power Transmission?

Electric power is generated at relatively low voltages in power stations, but it must travel hundreds or even thousands of kilometers to reach cities, industries, and homes. Transmitting electricity at these original low voltages would lead to immense energy loss, overheating of lines, and prohibitive infrastructure costs. Voltage conversion solves this problem by transforming power into a more transmission-efficient form. Transformers are the devices that make voltage conversion possible, enabling a power system that is both economically viable and technically safe. This article explores why voltage conversion is so important in power transmission, and how it supports efficiency, safety, and reliability across the electrical grid.

Voltage conversion is essential in power transmission because it allows electricity to be transmitted at high voltages and low currents, which significantly reduces resistive losses (I²R), minimizes conductor size and cost, improves efficiency, and ensures safe and stable power delivery over long distances. Stepping voltage up and down enables optimal energy flow from generation to end-use.

Without voltage conversion, large-scale power transmission would be inefficient, unsafe, and economically unsustainable.

High-voltage transmission reduces energy losses and enables efficient long-distance power delivery.True

By increasing voltage and reducing current, the I²R losses in conductors are minimized, preserving more of the generated power.

Electricity can be transmitted efficiently over long distances without changing its voltage.False

Without voltage conversion, high current would cause massive energy losses, require thicker cables, and overload transmission systems.

The Physics Behind Voltage Conversion Efficiency

Electric Power Formula:

- P = V × I (Power = Voltage × Current)

To deliver the same power:

- Higher voltage → Lower current

- Lower current → Lower resistive loss (I²R)

Transmission Losses:

- Loss due to heat = I² × R

- Reducing current exponentially reduces losses

| Transmission Voltage | Required Current for 100MW | Losses in Conductors (Relative) |

|---|---|---|

| 11kV | 5,250 A | Very High |

| 132kV | 757 A | Low |

| 400kV | 250 A | Very Low |

Transmitting at 400kV results in less than 10% of the losses seen at 11kV for the same power level.

Where Voltage Conversion Happens in the Grid

| Location | Voltage Conversion | Transformer Type |

|---|---|---|

| Power Generation Plant | 11kV → 220/400/765kV | Step-up transformer |

| Transmission Substation | 400kV ↔ 132kV ↔ 220kV | Interconnection transformer |

| Distribution Substation | 132kV → 33/11kV | Step-down transformer |

| Residential Distribution | 11kV → 400V/230V | Pole or pad-mounted transformer |

Each voltage level is optimized for a specific distance, application, or load type—ensuring both efficiency and safety.

Technical and Economic Benefits of Voltage Conversion

| Benefit | Impact on Power System |

|---|---|

| Lower Transmission Losses | Preserves more generated energy for consumption |

| Reduced Infrastructure Costs | Smaller conductor size = lower material and tower costs |

| Grid Stability | Maintains consistent voltage across variable load demands |

| Improved Safety | Local voltage kept at safe levels for human interaction |

| Increased Grid Capacity | Allows more power to flow through a given transmission line |

Voltage conversion allows utilities to transmit gigawatts of power across national grids reliably and cost-effectively.

Real-World Example: Long-Distance Power Transmission

| Component | Voltage Level | Purpose |

|---|---|---|

| Power Plant Generator | 13.8kV | Original generation voltage |

| Step-Up Transformer | 13.8kV → 400kV | Converts to high voltage for long-distance transport |

| Transmission Line | 400kV over 500km | Transmits power with minimal losses |

| Receiving Substation | 400kV → 132kV | Steps down for regional distribution |

| Local Transformer | 11kV → 230V | Final step-down for home and commercial use |

Voltage conversion is what makes this multi-stage journey efficient and safe.

Power Grid Optimization via Voltage Layers

| Voltage Level | Application Area | Transmission Efficiency |

|---|---|---|

| 400kV / 765kV | Interregional transmission | Very High |

| 132kV / 220kV | Regional transmission | High |

| 33kV / 11kV | Sub-transmission | Moderate |

| 400V / 230V | Distribution to end users | Local / Safe |

Transformers ensure these voltage layers remain distinct, coordinated, and optimized.

How Do Power Transformers Support Long-Distance Power Delivery?

Delivering electricity over long distances from power plants to distant cities, industrial centers, and rural areas is a monumental task—made possible only through the use of power transformers. Without them, enormous energy would be lost during transmission, and the infrastructure needed to move high currents over long distances would be prohibitively expensive and impractically large. Power transformers solve this problem by enabling high-voltage, low-current transmission, minimizing losses and maximizing delivery efficiency. This article explains how power transformers support long-distance power delivery, keeping national and regional power systems efficient, reliable, and safe.

Power transformers support long-distance power delivery by stepping up voltage at power generation sources to high levels (132kV–765kV), which reduces current and minimizes resistive (I²R) losses during transmission. At the receiving end, they step down the voltage to usable levels for distribution, enabling efficient energy transfer over hundreds or thousands of kilometers.

Their role is critical for the infrastructure that powers entire regions from a single generation source.

Power transformers reduce current and energy losses during long-distance transmission by stepping up voltage.True

Higher voltage reduces the current needed to transmit power, which significantly lowers resistive losses in transmission lines.

High-voltage transmission can be done without power transformers.False

Voltage must be increased from generator output levels using transformers to allow efficient, long-distance transmission.

Key Role of Power Transformers in Transmission Systems

| Transmission Stage | Transformer Function | Voltage Conversion |

|---|---|---|

| Generation Output | Step-up for transmission efficiency | 11–25kV → 132–765kV |

| Regional Interconnection Point | Voltage level coordination between grid segments | 765kV ↔ 400kV ↔ 220kV |

| Load Center Substation | Step-down for distribution | 220kV/132kV → 33/11kV |

Transformers are placed at every voltage interface to optimize energy transfer and match power flow with system requirements.

Why High Voltage Is Essential for Long Distances

Power Transmission Formula:

- P = V × I

- For a fixed power (P), increasing voltage (V) decreases current (I)

- Losses are proportional to I² × R (resistive heating in conductors)

| Voltage Level | Required Current for 100 MW | Relative Power Loss (I²R) |

|---|---|---|

| 11kV | \~5,250 A | Extremely High |

| 132kV | \~757 A | Much Lower |

| 400kV | \~250 A | Minimal |

Stepping up to 400kV reduces transmission loss by over 90% compared to using 11kV.

Transformer Placement in Long-Distance Transmission Projects

| System Location | Transformer Type | Role in Transmission |

|---|---|---|

| Power Plant Switchyard | Generator Step-Up Transformer (GSU) | Converts low-voltage generation to high-voltage output |

| HV Substations Along Route | Interconnecting Auto Transformer | Balances grid loads and voltages between transmission segments |

| Regional Receiving Substation | Step-Down Transformer | Lowers voltage for distribution and safe consumption |

These transformers typically range from 100 MVA to 1,200 MVA and are oil-immersed with advanced cooling systems.

Power Transformer Design Features for Transmission

| Feature | Purpose in Long-Distance Transmission |

|---|---|

| OLTC (On-Load Tap Changer) | Adjusts voltage under live load to stabilize the grid |

| Low Loss Core Materials | Reduces no-load and copper losses |

| Advanced Cooling (ONAF/OFWF) | Supports thermal stability during high load conditions |

| High BIL Ratings | Withstands lightning and switching surges |

| IoT-Based Monitoring | Enables remote diagnostics and predictive maintenance |

These features ensure reliability under 24/7 operation, even in extreme weather and loading conditions.

Real-World Transmission Example

| Location | Voltage Level | Transformer Application |

|---|---|---|

| Hydropower Plant | 13.8kV | GSU steps up to 220kV |

| National Transmission Line | 220kV → 400kV | Grid-tie transformer enables regional interflow |

| Urban Receiving Station | 400kV → 132kV | Supplies substations for local distribution |

| Industrial Estate | 132kV → 33kV | Feeds motors, drives, and automation panels |

Without power transformers at each point, energy loss and system incompatibility would cripple the grid.

Long-Distance Transmission Projects Powered by Transformers

| Project | Country | Voltage Level | Distance | Power Moved |

|---|---|---|---|---|

| Changji–Guquan UHVDC Link | China | ±1100kV | 3,284 km | 12 GW |

| Belo Monte HVDC Link | Brazil | ±800kV | 2,500 km | 11 GW |

| Western-Northern UHVAC Link | India | 765kV | 1,000+ km | 8 GW |

| Pacific AC Intertie | USA | 500kV | 1,400 km | 7 GW |

Each of these systems uses multiple power transformers per station, with redundancy and real-time monitoring.

What Role Do Power Transformers Play in Substations?

Substations are the backbone junction points of the electrical grid. They allow electricity to be transferred from one voltage level to another, direct power to different regions, and enable the grid to function efficiently and safely. But substations alone can’t handle voltage transformations—this is where power transformers come in. These robust, precision-engineered devices allow substations to perform their role in the transmission and distribution of electricity. This article explains the vital role power transformers play in substations and why they are essential to grid operation.

Power transformers in substations enable voltage transformation by stepping electricity up or down between transmission and distribution levels. They allow substations to route power efficiently, interconnect different parts of the grid, manage load flow, and maintain voltage stability across regions. Without them, substations would be unable to adapt voltage levels for safe transmission or end-user consumption.

They are the core energy conversion components inside every substation—from bulk transmission to city-level distribution.

Power transformers in substations allow voltage levels to be increased or decreased to match grid requirements.True

Voltage transformation enables high-efficiency transmission over long distances and prepares power for safe local use.

Substations do not require transformers to function as part of the grid.False

Without transformers, substations cannot perform voltage conversion, making them incapable of transferring or distributing electricity properly.

Types of Substations and Their Transformer Functions

| Substation Type | Voltage Role | Transformer Function |

|---|---|---|

| Transmission Substation | 400kV ↔ 220kV or 220kV ↔ 132kV | Interconnects high-voltage grids, balances regional flow |

| Receiving Substation | 132kV ↔ 33kV | Steps down power for regional or industrial feeders |

| Distribution Substation | 33kV ↔ 11kV | Prepares voltage for commercial and municipal networks |

| Collector Substation (Renewables) | 33kV ↔ 132kV | Aggregates solar/wind outputs for grid export |

| Industrial Substation | 132kV or 33kV ↔ 11kV / 6.6kV | Supplies high loads like factories or mining operations |

Power transformers are customized based on substation type, location, and load demand.

Key Functions of Power Transformers in Substations

1. Voltage Conversion

- Step-up transformers increase voltage for long-distance transmission

- Step-down transformers lower voltage for regional or urban consumption

2. Grid Interconnection

- Connect different voltage tiers (e.g., 400kV to 220kV or 132kV to 33kV)

- Enable power transfer between utility zones or countries

3. Load Management

- Balance electrical loads by directing energy where demand is highest

- Prevent overloads and optimize system performance

4. Voltage Stabilization

- Maintain consistent voltage through on-load tap changers (OLTCs)

- Adjust voltage during peak load or grid disturbances

5. System Protection

- Work with circuit breakers and relays to isolate faults

- Support grounding and neutral earthing systems

Common Power Transformer Configurations in Substations

| Configuration | Application | Voltage Example |

|---|---|---|

| Two-Winding Transformer | Standard step-up or step-down use | 400kV/220kV or 132kV/33kV |

| Auto-Transformer | For close voltage conversion with shared winding | 220kV ↔ 132kV |

| Tertiary Winding | Supports auxiliary services or capacitor banks | 220kV/33kV/11kV |

| Three-Phase Unit | Preferred in high MVA applications | 100MVA – 500MVA |

| Single-Phase Bank | Used in very high voltage (EHV/UHV) systems | 400kV / 765kV systems |

Transformer Ratings and Technical Parameters

| Parameter | Typical Value for Substation Transformers |

|---|---|

| Power Rating | 20 MVA – 1000 MVA |

| Voltage Levels | 11kV to 765kV |

| Frequency | 50 Hz / 60 Hz |

| Cooling Method | ONAN, ONAF, OFAF (Oil-based systems) |

| Impedance | 6% – 15% depending on load and system design |

| OLTC Range | ±10% in 1.25% steps |

These values are tailored based on network capacity, regional regulation, and expected demand.

Real-World Example: Substation Transformer Operation

| Grid Stage | Voltage | Transformer Role |

|---|---|---|

| Power Plant Output | 13.8kV | GSU steps up to 400kV for transmission |

| Transmission Substation | 400kV → 220kV | Auto transformer links interregional transmission |

| Regional Receiving Station | 220kV → 33kV | Step-down transformer prepares for local feeders |

| Distribution Substation | 33kV → 11kV | Final voltage conversion for urban and industrial use |

This multi-stage transformer deployment ensures stable, reliable power flows across the entire grid.

Substation Transformer Safety and Monitoring Features

| Feature | Purpose |

|---|---|

| Buchholz Relay | Detects internal transformer faults |

| Oil Temperature Sensors | Prevents overheating and warns of load stress |

| Pressure Relief Devices | Releases gas during internal fault |

| Surge Arresters | Protect against lightning and switching surges |

| Smart Monitoring Systems | Enable real-time SCADA and predictive maintenance |

These features enhance substation reliability, safety, and availability.

How Do Power Transformers Improve Grid Efficiency and Safety?

Power grids are vast, complex, and vulnerable systems. They must deliver energy over long distances, adapt to variable demand, and protect against faults—all while minimizing energy loss and ensuring user safety. Power transformers are the silent sentinels that make this possible. By stepping voltage up and down efficiently and safely, these devices not only enhance transmission performance but also ensure end-user protection and system reliability. This article explores how power transformers improve both grid efficiency and safety, and why they are essential in every high-functioning electrical system.

Power transformers improve grid efficiency by stepping up voltage to reduce transmission losses and stepping it down for safe distribution. They enhance safety by stabilizing voltage levels, isolating faults, preventing overloads, and enabling protective relay systems. Their role ensures that electricity is delivered reliably, with minimal waste and maximum protection for infrastructure and end-users.

From megawatt-scale generation to home lighting, transformers are vital for optimized, secure power delivery.

Power transformers reduce grid losses and enhance safety by converting voltage levels for efficient transmission and safe distribution.True

High-voltage transmission reduces I²R losses, while voltage step-down ensures compatibility and protection for residential and industrial systems.

Transformers have no impact on energy loss or safety in electrical transmission systems.False

Without transformers, transmission would require low voltage and high current, causing severe energy loss and safety hazards.

Grid Efficiency: The Role of Voltage Transformation

Transmission Efficiency Formula:

- P = V × I → For a given power (P), increasing voltage (V) reduces current (I)

- Losses = I² × R → Lower current = exponentially lower resistive losses

| Transmission Voltage | Current for 100 MW | Relative Line Loss |

|---|---|---|

| 11kV | 5,250 A | Extremely High |

| 132kV | 757 A | Moderate |

| 400kV | 250 A | Very Low |

Transformers make it possible to transmit at 400kV or higher, cutting energy losses by over 90% compared to low-voltage systems.

Where Transformers Improve Grid Efficiency

| Grid Segment | Voltage Conversion | Efficiency Role |

|---|---|---|

| Generation Station | 13.8kV → 132–765kV | Step-up reduces current for long-distance transmission |

| Transmission Substation | 400kV ↔ 220kV ↔ 132kV | Interconnection maintains energy balance |

| Distribution Substation | 132kV → 33/11kV | Step-down for regional use with minimal loss |

| Local Distribution Transformer | 11kV → 400/230V | Final voltage match for safe household use |

These transitions are managed by high-efficiency power transformers that are precision-engineered to reduce core and copper losses.

Safety Enhancements Provided by Power Transformers

1. Voltage Regulation

- On-load tap changers (OLTCs) adjust voltage to maintain safe levels during load fluctuations

2. Electrical Isolation

- Prevents fault propagation and isolates different segments of the grid

3. Overload and Fault Protection

- Works with relays, circuit breakers, and differential protection schemes

4. Grounding Support

- Supports system earthing to safely manage fault currents

5. Surge Protection Compatibility

- Integrates with lightning arresters and surge protectors

Power transformers act as gatekeepers, ensuring energy is transferred only under safe, controlled conditions.

Power Transformer Design Features for Efficiency and Safety

| Feature | Purpose |

|---|---|

| Low Loss Core Steel | Reduces no-load (core) losses |

| High-Quality Copper Windings | Reduces load (I²R) losses |

| OLTC (On-Load Tap Changer) | Adjusts voltage under varying load conditions |

| Bushing and Insulation Systems | Prevent flashovers and breakdowns |

| Smart Monitoring (IoT/SCADA) | Provides alerts for overheating, insulation failure, etc. |

These features are embedded in modern transformers for optimized performance and real-time safety diagnostics.

Example: Power Transformer in Action (Urban Grid Application)

| System Component | Voltage Levels | Transformer Function |

|---|---|---|

| Generator Output | 13.8kV | Step-up to 400kV for efficient transmission |

| Transmission Network | 400kV | Long-distance low-loss delivery |

| Urban Receiving Substation | 400kV → 132kV | Intertie transformer links transmission to city |

| Distribution Substation | 132kV → 33kV / 11kV | Feeds commercial zones and industrial parks |

| Local Transformer (Pole-Mounted) | 11kV → 400/230V | Final voltage conversion for residential safety |

Each transformation stage ensures both voltage compatibility and fault containment, protecting systems and people.

Performance Metrics of Efficient Power Transformers

| Parameter | Typical Value |

|---|---|

| Efficiency at Full Load | ≥ 98.5% |

| Core Losses (No-Load) | < 0.2% of rated power |

| Copper Losses (Load Losses) | < 1% at rated conditions |

| Regulation (Voltage Drop) | < 5% |

| Temperature Rise | ≤ 65°C in oil-immersed units |

These specifications ensure long lifespan, low maintenance, and consistent performance under demanding conditions.

What Industries and Applications Rely Most on Power Transformers?

Power transformers are at the heart of modern power systems—but their value extends far beyond substations and transmission lines. These vital components are embedded across a wide array of industries and applications, from manufacturing and healthcare to transportation and telecommunications. Wherever there is heavy electrical demand, critical uptime, or sensitive equipment, power transformers ensure that energy is delivered efficiently, safely, and at the right voltage. In this article, we explore which industries and applications rely most heavily on power transformers, and why these sectors depend on them for their daily operations and long-term growth.

Industries and applications that rely most on power transformers include manufacturing, data centers, hospitals, mining, oil and gas, renewable energy, transportation (railways and metros), commercial buildings, and utilities. Transformers in these sectors provide voltage adaptation, electrical isolation, power quality control, and fault protection—ensuring stable, efficient, and safe energy supply.

Transformers aren’t just passive components—they’re mission-critical systems that support productivity, safety, and energy performance.

Power transformers are essential to industries such as manufacturing, data centers, mining, and renewable energy for adapting and stabilizing voltage levels.True

These industries use transformers to match voltage to equipment needs, isolate systems, and ensure reliable, uninterrupted power.

Only utility companies use power transformers; they are not needed in private industry.False

Private industries heavily rely on transformers to power machinery, protect sensitive systems, and ensure voltage compliance within their operations.

Top Industries That Rely on Power Transformers

| Industry/Application | Typical Voltage Needs | Transformer Role |

|---|---|---|

| Manufacturing & Heavy Industry | 11kV, 6.6kV, 400V | Feed motors, automation lines, HVAC, and control panels |

| Data Centers & IT | 11kV → 400V / 230V | Stable voltage, K-rated isolation for UPS and servers |

| Hospitals & Healthcare | 400V / 230V | Isolation for life-support and diagnostic equipment |

| Mining & Metallurgy | 33kV, 11kV → 690V / 400V | Drives, crushers, pumps, conveyors, underground distribution |

| Oil & Gas (Onshore/Offshore) | 33kV → 11kV / 6.6kV | Zone isolation, explosion-proof transformer units |

| Railway Systems | 25kV, 11kV | Traction power, station services, signaling |

| Renewable Energy (Wind/Solar) | 400V → 11kV → 132kV | Grid integration and inverter output stepping |

| Commercial High-Rises | 11kV → 400V / 230V | Floor-wise power segmentation, lighting, HVAC |

| Airports & Transport Hubs | 11kV → 400V | Runway lighting, radar, baggage systems |

| Utilities & Power Plants | 11–25kV → 132–400kV | Transmission support, interconnection, voltage transformation |

These sectors demand stable power, efficient transmission, and high safety margins, all delivered by transformers.

Transformer Use Case Examples by Industry

1. Manufacturing Facility (Steel Plant)

- Input: 33kV utility supply

- Transformation: 33kV → 6.6kV (rolling mill motors), 6.6kV → 400V (control & lighting)

- Transformer Type: Oil-immersed, with OLTC and dry-type K-rated units

- Benefit: Supports 24/7 high-load operations with minimal downtime

2. Data Center (Tier IV)

- Input: 11kV

- Transformation: 11kV → 400V (UPS & HVAC), 400V → 230V (rack-level)

- Transformer Type: Shielded dry-type, K-13/K-20 rated

- Benefit: Harmonic filtering, redundancy, fault isolation, EMI protection

3. Hospital Campus

- Input: 11kV

- Transformation: 11kV → 400V (main), 400V → 230V (operating rooms)

- Transformer Type: Medical-grade isolation transformer, dry-type

- Benefit: Patient safety, ground-fault protection, uninterrupted operation

Functional Roles of Transformers in Industrial Applications

| Function | Impact on Industrial/Commercial Systems |

|---|---|

| Voltage Adaptation | Enables compatibility between grid voltage and equipment rating |

| Electrical Isolation | Protects sensitive systems from surges and ground faults |

| Energy Efficiency | Reduces losses and improves load distribution |

| Fault Containment | Prevents system-wide shutdown during localized electrical failures |

| Load Management | Balances heavy loads across multiple feeder transformers |

| Backup Power Coordination | Integrates with generators and UPS during power outages |

In these sectors, a transformer failure could halt entire operations or endanger lives.

Transformer Configurations by Industry

| Industry | Transformer Type | Features |

|---|---|---|

| Oil & Gas | Cast resin, flameproof dry-type | Explosion protection, compact footprint |

| Telecom/Data Centers | K-rated isolation dry-type | Harmonic tolerance, noise shielding |

| Railways | Outdoor oil-immersed, single-phase | High-voltage traction support, ruggedized |

| Renewable Energy | Pad-mounted, skid-based, collector-type | Outdoor-rated, inverter-compatible, SCADA-connected |

| Mining | Mobile transformer substations | Portable, vibration-resistant, high fault-tolerance |

These configurations meet specific voltage, environment, and reliability demands.

Conclusion

The main purpose of a power transformer is to change voltage levels to ensure the safe and efficient flow of electricity across long distances and into homes, businesses, and industries. By enabling high-voltage transmission and low-voltage distribution, power transformers are indispensable in connecting power generation to end users. Without them, modern energy systems would not be possible.

FAQ

Q1: What is the main purpose of a power transformer?

A1: The main purpose of a power transformer is to transfer electrical energy between circuits at different voltage levels. It does this by stepping up voltage for long-distance transmission and stepping down voltage for safe distribution to end users.

Q2: Why is voltage transformation important in power systems?

A2: High voltage allows electricity to be transmitted over long distances with minimal energy loss. However, high voltage is unsafe for direct use. Power transformers ensure efficient transmission and safe delivery by converting voltage as needed.

Q3: Where are power transformers used?

A3: Power transformers are typically used in:

Generating stations (to step up voltage)

Transmission substations (to manage voltage levels)

Industrial and utility substations (to step down voltage for local distribution)

Q4: How do power transformers support grid stability?

A4: They:

Balance voltage levels across networks

Enable interconnection between different grid segments

Improve reliability by preventing voltage drops and overloads

Support load sharing during peak demand

Q5: What’s the difference between power and distribution transformers?

A5: Power transformers are used in high-voltage transmission and are optimized for constant full-load operation, while distribution transformers operate at lower voltages and serve homes and businesses, often under variable load conditions.

References

"Power Transformer Basics and Purpose" – https://www.transformertech.com/power-transformer-purpose

"Main Role of Power Transformers in Transmission" – https://www.powermag.com/power-transformer-function

"Understanding Power Transformers" – https://www.electrical4u.com/power-transformer-basics

"Why Power Transformers Are Critical to the Grid" – https://www.energycentral.com/c/ee/role-of-power-transformers

"Smart Grid Use of Power Transformers" – https://www.smartgridnews.com/power-transformers-grid-importance

"ScienceDirect: Transformer Efficiency and Application" – https://www.sciencedirect.com/power-transformer-purpose

"ResearchGate: Transmission Efficiency via Transformers" – https://www.researchgate.net/power-transformer-role

"PowerGrid: Power Transformer Integration and Design" – https://www.powergrid.com/power-transformer-overview