Why Must Transformers Be Synchronized?

Transformer synchronization is a critical requirement in power systems, especially when transformers operate in parallel or are connected to interconnected grids. Proper synchronization ensures that

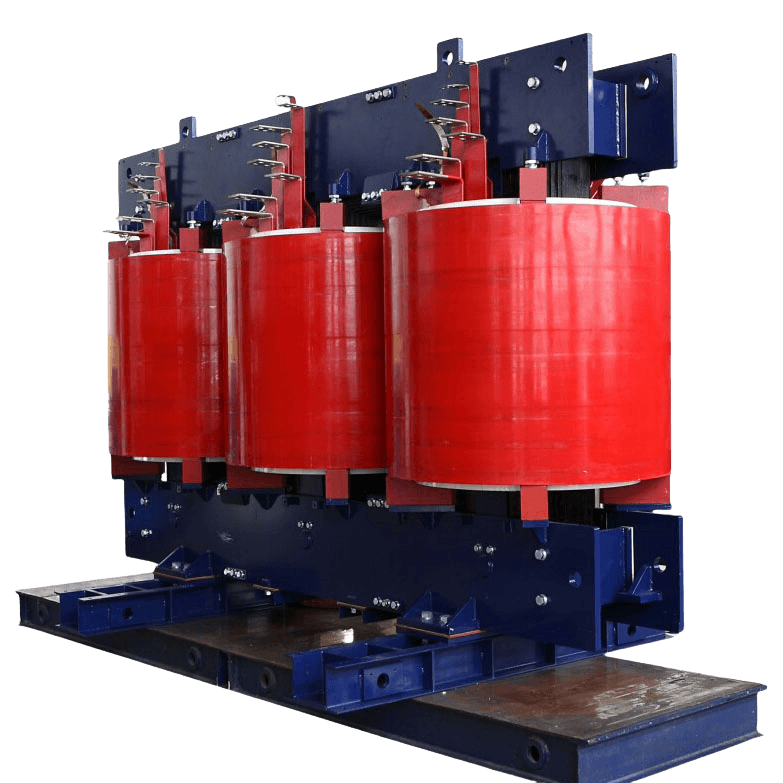

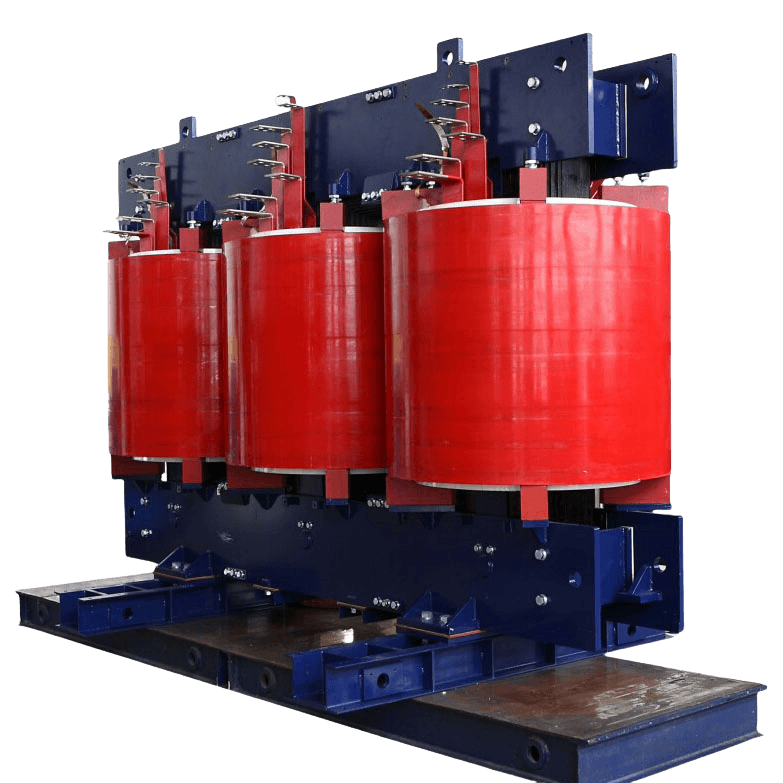

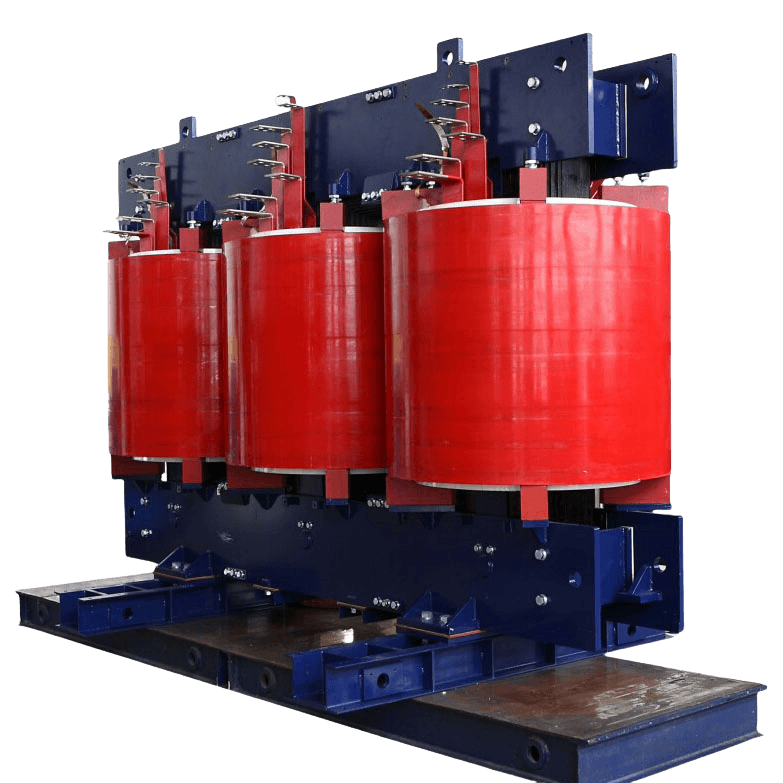

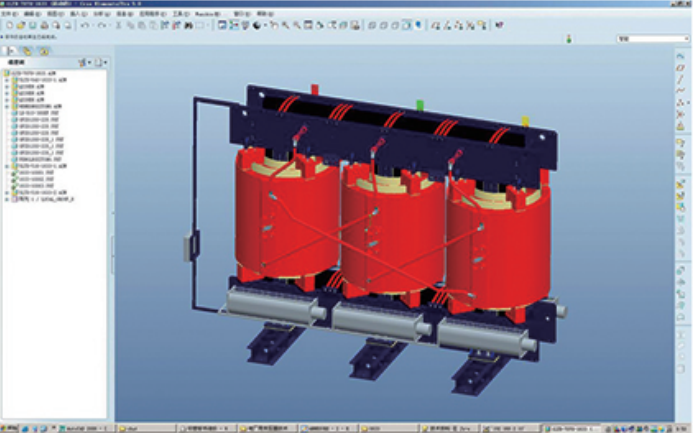

Taishan® Dry-type transformers with a self-cooling capacity of up to 25 MVA and a voltage level of 35 kV. The BIL (Basic Insulation Level) averages 170 kV, meeting Chinese national standards as well as international standards such as ANSI (USA) and British standards.

Taishan® Dry-type transformers with a self-cooling capacity of up to 25 MVA and a voltage level of 35 kV. The BIL (Basic Insulation Level) averages 170 kV, meeting Chinese national standards as well as international standards such as ANSI (USA) and British standards.

Transformer Capacity Range:

We specialize in medium to large capacity transformers tailored for industrial and utility-scale applications. Dry-type Transformers: Minimum capacity of 1000 kVA. We have extensive expertise in manufacturing high-capacity. transformers above 5000 kVA, offering customized solutions for complex and demanding power systems. Please note: While we are capable of producing low-capacity transformers (below 630 kVA), such as distribution transformers, we do not supply them as standalone products. These are only available as part of a complete solution in combination with medium- or large-capacity transformers.

SC(B)14 Series Distribution Transformer With Capacity 50-2500kVA And Voltage Level 20kV

SC(B)12 Series Distribution Transformer With Capacity 50-3150kVA And Voltage Level 35kV

SC12 Series Power Transformer With Capacity 800-25000kVA And Voltage Level 35kV

SC12 Series Power Transformer With Capacity 630-10000kVA And Voltage Level 10kV

SC(B)18 Series Distribution Transformer With Capacity 30-2500kVA And Voltage Level 10kV

SC(B)12 Series Distribution Transformer With Capacity 30-2500kVA And Voltage Level 10kV

SC(B)14 Series Distribution With Capacity 30-2500kVA And Voltage Level 10kV.

Trusted by world-class brands & organizations of all sizes

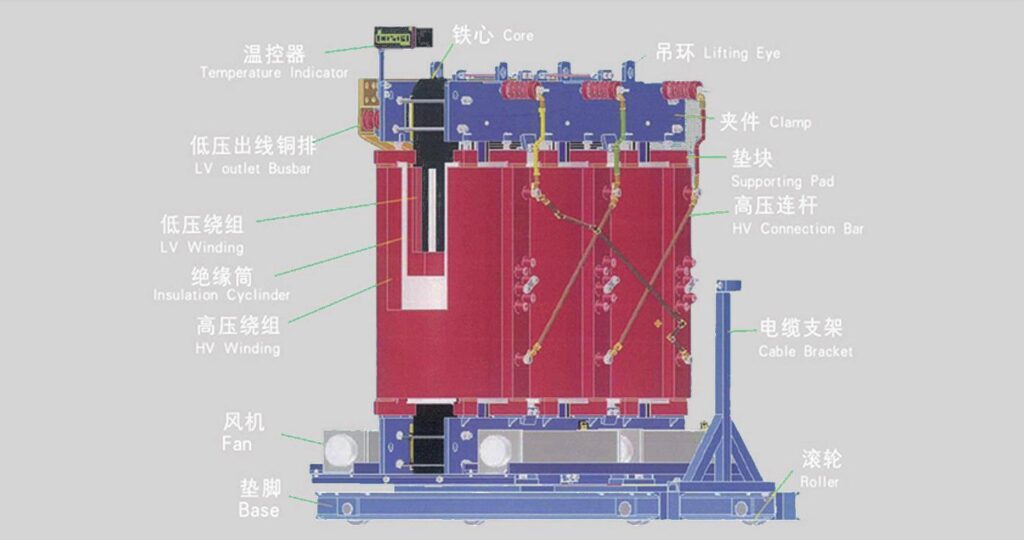

Characteristics of Dry-Type Power Transformers

Our resin casting dry-type transformer, the capacity has reached 25MVA, voltage reached 35kV of natural cooling. The BIL level is 170kV, in line with China’s national standards, ANSI, Britain, and other countries’ standards requirements.

The transformer also has the advantages of reliable operation and free of maintenance.

3.1 Impact Resistance

3.2 High Mechanical Strength and Short Circuit Resistance

3.3 Good Resistance to Cracking

3.4 Moisture Proof

3.5 Well Heat Dissipation

Taishan® resin casting dry-type transformer is designed for exceptional performance and reliability. With a capacity of 25 MVA, a voltage level of 35 kV, and a BIL level of 170 kV, it meets China’s national standards as well as ANSI and British standards. Known for its reliable operation and near-zero maintenance, it stands out as a high-quality, efficient solution.

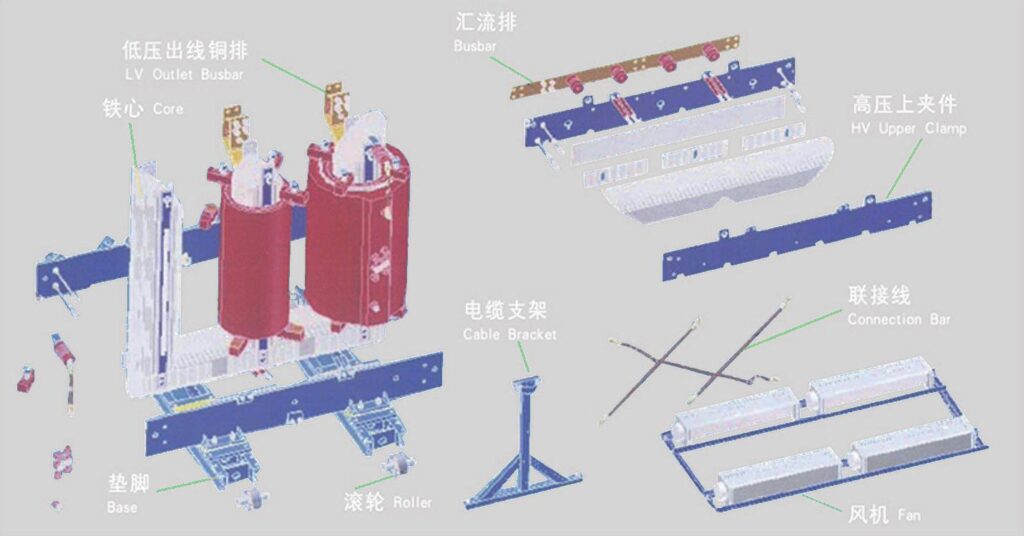

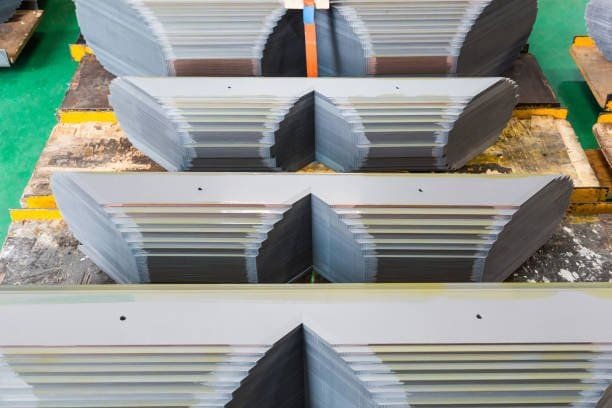

The resin casting dry-type transformer is divided into two main winding types:

The HV winding adopts a sectional cylindrical structure, where copper wire, resin, and fiberglass combine for optimized heat dissipation and insulation. During the casting process:

This advanced design ensures the transformer delivers stable, safe, and efficient performance, even under demanding operating conditions.

The LV winding has the same structure with the above HV winding except for the Spiral winding structure. It has high mechanical strength, good moisture resistance. Wire insulation immersed in the resin, axial mechanical force is unlikely to reach the fastening structure.

The LV winding are wound by copper foils. Putting strip into winding and formed airway cooling. The LV winding layer is low voltage and low leakage at terminals.

Winding leading-out terminal use copper bar leads out. When winding finishing, both ends sealed by resin, the whole body become very strong. The insulation and the copper foil are bond together and damp-proof. Besides, the processing property is nice, the efficiency is high, the additional consumption is low and the short-circuit resistance is high.

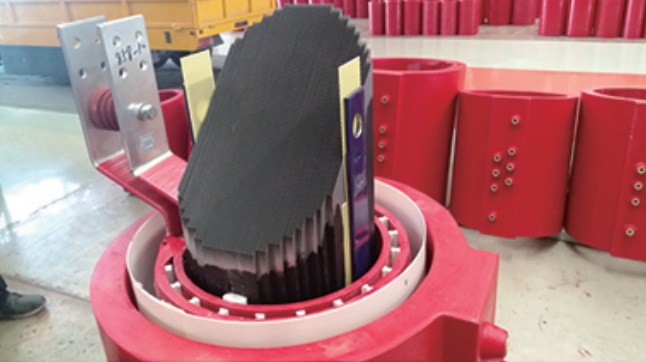

The iron core adopts five-stage stepping joint so as to lower the no load loss. And the no load loss and noise level can be reduced as well by using the well-qualified cold-rolled grain-oriented silicon sheet steel, which is fastened or shaped by clamps and the black elastic resin paint and no punching on the surface of the iron core.

The clamp is formed into an entirety by steel cutting once so the structure is simple but beautiful. As the lifting lugs and clamp have become an integrated entirety so lifting the transformer will be safer.

Winding casting, no painting process.

Air Cooling System

The low noise cross flow fan has the characteristics of low noise, uniform cooling, and easy installation. After the air-cooled system is started, the transformer capacity can be increased to 150%.

Temperature Control System

The temperature protection device of transformer adopts PT100 platinum resistance temperature measured and LED temperature display, MCU control, adjustable temperature control, automatic/manual start and stop the fan, automatic alarm, trip signal, remote control function (optional interface mode: 4~20mA analog output, RS232 interface, RS485 interface).

Enclosure

Protection level of enclosure are IP20 and IP23, using Aluminum Alloy, stainless steel, cold rolled steel materials. It is generally high and low voltage side door, convenient installation and disassembly, light weight, good ventilation. Enclosure also provides special protection levels, special door opening methods, and use different materials and spray different colors according to user requirements.

Enclosure protection level include the following: IP00 (no enclosure, installed indoors), IP20 (preventing a particle with a diameter larger than 12.5mm from entering into the enclosure, installed indoors), IP23 (preventing a particle with a diameter larger than 12.5mm from entering into the enclosure and preventing water drops, which is within an angle of 60°C from the vertical line as well, installed outdoors), and other protection levels.

The transformer enclosure can be made of aluminium alloy, stainless steel, or cold rolled plate, etc.

The method of lead can be divided into enter above and exit above, enter above and exit below, enter below and exit above, enter below and exit below, enter below and exit side (Please specify the method of lead when ordering. If exiting side, please identify the position, A phase or C phase or others. And provide low-voltage switch gear outlet size and phase sequence).

If there is a lot of conductive dust in the environment, it can provide dust-proof external enclosure.

The customer can choose the enclosure according to his own requirements.

Installed at the neutral point of the transformer, use for relay protection and installed in the phase line for electrical energy metering and current measurement.

The cross flow type cooling fan with the best quality is selected, performance conform to JB/T8971 dry-type transformer cross flow cooling fan industry standards by quality supervision and inspection of state.

Advantages

Large air flow, low energy consumption, reasonable structure, beautiful appearance, simple installation, uniform wind pressure, good cooling effect, low noise and light vibration.

Various Specifications

Top-blown, side-blown and the lengthened side blowing type (double wind wheel) and other models, the fan material is stainless steel, Aluminum Alloy, spray, etc.

Adaptive Capacity

Can be adapted to all dry-type transformers on capacity 30-25000kVA.

Temperature Indicator of Dry-type Transformer

The safe operation and service life of the power transformer largely depend on the safety and reliability of the transformer winding. The insulation damage is caused by the winding temperature exceeding the insulation withstand temperature, which is one of the important reasons that the transformer cannot work properly.

The dry-type transformer temperature indicator (referred to as temperature indicator) is a kind of intelligent controller specially designed for the safe operation of dry-type transformer.

The temperature indicator based on SCM technology, using three platinum thermal resistance embedded in the three-phase winding of dry-type transformer to detect and display the transformer winding temperature rise, can automatically start and stop the cooling fan for forced air cooling of winding, avoid or reduce the fault caused by the transformer due to high temperature, and can control the over temperature alarm and over temperature tripping output, in order to ensure the operation of transformer in a safe state, so as to prolong the working life of transformer.

Dry-type OLTC

The voltage regulation can be realized under the condition of no power interruption, and the output voltage of the secondary side can be kept stable under the condition of voltage fluctuation of the grid. Improve power supply quality.

Live Locking

This series of products are suitable for indoor HV electrical equipment with rated voltage 3.6~40.5kV and frequency of 50 and 60HZ. According to its performance, mainly can be divided into two major categories:

The first kind is used separately and only has unlock functions, cannot be forced locking of electromagnetic locks. This kind of electromagnetic lock must be used in conjunction with the indoor HV live display device, and the locking contact can be locked in order to achieve the function of forced locking. It is an electric control mechanism interlocking device for preventing electric misoperation of a high-voltage switch device. The main use of electrical interlock between the indoor isolating switch and circuit breaker operating mechanism of the human in the switch cabinet door and other places of mandatory safety interlock to prevent misoperation and into live space, can effectively improve the anti-error performance of power supply equipment.

Another kind is to use separately to achieve the mandatory locking function. The utility model integrates the live display and the forced locking function, and can be used in conjunction with the sensor to reflect the electrified condition of the HV circuit, and can realize the forced shutting function. The utility model is mainly assembled in front of the switch cabinet, the back door and other parts which need to be locked. The utility model can reliably prevent the electric misoperation, prevent the mistake from entering the electrified interval, and improve the error proofing performance of the matched products.

As mentioned before, due to the good performance of the resin casting dry transformer, the applicable range is very wide.

The power supply of the fast transient system will cause the transformer to suffer short-time burst overload, which can be several times of the rated continuous load. This happens when the electric locomotive accelerates the closing of feed connections. The greater the overload is, the greater the impact of short-term overload on the transformer. The thermal time constant of cast resin transformer winding is 40 minutes, the time constant of the corresponding oil-immersed transformer is not more than 10 minutes, the difference is great, that is to say, pouring type transformer can design smaller than the oil-immersed transformer, but the short-term overload capacity is high.

Other uses of the resin structure, such as motor starting device, core or coreless current limiting reactor, are also widely applied.

In fact, the transformer used in many occasions has higher reliability and economy by adopting the structure of pouring resin. Resin insulated transformer because of its low loss, low noise, low partial discharge, flame self-extinguishing, without maintenance, it can be widely used in high-rise residential, office buildings, business center, underground railway, etc. In any case where an oil-immersed transformer can not be used, the resin transformer can be used and has high reliability. It is comparable to an oil-immersed transformer in terms of electrical performance, but is a leader in mechanical properties.

In the design of distribution system, considering the application of cast resin transformer is a foresighted view. In most cases, the start-up cost of the resin transformer is higher, but the protection is low cost, low loss and almost no maintenance. As far as the total cost of installation is concerned, it is more economical.

Glass fiber resin pouring structure can achieve the same power frequency and impulse level as oil-immersed transformers, and some design structures have impulse levels exceeding 200kV.

The cast type transformer has already withstood the test voltage (HV to HV, HV to LV to ground) and operating voltage in the atmospheric environment. Wire winding inter-turn and inter-layer only have a tiny differential pressure, are absorbed by the resin itself, and reached a very safe level. The inter-layer voltage of the foil winding is only the minimum voltage of each turn, the end of the winding has no helical angle, the magnetic leakage area is small, and the axial short-circuit resistance is strong. As the air-based insulation, this part of the insulation system will not deteriorate, will not age.

The wire winding adopts vacuum casting to obtain a uniform insulation structure, eliminates bubbles and voids, and avoids partial discharge in the winding. The inter-layer voltage of the foil winding is low and no partial discharge.

According to the IEC60076 standard, partial discharge tests shall be carried out on fully assembled transformers. In order to confirm the high quality of the design and production, the partial discharge test of each HV winding is carried out before the assembly.

In this way, the insulation in the HV winding can be checked to meet the quality requirements. The partial discharge termination voltage is at least 1.2 times than the rated voltage, and in most cases, even 2 times than the rated voltage. It is proved by this test that the winding is qualified.

Glass fiber reinforced winding will not crack due to sudden fluctuations in temperature or thermal impulse.

Wire winding has been heated to the rated temperature, and then placed in ice water to cool for temperature change resistance test. All winding can pass such destructive tests.

Due to insulation and copper foil adhesive curing as a whole throughout the winding and the Foil winding is not cracking due to temperature fluctuations or sudden thermal shock.

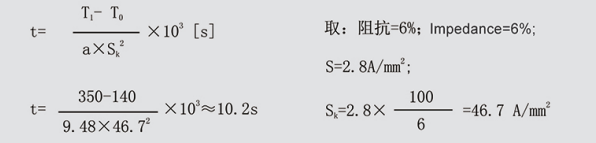

According to Table III of the IEC 60076-5 standard, the maximum allowable average temperature of conductors after a short circuit for B, F, and H-class insulated copper wires is 350°C. For F-class copper winding transformers, the time “t” is determined, and after this duration, the final temperature will be:

T1 = T0 + a.Sk2.10–3[℃]

Among this:

The following is calculated by the upper figure:

As all protection devices can cut off the transformer power within 10 seconds, the margin shown in this example is very large.

When the transformer is short-circuited, the conductor is heated rapidly in a matter of seconds. The resin around it is better than the conductor, can only be slowly heated, the conductor and resin surface temperature gradient will be great, and the greater the thickness of resin wrapped, and its gradient is too large. Even when the expansion coefficient is well matched, the mechanical strength of the winding must be taken into account, but the elastic glass fiber resin structure can be used to prevent cracking under the above conditions.

The wire wound products are very well protected against moisture due to the copper conductor complete encapsulation in resin insulation. The transformer can be networked after long-term storage, and can be input into the power grid no-load.

The foil winding shall be stored in damp proof, and when the insulation resistance is lowered, it should be heated and dried before it can be put into use. When using, only compressed air can be used to remove sediment or dust.

The main concern of resin casting dry-type transformer is environmental protection. This question is actually a justification for the development of a cast type transformer:

The main feature of the resin casting transformer is flame retardant and self-extinguishing. Tests have shown that once a fault occurs inside the transformer and the protection device cuts off the transformer within the specified time, the winding itself will self-extinguish, thereby stopping the fire. If the external environment catches fire and all equipment and buildings are on fire, the epoxy resin may also burn, but the burning of the resin will not promote the spread of the fire.

The toxic components of combustion products are a major concern. Simulated tests were conducted in laboratories. Depending on the conditions and analysis methods, the results vary. According to OSHA requirements, if toxic substances are present, their concentrations are very low, allowing for prolonged exposure without harm.

In the wire wound transformer, the winding is not mechanically connected with the core, but the support structure is used to prevent the core ferromagnetic vibration from transmitting to the winding.

The winding and the core are supported by special materials in the foil winding transformer structure, which effectively reduces the ferromagnetic vibration and reduces the superposition of noise.

The outer surface of the core is covered with elastic resin, which can prevent further noise transmission, and its noise level is better than the national standard.

Wire wound and foil wound transformers are completely dry structures with no liquid or gas insulation, so there is no leakage. There is no need to take additional measures to prevent leakage, so there is no pollution to the environment.

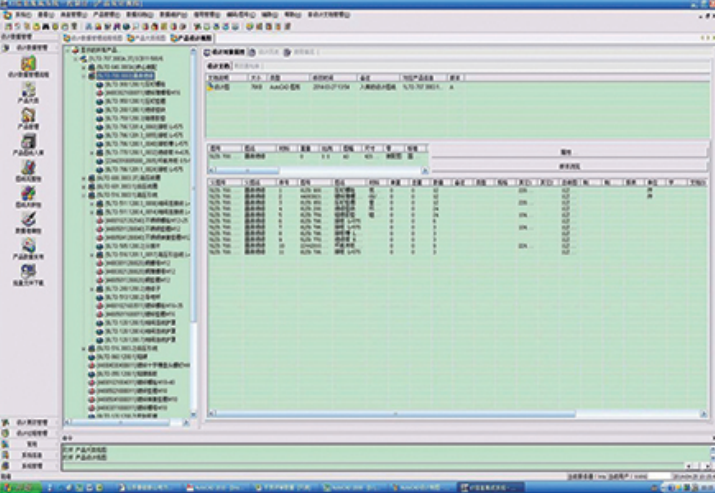

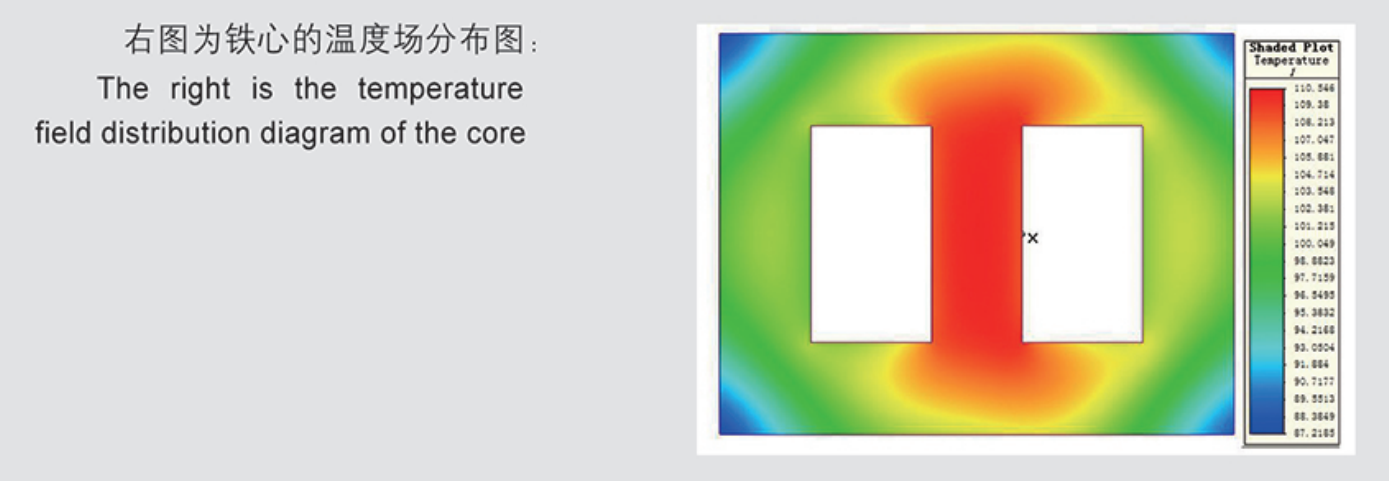

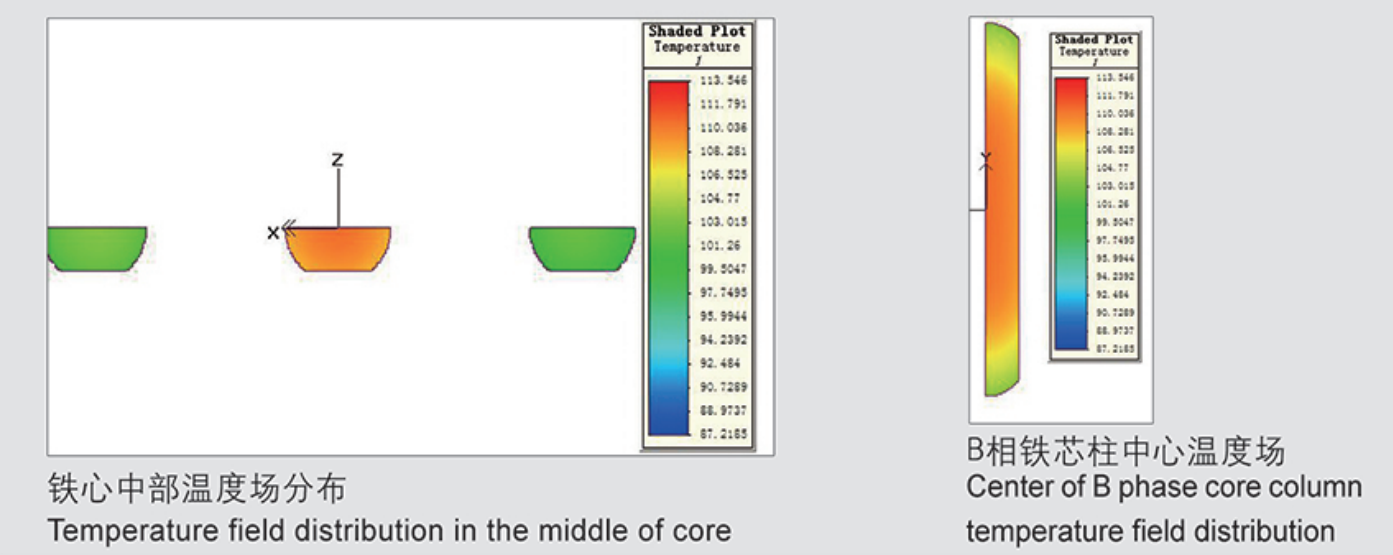

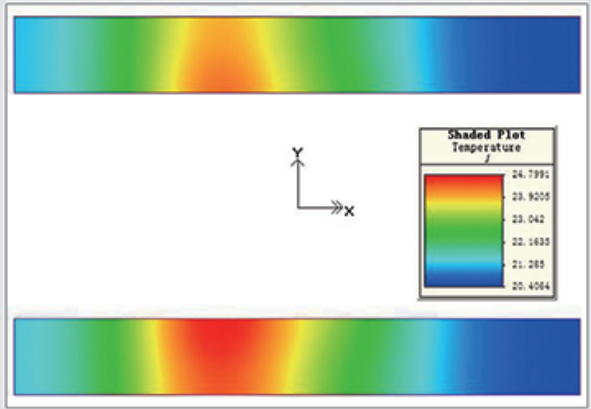

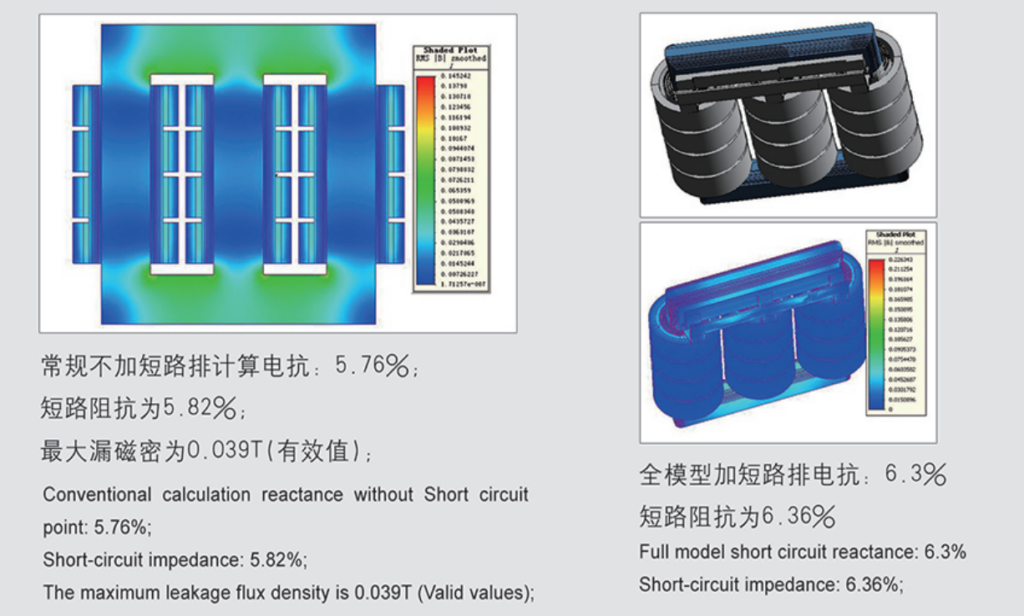

Company’s products are using Auto CAD and Pro/E 2D and 3D design platform, using software such as INFOLYTICA for electric, magnetic, thermal (fluid), and force analysis. Independently research and produce short circuit withstand analysis software, using PDM, ERP management system, effectively control the input and output of the design data, to ensure the reliability of product performance.

It Includes:

Through the electric, magnetic and thermal, stress, fluid, and other aspects of comprehensive analysis and calculation for designing, according to the results of simulation analysis, the use of technical means to control product technical data, optimize product structure, combined with mature manufacturing technology and a variety of finite element simulation analysis method, the design of the product can achieve the real value of the quantization. To ensure product quality, improve product safety and reliability in power grid.

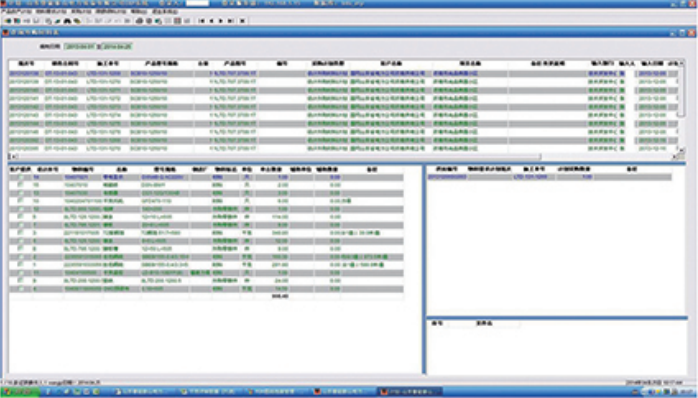

ERP (Enterprise Resource Planning) is the next generation of manufacturing systems and resource planning software. Except for the existing resource planning, manufacturing, financial, sales, purchasing, and other functions, the company also has quality management, laboratory management, business process management, product data management, inventory, distribution and transportation management, human resources management, and regular reporting system.

PDM (Product Data Management) is a kind of technology used to manage all product-related information (including the parts information, documents, files, CAD configuration, structure, rights, etc.) and all product-related processes (including process definition and management technology). Through the implementation of PDM, it can improve production efficiency, help to manage the whole life cycle of products, strengthen the efficient use of documents, drawings, and data, and standardize the workflow.

INFOLYTICA

INFOLYTICA is a new technology of much electromagnetic software founder and leader, the company has been committed to the field of electromagnetic finite element analysis technology research and development and committed to providing complete solutions for the electromagnetic design engineer.

The INFOLYTICA product line includes software such as MagNet, ElecNet, ThermNet, OptiNet, MotorSolve, allowing 2D and 3D analyses of the electric field, magnetic field, and thermal field independent and coupled at ease at the same interface.

1. General

2. Program Analysis and Calculation

As the product is unusually, the vector group is Diii, the primary voltage of the transformer is 10kV; the secondary side is six independent multi-tap single-phase coils, and the transformer capacity varies with the voltage level at the low voltage side. As per the LV side voltage level is 520V, the current is 6400A, and the transformer capacity is 9909kVA, for calculation.

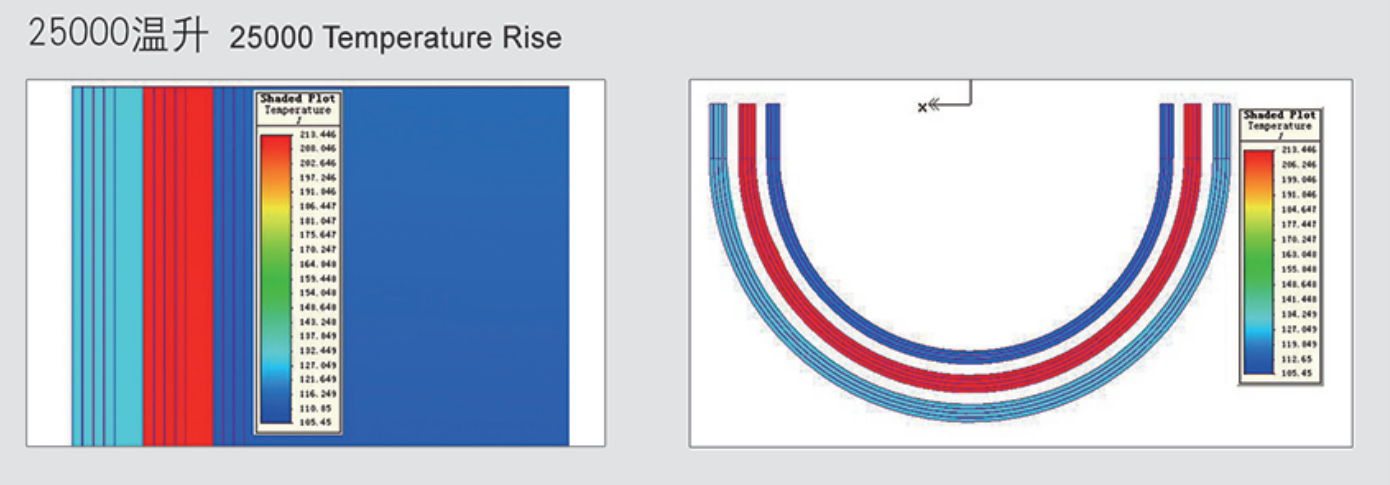

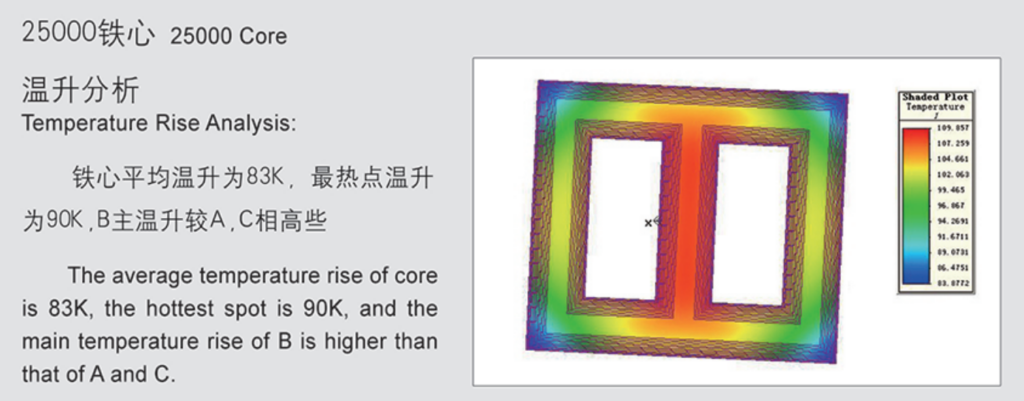

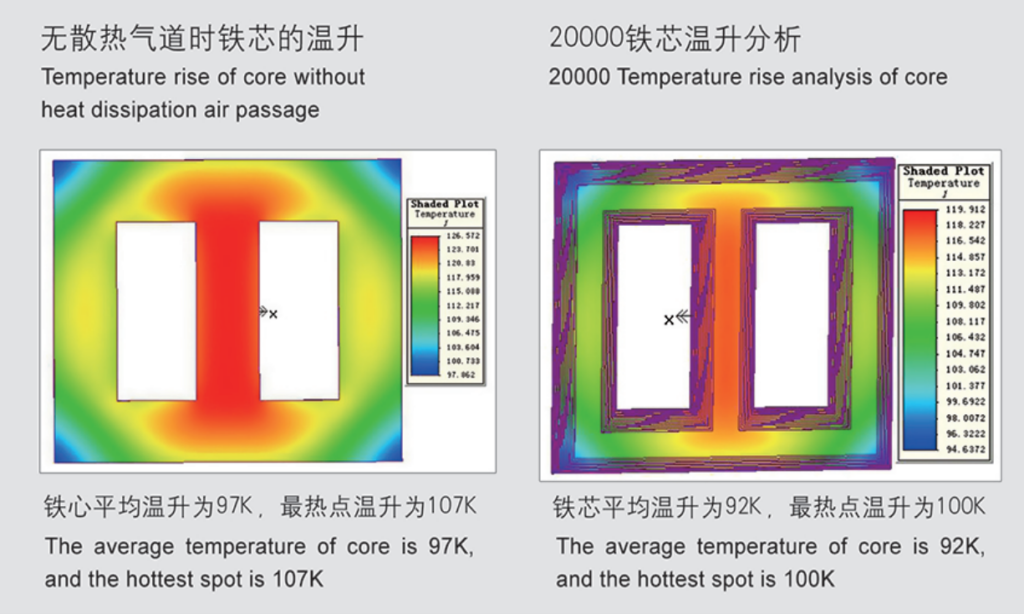

No-load loss and temperature field calculation:

| DL/T572-1995 | 《Operation Code of Power Transformers》 |

| DL/T596-1996 | 《Preventive Test Code of Electric Power Equipment》 |

| EC60076-11 /GB1094.11-2022 | 《Dry-type Power Transformers》 |

| GB/T10228-2023 | 《Technical Parameters and Requirements for Dry-type Power Transformers》 |

| GB/T1094. 10-2022 | 《Sound Level Measurement for Transformers and Mutual Inductors》 |

| GB/T1094. 3-2017 | 《Insulation Level, Insulation Test and External Insulation Clearances in Air》 |

| GB/Т26218. 1 (2) -2010 | 《External Insulation Pollution Classes of High-Voltage Electric Power Equipment》 |

| GB/Т50150-2016 | 《Standard for Hand-Over Test of Electric Equipment Electric Equipment Installation Engineering》 |

| GB20052-2020 | 《Power Transformer Energy Efficiency Limits and Energy Efficiency Levels》 |

| IEC529 /GB/Т4208 -2008 | 《Enclosure Protection Grade (IP Code)》 |

| IEC60060-1/ IEC60060-2 /GB/T16927. 1-2011 | 《High Voltage Test Technique》 |

| IEC60060-1/ IEC60060-2 /GB/Т16927. 2-2013 | 《High Voltage Test Technique》 |

| IEC60071-1 /GB/Т311. 1-2012 | 《Insulation Coordination of High Voltage Power Transmission and Transformation Equipment》 |

| IEC60076-1 GB/T1094. 1-2013 | 《Power Transformers Part 1 General》 |

| IEC60076-2 /GB/T1094. 2-2013 | 《Power Transformers Part 2 Temperature Rise》 |

| IEC60076-3 /GB/T1094. 3-2017 | 《Power Transformers Part 3 Insulation Level and Insulation Test》 |

| IEC60076-5 /GB/T1094. 5-2008 | 《Power Transformers Part 5 Short Circuit Withstand Ability》 |

| IEC60270 /GB/T7354-2003 | 《Partial Discharge Measurements》 |

| IEC60722-GB/T1094. 4-2005 | 《Guidance for Lightning Impulse Operation Test of Power Transformers and Reactors》 |

| IEC76-5 Part 5 | 《Short Circuit Current Withstand Ability》 |

| JB/T10088-2004 | 《6~220kV Transformers Sound Level》 |

| JB/T8971-2013 | 《Cross Flow Type Cooling Fan for Dry-type Transformers》 |

| JB/T9639-1999 | 《Enclosed Busbar》 |

| T/CEEIA258-2016 | 《6kV~35kV transformer energy efficiency limit value and energy efficiency class》 |

| TEC 905 /GB/T1094. 12-2013 | 《Load Loss Guidance for Dry-type Power Transformers》 |

Dry type transformers are versatile and widely used for industrial, commercial, and utility applications. Below are the key specifications for Dry Type Transformers available in the market:

The insulation class defines the maximum operating temperature the insulation system can handle:

Dry type transformers are designed to comply with various standards depending on region or application:

Many suppliers offer customization, such as:

Taishan® Dry-type transformers with a self-cooling capacity of up to 25 MVA and a voltage level of 35 kV. The BIL (Basic Insulation Level) averages 170 kV, meeting Chinese national standards as well as international standards such as ANSI (USA) and British standards.

Would you like more detailed specifications for a specific use case or voltage class?

Dry-type transformers are designed to meet high efficiency standards and comply with various energy efficiency regulations and programs worldwide. Below are the details on efficiency levels and compliance with energy efficiency standards:

Efficiency of dry-type transformers depends on their design, load conditions, and compliance with standards:

IEC 60076-20 (Energy Efficiency Standard for Transformers):

EU Ecodesign Regulations (Tier 1 & Tier 2):

MEPS (Minimum Energy Performance Standards):

DOE 2016 (Department of Energy):

CSA C802.2 (Canada):

The design, manufacture and inspection of Taishan® dry - type transformer and all its components and accessories produced by our company follow the following latest standards.

| DL/T572-1995 | 《Operation Code of Power Transformers》 |

| DL/T596-1996 | 《Preventive Test Code of Electric Power Equipment》 |

| EC60076-11 /GB1094.11-2022 | 《Dry-type Power Transformers》 |

| GB/T10228-2023 | 《Technical Parameters and Requirements for Dry-type Power Transformers》 |

| GB/T1094. 10-2022 | 《Sound Level Measurement for Transformers and Mutual Inductors》 |

| GB/T1094. 3-2017 | 《Insulation Level, Insulation Test and External Insulation Clearances in Air》 |

| GB/Т26218. 1 (2) -2010 | 《External Insulation Pollution Classes of High-Voltage Electric Power Equipment》 |

| GB/Т50150-2016 | 《Standard for Hand-Over Test of Electric Equipment Electric Equipment Installation Engineering》 |

| GB20052-2020 | 《Power Transformer Energy Efficiency Limits and Energy Efficiency Levels》 |

| IEC529 /GB/Т4208 -2008 | 《Enclosure Protection Grade (IP Code)》 |

| IEC60060-1/ IEC60060-2 /GB/T16927. 1-2011 | 《High Voltage Test Technique》 |

| IEC60060-1/ IEC60060-2 /GB/Т16927. 2-2013 | 《High Voltage Test Technique》 |

| IEC60071-1 /GB/Т311. 1-2012 | 《Insulation Coordination of High Voltage Power Transmission and Transformation Equipment》 |

| IEC60076-1 GB/T1094. 1-2013 | 《Power Transformers Part 1 General》 |

| IEC60076-2 /GB/T1094. 2-2013 | 《Power Transformers Part 2 Temperature Rise》 |

| IEC60076-3 /GB/T1094. 3-2017 | 《Power Transformers Part 3 Insulation Level and Insulation Test》 |

| IEC60076-5 /GB/T1094. 5-2008 | 《Power Transformers Part 5 Short Circuit Withstand Ability》 |

| IEC60270 /GB/T7354-2003 | 《Partial Discharge Measurements》 |

| IEC60722-GB/T1094. 4-2005 | 《Guidance for Lightning Impulse Operation Test of Power Transformers and Reactors》 |

| IEC76-5 Part 5 | 《Short Circuit Current Withstand Ability》 |

| JB/T10088-2004 | 《6~220kV Transformers Sound Level》 |

| JB/T8971-2013 | 《Cross Flow Type Cooling Fan for Dry-type Transformers》 |

| JB/T9639-1999 | 《Enclosed Busbar》 |

| T/CEEIA258-2016 | 《6kV~35kV transformer energy efficiency limit value and energy efficiency class》 |

| TEC 905 /GB/T1094. 12-2013 | 《Load Loss Guidance for Dry-type Power Transformers》 |

Would you like recommendations for specific transformer models or a detailed loss calculation?

The expected lifespan of dry-type transformers under normal operating conditions typically ranges from 20 to 30 years, with proper maintenance and optimal usage. In some cases, with excellent care and favorable conditions, they can last even longer, up to 40 years or more.

Design and Quality of Materials

Operating Conditions

Environment

Maintenance Practices

Thermal Aging of Insulation

Taishan ® Product Lifespan Guarantee: The operational lifespan of our transformers is no less than 30 years.

Would you like recommendations for maintenance schedules or specific monitoring solutions to maximize lifespan?

Dry-type transformers are available with various cooling methods to meet different application requirements. The most common cooling methods include:

Choosing the appropriate cooling method depends on your specific application, ambient temperature, load profile, and installation conditions. Let me know if you need tailored recommendations!

Dry-type transformers are designed to meet rigorous environmental and safety standards to ensure reliability, safety, and sustainability. The certifications and standards typically associated with dry-type transformers include:

When choosing a dry-type transformer, verify the certifications required for your region and application. Manufacturers typically provide certificates of compliance for their products. If you need additional details about specific certifications or test results, let me know!

The installation of dry-type transformers requires careful planning to ensure safety, proper performance, and compliance with standards. Below are the key installation requirements and space considerations:

By ensuring compliance with these requirements and consulting the transformer’s technical manual, you can achieve safe, efficient, and long-lasting operation. Let me know if you need help with specific installation guidelines or accessories!

Yes, dry-type transformers offer a wide range of customizable options to suit specific applications and operational requirements. Customization ensures that the transformer aligns with your technical, environmental, and operational needs. Below are the key areas where customization is commonly available:

Manufacturers typically work with you to analyze your application requirements, operational conditions, and technical specifications. A detailed consultation ensures that the transformer is designed to meet all your needs effectively.

Let me know if you’d like further details or assistance with specifying options for your application!

Certainly! Here’s a detailed comparison of dry-type transformers and oil-filled transformers, which highlights their key differences and can help you decide which option is best for your application:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Dry-Type Transformers:

Oil-Filled Transformers:

Let me know more about your application, such as power requirements, installation site, or environmental conditions, and I can help refine the recommendation!

The noise level of a dry-type transformer during operation depends on its design, size, and cooling method. It typically ranges between 40 and 70 dB under normal conditions, with the following factors influencing noise levels:

Most dry-type transformers are designed to meet international and local noise regulations, such as:

For example:

If noise is a concern, manufacturers can include the following options to meet stricter requirements:

To ensure compliance with local regulations:

Let me know your specific noise requirements, installation location, or local regulations, and I can provide tailored guidance or options!

The maximum operating altitude and temperature range for a dry-type transformer depend on its design and construction. Below is a detailed explanation:

Standard Altitude Rating:

Effects of Higher Altitudes:

Altitude Derating Example:

Manufacturers can customize dry-type transformers to meet specific altitude or temperature needs:

| Parameter | Standard Rating | Customizable Range |

|---|---|---|

| Altitude | Up to 1,000 meters (3,300 feet) | Up to 4,000 meters (13,000 feet) with derating |

| Operating Temperature Range | -25°C to +40°C (-13°F to +104°F) | -50°C to +50°C (-58°F to +122°F) or higher |

Let me know your specific altitude, temperature requirements, or environmental conditions, and I can recommend an appropriate transformer or custom options!

Taishan Transformer is a key national-level manufacturer specializing in transformers, recognized as a “Contract-Honoring and Promise-Keeping” enterprise, a high-tech enterprise, and a national-level enterprise technology center. It is recommended in the national directory for rural and urban power grid construction and renovation, as well as a recommended supplier of major electromechanical equipment for hydropower projects. Its products have been awarded the title of “National Quality Inspection Qualified Product – Quality Trustworthy Product” and “Nationally Recognized Product for Mechanical Industry Users.

Our products not only dominate the domestic market but are also exported to more than 30 countries and regions, including Russia, Southeast Asia, Africa, and the Americas, serving industries such as power, municipal engineering, metallurgy, and petrochemicals.

This guidebook serves as an extensive resource for professionals, engineers, and researchers interested in Dry Type Transformer. It covers the fundamental principles, technology advancements, design considerations, operational challenges, and environmental impacts of Dry Type Transformer. Through detailed explanations, case studies, and practical insights, readers will gain a deep understanding of Dry Type Transformer technology and its applications in modern power.

Transformer synchronization is a critical requirement in power systems, especially when transformers operate in parallel or are connected to interconnected grids. Proper synchronization ensures that

Dry Type Transformer Blogs

Transformer synchronization is a critical requirement in power systems, especially

The core is one of the most fundamental components of

Overloading is a common operational challenge for power and distribution

We're here for you !

let's Talk about your Project!