Power transformers are critical components in electrical networks, and their classification determines their suitability for specific applications. They are typically categorized based on voltage rating, cooling method, and phase type—each factor influencing design, operation, and installation.

How Are Transformers Classified by Voltage Levels?

Transformer classification by voltage level is fundamental to their application in the power system. Voltage dictates everything from insulation thickness and bushing size to core design and installation requirements. Selecting the right voltage class ensures safe operation, optimal efficiency, and system compatibility in residential, industrial, and utility environments.

Transformers are classified by voltage into four main categories: Low Voltage (LV: ≤1 kV), Medium Voltage (MV: >1 kV to ≤35 kV), High Voltage (HV: >35 kV to ≤230 kV), and Extra High Voltage (EHV: >230 kV to 765 kV or more). These categories are based on the rated primary or secondary voltage and are used to define the transformer's insulation, construction, and application within the power grid.

The classification system allows engineers and utilities to standardize selection, testing, and safety protocols.

Transformers are classified by voltage into low, medium, high, and extra-high categories based on rated voltage.True

This classification reflects insulation design, testing standards, and grid-level application.

All transformers operate under the same voltage regardless of application.False

Transformers must be matched to system voltage, which varies widely between residential, industrial, and utility grids.

1. Low Voltage Transformers (LV)

| Voltage Range | Up to 1 kV |

|---|---|

| Typical Use | Electronics, lighting, building control panels |

| Example | 230 V/24 V doorbell transformer, 400 V/12 V LED driver |

| Insulation Class | Class A/B, compact air-cooled units |

LV transformers are mostly dry-type, safe for indoor and commercial environments.

2. Medium Voltage Transformers (MV)

| Voltage Range | Above 1 kV up to 35 kV |

|---|---|

| Common Ratings | 3.3 kV, 6.6 kV, 11 kV, 20 kV, 33 kV |

| Typical Applications | Distribution substations, industrial motors, wind farms |

| Design Type | Oil-immersed or cast-resin dry type |

MV transformers are widely used in primary distribution networks and localized grid supply.

3. High Voltage Transformers (HV)

| Voltage Range | Above 35 kV up to 230 kV |

|---|---|

| Common Ratings | 66 kV, 110 kV, 132 kV, 220 kV |

| Application | Regional transmission, utility substations |

| Design Characteristics | High insulation coordination, large bushings, on-load tap changers |

HV transformers serve as key grid interfaces, linking transmission and sub-transmission levels.

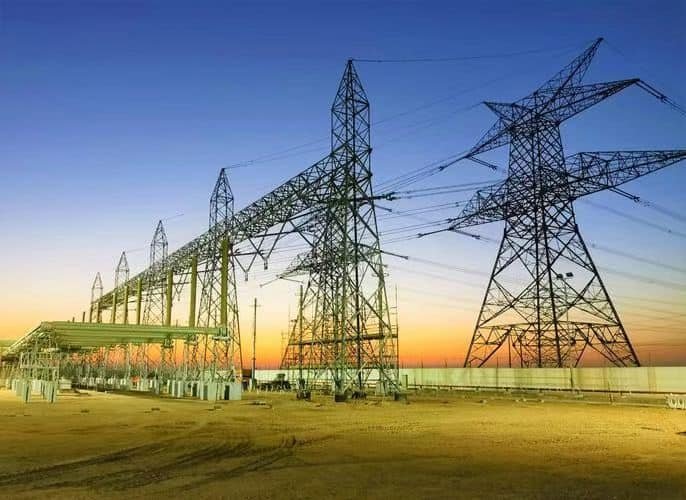

4. Extra High Voltage Transformers (EHV)

| Voltage Range | Above 230 kV up to 765 kV and beyond |

|---|---|

| Standard Levels | 275 kV, 400 kV, 500 kV, 765 kV |

| Application | Bulk power transmission over long distances |

| Key Features | Advanced cooling, capacitive bushings, nitrogen blanket, digital monitoring |

EHV transformers are custom-built for large utilities and national grids.

5. Ultra High Voltage (UHV) – Emerging Class

| Voltage Range | ≥800 kV AC or ±500 kV DC |

|---|---|

| Use Case | Ultra-long distance HVDC transmission |

| Examples | China, India, Brazil HVDC corridors |

| Special Design Needs | SF₆ bushings, modular cooling, GIS integration |

UHV is critical for cross-continent power transmission and inter-grid stability.

Summary Table: Transformer Voltage Classifications

| Voltage Class | Range | Typical Use Case |

|---|---|---|

| Low Voltage (LV) | ≤ 1 kV | Building electronics, lighting, control panels |

| Medium Voltage (MV) | > 1 kV to ≤ 35 kV | Industrial equipment, local grids, renewables |

| High Voltage (HV) | > 35 kV to ≤ 230 kV | Utility substations, long feeders |

| Extra High Voltage (EHV) | > 230 kV to ≤ 765 kV | National grid transmission |

| Ultra High Voltage (UHV) | > 800 kV or ±500 kV DC | Intercontinental HVDC systems |

6. Why Voltage Classification Matters in Practice

| Engineering Impact | Why It Matters |

|---|---|

| Insulation Design | Voltage determines insulation thickness and clearance |

| Testing Requirements | Higher voltages require high impulse and breakdown tests |

| Grid Integration | Must match regional voltage standards |

| Cooling Method | Higher voltage → higher heat → advanced cooling |

| Component Sizing | Bushings, cores, tap changers vary by voltage class |

Mismatching voltage levels can cause instant dielectric failure or overload.

What Is the Difference Between Medium, High, and Extra-High Voltage Transformers?

Understanding the distinction between medium, high, and extra-high voltage transformers is crucial for choosing the right equipment for a specific grid application. These categories reflect not only the voltage ratings, but also the construction scale, insulation design, testing protocols, and grid integration level. Selecting the wrong type can lead to mismatched performance, underutilized capacity, or catastrophic failure.

Medium voltage transformers operate between >1 kV and ≤35 kV, typically serving distribution-level grids or industrial facilities. High voltage transformers operate from >35 kV up to ≤230 kV and are used in transmission and inter-substation applications. Extra-high voltage transformers handle >230 kV to 765 kV, enabling long-distance, high-capacity transmission and interconnection of regional or national grids.

These categories help engineers match transformer design to grid function, distance, and power capacity.

Medium, high, and extra-high voltage transformers differ in voltage range, application, insulation requirements, and physical size.True

Each voltage class is engineered for a specific role in the power grid, with corresponding design and testing standards.

There is no technical difference between medium, high, and extra-high voltage transformers—they are interchangeable.False

Voltage class directly affects insulation, construction, testing, and intended use in the grid. They are not interchangeable.

1. Voltage Range Classification

| Transformer Type | Voltage Range (Primary Side) |

|---|---|

| Medium Voltage (MV) | >1 kV to ≤35 kV |

| High Voltage (HV) | >35 kV to ≤230 kV |

| Extra-High Voltage (EHV) | >230 kV to 765 kV |

These ranges are based on international standards such as IEC 60076 and ANSI/IEEE C57.

2. Application within the Power Grid

| Voltage Class | Typical Use |

|---|---|

| MV Transformers | Local distribution, commercial/industrial loads, renewable step-up |

| HV Transformers | Regional substations, long-distance feeders, step-down near cities |

| EHV Transformers | Bulk transmission across regions or nations, grid interconnection points |

As voltage increases, the transformer’s role shifts from localized delivery to system-wide transmission.

3. Design and Construction Differences

| Aspect | MV Transformer | HV Transformer | EHV Transformer |

|---|---|---|---|

| Size and weight | Compact (2–10 tons) | Medium (10–60 tons) | Massive (60–400+ tons) |

| Cooling type | ONAN/AN (air or oil natural) | ONAF/ONWF (forced air/oil) | OFAF/ODAF/OFWF (multi-stage cooling) |

| Bushing type | Solid or porcelain | Oil-filled or capacitive | Capacitive with SF₆ or composite |

| Core structure | Core-type | Core or shell-type | Reinforced multi-leg core with flux shielding |

| Winding insulation | Paper + oil | High dielectric kraft paper | Advanced thermally upgraded insulation systems |

EHV units require higher mechanical strength, insulation coordination, and advanced cooling.

4. Installation and Operation Requirements

| Requirement | MV | HV | EHV |

|---|---|---|---|

| Footprint | Small kiosk or pad-mount | Yard or bay inside substation | Custom fenced substation with cranes |

| Maintenance needs | Minimal – annual oil checks | Moderate – tap changer servicing | High – continuous monitoring systems |

| Protection systems | Basic fuses or relays | Differential, Buchholz, temperature | Comprehensive: DGA, RTDs, surge arresters |

Higher voltage = greater need for real-time condition monitoring and diagnostics.

5. Performance and Testing Standards

| Characteristic | MV Transformers | HV Transformers | EHV Transformers |

|---|---|---|---|

| Impulse voltage rating | Up to 170 kV BIL | 325–750 kV BIL | >1050 kV BIL |

| Short-circuit withstand | 25–40 kA for 2–3 seconds | 40–63 kA | Custom high-fault-duty design |

| Routine tests | Ratio, resistance, insulation | Includes FRA and partial discharge | Full dielectric and temperature cycling |

| Type testing | Per lot | Per project | Always project-specific and factory-type tested |

Testing protocols are more rigorous and complex as voltage class increases.

6. Cost and Lead Time Differences

| Parameter | MV | HV | EHV |

|---|---|---|---|

| Unit Cost | \$5,000 – \$50,000 | \$100,000 – \$800,000 | \$1M – \$5M+ |

| Manufacturing Lead Time | 6–12 weeks | 4–8 months | 8–18 months (or longer) |

| Logistics | Local transport | Heavy haul or crane lift | Specialized global logistics |

EHV transformers are strategic capital assets that require multi-year planning.

Summary Table: Medium vs. High vs. Extra-High Voltage Transformers

| Attribute | Medium Voltage (MV) | High Voltage (HV) | Extra-High Voltage (EHV) |

|---|---|---|---|

| Voltage Range | >1 kV to ≤35 kV | >35 kV to ≤230 kV | >230 kV to 765 kV |

| Grid Role | Distribution, renewables | Transmission, substations | Bulk transmission, interconnection |

| Size/Weight | Small to mid-sized | Large outdoor units | Extra-large, highly customized |

| Cooling | Natural air/oil | Forced air or oil cooling | Multi-stage, advanced cooling |

| Installation Site | Pole, pad, kiosk | Substation yard | High-security substation hub |

| Maintenance Level | Basic | Moderate | Intensive with real-time systems |

What Are the Main Cooling Methods for Power Transformers?

Power transformers operate continuously under high electrical and thermal stress, making efficient cooling essential to maintain safe temperatures, prevent insulation degradation, and extend service life. As transformer capacity increases, so does the demand for more advanced cooling systems. The cooling method directly affects the transformer's load capacity, physical design, and maintenance requirements.

The main cooling methods for power transformers include ONAN (Oil Natural Air Natural), ONAF (Oil Natural Air Forced), OFAF (Oil Forced Air Forced), and ODAF (Oil Directed Air Forced). These systems use combinations of natural or forced circulation of oil and air to dissipate the heat generated by core and winding losses. The selection depends on transformer size, MVA rating, environmental conditions, and operational demands.

Proper cooling ensures thermal balance, efficiency, and safety in medium, high, and extra-high voltage transformers.

ONAN, ONAF, OFAF, and ODAF are standard cooling methods used in power transformers.True

Each method utilizes different combinations of oil and air flow, either naturally or with forced mechanisms, to manage transformer temperature.

Power transformers do not require dedicated cooling systems.False

Transformers generate significant heat that must be dissipated to prevent failure; cooling systems are essential.

1. ONAN – Oil Natural Air Natural

| Full Form | Oil Natural Air Natural |

|---|---|

| How It Works | Hot oil rises naturally and flows to radiators, cooled by ambient air |

| No moving parts | Passive cooling system—relies on convection |

| Transformer Size Range | Small to medium (up to \~10–20 MVA) |

| Maintenance Need | Minimal—no fans or pumps |

ONAN is simple, quiet, and low-maintenance, but limited in cooling capacity.

2. ONAF – Oil Natural Air Forced

| Full Form | Oil Natural Air Forced |

|---|---|

| How It Works | Natural oil circulation, but air cooling is enhanced with fans |

| Additional components | Radiator-mounted axial or centrifugal fans |

| Capacity Increase | \~33–50% more than ONAN |

| Used In | Transformers between 10–100 MVA |

ONAF offers a flexible two-stage cooling system: fans activate as needed based on temperature.

3. OFAF – Oil Forced Air Forced

| Full Form | Oil Forced Air Forced |

|---|---|

| How It Works | Oil is pumped through the core and radiators; cooled by forced air |

| Additional hardware | Oil circulation pumps and radiator-mounted fans |

| Transformer Size | Typically >100 MVA |

| Efficiency | Significantly improved heat transfer rate |

OFAF supports larger transformers with higher thermal loads and tighter regulation requirements.

4. ODAF – Oil Directed Air Forced

| Full Form | Oil Directed Air Forced |

|---|---|

| Mechanism | Oil is pumped and directed through winding channels, cooled by fans |

| Advanced Flow Control | Improves internal cooling uniformity |

| Used In | EHV and critical transformers (>150–500+ MVA) |

| Advantages | Reduces thermal gradients, prevents local overheating |

ODAF is used in extra-high voltage and generator step-up transformers, where precise heat control is vital.

5. Other Specialized Cooling Methods

| Type | Description | Application |

|---|---|---|

| OFWF | Oil Forced Water Forced – oil cooled via water heat exchangers | Coastal, nuclear, or space-constrained sites |

| KNAN/KNAF | Synthetic/ester fluid cooling for fire safety | Indoor substations, environmentally sensitive areas |

| Dry-type (AF/AN) | Air-cooled, no oil (for dry transformers) | Indoors, commercial, or special ventilated zones |

These are non-standard but critical for specific environmental or operational conditions.

Summary Table: Main Cooling Methods for Power Transformers

| Method | Oil Flow | Air Flow | Typical Size Range | Cooling Capacity |

|---|---|---|---|---|

| ONAN | Natural | Natural | <10–20 MVA | Baseline |

| ONAF | Natural | Forced (fans) | 10–100 MVA | \~50% increase over ONAN |

| OFAF | Forced (pumps) | Forced (fans) | 100–250 MVA | High efficiency |

| ODAF | Directed (pumps) | Forced (fans) | >250–500+ MVA | Maximum thermal performance |

| OFWF | Forced (pumps) | Water-cooled | 50–300 MVA | Quiet, efficient, compact |

6. Cooling System Monitoring and Control

| Component | Function |

|---|---|

| WTI (Winding Temp Indicator) | Monitors winding temperature via thermal image |

| OTI (Oil Temp Indicator) | Tracks top oil temperature |

| Fan/Pump controllers | Activate based on set thermal thresholds |

| Pressure/vacuum relief devices | Protect from system overpressure or vacuum collapse |

| SCADA integration | Enables remote diagnostics and failure prediction |

A healthy cooling system is a critical part of transformer asset management.

How Do Oil-Immersed and Dry-Type Transformers Differ in Cooling?

Cooling is one of the most critical functions in transformer operation. Whether you're dealing with an oil-immersed transformer or a dry-type transformer, effective heat management is essential to protect windings, insulation, and core from thermal degradation. The two types differ not just in the medium they use for cooling, but also in design complexity, safety, maintenance, and application environments.

Oil-immersed transformers use insulating oil as the primary cooling and insulation medium, dissipating heat via natural or forced oil and air flow (ONAN, ONAF, OFAF, etc.). Dry-type transformers rely on air (natural or forced) to cool the windings and core, using open ventilation or enclosed ducts without any liquid coolant. Oil-immersed systems offer higher capacity and better thermal performance, while dry-types are preferred for indoor, fire-sensitive environments.

The cooling method directly influences the transformer’s design, efficiency, fire safety rating, and application suitability.

Oil-immersed transformers use liquid oil for cooling and insulation, while dry-type transformers use air.True

Oil serves as both coolant and dielectric medium in liquid-filled transformers, whereas dry-type units rely on airflow to dissipate heat.

Dry-type transformers cool more efficiently than oil-immersed transformers at high capacities.False

Oil-immersed transformers offer superior heat dissipation and are more efficient at handling high loads and thermal stress.

1. Cooling Mechanism: Oil vs. Air

| Feature | Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|---|

| Cooling Medium | Mineral oil or synthetic ester | Air |

| Heat Transfer Process | Convection through oil, dissipated via radiators | Airflow across exposed coils and core |

| Cooling Enhancement | Radiators, fans, oil pumps | Fans, heat sinks, ventilation ducts |

| System Type | ONAN, ONAF, OFAF, ODAF | AN (Air Natural), AF (Air Forced), ANAF |

Oil-immersed transformers cool both internal and external components, while dry-types rely on surface cooling.

2. Heat Dissipation Efficiency

| Characteristic | Oil-Immersed | Dry-Type |

|---|---|---|

| Thermal conductivity | High (0.12–0.14 W/m·K) | Low (air: 0.026 W/m·K) |

| Heat absorption rate | Oil absorbs and transfers heat rapidly | Air heats quickly, dissipates slowly |

| Winding hot-spot temperature | Lower, better controlled | Higher and more localized |

Oil-based cooling is more thermally efficient, especially at higher MVA ratings.

3. Cooling Capacity and Transformer Rating

| Application Capacity | Oil-Immersed | Dry-Type |

|---|---|---|

| Small-scale (≤2.5 MVA) | ✅ Widely used | ✅ Preferred indoors |

| Medium-scale (5–50 MVA) | ✅ Efficient and compact | 🚫 Less preferred due to heat limitations |

| Large-scale (100+ MVA) | ✅ Industry standard | 🚫 Not viable |

Oil-immersed transformers scale better in size, rating, and duty cycle.

4. Cooling Components and Maintenance

| System Element | Oil-Immersed Transformers | Dry-Type Transformers |

|---|---|---|

| Radiators and conservators | Required for large sizes | Not applicable |

| Cooling fans/pumps | Optional, often added | Optional, used in high-load designs |

| Thermal protection devices | WTI, OTI, Buchholz relay | Thermal sensors, RTDs, fan relays |

| Maintenance frequency | Higher – oil testing, leak checks | Lower – visual inspection, dust removal |

Dry-types are lower maintenance, but require better airflow and environmental cleanliness.

5. Environmental and Safety Factors

| Consideration | Oil-Immersed | Dry-Type |

|---|---|---|

| Fire risk | High (combustible oil) | Low (self-extinguishing resin or open design) |

| Indoor use | Needs fireproof vault, containment | Safe for basements, tunnels, buildings |

| Eco-friendliness | Risk of oil leakage into soil/water | Cleaner, greener operation |

| Cooling noise level | Moderate (fans/pumps) | Low (natural air convection) |

Dry-type transformers are better suited for environmentally sensitive and indoor applications.

Summary Table: Oil-Immersed vs. Dry-Type Cooling Comparison

| Aspect | Oil-Immersed Transformers | Dry-Type Transformers |

|---|---|---|

| Cooling Medium | Liquid oil | Air |

| Cooling Method | Natural or forced oil + air | Natural or forced air |

| Capacity Range | Broad: ≤500+ MVA | Limited: ≤5–10 MVA typical |

| Heat Dissipation | Excellent | Moderate to poor at high loads |

| Fire Safety | Requires containment | Intrinsically safer |

| Maintenance Needs | High – oil management | Low – clean air path maintenance |

| Installation Environment | Outdoor, substations | Indoor, commercial, sensitive sites |

| Cost | Lower per MVA | Higher per MVA |

What Is the Difference Between Single-Phase and Three-Phase Transformers?

Transformers are the backbone of electricity delivery, and the way they are constructed—single-phase or three-phase—determines how they interact with different parts of the power system. The distinction isn’t just about the number of wires; it affects everything from transformer design and cost to efficiency and application type.

Single-phase transformers transfer power using one alternating current (AC) waveform and consist of one primary and one secondary winding. In contrast, three-phase transformers handle three AC waveforms offset by 120 degrees, and consist of either three windings or a three-limb core with combined windings. Single-phase transformers are commonly used in residential and light-load applications, while three-phase transformers are essential for industrial, commercial, and transmission-level systems due to their higher efficiency and balanced power delivery.

This core distinction helps determine where and how transformers are deployed in the power grid.

Single-phase transformers use a single alternating voltage, while three-phase transformers handle three voltages offset by 120 degrees.True

Single-phase units are suited for homes, while three-phase units deliver power to industrial and high-load applications.

Single-phase and three-phase transformers perform identically and are interchangeable in all situations.False

Each type is designed for specific loads and systems—interchanging them can cause imbalance, inefficiency, or failure.

1. Basic Electrical Difference

| Transformer Type | Waveform Carried | Voltage Phases |

|---|---|---|

| Single-Phase | One sine wave of AC power | Phase + Neutral |

| Three-Phase | Three sine waves, 120° apart | Phase A, Phase B, Phase C (balanced) |

Three-phase power delivers continuous, balanced energy, making it more efficient for high-load systems.

2. Construction and Configuration

| Feature | Single-Phase Transformer | Three-Phase Transformer |

|---|---|---|

| Windings | One primary, one secondary | Three sets of windings (or three cores) |

| Core Design | One magnetic leg (core-type) | Three-legged or shell-type |

| Cooling and size | Smaller, simpler | Larger, more complex |

| Mounting | Pole-mounted, wall-mounted | Pad-mounted, skid-based, or substation |

Some three-phase transformers are built as three single-phase units, but most modern designs are integrated.

3. Power Capacity and Application

| Parameter | Single-Phase | Three-Phase |

|---|---|---|

| Power Rating | Up to \~250 kVA | 500 kVA to 1000+ MVA |

| Load Type | Residential loads, lighting circuits | Industrial motors, grid feeders, factories |

| Efficiency | Lower efficiency | High efficiency under balanced loads |

| Cost per kVA | Higher | Lower (economy of scale) |

Three-phase transformers are more efficient and economical for transmitting large amounts of power.

4. Where They Are Used

| Use Case | Single-Phase Transformer | Three-Phase Transformer |

|---|---|---|

| Homes and rural areas | ✅ Pole-mounted service transformers | ❌ Not typically used |

| Commercial buildings | ✅ Lighting or HVAC split loads | ✅ Main incoming supply |

| Industrial motors and equipment | ❌ Inadequate for heavy machinery | ✅ Essential for 3-phase motor operation |

| Utility substations | ❌ Rarely used | ✅ Grid standard |

Single-phase systems are common at the edge of the grid, while three-phase dominates transmission and distribution.

5. Wiring and Connection Methods

| Transformer Type | Primary Connections | Secondary Connections |

|---|---|---|

| Single-Phase | Line-to-neutral or line-to-line | Same as input phase |

| Three-Phase | Delta or Wye (Star) configurations | Delta, Wye, or Zig-Zag (based on need) |

The flexibility of delta-wye connections in three-phase systems allows voltage transformation, grounding, and phase balancing.

Summary Table: Single-Phase vs. Three-Phase Transformers

| Feature | Single-Phase | Three-Phase |

|---|---|---|

| Voltage Supply | 1 AC phase | 3 AC phases (120° apart) |

| Core Design | Single-leg or shell | Three-leg or triple-core design |

| Power Capacity | Up to \~250 kVA | 500 kVA to 1000+ MVA |

| Efficiency | Moderate | High (especially under full load) |

| Installation Area | Rural, residential | Industrial, commercial, utility grid |

| Common Mounting | Pole or wall-mounted | Ground pad-mounted, substation-based |

How Do These Classifications Affect Transformer Applications?

Transformers are classified in multiple ways: by voltage level, phase configuration, and cooling method. Each classification dictates the transformer's role, design complexity, installation environment, and maintenance needs. Choosing the wrong type for a specific application can result in poor performance, safety risks, or complete system mismatch.

Transformer classifications—such as voltage rating (MV, HV, EHV), phase type (single-phase or three-phase), and cooling system (oil-immersed or dry-type)—determine the appropriate application, installation environment, load capacity, and performance profile. These specifications guide engineers in matching transformers to residential, commercial, industrial, or utility-scale power needs.

The right transformer is not just about capacity—it’s about suitability and system compatibility.

Transformer classifications such as voltage level, phase type, and cooling method determine their suitability for different applications.True

Each classification reflects operational limits and environmental considerations that must match the intended use.

Transformer types are interchangeable across all voltage levels and applications.False

Misapplying transformer classifications can lead to overloads, inefficiency, and serious safety risks.

1. Voltage Classification and Application

| Voltage Class | Application Context | Examples |

|---|---|---|

| Medium Voltage (MV) | Distribution substations, buildings, renewable farms | 11 kV/415 V dry-type transformer for a factory |

| High Voltage (HV) | Transmission substations, regional grids | 132 kV/33 kV oil-immersed step-down unit |

| Extra-High Voltage | Long-distance transmission, national interconnects | 400 kV/132 kV grid transformer for utility |

Voltage rating determines where the transformer fits within the grid hierarchy and its insulation design.

2. Phase Classification and Application

| Phase Type | Application Context | Typical Use |

|---|---|---|

| Single-Phase | Residential homes, street lighting | 11 kV/230 V pole-mounted transformer |

| Three-Phase | Industrial plants, commercial buildings, utility substations | 33 kV/11 kV three-phase pad-mounted unit |

Three-phase transformers are used where power quality, load balancing, and efficiency are priorities.

3. Cooling Method and Application Environment

| Cooling Type | Best For | Example Setting |

|---|---|---|

| Oil-Immersed | Outdoor, utility, high-capacity systems | Power substation step-up transformer |

| Dry-Type | Indoor, fire-sensitive, commercial facilities | Basement-mounted transformer in a hospital |

Cooling type affects site selection, fire safety requirements, and maintenance protocols.

4. Combined Impact: Application Mapping Chart

| Application Scenario | Recommended Classifications |

|---|---|

| Rural distribution line | Medium voltage, single-phase, oil-immersed |

| Urban substation | High voltage, three-phase, oil-immersed with OFAF/ONAF cooling |

| Office building (indoor) | Medium voltage, three-phase, dry-type (AF or AN) |

| Data center (critical load) | Medium voltage, three-phase, dry-type with fire-retardant resin |

| Wind or solar plant | Medium to high voltage, three-phase, oil-immersed skid-type |

| National transmission node | Extra-high voltage, three-phase, oil-immersed with ODAF cooling |

Each environment requires a custom-matched transformer design to meet performance and safety standards.

5. Impact on Efficiency, Safety, and Cost

| Classification | Impact Area | Explanation |

|---|---|---|

| Voltage Level | Insulation, conductor clearance | Higher voltage = thicker insulation and more space needed |

| Phase Configuration | Load balance and cost per kVA | Three-phase more efficient and compact per power unit delivered |

| Cooling System | Maintenance, safety, and footprint | Dry-type safer indoors; oil-type more efficient for high loads |

Misclassification increases risk of overheating, transformer failure, and operational inefficiency.

Summary Table: Classification Effects on Transformer Applications

| Classification Type | Determines | Real-World Outcome |

|---|---|---|

| Voltage Rating | Grid level, insulation strength | Utility vs distribution vs end-user |

| Phase Type | Load profile compatibility | Residential vs industrial |

| Cooling Method | Installation location and fire safety | Outdoor substations vs indoor buildings |

| Transformer Core Design | Load capacity and physical footprint | Efficiency and spatial requirements |

Conclusion

Power transformers are classified to match specific grid requirements. Voltage classification determines insulation and operational capacity (e.g., medium <72.5 kV, high 72.5–245 kV, extra-high >245 kV). Cooling classification—such as ONAN, ONAF (oil-cooled) or AN, AF (air-cooled)—affects heat dissipation and reliability. Phase classification—single-phase or three-phase—relates to system configuration and efficiency. Understanding these categories ensures proper transformer selection, performance, and longevity across diverse power systems.

FAQ

Q1: How are power transformers classified by voltage?

A1: Power transformers are classified by voltage level as follows:

Medium Voltage Transformers: 1kV – 33kV

High Voltage Transformers: 33kV – 220kV

Extra High Voltage (EHV) Transformers: 220kV – 400kV

Ultra High Voltage (UHV) Transformers: Above 400kV

These classifications align with transmission and sub-transmission system requirements.

Q2: What are the cooling method classifications for power transformers?

A2: Cooling methods are vital for regulating temperature and include:

ONAN: Oil Natural Air Natural (passive cooling)

ONAF: Oil Natural Air Forced (fans added)

ODAF: Oil Directed Air Forced (forced oil and air)

OFWF: Oil Forced Water Forced (for large transformers)

Dry-Type Cooling: Air-cooled or cast resin (used indoors or in fire-prone areas)

The selection depends on load capacity, installation location, and environmental safety.

Q3: How are power transformers classified by phase?

A3: By phase configuration:

Single-Phase Transformers: Used in light-load or small-scale applications like rural areas and backup systems

Three-Phase Transformers: Standard in industrial plants, substations, and grid networks for balanced power delivery and high efficiency

Three-phase units are more space-efficient and cost-effective for large-scale power handling.

Q4: Why are these classifications important in transformer selection?

A4: Understanding these classifications helps:

Match the transformer to system voltage requirements

Ensure safe and effective heat dissipation

Align with network phase configuration

This optimizes performance, safety, and lifecycle in different applications.

Q5: Can a transformer be custom-built with specific voltage, cooling, and phase specifications?

A5: Yes. Manufacturers offer custom designs to meet exact operational demands, such as:

Unique voltage transformation ratios

Hybrid cooling systems

Split-phase or zigzag windings for special grounding needs

Custom units are tailored for renewable energy, industrial, or mission-critical environments.

References

"Transformer Classification Guide" – https://www.transformertech.com/transformer-classification-voltage-cooling-phase

"Types of Transformers Based on Voltage and Application" – https://www.electrical4u.com/types-of-transformers

"Cooling Systems in Power Transformers" – https://www.powermag.com/transformer-cooling-methods

"Energy Central: Choosing the Right Transformer by Voltage" – https://www.energycentral.com/c/ee/transformer-selection

"Smart Grid News: Cooling and Voltage Criteria for Transformers" – https://www.smartgridnews.com/transformer-classification-guide

"ScienceDirect: Design of Transformers by Cooling and Voltage" – https://www.sciencedirect.com/transformer-design-voltage-cooling

"ResearchGate: Comparative Analysis of Cooling Methods in Transformers" – https://www.researchgate.net/transformer-cooling-comparison

"PowerGrid: Phase Types and Industrial Transformer Use" – https://www.powergrid.com/transformer-types-by-phase