Why Must Transformers Be Synchronized?

Transformer synchronization is a critical requirement in power systems, especially when transformers operate in parallel or are connected to interconnected grids. Proper synchronization ensures that

Designed to meet international standards such as IEC, ANSI, and GB, Taishan® oil-immersed transformers are energy-efficient with high electrical, mechanical, and thermal strength. They feature low or no partial discharge and operate with minimal noise, making them ideal for stable and reliable power distribution.

Taishan® Special Transformers are engineered for high-efficiency performance in specialized applications, ensuring reliability and long-term operation. Customizable to meet your specific needs, they are ideal for industries requiring precision and safety. Contact us for tailored solutions.

Trusted by world-class brands & organizations of all sizes

Our products not only dominate the domestic market but are also exported to more than 30 countries and regions, including Russia, Southeast Asia, Africa, and the Americas, serving industries such as power, municipal engineering, metallurgy, and petrochemicals.

Taishan Transformer is a key national-level manufacturer specializing in transformers, recognized as a “Contract-Honoring and Promise-Keeping” enterprise, a high-tech enterprise, and a national-level enterprise technology center. It is recommended in the national directory for rural and urban power grid construction and renovation, as well as a recommended supplier of major electromechanical equipment for hydropower projects. Its products have been awarded the title of “National Quality Inspection Qualified Product – Quality Trustworthy Product” and “Nationally Recognized Product for Mechanical Industry Users.

Transformer synchronization is a critical requirement in power systems, especially when transformers operate in parallel or are connected to interconnected grids. Proper synchronization ensures that

Special Transformer Blogs

Transformer synchronization is a critical requirement in power systems, especially

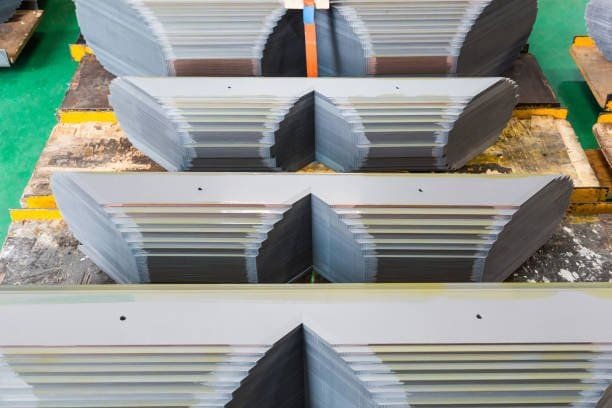

The core is one of the most fundamental components of

Overloading is a common operational challenge for power and distribution

We're here for you !

let's Talk about your Project!