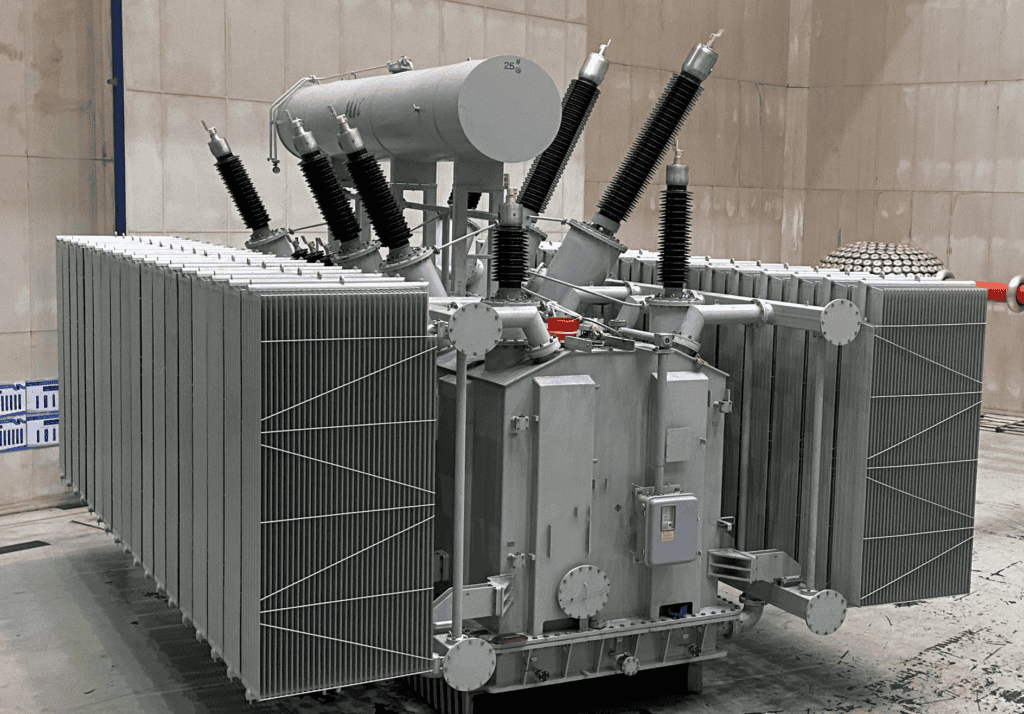

Selecting the right power transformer is vital for ensuring efficiency, reliability, and safety in electrical systems. Since transformers are long-term infrastructure assets, engineers and buyers must carefully evaluate performance parameters before making a decision. The following key criteria help determine whether a transformer is suitable for its intended application.

What Does Rated Power (kVA/MVA Capacity) Mean for a Transformer?

When selecting a transformer, one of the most critical specifications is its rated power, usually expressed in kilovolt-amperes (kVA) for distribution transformers and megavolt-amperes (MVA) for larger power transformers. The rated power defines the maximum apparent power the transformer can deliver continuously under specified conditions of voltage, frequency, cooling, and temperature rise. If a transformer is undersized, it will overheat, age prematurely, and risk failure, while an oversized unit leads to higher capital cost and underutilization.

The rated power (kVA/MVA) is the measure of the transformer's capacity to handle electrical load safely and continuously without exceeding thermal limits. It reflects the combined capability of the transformer’s windings, core, and cooling system, ensuring efficient operation within the designed service life.

This rating provides asset managers, engineers, and facility owners with a direct guideline for load planning, system reliability, and lifecycle cost optimization.

A transformer’s kVA rating indicates the amount of real power (kW) it can deliver.False

A transformer’s kVA rating refers to apparent power (combination of real and reactive power), not purely real power in kW. The actual usable kW depends on the load’s power factor.

1. The Basis of kVA/MVA Rating

Apparent power (S): kVA or MVA is the vector sum of real power (kW) and reactive power (kVAR).

Formula:

S (kVA) = \frac{V \times I}{1000}

S (MVA) = \frac{V \times I}{1,000,000}

The rating is determined by the thermal limits of insulation and windings, not by the load type.

A transformer at rated kVA can carry different real power values (kW) depending on the load’s power factor.

2. Typical Transformer Ratings

| Transformer Type | Common Ratings | Application |

|---|---|---|

| Small Distribution | 25–500 kVA | Residential and commercial loads |

| Medium Distribution | 500 kVA – 5 MVA | Industrial facilities, small substations |

| Large Power | 5–100 MVA | Utility substations, heavy industries |

| Extra High Voltage (EHV) | 100–1000+ MVA | Grid interconnection, bulk transmission |

3. How Rating Affects Operation

- Continuous operation: Transformers must carry rated load indefinitely without overheating.

- Overloading: Allowed only for short durations (per IEC/IEEE loading guides).

- Temperature rise: Linked directly to rated capacity and cooling method (ONAN, ONAF, OFAF, etc.).

- Life expectancy: Operation above rated kVA accelerates insulation degradation, shortening service life.

4. Practical Example

A 2000 kVA (2 MVA) transformer:

- Can handle 2000 kVA apparent power continuously.

- At a load with 0.9 power factor, usable power = 2000 × 0.9 = 1800 kW.

- If the load’s power factor drops to 0.7, usable power falls to 1400 kW, even though the transformer is still operating at 2000 kVA.

5. Engineering Considerations

- Always size the transformer for future load growth (typically 20–30% spare capacity).

- Account for ambient conditions (high altitude or temperature may reduce capacity).

- Match with protection settings to avoid nuisance trips.

- Evaluate load profile: steady vs. fluctuating industrial demand affects required kVA.

What Do Rated Voltage and Insulation Level Mean in Transformers?

When selecting or specifying a transformer, two of the most critical parameters are the rated voltage and the insulation level. If either is misunderstood or mismatched to system requirements, the result can be overheating, insulation breakdown, or catastrophic dielectric failure. These failures may not only cause extended outages and expensive equipment replacement but also create safety hazards for operators. The solution lies in understanding what each parameter means, how they interact, and why both are essential for transformer performance and safety.

Rated voltage refers to the nominal operating voltage a transformer’s windings are designed to handle under normal continuous service, while insulation level refers to the maximum temporary voltage stresses (such as lightning surges or switching transients) that the transformer can safely withstand without dielectric breakdown.

By recognizing that rated voltage governs everyday operation and insulation level secures protection against abnormal events, engineers and users can ensure transformers are both economical and safe for their intended application.

The insulation level of a transformer is the same as its rated operating voltage.False

Rated voltage defines the nominal service voltage, while insulation level is tested to withstand much higher impulse or surge voltages.

1. Rated Voltage

- Indicates the nominal system voltage assigned to the primary and secondary windings.

- Expressed in kV (e.g., 33 kV / 11 kV transformer).

- Allows ±5% to ±10% variation depending on tap-changer adjustments.

- Determines system compatibility with the grid or load requirements.

Example: A transformer rated 132/33 kV is designed to continuously operate at those system voltages, even with typical fluctuations.

2. Insulation Level

Insulation level represents the transformer’s ability to withstand abnormal high-voltage stresses, which occur due to lightning strikes, switching surges, or system faults. It is verified by specific dielectric tests:

- Power Frequency Withstand Test (50/60 Hz overvoltage for 1 min).

- Lightning Impulse Test (BIL – Basic Insulation Level).

- Switching Impulse Test (for EHV/UHV applications).

| Nominal Voltage Class | Typical Power Frequency Test (kV) | Typical BIL (kV) | Application |

|---|---|---|---|

| 11 kV | 28 kV | 95 kV | Distribution |

| 33 kV | 70 kV | 170 kV | Substations |

| 132 kV | 275 kV | 550 kV | Transmission |

| 400 kV | 630 kV | 1425 kV | EHV grids |

| 765 kV | 1550 kV | 2400 kV | UHV grids |

3. Relationship Between Rated Voltage and Insulation Level

- Rated Voltage → normal operating condition.

- Insulation Level → protection against surges and faults.

- Both must be balanced to avoid under-design (unsafe) or over-design (uneconomical).

Case Study:

A 33/11 kV distribution transformer may have:

- Rated voltage: 33 kV (HV), 11 kV (LV).

- BIL: 170 kV (HV), 95 kV (LV).

This ensures that while it operates at 33 kV nominal, it can withstand a surge nearly 5 times higher without insulation breakdown.

4. Cost and Design Implications

- Higher insulation levels → more dielectric material, larger clearances, heavier design, higher price.

- Insufficient insulation → higher failure risk and shorter service life.

- International standards (IEC 60076, IEEE C57) set minimum values for coordination, ensuring safety and global consistency.

What Do Impedance and Short-Circuit Strength Mean in Transformers?

One of the most misunderstood but critical aspects of transformer specification is the impedance and short-circuit strength. An incorrect choice can lead to excessive fault currents, equipment damage, voltage instability, or even catastrophic mechanical failure of the transformer windings. For utilities and industries, this translates into high repair costs, long outages, and safety risks. Understanding these two parameters ensures transformers are properly sized, protected, and integrated into the grid.

In simple terms, transformer impedance (usually given in %) determines how much the transformer resists current flow during a short-circuit, thereby limiting fault currents, while short-circuit strength defines the mechanical and thermal ability of the transformer to withstand those fault currents without permanent damage.

Knowing both ensures system protection devices coordinate properly, fault levels remain within safe limits, and the transformer maintains long-term reliability under stress.

Transformer impedance only affects energy efficiency.False

Impedance also controls short-circuit current levels and voltage regulation, not just efficiency.

1. Transformer Impedance (Z%)

- Defined as the voltage drop percentage needed to circulate rated current when one winding is shorted.

- Usually 4%–10% for distribution transformers, 10%–20% for power transformers.

- Expressed on the transformer’s nameplate.

Formula for Fault Current:

I{sc} = \frac{I{rated}}{Z\% / 100}

Example:

- Transformer rating: 10 MVA, 11 kV / 0.415 kV.

- Rated LV current: 13,900 A.

- Impedance: 6%.

- Short-circuit current:

I_{sc} = \frac{13,900}{0.06} \approx 231,667 \, A

This is nearly 16.7 times the rated current, showing why impedance is critical in fault analysis.

2. Short-Circuit Strength

While impedance sets the magnitude of fault current, short-circuit strength defines whether the transformer can survive it. Two aspects matter:

Thermal Withstand:

Ability of winding insulation to handle heat from I²t during fault duration (typically 1–3 seconds).Mechanical Withstand:

Ability of windings, spacers, and clamping structures to resist electrodynamic forces proportional to I².

| Transformer Rating | Typical Withstand Duration | Forces Encountered |

|---|---|---|

| 1–5 MVA | 2 s | 5–10 kN/m |

| 10–50 MVA | 2 s | 20–40 kN/m |

| >100 MVA | 3 s | 50–100 kN/m |

Standards:

- IEC 60076-5 (Short-circuit withstand tests).

- IEEE C57.12.90 (Thermal & dynamic tests).

3. Relationship Between Impedance and Short-Circuit Strength

- Low impedance → higher fault currents → higher mechanical stress.

- High impedance → lower fault currents but higher voltage drop during normal load.

- Transformer design must balance fault current limitation with voltage regulation needs.

4. Practical Design and Cost Implications

- Higher short-circuit strength requires robust mechanical clamping, stronger insulation, more copper → higher cost and weight.

- Lower impedance improves voltage regulation but may exceed switchgear fault ratings.

- Utilities often specify a minimum impedance (e.g., ≥8% for large transformers) to ensure protection system safety.

5. Case Example

A 100 MVA 132/33 kV transformer with 12% impedance reduces fault current significantly compared to a 6% impedance design. However, the higher impedance also means greater voltage drop under heavy load, so system planners must balance short-circuit limitation vs. regulation performance.

What Do Efficiency and Losses (No-Load & Load Losses) Mean in Transformers?

Transformers are designed to transfer electrical energy with high efficiency, yet no device is free from losses. These losses translate into wasted energy, additional heat, higher operating costs, and reduced service life if not properly managed. Since transformers are often operated continuously for decades, even a small percentage of loss can mean significant financial and environmental impact over time. Thus, understanding efficiency and losses (no-load & load losses) is crucial for utilities, industries, and facility managers seeking to optimize performance and lifecycle cost.

In simple terms, transformer efficiency is the ratio of useful output power to input power, while losses are the portion of input power dissipated as heat or noise. No-load losses occur when the transformer is energized but not supplying load, while load losses occur when it is delivering current. Both must be minimized for long-term economic and reliable operation.

Transformer efficiency is always constant regardless of load.False

Efficiency varies with load because no-load losses remain constant, while load losses increase with the square of load current.

1. Transformer Efficiency

\eta = \frac{P{out}}{P{out} + P_{losses}} \times 100\%

Where:

- $P_{out}$ = Output power

- $P{losses}$ = $P{no-load} + P_{load}$

Typical efficiencies:

- Small distribution transformers: 96–98%

- Large power transformers: 98.5–99.7%

2. No-Load Losses (Core Losses)

- Present whenever transformer is energized, independent of load.

- Caused mainly by hysteresis and eddy currents in the core.

- Typically 0.1–0.5% of rated power.

- Sensitive to voltage level, not current.

| Factor | Impact on No-Load Loss |

|---|---|

| Core material (CRGO vs. amorphous) | Amorphous reduces losses up to 70% |

| Flux density | Higher flux increases hysteresis loss |

| Supply voltage | Directly proportional – overvoltage increases loss |

| Operating hours | Since constant, 24/7 operation makes them significant |

3. Load Losses (Copper Losses & Stray Losses)

- Occur only when load current flows.

- Proportional to I²R (copper resistance heating).

- Includes stray losses from leakage flux, eddy currents in conductors and structural parts.

- Increase with square of current → dominant at high load.

| Load % | Load Loss (per unit) | Efficiency Trend |

|---|---|---|

| 0% | 0 | Lowest (no output) |

| 50% | 0.25 | Often peak efficiency |

| 100% | 1.0 | Efficiency slightly drops |

| 150% | 2.25 | Overload, efficiency drops further |

4. Combined Effect and “Maximum Efficiency Point”

- No-load loss = constant.

- Load loss = variable with load².

- Optimum design = balance between the two.

For example:

- Distribution transformers (run lightly loaded most of time) → focus on reducing no-load loss.

- Industrial/utility transformers (heavily loaded) → focus on reducing load loss.

5. Efficiency Standards and Regulations

- IEC 60076-20 and IEEE C57.12.90 define testing.

- DOE (USA), EU Ecodesign, BIS (India) mandate minimum efficiency levels.

- “Star-rated” or “Tier-rated” transformers directly affect operating cost and compliance.

6. Practical Case Example

1000 kVA distribution transformer:

- No-load loss: 1.2 kW

- Load loss: 10 kW at full load

If running 24/7 at 40% load:

- Annual energy wasted ≈ 1.2 × 8760 + (0.16 × 10 × 8760) = 21,024 kWh

- With average electricity cost of \$0.12/kWh → \$2,522 lost annually just in heat.

What Does Cooling Method (ONAN, ONAF, Dry Type, etc.) Mean in Transformers?

Transformers convert electrical energy continuously and, in the process, generate heat due to copper and core losses. Without proper cooling, excessive temperatures lead to insulation degradation, reduced service life, higher failure risk, and potential fire hazards. Different cooling methods are employed depending on transformer rating, installation environment, and required performance. These methods are designated by codes such as ONAN, ONAF, OFAF, ODAF, and Dry Type cooling, each reflecting how heat is removed.

In short, the cooling method of a transformer describes how the internal heat generated by electrical losses is dissipated—using oil, air, or a combination of natural and forced circulation. ONAN is natural oil and air cooling, ONAF adds fans for forced air, while Dry Type transformers use air or resin encapsulation without oil.

ONAN and ONAF are two identical cooling systems for transformers.False

ONAN relies only on natural circulation of oil and air, while ONAF uses forced air with fans to increase cooling capacity.

1. Understanding Cooling Method Codes

The four-letter IEC/IEEE designation follows this rule:

- 1st letter: Internal cooling medium (O = Oil, A = Air, D = Direct cooling, etc.)

- 2nd letter: Circulation method inside transformer (N = Natural, F = Forced, D = Directed)

- 3rd letter: External cooling medium (A = Air, W = Water, etc.)

- 4th letter: Circulation method externally (N = Natural, F = Forced)

Example: ONAF = Oil Natural Air Forced

2. Common Transformer Cooling Methods

| Cooling Method | Description | Typical Application | Cooling Capacity |

|---|---|---|---|

| ONAN (Oil Natural Air Natural) | Heat carried by oil via natural convection, dissipated to air via radiators. | Small/medium distribution transformers (up to ~30 MVA). | Base rating. |

| ONAF (Oil Natural Air Forced) | Same as ONAN, but fans blow air over radiators for increased heat dissipation. | Medium/large transformers where higher load is expected. | ~130–150% of ONAN rating. |

| OFAF (Oil Forced Air Forced) | Oil pumped through radiators with fans for cooling. | Large power transformers (>100 MVA). | ~200% of ONAN rating. |

| ODAF (Oil Directed Air Forced) | Directed oil circulation with pumps and ducts, fans for air. | Extra-high voltage and generator transformers. | Very high cooling efficiency. |

| Dry Type (AN/AF) | No oil, cooling by air (natural or forced), often with resin-encapsulated windings. | Indoor, fire-sensitive areas (schools, hospitals, high-rises). | Lower capacity, safer. |

3. Practical Considerations in Selection

- ONAN: Low cost, simple, quiet, minimal maintenance. Limited for larger ratings.

- ONAF: Adds flexibility for higher peak loads, requires fan maintenance.

- OFAF / ODAF: High reliability, controlled cooling, but complex and costly. Needs pumps and redundant systems.

- Dry Type: Safer in fire-prone or environmentally sensitive areas, but more expensive for higher capacities.

4. Performance and Efficiency Impact

Cooling method directly affects:

- Permissible loading: Higher cooling capacity allows temporary or permanent overloads.

- Temperature rise class: Defined per IEC 60076 & IEEE C57.12 (e.g., 55°C, 65°C).

- Service life: Each 6–8°C rise above rated insulation temperature halves transformer life.

- Reliability: Forced systems require auxiliary power and maintenance.

5. Case Example

- A 20 MVA ONAN transformer operates safely at base rating.

- By adding ONAF cooling with fans, the same unit can deliver up to 26–28 MVA without overheating.

- This flexibility avoids buying a larger transformer and provides operational savings.

What Does Temperature Rise and Thermal Class Mean in Transformers?

One of the most critical factors in transformer performance and longevity is temperature control. Every transformer generates heat during operation, and excessive heat accelerates insulation aging, leading to premature failure. This is why temperature rise limits and thermal insulation classes are specified in international standards—they define how hot the transformer can safely operate under rated conditions. Without adhering to these parameters, utilities and industries face higher energy losses, reduced reliability, and costly outages.

In simple terms, temperature rise refers to how much hotter a transformer’s windings and oil get compared to the surrounding ambient temperature under rated load. Thermal class specifies the maximum insulation temperature a transformer can withstand without deterioration. Together, they define safe operating limits and service life expectations.

Thermal class only indicates the insulation material type, not the maximum permissible temperature.False

Thermal class directly defines the highest temperature the insulation can endure without rapid aging, ensuring safe transformer operation.

1. Temperature Rise in Transformers

- Definition: The difference between the average temperature of windings (or top oil in oil-filled transformers) and the surrounding ambient air, measured at rated load.

- Typical ambient reference: 40°C (as per IEC/IEEE).

- Example: A transformer with 55°C rise will have winding temperatures of approx. 95°C (40°C + 55°C).

Standard Temperature Rise Limits (IEC 60076 & IEEE C57):

| Cooling Method | Top-Oil Rise (°C) | Winding Rise (°C) |

|---|---|---|

| ONAN | 55–60 | 60–65 |

| ONAF | 60–65 | 65–70 |

| Dry Type (Class F/H) | 80–100 | 90–120 |

2. Thermal Insulation Classes

Insulation materials are classified by maximum permissible "hot-spot" temperature.

| Class | Max Hot-Spot Temp (°C) | Common Use |

|---|---|---|

| A (105°C) | Cotton, paper, natural materials with varnish | Small dry-type transformers |

| B (130°C) | Improved organic materials | Industrial dry-type |

| F (155°C) | Epoxy resins, synthetics | High-reliability dry type |

| H (180°C) | Silicon resins, advanced composites | Special applications (marine, mining, offshore) |

3. Link Between Temperature and Lifetime

- Rule of thumb: Each 6–8°C rise above design temperature halves insulation life.

- A transformer designed for 55°C rise with Class A insulation may last 25–30 years.

- If consistently overloaded (running at higher rise), lifespan could shrink to 10–12 years.

4. Practical Engineering Considerations

- Oil-filled transformers: Must balance oil temperature rise and winding temperature rise for safe operation.

- Dry-type transformers: Higher insulation classes (F, H) allow use in confined indoor environments with limited cooling.

- High-reliability sites (data centers, hospitals): Lower rise ratings are often preferred to maximize life expectancy.

- Overload conditions: Cooling enhancements (fans, pumps) can temporarily allow more load without exceeding thermal limits.

5. Case Example

A 2000 kVA dry-type transformer designed with Class F insulation (155°C) and 100°C rise can handle more load in compact indoor spaces compared to a Class A unit. However, if a customer wants longer service life with less thermal stress, they may specify 80°C rise Class F, trading off load density for durability.

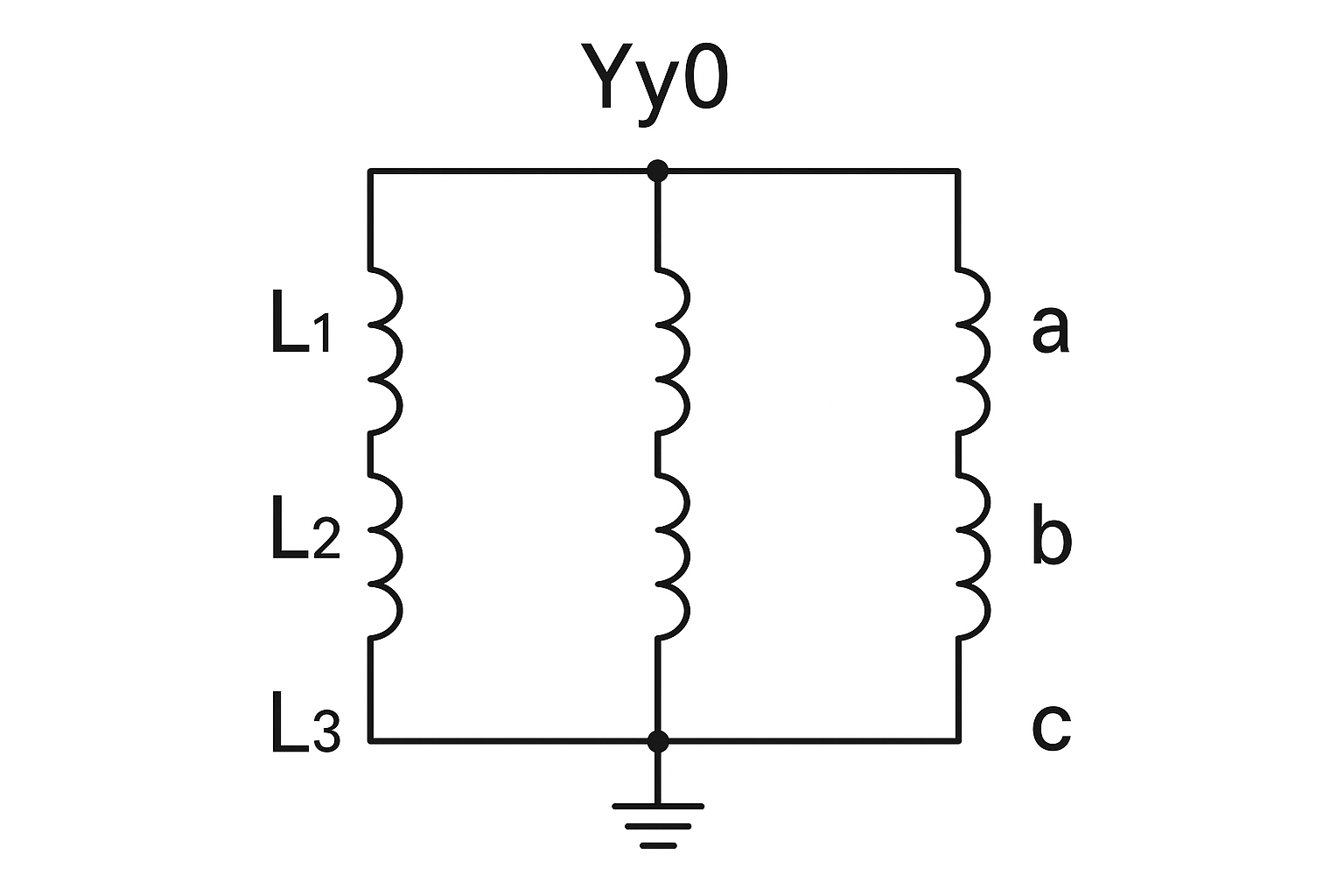

What Do Vector Group and Phase Displacement Mean in Transformers?

When engineers design or select a transformer for a power system, two fundamental properties they must consider are its vector group and phase displacement. These parameters define how the primary and secondary windings are interconnected (e.g., delta, star, zig-zag) and how the secondary voltage phasors are shifted relative to the primary. Incorrect vector group selection can lead to phase mismatches, circulating currents, unstable operation, or failure of parallel transformers, making this concept vital for grid stability and industrial power systems.

In simple terms, the vector group describes the winding configuration (star, delta, or zig-zag) and the clock-position notation that shows the phase angle difference between the primary and secondary voltages. Phase displacement refers to this angular shift (typically 0°, ±30°, ±150°) and determines how the transformer integrates with the system.

Vector group only matters for three-phase transformers.True

Vector groups are only defined for three-phase transformers, since single-phase transformers have no phase displacement between windings.

1. Vector Group Basics

- Winding connection: Indicates if primary/secondary are Star (Y), Delta (D), or Zig-Zag (Z).

- Neutral availability: A star connection may provide a neutral point (e.g., Yyn0).

- Notation system: Written as Primary winding symbol – Secondary winding symbol – Phase displacement. Example: Dyn11.

2. Phase Displacement and Clock Notation

The phase displacement between primary and secondary is expressed using a clock-hour system:

- Primary phasor is fixed at 12 o’clock.

- Secondary phasor position indicates displacement.

Example:

- 0° → 12 o’clock → Yy0

- +30° → 1 o’clock → Dyn1

- –30° → 11 o’clock → Dyn11

Common Phase Displacements:

- 0° (Yy0, Dd0): In-phase systems.

- ±30° (Dyn11, Dyn1, Yd11, Yd1): Most widely used in distribution networks.

- ±150°: Less common, used in special applications like harmonic reduction.

3. Examples of Common Vector Groups

| Vector Group | Primary | Secondary | Displacement | Typical Use |

|---|---|---|---|---|

| Dyn11 | Delta | Star (neutral) | –30° (11h) | Distribution transformers |

| Yyn0 | Star | Star (neutral) | 0° (12h) | Auxiliary services |

| Yd11 | Star | Delta | –30° (11h) | Step-up in power stations |

| Dd0 | Delta | Delta | 0° (12h) | Industrial parallel loads |

4. Why Vector Group & Phase Displacement Matter

- Parallel operation: Only transformers with the same vector group (or compatible ones) can be paralleled.

- System grounding: Star connections allow neutral grounding, delta does not.

- Harmonic suppression: Zig-zag connections help reduce triplen harmonics.

- Grid integration: Phase displacement must align with utility requirements to avoid mismatched phasors.

5. Case Study Example

A 11 kV/433 V distribution transformer is typically Dyn11. The delta primary avoids third harmonic circulation, while the star secondary provides a neutral for 3-phase + N distribution. The –30° displacement matches standard distribution system phasing, ensuring safe parallel operation with other network transformers.

What Are Noise Level and Environmental Considerations in Transformers?

Transformers are essential for power distribution, but they can also produce audible noise and environmental impacts that affect human comfort, regulatory compliance, and site planning. In densely populated urban areas, hospitals, schools, or environmentally sensitive locations, excessive transformer noise or poor environmental safeguards can lead to regulatory penalties, operational restrictions, or community complaints. To address these challenges, designers and operators must consider noise level management and environmental impact control as part of transformer selection, installation, and maintenance.

Transformer noise levels mainly originate from magnetostriction in the core (hum), vibration of tank and windings, and forced cooling equipment (fans, pumps). Environmental considerations include oil leakage prevention, fire safety, emissions, and compliance with international standards. Proper design, location planning, and soundproofing ensure reliable operation without disturbing surrounding environments.

Transformer noise is only generated when load current is present.False

Transformers also generate core noise (50/60 Hz hum) under no-load conditions due to magnetostriction in the core laminations.

1. Sources of Transformer Noise

- Core noise (no-load hum): Caused by magnetostriction in laminated steel core, typically dominant at 100 Hz or 120 Hz.

- Load noise: Arises from winding vibrations due to electromagnetic forces under load.

- Cooling system noise: Fans, pumps, and radiators add mechanical and aerodynamic noise.

- Structural resonance: Poor mounting or rigid connections can amplify vibrations.

2. Typical Noise Levels (dB) of Transformers

| Transformer Rating (MVA) | Typical Noise Level (dB at 1 m) | Dominant Source |

|---|---|---|

| < 5 MVA (distribution) | 55 – 65 dB | Core hum |

| 5 – 50 MVA (medium power) | 65 – 75 dB | Core + fans |

| > 50 MVA (large power) | 75 – 95 dB | Core + cooling |

Note: Local regulations may limit noise levels at site boundaries (e.g., ≤50 dB at night in residential areas).

3. Environmental Considerations

- Oil containment: Bund walls or catch basins prevent soil and water contamination in case of leaks.

- Fire risk management: Use of non-flammable fluids (ester-based) or dry-type designs in sensitive buildings.

- PCB-free insulation: Modern transformers are designed without hazardous polychlorinated biphenyls.

- Energy efficiency: Lower losses reduce CO₂ footprint and long-term environmental impact.

- EMF (Electromagnetic Fields): Proper shielding and layout minimize exposure in public areas.

4. Noise and Environmental Mitigation Strategies

- Low-noise core design: Step-lap joints, high-grade silicon steel, and optimized clamping reduce magnetostriction noise.

- Acoustic enclosures: Soundproof barriers or housings in urban/substation installations.

- Vibration isolation: Flexible supports or dampers minimize structure-borne noise.

- Eco-friendly fluids: Biodegradable natural esters or synthetic esters for fire safety and environmental protection.

- Strategic placement: Position transformers away from noise-sensitive boundaries.

5. Regulatory Compliance

- IEC 60076-10: Defines transformer sound level measurement and limits.

- ANSI/IEEE standards: Specify acceptable noise levels based on MVA rating.

- Local environmental laws: May impose stricter site-specific requirements.

Conclusion

The critical performance parameters for transformer selection include rated power, voltage, efficiency, impedance, thermal characteristics, and vector group alignment. Additionally, environmental conditions and application-specific factors such as noise level, cooling method, and installation space should be considered. A well-matched transformer not only ensures reliable operation but also optimizes lifecycle costs and system efficiency.

FAQ

Q1: What are the key performance parameters of a power transformer?

The most critical parameters include kVA/MVA rating, primary and secondary voltage, frequency, vector group, impedance, efficiency, cooling type (ONAN, ONAF, etc.), and insulation class. Each parameter impacts transformer performance, safety, and compatibility with the electrical system.

Q2: Why is kVA/MVA rating important when selecting a transformer?

The kVA/MVA rating determines the transformer’s load capacity. Choosing a rating too low risks overload and premature failure, while oversizing can lead to inefficiency and higher costs. Correct sizing ensures safe, reliable, and cost-effective operation.

Q3: How does efficiency affect transformer selection?

Transformer efficiency indicates how much input power is converted into usable output power. Higher efficiency reduces energy losses and operating costs. In large-scale installations like utilities or data centers, even small efficiency differences can significantly impact long-term energy savings.

Q4: What role do cooling and insulation systems play in transformer performance?

Cooling systems (like oil-filled ONAN/ONAF or dry-type cooling) affect heat dissipation and operational reliability. Insulation class determines the transformer’s ability to withstand electrical and thermal stresses. Together, they ensure safe performance under rated conditions.

Q5: Why is impedance an important transformer parameter?

Impedance affects voltage regulation and fault current levels. A transformer with improper impedance may cause poor voltage stability or excessive fault currents, leading to protection failures. Correct impedance ensures system safety and parallel operation compatibility.

References

IEEE - Transformer Performance Standards: https://ieeexplore.ieee.org

IEC 60076 - Power Transformer Parameters: https://webstore.iec.ch

NEMA - Transformer Specification Guide: https://www.nema.org

Electrical4U - Transformer Performance Parameters: https://www.electrical4u.com

EEP - Key Transformer Selection Parameters: https://electrical-engineering-portal.com

Energy.gov - Transformer Efficiency and Reliability: https://www.energy.gov

All About Circuits - Transformer Design and Performance: https://www.allaboutcircuits.com