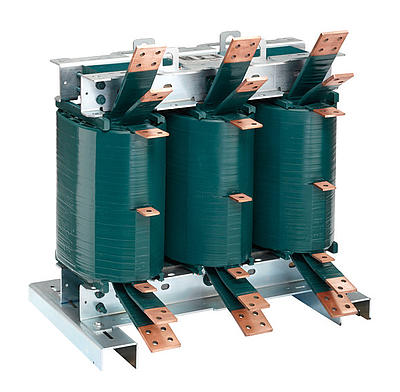

A starting transformer is a vital component for motor-driven applications, particularly in industrial and commercial sectors. Its primary role is to reduce the initial inrush current during motor startup, ensuring smoother operations and enhanced equipment longevity. Starting transformers are specially designed to handle high transient currents while protecting electrical systems from voltage spikes that could otherwise lead to operational disruptions or equipment damage.

These transformers are typically used with large motors, where the initial surge of current can be several times higher than the normal running current. By reducing this surge, the starting transformer prevents overloading the power supply and mitigates the risk of damaging sensitive electrical components.

Trusted by world-class brands & organizations of all sizes

Voltage Ratio: 11kV/380V, 6.3kV/380V, 3.3kV/380V (Customized according to customer needs)

Frequency: 50Hz/60Hz

Cooling Type: ONAN (Oil Natural Air Natural)

Primary Winding Impedance: Typically 5-10%

Secondary Voltage: 380V (standard); can be customized for different applications

Short-Circuit Impedance: Designed for low impedance to limit inrush current.

Start Duration: Typically 5-10 seconds (for gradual voltage ramp-up)

Contact us to upgrade or install your energy system.

Our starting transformer ensures smooth and reliable motor startups in industrial and commercial settings. Designed for high inrush currents, it minimizes power fluctuations and optimizes energy efficiency. Secure your operation’s stability today!

These transformers are typically used with large motors, where the initial surge of current can be several times higher than the normal running current. By reducing this surge, the starting transformer prevents overloading the power supply and mitigates the risk of damaging sensitive electrical components.

Applications include industrial machinery, HVAC systems, pumps, compressors, and other large motor-driven equipment, where reliable and efficient startup is critical. They come in a variety of configurations, including autotransformers and isolated types, depending on the specific needs of the electrical system.

Key Advantages:

By choosing a quality starting transformer, you ensure the smooth and efficient operation of your systems while reducing operational risks. Whether you are upgrading your facilities or designing a new system, our starting transformers provide unmatched reliability and performance.

Applications:

Suitable for large motors, pumps, compressors, and other industrial machinery requiring controlled startup.

Large Industrial Motors:

Used to limit starting current in motors driving heavy equipment like compressors, large fans, and pumps.

Power Stations:

Often employed in power plants to start large generator motors or other significant electrical equipment.

Oil & Gas:

Essential for starting large pumps and compressors used in oil and gas facilities.

In response to fierce market competition and to meet customer demands, our company adheres to a market-oriented approach and a customer-centric philosophy. We have earned widespread recognition from our clients through efficient, comprehensive services and superior product quality.

We offer comprehensive after-sales services, including free guidance for installation and commissioning. After the product is operational, if the customer requires support, our service team will respond promptly:

Additionally, we have established a robust regular follow-up system. We conduct periodic written or on-site visits to monitor the performance of in-service products, ensuring our customers have continuous peace of mind.

Remote Technical Assistance

Our service team provides 24/7 online technical support, including video calls, troubleshooting guides, and documentation, ensuring immediate assistance regardless of time zones.

Detailed remote diagnostics can be conducted using customer-provided data or live visual inspections.

On-Site Support

For complex issues, we dispatch experienced technicians to the customer site promptly, adhering to the agreed international response timelines.

On-site services include installation guidance, commissioning, maintenance, and repairs.

Dedicated Service Representatives

Each international client is assigned a dedicated service representative to coordinate all aspects of after-sales support, including issue resolution and regular follow-ups.

Local Service Partnerships

We collaborate with certified local service partners in key markets to ensure faster response times and efficient support. These partners are fully trained in our products and processes to uphold our quality standards.

Regular Follow-Up Visits

Post-installation, we perform scheduled follow-up visits, either in person or virtually, to monitor product performance and address customer feedback. This proactive approach ensures optimal operation and customer satisfaction.

Why This Matters

Our comprehensive international service system combines swift response, advanced technical support, and localized expertise to provide our global clients with reliable and professional after-sales services. We are committed to building lasting partnerships through consistent support and excellence.

When purchasing an Starting Transformer, you may want to know the following questions & answers.

The voltage rating of a starting autotransformer is typically designed to match the line voltage (the supply voltage) and the motor’s voltage. The transformer reduces the voltage to a specific level to facilitate safe and smooth motor startup, depending on the desired reduction factor.

Low-Voltage Autotransformer Starters:

Medium-Voltage Autotransformer Starters:

High-Voltage Autotransformer Starters:

Primary and Secondary Voltage:

Voltage Reduction Ratio:

Motor Voltage Matching:

The power ratings for starting transformers (often used in autotransformer starter applications) are generally specified in kVA (kilovolt-amperes) or MVA (megavolt-amperes). The power rating depends on the motor’s size and the characteristics of the electrical system.

Here is a breakdown of the available power ratings for starting transformers:

Motor Power and Starting Current:

Voltage Rating:

Power Factor:

For a motor rated at 1000 HP (approximately 750 kW):

For a 2500 HP (approximately 1800 kW) motor:

For very large motors (e.g., 5000 HP or higher):

The rated current of a starting transformer is the amount of current that the transformer can handle safely at its rated voltage under normal operating conditions. The current rating is critical because it dictates the transformer’s ability to supply the required power to the motor during startup, especially when using techniques like the autotransformer method.

To calculate the rated current of a starting transformer, we use the formula:

Irated=Srated3×VprimaryI_{rated} = \frac{S_{rated}}{\sqrt{3} \times V_{primary}}

Where:

Primary Voltage:

Power Rating (kVA or MVA):

Secondary Voltage and Autotransformer Configuration:

For an autotransformer, the secondary voltage (voltage delivered to the motor) is reduced based on the starting voltage (e.g., 50%, 60%, or 80%). However, the primary current is based on the total kVA rating, and not the voltage reduction factor, because the transformer is designed to supply the power for starting.

For instance, with a 50% voltage reduction in the autotransformer, the current to the motor will be reduced, but the starting transformer will still handle the full current based on the motor’s full power demand.

Let’s say we have a starting transformer rated at 1000 kVA with a primary voltage of 400V (a common low-voltage industrial system).

Irated=1000 kVA3×400 VI_{rated} = \frac{1000 \, \text{kVA}}{\sqrt{3} \times 400 \, \text{V}} Irated=1000×10001.732×400I_{rated} = \frac{1000 \times 1000}{1.732 \times 400} Irated=1,000,000692.8=1443.4 AI_{rated} = \frac{1,000,000}{692.8} = 1443.4 \, \text{A}

So, the rated current for this 1000 kVA transformer is approximately 1443 A at 400V.

For a 2500 kVA starting transformer with a 6.6 kV primary voltage:

Irated=2500 kVA3×6600 VI_{rated} = \frac{2500 \, \text{kVA}}{\sqrt{3} \times 6600 \, \text{V}} Irated=2500×10001.732×6600I_{rated} = \frac{2500 \times 1000}{1.732 \times 6600} Irated=2,500,00011,419.2=219.2 AI_{rated} = \frac{2,500,000}{11,419.2} = 219.2 \, \text{A}

The rated current for this 2500 kVA transformer is approximately 219 A at 6600V.

Motor Starting Current: The transformer must be capable of handling the inrush current during motor startup, which is typically 6-8 times the motor’s full-load current. However, since starting transformers are designed to reduce the voltage during the motor’s startup, the actual current delivered to the motor will be much lower than the full load current.

Autotransformer Effect: In the case of an autotransformer, the starting transformer’s current rating is not reduced by the voltage reduction. The starting transformer must still supply power at the full kVA rating, even though the voltage supplied to the motor is reduced.

Transformer Sizing: The current rating of the transformer is directly linked to the total amount of power it must supply. It is important to properly size the transformer to handle both the steady-state load and the inrush current during motor startup.

The core material used in starting transformers is a critical component for their performance, as it affects the transformer’s efficiency, cost, and ability to handle high inrush currents during motor startup. The core material is primarily chosen for its magnetic properties—specifically, its ability to handle the alternating current (AC) flux with minimal losses.

Type: Grain-Oriented Electrical Steel (GOES) or Non-Grain-Oriented Electrical Steel (NGOES)

Description: Silicon steel is the most common core material for transformers, including starting transformers. Silicon is added to steel to enhance its magnetic permeability, reduce core losses, and increase efficiency in the AC frequency range. Silicon steel provides good magnetic flux density and low hysteresis loss, making it highly effective for handling the fluctuating magnetic fields in transformers.

Key Features:

Usage:

Type: Amorphous Steel (Non-Crystalline Steel)

Description: Amorphous steel, also known as metallic glass, is a newer core material that is gaining attention in transformer design due to its ultra-low core losses. It has a random atomic structure, unlike crystalline materials like silicon steel. This structure leads to extremely low hysteresis loss, making it a highly efficient core material for transformers.

Key Features:

Usage:

Type: Ferrite

Description: Ferrite cores are primarily used in high-frequency transformers (e.g., in electronics, radio frequency applications), rather than in traditional industrial power transformers. Ferrites are ceramics made from iron oxide and other metals and have high resistance to eddy currents, which makes them ideal for high-frequency applications.

Key Features:

Usage:

Efficiency and Core Loss:

Magnetic Saturation:

Thermal Stability:

Cost-Effectiveness:

Primary Core Material: Silicon Steel (Electrical Steel)

Secondary Core Material: Amorphous Steel (for ultra-low core losses but higher cost).

Rarely Used in Power Transformers: Ferrite Cores (mainly for high-frequency applications, not typical for motor starting transformers).

The most commonly used core material for starting transformers is silicon steel, particularly grain-oriented electrical steel (GOES), due to its high efficiency, low core losses, and cost-effectiveness. Amorphous steel is an alternative for high-efficiency applications but comes with a higher cost. Ferrite cores are not typically used in industrial starting transformers but might be used in high-frequency applications.

The maximum short-circuit withstand capacity of a starting transformer refers to the highest amount of short-circuit current the transformer can handle without sustaining damage during a short-circuit event. This capacity is critical because, during a short-circuit, the transformer experiences a large and sudden surge in current, which could cause thermal damage to the windings and core if the transformer is not rated to withstand such high current levels.

The short-circuit withstand capacity is usually specified in terms of kA (kiloamperes) or MVA (megavolt-amperes) and is often given as the maximum fault current that the transformer can endure for a specific duration, typically in seconds. This is important for ensuring that the transformer can survive short-circuit events without failure and can be quickly disconnected from the system by protective devices.

Transformer Size (Power Rating):

Short-Circuit Duration:

Impedance of the Transformer:

Cooling Type:

Construction and Standards:

The maximum short-circuit withstand capacity of a transformer is typically defined in terms of kA (kilamperes) or MVA (megavolt-amperes) for a specified duration, but the exact value will depend on the transformer’s rated power, impedance, and design parameters. To calculate the approximate short-circuit current, you can use the following formula:

Isc=VratedZtransformerI_{sc} = \frac{V_{rated}}{Z_{transformer}}

Where:

For example, for a 1000 kVA transformer with a 6.6 kV rated voltage and 5% impedance, the approximate short-circuit current would be calculated as follows:

Transformer Base Current (Full-load Current):

IFL=Srated3×Vrated=1000 kVA3×6600 V=87.1 AI_{FL} = \frac{S_{rated}}{\sqrt{3} \times V_{rated}} = \frac{1000 \, \text{kVA}}{\sqrt{3} \times 6600 \, \text{V}} = 87.1 \, \text{A}Short-Circuit Current (with 5% impedance):

Isc=VratedZtransformer=6600 V0.05×6600 V=20 kAI_{sc} = \frac{V_{rated}}{Z_{transformer}} = \frac{6600 \, \text{V}}{0.05 \times 6600 \, \text{V}} = 20 \, \text{kA}Thus, the short-circuit withstand capacity of this transformer would be approximately 20 kA for a fault duration of 1 second (or whatever duration is specified by the manufacturer).

Small Transformers (up to 500 kVA):

Medium Transformers (500 kVA to 2500 kVA):

Large Transformers (2500 kVA and above):

Taishan Transformer is a key national-level manufacturer specializing in transformers, recognized as a “Contract-Honoring and Promise-Keeping” enterprise, a high-tech enterprise, and a national-level enterprise technology center. It is recommended in the national directory for rural and urban power grid construction and renovation, as well as a recommended supplier of major electromechanical equipment for hydropower projects. Its products have been awarded the title of “National Quality Inspection Qualified Product – Quality Trustworthy Product” and “Nationally Recognized Product for Mechanical Industry Users.

Our products not only dominate the domestic market but are also exported to more than 30 countries and regions, including Russia, Southeast Asia, Africa, and the Americas, serving industries such as power, municipal engineering, metallurgy, and petrochemicals.

We're here for you !

let's Talk about your Project!