Efficient cooling and thermal management are essential for maintaining transformer performance and longevity. Without proper cooling, transformers can overheat, leading to insulation degradation, energy losses, and potential failures. Many operators underestimate the importance of selecting the right cooling method and monitoring temperature levels, which can result in costly maintenance and downtime.

This article explores the various transformer cooling methods, their advantages, and best practices for effective thermal management to ensure reliable and efficient operation.

Why Is Cooling Essential for Transformer Performance?

Transformers play a crucial role in power transmission and distribution, converting voltage levels efficiently. However, during operation, transformers generate significant heat due to electrical losses in the windings and core. Without an effective cooling system, overheating can lead to insulation breakdown, reduced efficiency, and premature failure.

Cooling is essential for transformer performance because it prevents overheating, maintains insulation integrity, improves energy efficiency, and extends transformer lifespan. Proper cooling ensures stable operation by dissipating excess heat generated in the core and windings, reducing thermal stress on internal components.

This guide explores why transformer cooling is critical, the different cooling methods, and best practices for maintaining optimal thermal performance.

Transformers can operate efficiently without a dedicated cooling system.False

Transformers require effective cooling to dissipate heat, prevent overheating, and ensure reliable performance.

1. Why Cooling Is Critical for Transformer Performance

A. Heat Generation in Transformers

Heat is generated in transformers due to:

✅ Copper losses (I²R losses): Electrical resistance in windings converts current into heat.

✅ Core losses (Hysteresis and Eddy Currents): Magnetic flux variations create heat in the core.

✅ Stray losses: Additional losses due to leakage flux and harmonics.

💡 If heat is not dissipated effectively, transformer efficiency decreases, and insulation degrades.

B. Consequences of Poor Cooling

| Issue | Cause | Consequence |

|---|---|---|

| Overheating | Insufficient heat dissipation | Reduces transformer lifespan |

| Insulation Breakdown | Excessive temperature stress | Increases failure risk |

| Oil Degradation | Prolonged exposure to high temperatures | Lowers dielectric strength |

| Core and Winding Damage | Expansion and contraction due to heat cycles | Leads to electrical faults |

✅ Proper cooling maintains stable temperatures, preventing failures and improving performance.

2. Transformer Cooling Methods and Their Efficiency

Different cooling techniques ensure safe operating temperatures, depending on the transformer size and application.

A. Natural Cooling Methods

| Cooling Type | Description | Applications | Efficiency |

|---|---|---|---|

| ONAN (Oil Natural Air Natural) | Heat is dissipated naturally through radiators and air convection. | Distribution transformers (small/medium size) | Moderate |

| AN (Air Natural) | Air-circulated cooling used in dry-type transformers. | Indoor and industrial transformers | Low |

💡 ONAN cooling is cost-effective and requires minimal maintenance.

B. Forced Cooling Methods

| Cooling Type | Description | Applications | Efficiency |

|---|---|---|---|

| ONAF (Oil Natural Air Forced) | Uses fans to accelerate air circulation over radiators. | Power transformers (medium/large size) | High |

| OFWF (Oil Forced Water Forced) | Uses water-cooled heat exchangers for rapid cooling. | Industrial and high-power transformers | Very High |

✅ Forced cooling is used in high-load transformers to improve heat dissipation.

C. Comparing Transformer Cooling Systems

| Cooling Method | Complexity | Maintenance | Cost | Cooling Efficiency |

|---|---|---|---|---|

| ONAN | Low | Low | Low | Moderate |

| ONAF | Medium | Moderate | Moderate | High |

| OFWF | High | High | High | Very High |

💡 Selecting the right cooling method depends on transformer power rating and environmental conditions.

3. How Cooling Improves Transformer Efficiency

Cooling enhances transformer performance by:

✅ Reducing winding resistance – Cooler windings reduce I²R losses and improve efficiency.

✅ Maintaining stable insulation properties – Prevents thermal degradation of insulation.

✅ Enhancing load-handling capability – Well-cooled transformers can operate at higher loads.

✅ Extending transformer lifespan – Lower operating temperatures slow down aging effects.

💡 A properly cooled transformer operates more efficiently and lasts longer.

4. Best Practices for Transformer Cooling System Maintenance

A. Regular Temperature Monitoring

| Measurement Point | Normal Range (°C) | Alarm Level (°C) | Shutdown Level (°C) |

|---|---|---|---|

| Top-Oil Temperature | 40 - 85°C | >95°C | >110°C |

| Winding Hot Spot | 60 - 105°C | >120°C | >140°C |

✅ Install temperature sensors and alarms to detect overheating early.

B. Cooling System Inspection Checklist

| Component | Maintenance Action | Frequency |

|---|---|---|

| Radiators & Cooling Fans | Clean dust and debris | Every 6 months |

| Oil Circulation Pumps | Check for proper operation | Yearly |

| Water Cooling Pipes (OFWF systems) | Inspect for leaks and blockages | Quarterly |

| Silica Gel Breathers | Replace when color changes | Every 6 months |

✅ Well-maintained cooling systems improve transformer reliability.

5. Common Cooling System Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Overheating | Insufficient airflow or oil circulation | Clean radiators, check oil levels |

| Oil Temperature Too High | Blocked cooling ducts or pump failure | Inspect and repair oil pumps |

| Fan or Pump Malfunction | Electrical or mechanical failure | Test and replace faulty components |

| Excessive Noise from Fans | Imbalanced or worn-out fan blades | Lubricate or replace fans |

✅ Addressing cooling issues early prevents transformer damage.

6. Future Advancements in Transformer Cooling

Emerging technologies improve transformer cooling efficiency:

🚀 Smart Cooling Systems: IoT-based sensors for real-time temperature monitoring.

🚀 High-Efficiency Radiators: Enhanced heat exchange materials for better cooling.

🚀 Eco-Friendly Cooling Fluids: Ester-based oils for improved heat dissipation and fire safety.

💡 Advancements in cooling technology improve transformer safety and efficiency.

What Are the Main Cooling Methods Used in Transformers?

Transformers generate significant heat during operation due to electrical losses in the core and windings. Without proper cooling, excessive heat can degrade insulation, reduce efficiency, and lead to transformer failure. To ensure stable operation and extend transformer lifespan, various cooling methods are used based on transformer size, power rating, and environmental conditions.

The main cooling methods used in transformers include Oil Natural Air Natural (ONAN), Oil Natural Air Forced (ONAF), Oil Forced Water Forced (OFWF), and Air Natural (AN). These methods regulate transformer temperature by dissipating heat through air, oil, or water, ensuring efficient performance and insulation longevity.

This guide explores different transformer cooling techniques, their applications, advantages, and best maintenance practices.

Transformers do not require cooling systems for efficient operation.False

Cooling systems are essential for dissipating heat, preventing insulation breakdown, and maintaining transformer efficiency.

1. Why Transformer Cooling Is Essential

A. Heat Generation in Transformers

Heat is generated in transformers due to:

✅ Copper losses (I²R losses): Resistance in windings converts current into heat.

✅ Core losses (Hysteresis and Eddy Currents): Magnetic flux variations create heat in the core.

✅ Stray losses: Additional losses due to leakage flux and harmonics.

💡 Without cooling, heat buildup can degrade insulation and cause failure.

B. Consequences of Poor Cooling

| Issue | Cause | Consequence |

|---|---|---|

| Overheating | Insufficient heat dissipation | Reduces transformer lifespan |

| Insulation Breakdown | Excessive temperature stress | Increases failure risk |

| Oil Degradation | Prolonged exposure to high temperatures | Lowers dielectric strength |

| Core and Winding Damage | Expansion and contraction due to heat cycles | Leads to electrical faults |

✅ Proper cooling prevents failures and improves transformer efficiency.

2. Main Cooling Methods Used in Transformers

A. Oil-Immersed Transformer Cooling Methods

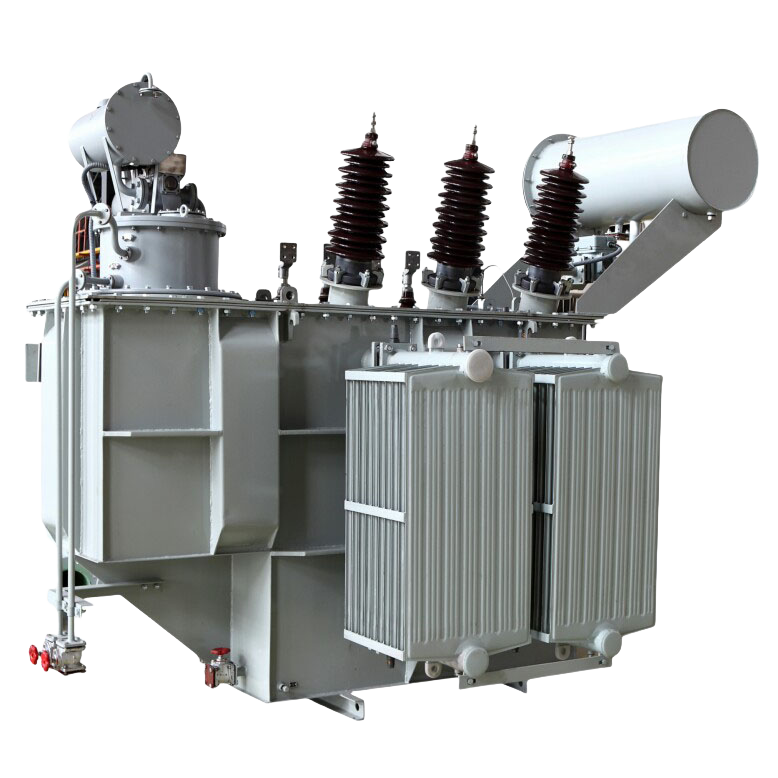

Oil-immersed transformers use insulating oil to transfer heat from windings to radiators, where it dissipates into the surrounding air.

| Cooling Type | Description | Applications | Efficiency |

|---|---|---|---|

| ONAN (Oil Natural Air Natural) | Heat dissipates naturally through radiators and air convection. | Distribution transformers (small/medium size) | Moderate |

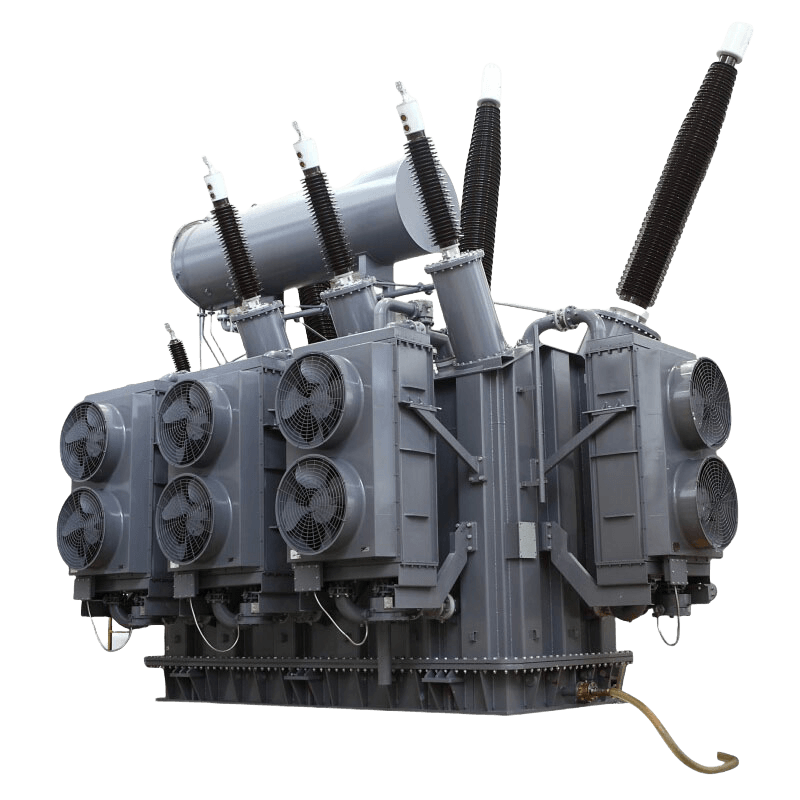

| ONAF (Oil Natural Air Forced) | Uses fans to accelerate air circulation over radiators. | Power transformers (medium/large size) | High |

| OFWF (Oil Forced Water Forced) | Uses oil pumps and water-cooled heat exchangers for rapid cooling. | Industrial and high-power transformers | Very High |

| ODAF (Oil Directed Air Forced) | Oil is forced through cooling channels using pumps, with air-forced heat dissipation. | Large power transformers | High |

💡 ONAN is cost-effective for small transformers, while OFWF is used for high-load applications requiring maximum cooling.

B. Dry-Type Transformer Cooling Methods

Dry-type transformers use air instead of oil for cooling. These are typically used indoors or in fire-sensitive areas.

| Cooling Type | Description | Applications | Efficiency |

|---|---|---|---|

| AN (Air Natural) | Heat dissipates naturally into surrounding air. | Small indoor transformers | Low |

| AF (Air Forced) | Uses fans to enhance air circulation. | Medium-sized transformers in buildings | Moderate |

💡 Air-cooled transformers are ideal for areas where oil-based cooling is not feasible due to fire risks.

C. Comparison of Transformer Cooling Systems

| Cooling Method | Complexity | Maintenance | Cost | Cooling Efficiency |

|---|---|---|---|---|

| ONAN | Low | Low | Low | Moderate |

| ONAF | Medium | Moderate | Moderate | High |

| OFWF | High | High | High | Very High |

| AN | Low | Low | Low | Low |

| AF | Medium | Moderate | Moderate | Moderate |

💡 Choosing the right cooling method depends on transformer power rating, location, and required efficiency.

3. How Cooling Improves Transformer Efficiency

Cooling enhances transformer performance by:

✅ Reducing winding resistance – Cooler windings lower I²R losses, improving efficiency.

✅ Maintaining insulation properties – Prevents thermal degradation of insulation.

✅ Enhancing load-handling capacity – Well-cooled transformers operate at higher loads safely.

✅ Extending transformer lifespan – Lower operating temperatures slow down aging effects.

💡 A well-cooled transformer operates efficiently and lasts longer.

4. Best Practices for Transformer Cooling System Maintenance

A. Regular Temperature Monitoring

| Measurement Point | Normal Range (°C) | Alarm Level (°C) | Shutdown Level (°C) |

|---|---|---|---|

| Top-Oil Temperature | 40 - 85°C | >95°C | >110°C |

| Winding Hot Spot | 60 - 105°C | >120°C | >140°C |

✅ Install temperature sensors and alarms to detect overheating early.

B. Cooling System Inspection Checklist

| Component | Maintenance Action | Frequency |

|---|---|---|

| Radiators & Cooling Fans | Clean dust and debris | Every 6 months |

| Oil Circulation Pumps | Check for proper operation | Yearly |

| Water Cooling Pipes (OFWF systems) | Inspect for leaks and blockages | Quarterly |

| Silica Gel Breathers | Replace when color changes | Every 6 months |

✅ Well-maintained cooling systems improve transformer reliability.

5. Common Cooling System Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Overheating | Insufficient airflow or oil circulation | Clean radiators, check oil levels |

| Oil Temperature Too High | Blocked cooling ducts or pump failure | Inspect and repair oil pumps |

| Fan or Pump Malfunction | Electrical or mechanical failure | Test and replace faulty components |

| Excessive Noise from Fans | Imbalanced or worn-out fan blades | Lubricate or replace fans |

✅ Addressing cooling issues early prevents transformer damage.

6. Future Advancements in Transformer Cooling

Emerging technologies improve transformer cooling efficiency:

🚀 Smart Cooling Systems: IoT-based sensors for real-time temperature monitoring.

🚀 High-Efficiency Radiators: Advanced heat exchange materials for better cooling.

🚀 Eco-Friendly Cooling Fluids: Ester-based oils for improved heat dissipation and fire safety.

💡 Advancements in cooling technology improve transformer safety and efficiency.

How Does Oil-Based Cooling Enhance Transformer Efficiency?

Transformers generate significant heat during operation due to electrical losses in the windings and core. Without effective cooling, excessive heat can degrade insulation, reduce efficiency, and lead to premature failure. Oil-based cooling systems are widely used to dissipate heat efficiently, maintain stable operating temperatures, and extend transformer lifespan.

Oil-based cooling enhances transformer efficiency by improving heat dissipation, reducing insulation stress, minimizing energy losses, and allowing higher load capacities. The superior thermal conductivity of transformer oil ensures even temperature distribution, preventing hotspots and improving overall performance.

This guide explains why oil-based cooling is essential, its working principles, and how it improves transformer efficiency.

Transformer efficiency is not affected by cooling systems.False

Efficient cooling systems, particularly oil-based cooling, play a crucial role in maintaining optimal transformer performance and preventing overheating-related losses.

1. Why Is Oil-Based Cooling Essential for Transformer Efficiency?

A. Understanding Heat Generation in Transformers

Heat is generated in transformers due to:

✅ Copper losses (I²R losses): Electrical resistance in windings converts energy into heat.

✅ Core losses (Hysteresis and Eddy Currents): Magnetic flux variations create heat in the core.

✅ Stray losses: Additional losses due to leakage flux and harmonics.

💡 Excessive heat reduces efficiency and accelerates insulation aging.

B. How Overheating Affects Transformer Performance

| Issue | Cause | Consequence |

|---|---|---|

| Insulation Breakdown | High temperatures weaken insulation materials. | Increased failure risk |

| Oil Degradation | Prolonged exposure to excessive heat oxidizes oil. | Lowers dielectric strength |

| Higher Energy Losses | Increased resistance in windings due to heat. | Reduces transformer efficiency |

| Core Expansion & Mechanical Stress | Heat cycles cause expansion and contraction. | Leads to winding displacement and faults |

✅ Oil-based cooling prevents overheating, reducing these risks and improving efficiency.

2. How Oil-Based Cooling Works in Transformers

Transformer oil acts as both an insulating and cooling medium, absorbing heat from the windings and core and transferring it to external cooling elements like radiators.

A. Heat Dissipation Process

- Heat is generated in transformer windings and core.

- Oil absorbs heat and circulates through the cooling system.

- Heat is dissipated through radiators or cooling fins.

- Cooled oil returns to the transformer tank to repeat the process.

💡 Continuous circulation ensures stable operating temperatures, improving efficiency.

B. Key Properties of Transformer Oil for Cooling

| Property | Importance for Cooling |

|---|---|

| High Thermal Conductivity | Transfers heat efficiently from windings to cooling surfaces. |

| High Dielectric Strength | Prevents electrical breakdown while acting as a coolant. |

| Oxidation Stability | Prevents sludge formation that can block cooling pathways. |

| Low Viscosity | Ensures smooth oil flow through cooling channels. |

✅ Choosing high-quality transformer oil improves heat transfer and efficiency.

3. Oil-Based Cooling Methods and Their Efficiency

A. Types of Oil-Based Cooling Systems

| Cooling Type | Description | Applications | Efficiency |

|---|---|---|---|

| ONAN (Oil Natural Air Natural) | Heat dissipates naturally through radiators and air convection. | Distribution transformers (small/medium size) | Moderate |

| ONAF (Oil Natural Air Forced) | Uses fans to accelerate air circulation over radiators. | Power transformers (medium/large size) | High |

| OFWF (Oil Forced Water Forced) | Uses oil pumps and water-cooled heat exchangers for rapid cooling. | Industrial and high-power transformers | Very High |

| ODAF (Oil Directed Air Forced) | Pumps circulate oil through cooling ducts, with air-forced heat dissipation. | Large power transformers | High |

💡 Forced cooling methods significantly improve heat dissipation and efficiency.

B. How Oil-Based Cooling Increases Efficiency

✅ Reduces winding resistance: Cooler windings have lower electrical resistance, reducing I²R losses.

✅ Prevents hot spots: Even temperature distribution prevents localized overheating, preserving insulation.

✅ Improves load capacity: Proper cooling allows transformers to handle higher loads safely.

✅ Extends transformer lifespan: Lower operating temperatures slow down insulation aging.

💡 A properly cooled transformer operates efficiently and lasts longer.

4. Best Practices for Maintaining Transformer Oil Cooling Efficiency

A. Regular Oil Quality Testing

| Test | Purpose | Recommended Frequency | Acceptable Limit |

|---|---|---|---|

| Dielectric Strength (BDV) | Ensures insulation capability | Every 6-12 months | >30 kV |

| Moisture Content | Prevents insulation degradation | Yearly | <10 ppm |

| Acidity (TAN Test) | Monitors oxidation levels | Yearly | <0.05 mg KOH/g |

| Dissolved Gas Analysis (DGA) | Detects arcing and overheating | Yearly | Gas-specific limits |

✅ Regular oil testing ensures optimal cooling performance.

B. Cooling System Maintenance Checklist

| Component | Maintenance Action | Frequency |

|---|---|---|

| Radiators & Cooling Fans | Clean dust and debris | Every 6 months |

| Oil Circulation Pumps | Check for proper operation | Yearly |

| Oil Levels & Quality | Monitor for degradation | Every 6 months |

| Silica Gel Breathers | Replace when color changes | Every 6 months |

✅ Well-maintained cooling systems enhance efficiency and reliability.

5. Common Oil Cooling System Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Overheating | Insufficient airflow or oil circulation | Clean radiators, check oil levels |

| Oil Temperature Too High | Blocked cooling ducts or pump failure | Inspect and repair oil pumps |

| Fan or Pump Malfunction | Electrical or mechanical failure | Test and replace faulty components |

| Oil Sludge Formation | Oxidation of oil due to high temperature | Perform oil filtration or replacement |

✅ Early issue detection prevents major transformer failures.

6. Future Innovations in Oil-Based Cooling

Emerging technologies enhance transformer cooling efficiency:

🚀 Smart Cooling Systems: IoT-based sensors for real-time temperature monitoring.

🚀 High-Efficiency Radiators: Advanced heat exchange materials for better cooling.

🚀 Eco-Friendly Cooling Fluids: Ester-based oils for improved heat dissipation and fire safety.

💡 New cooling advancements improve transformer safety and energy efficiency.

What Role Do Radiators and Fans Play in Transformer Thermal Management?

Transformers generate significant heat during operation due to electrical losses in the windings and core. If this heat is not dissipated efficiently, it can lead to insulation degradation, reduced efficiency, and transformer failure. Radiators and fans are critical components of transformer cooling systems, ensuring stable operation by maintaining optimal temperatures.

Radiators and fans play a vital role in transformer thermal management by dissipating excess heat, maintaining stable oil temperature, and preventing insulation breakdown. Radiators provide passive heat dissipation through natural convection, while fans enhance cooling efficiency by increasing airflow over radiators, improving heat exchange and ensuring transformer reliability.

This guide explains how radiators and fans contribute to transformer cooling, their operating principles, and best maintenance practices for effective thermal management.

Radiators and fans are not essential for transformer cooling.False

Radiators and fans are critical for dissipating heat and preventing transformer overheating, ensuring safe and efficient operation.

1. Why Is Thermal Management Essential in Transformers?

A. Heat Generation in Transformers

Heat is generated in transformers due to:

✅ Copper losses (I²R losses): Electrical resistance in windings produces heat.

✅ Core losses (Hysteresis and Eddy Currents): Magnetic flux variations generate heat in the core.

✅ Stray losses: Additional heat from leakage flux and harmonics.

💡 Excess heat must be dissipated effectively to prevent performance degradation.

B. Effects of Poor Thermal Management

| Issue | Cause | Consequence |

|---|---|---|

| Overheating | Insufficient heat dissipation | Reduced transformer lifespan |

| Insulation Breakdown | Excessive temperature stress | Increases failure risk |

| Oil Degradation | Prolonged exposure to high temperatures | Lowers dielectric strength |

| Core and Winding Damage | Expansion and contraction due to heat cycles | Leads to electrical faults |

✅ Proper cooling ensures consistent transformer performance and longevity.

2. The Role of Radiators in Transformer Cooling

A. How Radiators Work

Radiators act as heat exchangers, transferring heat from transformer oil to the surrounding air.

Heat dissipation process:

- Transformer oil absorbs heat from the core and windings.

- Hot oil flows into the radiator through connecting pipes.

- Heat is released into the air as the oil passes through radiator fins.

- Cooled oil returns to the transformer to continue the cycle.

💡 Radiators rely on natural convection or forced cooling to dissipate heat efficiently.

B. Types of Radiator Cooling

| Radiator Type | Cooling Mechanism | Applications | Efficiency |

|---|---|---|---|

| ONAN (Oil Natural Air Natural) | Heat dissipates naturally through air convection. | Small/medium transformers | Moderate |

| ONAF (Oil Natural Air Forced) | Uses fans to increase airflow over radiators. | Medium/large transformers | High |

| OFWF (Oil Forced Water Forced) | Oil circulates through a water-cooled heat exchanger. | High-power industrial transformers | Very High |

✅ ONAF and OFWF systems improve cooling efficiency, preventing overheating.

3. The Role of Fans in Transformer Cooling

A. How Fans Improve Heat Dissipation

Fans are used in forced-air cooling systems to increase the heat transfer rate.

Working process:

- Fans blow air over radiator fins, accelerating heat dissipation.

- Forced airflow enhances convection, reducing oil temperature faster.

- Cooled oil circulates back to absorb more heat from the transformer.

💡 Fans help transformers handle higher loads by preventing excessive temperature rise.

B. Types of Transformer Fans

| Fan Type | Cooling Function | Applications |

|---|---|---|

| Axial Fans | Direct airflow along radiator fins for efficient cooling. | Power transformers, substations |

| Centrifugal Fans | Generate higher pressure airflow for improved heat dissipation. | Large industrial transformers |

✅ Proper fan selection enhances transformer thermal performance.

4. How Radiators and Fans Improve Transformer Efficiency

A. Benefits of Radiators in Cooling Efficiency

✅ Passive cooling mechanism lowers maintenance requirements.

✅ Even heat distribution prevents localized hot spots.

✅ Energy-efficient operation in ONAN systems (no external power needed).

B. Benefits of Fans in Cooling Efficiency

✅ Reduces oil and winding temperature, improving insulation lifespan.

✅ Allows transformers to handle higher loads without overheating.

✅ Improves efficiency in hot environments where natural convection is insufficient.

💡 Combining radiators with fans increases cooling efficiency, enabling transformers to operate at optimal performance levels.

5. Best Practices for Maintaining Radiators and Fans

A. Cooling System Inspection Checklist

| Component | Maintenance Action | Frequency |

|---|---|---|

| Radiator Fins | Clean dirt and debris for optimal airflow | Every 6 months |

| Fan Bearings & Motors | Lubricate and check for wear | Every 12 months |

| Temperature Sensors | Test for accurate readings | Quarterly |

| Cooling Oil Levels | Monitor and refill if needed | Every 6 months |

✅ Regular maintenance prevents overheating and improves cooling efficiency.

B. Common Cooling System Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Overheating | Blocked radiator fins or fan failure | Clean radiators, check oil levels |

| Fan Motor Failure | Electrical or mechanical issues | Inspect and replace faulty components |

| Insufficient Airflow | Damaged or dirty fans | Lubricate, clean, or replace fans |

| Oil Leaks in Radiators | Loose connections or cracked pipes | Inspect and repair leaks |

✅ Addressing cooling issues early prevents transformer damage and energy losses.

6. Advanced Cooling Technologies for Transformers

🚀 Smart Cooling Systems: IoT sensors monitor temperature and adjust fan speed automatically.

🚀 High-Efficiency Radiators: Advanced materials improve heat exchange rates.

🚀 Eco-Friendly Cooling Fluids: Biodegradable oils enhance cooling performance.

💡 Technological advancements in cooling improve transformer safety and efficiency.

How Can Temperature Monitoring Prevent Transformer Failures?

Transformers generate significant heat due to electrical and core losses during operation. Without proper thermal management, overheating can cause insulation breakdown, oil degradation, and even catastrophic failure. Temperature monitoring is essential to detect early warning signs of overheating, enabling proactive maintenance and preventing costly transformer failures.

Temperature monitoring prevents transformer failures by detecting excessive heating, ensuring insulation integrity, preventing oil degradation, and reducing thermal stress on components. Real-time monitoring allows early fault detection, minimizing downtime and extending transformer lifespan.

This guide explores the importance of temperature monitoring, the types of temperature sensors used, and best practices for thermal management in transformers.

Transformers do not require temperature monitoring as long as they are operational.False

Regular temperature monitoring is crucial for detecting overheating and preventing insulation breakdown, oil degradation, and transformer failures.

1. Why Is Temperature Monitoring Essential for Transformers?

A. How Heat Affects Transformer Performance

Heat is generated in transformers due to:

✅ Copper losses (I²R losses): Electrical resistance in windings produces heat.

✅ Core losses (Hysteresis and Eddy Currents): Magnetic flux variations generate heat in the core.

✅ Stray losses: Additional heat from leakage flux and harmonics.

💡 Uncontrolled heat buildup leads to increased energy losses, reduced efficiency, and component degradation.

B. Consequences of Overheating in Transformers

| Issue | Cause | Consequence |

|---|---|---|

| Insulation Breakdown | Excessive thermal stress on winding insulation | Increased risk of electrical faults |

| Oil Degradation | High temperatures accelerate oxidation | Reduces dielectric strength |

| Core Expansion & Mechanical Stress | Repeated thermal cycling weakens structural integrity | Leads to winding displacement and short circuits |

| Increased Energy Losses | Overheated windings have higher resistance | Reduces efficiency and increases operational costs |

✅ Continuous temperature monitoring helps detect early signs of overheating, preventing failures.

2. Key Temperature Monitoring Points in Transformers

To ensure effective thermal management, monitoring should focus on:

| Monitoring Point | Purpose | Normal Range (°C) | Alarm Level (°C) | Shutdown Level (°C) |

|---|---|---|---|---|

| Top-Oil Temperature | Indicates overall transformer heating | 40 - 85°C | >95°C | >110°C |

| Winding Hot Spot | Detects insulation stress in windings | 60 - 105°C | >120°C | >140°C |

| Radiator & Cooling System | Ensures effective heat dissipation | <80°C | >90°C | >100°C |

💡 Monitoring these points helps identify early warning signs of transformer issues.

3. Types of Temperature Monitoring Systems

Temperature sensors provide real-time data for proactive maintenance.

A. Traditional Temperature Monitoring Devices

| Sensor Type | Function | Application |

|---|---|---|

| Bimetallic Thermometers | Measures top-oil temperature | Small transformers |

| Resistance Temperature Detectors (RTDs) | Measures winding temperature | Medium/large transformers |

| Capillary Thermometers | Provides local temperature readings | General-purpose monitoring |

💡 Traditional sensors provide basic temperature monitoring but lack real-time remote access.

B. Advanced Digital Monitoring Systems

| Sensor Type | Function | Application |

|---|---|---|

| Fiber Optic Temperature Sensors | Directly measure winding hot-spot temperatures | High-voltage transformers |

| Infrared Thermal Imaging | Detects overheating in live transformers | Condition-based maintenance |

| IoT-Based Wireless Sensors | Real-time remote temperature monitoring | Smart grid applications |

✅ Advanced sensors improve accuracy, data logging, and predictive maintenance capabilities.

4. How Temperature Monitoring Prevents Transformer Failures

A. Early Fault Detection

✅ Identifies abnormal temperature rises, preventing sudden failures.

✅ Detects cooling system malfunctions before they lead to overheating.

✅ Allows maintenance teams to take preventive action, reducing downtime.

💡 Real-time temperature alerts enable quick responses to prevent damage.

B. Preventing Insulation Degradation

✅ Maintains safe operating temperatures, reducing insulation aging.

✅ Prevents excessive hot-spot temperatures, which accelerate insulation breakdown.

✅ Extends transformer lifespan by keeping thermal stress minimal.

💡 Well-monitored transformers last longer and operate more efficiently.

C. Optimizing Cooling System Performance

✅ Ensures cooling fans and oil pumps function properly.

✅ Prevents radiator blockages by monitoring heat dissipation efficiency.

✅ Detects oil degradation early, maintaining cooling and insulation properties.

💡 Proper cooling management enhances transformer efficiency and reliability.

5. Best Practices for Transformer Temperature Monitoring

| Action | Purpose | Frequency |

|---|---|---|

| Check top-oil and winding temperatures | Detect overheating early | Continuous |

| Inspect cooling system performance | Ensure proper heat dissipation | Monthly |

| Perform infrared thermal imaging | Identify hot spots and insulation weaknesses | Every 6-12 months |

| Calibrate temperature sensors | Maintain accuracy of monitoring devices | Yearly |

| Set temperature alarms and shutdown triggers | Automatic response to excessive heat | Continuous |

✅ Proactive monitoring ensures safe and efficient transformer operation.

6. Common Temperature Monitoring Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Sudden Temperature Spike | Overloading or cooling system failure | Reduce load, check fans/radiators |

| Inaccurate Readings | Faulty sensor calibration | Recalibrate or replace sensors |

| Delayed Temperature Response | Slow sensor feedback | Upgrade to fiber-optic or IoT sensors |

| Hot Spots in Windings | Uneven heat dissipation | Improve oil circulation, check insulation |

✅ Addressing monitoring issues early prevents major transformer failures.

7. Future Innovations in Temperature Monitoring

🚀 AI-Based Predictive Analytics: Machine learning models predict failures based on temperature trends.

🚀 IoT-Enabled Smart Sensors: Wireless sensors provide real-time temperature data via cloud-based monitoring.

🚀 Automated Cooling System Control: Intelligent fans and pumps adjust cooling based on real-time heat load.

💡 Next-generation monitoring systems enhance transformer reliability and efficiency.

What Are the Best Practices for Maintaining an Efficient Cooling System in Transformers?

A transformer’s cooling system is essential for dissipating excess heat, ensuring stable operation, and preventing failures. Without proper maintenance, cooling inefficiencies can lead to insulation degradation, overheating, and reduced transformer lifespan.

The best practices for maintaining an efficient transformer cooling system include regular inspections, cleaning radiators and fans, monitoring oil circulation, ensuring proper airflow, and using advanced temperature monitoring systems. Implementing preventive maintenance strategies improves cooling efficiency, enhances performance, and extends transformer life.

This guide covers key cooling system components, common issues, and best maintenance practices to ensure optimal transformer performance.

Transformer cooling systems do not require regular maintenance.False

Regular maintenance of transformer cooling systems is essential to prevent overheating, maintain efficiency, and extend the lifespan of the transformer.

1. Why Is Cooling System Maintenance Essential?

A. The Role of the Cooling System in Transformer Performance

Heat is generated in transformers due to:

✅ Copper losses (I²R losses): Electrical resistance in windings converts energy into heat.

✅ Core losses (Hysteresis and Eddy Currents): Magnetic flux variations generate heat in the core.

✅ Stray losses: Additional heat from leakage flux and harmonics.

💡 Without proper cooling, these losses lead to excessive temperatures, insulation breakdown, and reduced efficiency.

B. Common Problems Caused by Poor Cooling System Maintenance

| Issue | Cause | Consequence |

|---|---|---|

| Overheating | Blocked radiators, faulty fans, or insufficient oil circulation | Reduces transformer lifespan |

| Insulation Breakdown | Excessive temperature stress on winding insulation | Increased failure risk |

| Oil Degradation | High temperatures accelerate oxidation | Lowers dielectric strength |

| Cooling System Failure | Clogged heat exchangers or malfunctioning pumps | Leads to transformer shutdown |

✅ Regular cooling system maintenance prevents failures and improves efficiency.

2. Key Components of Transformer Cooling Systems

A well-maintained cooling system ensures effective heat dissipation.

A. Types of Transformer Cooling Systems

| Cooling Type | Description | Applications | Efficiency |

|---|---|---|---|

| ONAN (Oil Natural Air Natural) | Heat dissipates naturally through radiators and air convection. | Distribution transformers | Moderate |

| ONAF (Oil Natural Air Forced) | Uses fans to increase airflow over radiators. | Power transformers | High |

| OFWF (Oil Forced Water Forced) | Oil pumps circulate through water-cooled heat exchangers. | Industrial transformers | Very High |

| ODAF (Oil Directed Air Forced) | Pumps force oil through cooling ducts, with fan-assisted heat dissipation. | Large power transformers | High |

✅ Forced cooling systems require more maintenance but improve heat dissipation efficiency.

B. Essential Cooling System Components

| Component | Function | Maintenance Importance |

|---|---|---|

| Radiators | Dissipate heat from transformer oil | Must be cleaned to prevent blockages |

| Fans | Improve air circulation for faster cooling | Need lubrication and performance checks |

| Oil Pumps | Circulate oil through cooling system | Ensure smooth operation and prevent failures |

| Heat Exchangers | Transfer heat from oil to air or water | Require periodic flushing to maintain efficiency |

| Silica Gel Breathers | Prevent moisture contamination in oil | Must be replaced when saturated |

✅ Regular inspections keep all cooling system components operating efficiently.

3. Best Practices for Cooling System Maintenance

A. Regular Cleaning and Inspection

Why? Dust, dirt, and oil residue reduce heat dissipation efficiency and cause overheating.

| Maintenance Task | Purpose | Frequency |

|---|---|---|

| Clean radiator fins | Removes dirt and improves airflow | Every 6 months |

| Inspect oil circulation pumps | Ensures proper oil flow | Every 12 months |

| Check for oil leaks | Prevents loss of insulation and cooling efficiency | Quarterly |

| Flush cooling system pipes | Removes sludge and blockages | Every 2-3 years |

💡 Keeping cooling components clean improves heat dissipation and efficiency.

B. Monitoring Oil Levels and Circulation

Why? Low oil levels or poor circulation lead to hot spots and overheating.

| Maintenance Task | Purpose | Frequency |

|---|---|---|

| Check oil level | Ensures proper heat transfer | Monthly |

| Monitor oil temperature | Detects circulation issues early | Continuous |

| Perform oil filtration | Removes contaminants affecting heat dissipation | Every 3-5 years |

✅ Regular oil monitoring prevents thermal imbalances and cooling inefficiencies.

C. Testing Cooling System Performance

Why? Early detection of cooling system faults prevents transformer failures.

| Test | Purpose | Frequency |

|---|---|---|

| Infrared Thermal Imaging | Detects hot spots in radiators, fans, and windings | Every 6-12 months |

| Fan Speed & Vibration Analysis | Ensures optimal airflow and detects mechanical faults | Quarterly |

| Oil Flow Rate Testing | Confirms circulation pump efficiency | Annually |

💡 Advanced monitoring tools improve maintenance accuracy and reliability.

D. Preventing Moisture and Oxidation in Cooling Oil

Why? Moisture lowers dielectric strength and causes oil degradation.

| Maintenance Task | Purpose | Frequency |

|---|---|---|

| Replace silica gel breathers | Prevents moisture contamination | Every 6 months |

| Perform dissolved gas analysis (DGA) | Detects oil oxidation and overheating | Annually |

| Replace degraded oil | Ensures proper heat dissipation and insulation | Every 10-15 years |

✅ Dry and clean oil improves both cooling and insulation efficiency.

4. Using Advanced Cooling System Monitoring

🚀 Smart Sensors: IoT-based devices provide real-time temperature and oil flow data.

🚀 Automatic Cooling System Control: AI-driven fans and pumps adjust speed based on heat load.

🚀 High-Efficiency Heat Exchangers: Modern cooling materials improve heat transfer rates.

💡 Future cooling technologies improve efficiency and reduce maintenance costs.

5. Common Cooling System Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Overheating | Dust accumulation, poor airflow | Clean radiators, check oil levels |

| Oil Temperature Too High | Blocked cooling ducts or pump failure | Inspect and repair oil pumps |

| Fan Malfunction | Electrical or mechanical failure | Test and replace faulty components |

| Moisture Contamination | Damaged breather or leaking seals | Replace silica gel and check seals |

✅ Addressing issues early prevents major transformer failures.

Conclusion

Proper cooling and thermal management are crucial for preventing overheating, reducing energy losses, and extending transformer lifespan. By understanding different cooling methods, implementing temperature monitoring systems, and maintaining cooling components, operators can ensure optimal transformer performance and reliability.

Investing in effective thermal management not only enhances efficiency but also minimizes risks and long-term maintenance costs.

Need expert advice on transformer cooling solutions? Contact us today for professional guidance!

References

- Transformer Cooling Systems Overview - https://www.electricalengineeringportal.com/ - Electrical Engineering Portal

- Thermal Management in Power Transformers - https://www.sciencedirect.com/ - ScienceDirect

- Best Practices for Transformer Cooling - https://www.eaton.com/ - Eaton

- Guide to Transformer Heat Dissipation - https://www.se.com/ - Schneider Electric

- How to Prevent Transformer Overheating - https://www.powermag.com/ - Power Magazine

- Cooling Techniques for Electrical Transformers - https://www.ieee.org/ - IEEE

- Transformer Oil Cooling Methods - https://www.emerson.com/ - Emerson

- Advances in Transformer Thermal Management - https://www.springer.com/ - Springer

- Importance of Cooling in Transformer Efficiency - https://www.abb.com/ - ABB

- Transformer Maintenance and Cooling Strategies - https://www.nrel.gov/ - NREL