Step-up and step-down transformers play crucial roles in the transmission and distribution of electrical power, but their design, materials, and application differences significantly influence their pricing. Understanding these differences is essential for buyers, engineers, and project managers who want to make informed purchasing decisions. While both types serve to adjust voltage levels for efficient power transfer, their costs depend on various technical and operational factors such as voltage rating, winding configuration, core design, and insulation requirements. This article provides a comprehensive comparison of step-up and step-down transformer prices, examining what drives their cost variations and how to choose the most cost-effective solution for your project.

What Is the Difference Between Step-Up and Step-Down Power Transformers?

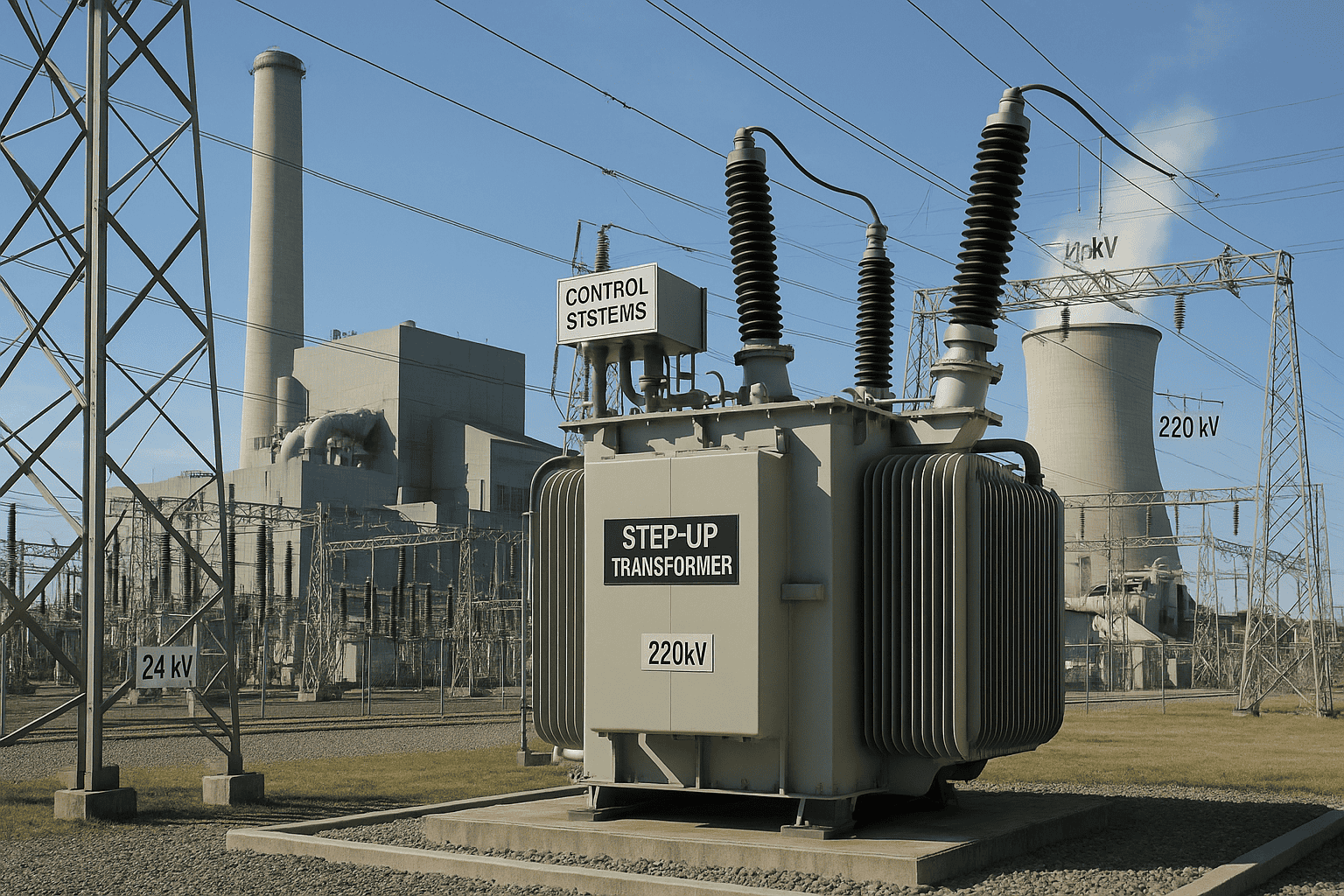

In every electrical network — from massive generating stations to the grid feeding your factory or home — step-up and step-down transformers play opposite but equally vital roles. Understanding the distinction between them is crucial for engineers, procurement professionals, and maintenance teams when selecting the right transformer for a given application. Choosing incorrectly can lead to inefficient operation, overheating, voltage instability, and increased lifecycle costs.

In short: a step-up transformer increases voltage from a lower to a higher level (for efficient power transmission), while a step-down transformer decreases voltage from a higher to a lower level (for safe distribution and end-user use).

Let’s explore their functions, designs, and cost differences in detail.

1. Core Operating Principle

Both transformer types work on Faraday’s Law of Electromagnetic Induction, transferring power between circuits through electromagnetic coupling — without any physical electrical connection.

However, the ratio of turns between the primary and secondary windings determines whether it steps voltage up or down:

| Type | Turns Ratio (N₂/N₁) | Function | Example Voltage Conversion |

|---|---|---|---|

| Step-Up | > 1 | Increases voltage | 11 kV → 132 kV |

| Step-Down | < 1 | Decreases voltage | 132 kV → 11 kV |

Step-Up Transformers raise voltage levels to reduce current and transmission losses over long distances.

Step-Down Transformers lower voltage to safe levels for industrial and domestic use.

Step-up transformers are used at power generation sites to increase transmission voltage.False

No explanation available.

2. Typical Applications in the Power Grid

Understanding where each transformer type is deployed clarifies their function within the generation–transmission–distribution system.

| Stage of Power System | Transformer Type | Typical Voltage Conversion | Main Purpose |

|---|---|---|---|

| Generation | Step-Up | 11 kV → 132/220/400 kV | Reduce transmission current and losses |

| Transmission | Step-Down | 400 kV → 132/66 kV | Distribute power regionally |

| Distribution | Step-Down | 33/11 kV → 415/230 V | Supply industrial and consumer loads |

In short, step-up transformers move energy into the grid, while step-down transformers deliver it out of the grid to end users.

Step-down transformers are primarily used in transmission substations.False

No explanation available.

3. Construction and Design Differences

While the electromagnetic principles are the same, construction varies slightly due to the voltage and insulation requirements.

| Component | Step-Up Transformer | Step-Down Transformer |

|---|---|---|

| Primary Winding | Low-voltage, high-current | High-voltage, low-current |

| Secondary Winding | High-voltage, low-current | Low-voltage, high-current |

| Insulation | Heavier on secondary side | Heavier on primary side |

| Core Design | Optimized for high magnetic flux | Optimized for thermal management |

| Applications | Power stations, solar farms, wind plants | Distribution substations, factories, buildings |

A step-up transformer must handle high induced voltage and insulation stress, whereas a step-down transformer focuses on high load currents and cooling efficiency.

4. Efficiency and Energy Losses

Both types achieve high efficiency (typically 98–99.5%) when designed and maintained according to IEC 60076 standards.

However, efficiency differs slightly depending on the load profile and operating voltage:

| Transformer Type | Typical Efficiency Range | Dominant Loss Type |

|---|---|---|

| Step-Up | 99.0–99.6% | Core losses (constant) |

| Step-Down | 98.5–99.2% | Copper losses (load-dependent) |

Step-up units operate mostly at constant load (generation), while step-down units experience load variation, which slightly increases losses.

5. Cost and Material Factors

Step-up transformers are typically larger, heavier, and more expensive, owing to higher insulation requirements and voltage ratings.

| Capacity | Step-Up (Approx. Cost USD) | Step-Down (Approx. Cost USD) |

|---|---|---|

| 1 MVA, 11/66 kV | $35,000 – $50,000 | $25,000 – $35,000 |

| 10 MVA, 11/132 kV | $90,000 – $120,000 | $75,000 – $100,000 |

| 40 MVA, 33/220 kV | $250,000 – $400,000 | $220,000 – $320,000 |

Material usage (especially copper, core steel, and insulation) strongly affects cost.

Step-up transformers are always cheaper than step-down types.False

No explanation available.

6. Maintenance and Reliability Factors

Both transformer types require similar maintenance routines — oil testing, DGA (Dissolved Gas Analysis), insulation resistance, and thermal monitoring.

However, their operational risks differ:

- Step-Up Transformers: prone to insulation breakdown due to high voltage stress.

- Step-Down Transformers: more likely to face overheating or overloading from variable demand.

| Maintenance Task | Recommended Interval | Purpose |

|---|---|---|

| Oil BDV & Moisture Test | Every 12 months | Check dielectric strength |

| DGA Analysis | Every 6–12 months | Detect internal faults |

| Thermographic Scan | Every 6 months | Identify hot spots |

| Tap Changer Servicing | Every 2–3 years | Ensure voltage stability |

7. Emerging Technologies and Efficiency Standards

Under new IEC 60076-20 efficiency classifications, both transformer types are being upgraded with:

- Amorphous metal cores to reduce no-load losses.

- High-temperature ester oils for better cooling.

- Digital monitoring sensors (IoT-based for predictive maintenance).

- Eco-designs aligning with EU Eco Directive 548/2014.

These improvements help utilities meet modern energy efficiency and environmental compliance targets, regardless of transformer type.

8. Real-World Example: Solar Power Station

A solar farm with 33 kV grid interconnection typically uses both types:

- A step-up transformer converts inverter output (690 V) to 33 kV for grid export.

- A step-down transformer at the local substation reduces grid voltage (33 kV) to 415 V for internal equipment.

Thus, both types work together in complementary roles within the same power system.

9. Summary Table: Step-Up vs. Step-Down Transformers

| Aspect | Step-Up Transformer | Step-Down Transformer |

|---|---|---|

| Function | Increases voltage | Decreases voltage |

| Voltage Flow | Low → High | High → Low |

| Application | Generation and transmission | Distribution and end use |

| Primary Side | Low voltage | High voltage |

| Secondary Side | High voltage | Low voltage |

| Efficiency | Slightly higher at constant load | Slightly lower due to load variation |

| Cost | Higher (more insulation) | Lower |

| Maintenance Focus | Insulation health | Load management |

How Do Design and Application Affect Power Transformer Pricing?

In the transformer industry, pricing is never arbitrary — it directly reflects the design complexity, intended application, material selection, and operational environment. Many buyers wonder why two transformers with similar kVA ratings can differ so much in price. The answer lies in the engineering and customization hidden beneath the surface.

A transformer is not a simple off-the-shelf product; it’s a highly customized electrical system designed for specific performance, safety, and environmental requirements.

Failing to match design to application can result in overheating, energy loss, or premature failure — all of which cost more in the long run.

In short: the design configuration and application environment are the primary factors that determine transformer cost — influencing core material, insulation level, cooling method, and efficiency class.

1. Design Configuration and Its Cost Impact

The design configuration — including voltage class, phase type, vector group, and cooling system — has the most direct impact on pricing.

| Design Parameter | Variants | Effect on Cost | Reason |

|---|---|---|---|

| Voltage Class | 11 kV, 33 kV, 132 kV, 220 kV | ↑ with voltage | Higher insulation and clearances needed |

| Cooling Type | ONAN, ONAF, OFAF, OFWF | ↑ with complexity | Fans and pumps add components |

| Core Type | CRGO, Amorphous, Cold-Rolled Silicon Steel | ↑ with core grade | Better magnetic efficiency costs more |

| Phase Type | Single-phase vs. Three-phase | ↑ for 3-phase | Larger core and windings |

| Frequency | 50 Hz or 60 Hz | Neutral | Minimal impact unless exported |

For example, a 10 MVA ONAN transformer at 33/11 kV might cost $90,000–$110,000, while the same unit with ONAF cooling (fans added) can reach $120,000–$135,000, due to increased copper, steel, and accessories.

Transformer price increases linearly with capacity (kVA or MVA).False

No explanation available.

2. Application Environment and Installation Site

Transformers designed for different applications or site conditions require varying mechanical and thermal properties, directly influencing cost.

| Application Type | Typical Environment | Design Features | Cost Impact |

|---|---|---|---|

| Power Generation | Power plant substation | High-voltage insulation, step-up function | High |

| Distribution Utility | Outdoor substation | Standard insulation, corrosion protection | Medium |

| Industrial | Factory or plant | Robust mechanical design, custom voltage | Medium–High |

| Renewable Energy | Solar or wind farm | Compact footprint, high harmonic tolerance | High |

| Marine/Mining | Coastal or underground | Anti-corrosive coating, vibration resistance | High |

A mining-site transformer, for instance, may include special enclosures, stainless steel tanks, and enhanced oil seals, adding 10–20% to the base price compared with a standard substation model.

Environmental conditions have no significant effect on transformer pricing.False

No explanation available.

3. Efficiency and Energy Loss Class

Energy efficiency is a key design factor under IEC 60076-20 and EU Eco Design Regulation 548/2014.

Higher efficiency transformers reduce lifecycle losses but increase upfront cost due to superior materials.

| Efficiency Class | Core Material | No-Load Loss (kW) | Typical Cost Increase |

|---|---|---|---|

| Tier 1 | CRGO Core | 9 | Base |

| Tier 2 | High-Grade CRGO | 7 | +10–12% |

| Tier 3 (Eco) | Amorphous Core | 5 | +18–25% |

While Tier 3 transformers cost more initially, they can save $4,000–$8,000 annually in energy loss per MVA rating — yielding long-term ROI within 3–5 years.

4. Insulation and Cooling System Design

The insulation system (solid, oil, or gas-based) and cooling class (ONAN, ONAF, OFAF, OFWF) play major roles in determining both performance and cost.

| Cooling Class | System Description | Relative Cost | Typical Use Case |

|---|---|---|---|

| ONAN | Oil Natural Air Natural | ★ | Distribution transformers |

| ONAF | Oil Natural Air Forced | ★★ | Industrial & medium power |

| OFAF | Oil Forced Air Forced | ★★★ | High power or high ambient temperature |

| OFWF | Oil Forced Water Forced | ★★★★ | Compact or marine applications |

For example, an OFAF-cooled transformer may require external heat exchangers and pumps, increasing cost by 20–30% compared to an ONAN type.

5. Material Quality and Origin

Material selection — especially copper vs. aluminum windings, core steel grade, and insulating oil type — strongly affects both cost and performance.

| Material Option | Performance Impact | Relative Cost |

|---|---|---|

| Copper Windings | Lower resistance, better thermal performance | High |

| Aluminum Windings | Lighter, lower cost | 20–30% lower |

| CRGO Steel Core | Standard grade | Base |

| Amorphous Core | Low loss, eco-efficient | +15–25% |

| Mineral Oil | Standard dielectric | Base |

| Natural Ester Oil | Fire-safe, biodegradable | +10–15% |

For example, switching from copper to aluminum windings in a 5 MVA transformer can save $7,000–$12,000, though at the cost of slightly higher losses and reduced lifespan.

6. Standards and Certification Requirements

Compliance with international standards (IEC, IEEE, ANSI) and third-party certifications (e.g., KEMA, CESI, or UL) adds engineering, testing, and documentation costs.

| Standard / Certification | Impact on Cost | Reason |

|---|---|---|

| IEC 60076 | Base standard | Reference design |

| IEEE C57 | +5–8% | U.S. design conformity |

| KEMA/CE Certification | +10–15% | Third-party type testing |

| Seismic / Explosion Proof | +10–20% | Special mechanical design |

Projects in regulated industries — such as utility grids, offshore installations, or renewable farms — almost always require third-party test verification, which raises total cost but guarantees reliability and compliance.

7. Custom Design, Accessories, and Monitoring Systems

Customization is often necessary for integration with digital systems, SCADA networks, or non-standard installation conditions.

Optional features that affect cost include:

- Tap changers (manual vs. on-load)

- Temperature sensors and RTDs

- Online DGA (Dissolved Gas Analysis) monitors

- Buchholz and pressure relief relays

- Remote control interfaces (IoT-ready)

Adding such smart monitoring systems may increase upfront cost by 10–18%, but enables predictive maintenance that reduces unplanned outages and extends service life.

Adding smart monitoring systems only increases cost without operational benefit.False

No explanation available.

8. Application-Specific Examples

a) Utility Transmission Transformer (132/33 kV, 40 MVA)

- Cooling: OFAF

- Insulation: High-grade oil, reinforced paper

- Certification: KEMA type tested

- Cost: $380,000–$450,000

b) Industrial Distribution Transformer (33/11 kV, 10 MVA)

- Cooling: ONAN

- Copper windings, CRGO core

- Standard IEC design

- Cost: $95,000–$120,000

c) Solar Step-Up Transformer (690 V/33 kV, 5 MVA)

- High harmonic design, low-loss amorphous core

- Ester oil for eco safety

- Digital monitoring

- Cost: $130,000–$150,000

These examples demonstrate how application and environment dictate both design and pricing.

9. Total Cost of Ownership (TCO) Perspective

The lowest purchase price does not always equal the lowest lifecycle cost.

Over 30 years, energy losses can exceed 3–5 times the purchase cost of a transformer.

| Transformer Type | Initial Price (USD) | Annual Loss Cost (USD) | 30-Year Lifecycle Cost (USD) |

|---|---|---|---|

| Standard ONAN Copper | $100,000 | $5,000 | $250,000 |

| High-Efficiency Tier 2 | $115,000 | $3,000 | $205,000 |

| Amorphous Core Eco | $130,000 | $2,000 | $190,000 |

Thus, investing in a better-designed transformer for the intended application reduces total ownership costs and enhances long-term reliability.

Which Transformer Type Requires More Expensive Materials or Components?

When comparing oil-immersed and dry-type power transformers, one of the most important cost-related questions is:

“Which type uses more expensive materials or components?”

The answer depends on the design, insulation system, and application environment — but in general, dry-type transformers require more costly materials and specialized components per unit of capacity.

Let’s examine why.

1. Material Composition Differences

| Component | Oil-Immersed Transformer | Dry-Type Transformer | Relative Cost Impact |

|---|---|---|---|

| Core | CRGO or Amorphous Steel | CRGO or Amorphous Steel | ≈ Equal |

| Windings | Copper or Aluminum (immersed in oil) | High-grade Copper (encapsulated or cast) | ↑ Higher (Dry type) |

| Insulation System | Mineral Oil or Ester Oil | Epoxy Resin or Nomex Paper | ↑ Higher (Dry type) |

| Cooling System | Oil circulation (ONAN/ONAF) | Air natural or forced ventilation | ↓ Lower (Oil type) |

| Tank / Enclosure | Steel tank with oil seals | Enclosed cast resin housing | ↑ Higher (Dry type) |

| Protection Devices | Buchholz, pressure relief, oil level gauges | Temperature sensors, thermal relays | ≈ Equal |

Summary:

Dry-type transformers eliminate oil but must compensate with high-grade resin insulation, copper conductors, and heat-resistant materials, which raise material costs by 15–25% compared with equivalent oil-immersed models.

2. Insulation System Cost and Complexity

Oil-Immersed Transformer:

- Uses transformer oil (mineral or ester-based) as both coolant and dielectric medium.

- The oil provides self-healing insulation and easy heat dissipation.

- Insulating materials are simple — kraft paper, pressboard, and mineral oil — all relatively low-cost.

Dry-Type Transformer:

- Uses solid insulation such as epoxy resin, silicone resin, or Nomex paper, designed to withstand high thermal stress.

- The resin casting or vacuum pressure impregnation (VPI) process requires specialized equipment and controlled curing, increasing manufacturing cost.

💡 Result:

The insulation system alone in a dry-type transformer can add 10–20% more to total material cost than that of an oil-immersed unit of similar rating.

3. Winding and Conductor Material

- Dry-type transformers require thicker copper conductors to handle heat buildup since air cooling is less efficient than oil.

- Oil-immersed transformers benefit from better cooling and can use smaller conductor cross-sections.

| Transformer Type | Typical Winding Material | Relative Copper Usage | Cost Effect |

|---|---|---|---|

| Oil-Immersed | Copper or Aluminum | 100% baseline | — |

| Dry-Type | High-purity Copper only | 110–130% | ↑ +10–15% material cost |

Because aluminum is rarely used in dry-type designs (due to poor mechanical rigidity and resin adhesion), copper — a more expensive metal — dominates.

4. Enclosure and Mechanical Design

- Oil-immersed transformers are enclosed in a sealed steel tank filled with oil, which naturally provides cooling and protection.

- Dry-type transformers need fire-resistant, dust-proof, and moisture-proof enclosures, especially in outdoor or industrial applications.

Typical dry-type enclosures include:

- IP23/IP44 rated housings for dust and splash protection

- Stainless steel or aluminum frames for corrosion resistance

- Ventilation ducts for forced air cooling

💡 These enclosures add 8–12% to the cost compared to a standard oil tank.

5. Cooling System Requirements

| Cooling Method | Oil-Immersed Type | Dry-Type | Cost Comparison |

|---|---|---|---|

| Natural Cooling (ONAN / AN) | Oil circulation, efficient | Air natural, less efficient | ↓ Lower for oil type |

| Forced Cooling (ONAF / AF) | Fans + radiators | Fans + air ducts | ≈ Similar |

| Advanced Cooling | Oil pumps, heat exchangers | High-speed blowers | ↑ Higher for dry type (in large ratings) |

Because oil has higher heat transfer efficiency, oil-immersed units require fewer external cooling accessories, saving cost.

6. Manufacturing and Processing Costs

Dry-type transformers demand high-precision vacuum processes and resin casting equipment, which are more expensive to operate and maintain.

Oil-immersed transformers, in contrast, use standard tank welding, oil filling, and drying — more established and less costly manufacturing processes.

| Manufacturing Stage | Oil-Immersed | Dry-Type | Cost Impact |

|---|---|---|---|

| Core Assembly | Standard | Standard | Equal |

| Coil Manufacturing | Oil-immersed impregnation | Resin casting / VPI | ↑ Higher (Dry type) |

| Tanking | Simple steel tank | Fire-resistant enclosure | ↑ Higher (Dry type) |

| Testing | Standard IEC tests | Thermal & partial discharge tests | ↑ Higher (Dry type) |

On average, dry-type transformer manufacturing costs are 20–30% higher than oil-immersed models of the same capacity.

7. When Oil-Immersed Becomes More Expensive

While dry types are usually costlier in small and medium capacities, oil-immersed transformers become more expensive at very high ratings (above 30–50 MVA or 220 kV), because:

- Larger oil volume and tank size

- Heavy-duty radiators and pumps

- Stringent testing and certification (e.g., type test at 220 kV)

So:

- Below 5 MVA → Dry-type more expensive

- 5–30 MVA → Oil-immersed more economical

- Above 50 MVA → Oil-immersed cost rises sharply due to scale

8. Example Cost Comparison

| Transformer Type | Capacity | Voltage Class | Approx. Cost (USD) | Relative Cost Index |

|---|---|---|---|---|

| Oil-Immersed (ONAN) | 2000 kVA | 33/0.4 kV | $25,000 – $30,000 | 1.00 |

| Dry-Type (VPI) | 2000 kVA | 33/0.4 kV | $35,000 – $40,000 | 1.30 |

| Oil-Immersed (ONAF) | 10 MVA | 33/11 kV | $95,000 – $120,000 | 1.00 |

| Dry-Type (Cast Resin) | 10 MVA | 33/11 kV | $130,000 – $150,000 | 1.25 |

👉 Result: Dry-type transformers generally cost 25–35% more than oil-immersed ones of similar capacity, due to material and manufacturing differences.

How Do Efficiency and Cooling Systems Impact the Overall Cost of Power Transformers?

When purchasing or designing a power transformer, two of the most important factors influencing both initial and long-term costs are efficiency and cooling system design. While most buyers focus on upfront price, real-world operational economics depend far more on how efficiently a transformer converts energy and how well it manages heat. A poor efficiency rating or an undersized cooling system can lead to excessive energy losses, higher lifecycle costs, and shorter service life — a costly mistake over decades of operation.

In essence, transformer efficiency determines how much power is wasted as heat, while the cooling system defines how effectively that heat is managed. Both directly affect total cost of ownership, not just the purchase price.

1. Transformer Efficiency: The Silent Cost Driver

Every power transformer loses a small portion of energy during operation. These losses — though minor per hour — occur continuously, 24/7, throughout the transformer's lifespan.

| Loss Type | Description | Influence on Cost |

|---|---|---|

| Core (No-Load) Losses | Occur whenever the transformer is energized, due to magnetization of the steel core. | Constant energy cost, even at zero load. |

| Copper (Load) Losses | Occur due to resistance in windings when current flows. | Increases with load; more copper reduces losses but adds material cost. |

Typical efficiencies under IEC 60076 standards:

| Transformer Class | Efficiency Range |

|---|---|

| Distribution (≤2.5 MVA) | 98.0–99.2% |

| Medium Power (2.5–30 MVA) | 99.0–99.5% |

| Large Power (≥100 MVA) | 99.5–99.7% |

Even small efficiency improvements dramatically affect long-term economics.

Example:

For a 10 MVA transformer operating continuously:

- 99.2% efficiency → 80 kW of losses

- 99.5% efficiency → 50 kW of losses

This 30 kW difference equals 262,800 kWh per year, saving about $26,000 annually at $0.10/kWh.

Over 25 years, that’s >$600,000 saved, far exceeding any additional purchase cost for higher-efficiency materials.

Transformer efficiency has minimal impact on lifetime cost.False

No explanation available.

2. How Higher Efficiency Increases Initial Cost but Reduces Lifecycle Cost

| Efficiency Level | Initial Cost | Operating Cost (25 yrs) | Total Lifecycle Cost |

|---|---|---|---|

| Standard (98.8%) | $100,000 | $85,000 | $185,000 |

| High Efficiency (99.3%) | $110,000 | $60,000 | $170,000 |

| Premium (99.5%) | $118,000 | $45,000 | $163,000 |

Higher efficiency requires better magnetic steel, thicker copper conductors, and precise winding geometry, all of which increase the initial price by 10–20%.

However, operating cost drops significantly, leading to lower total ownership cost.

3. The Role of Cooling Systems in Cost and Performance

Every watt of loss turns into heat. The cooling system determines whether this heat is removed efficiently — directly influencing lifespan and reliability.

| Cooling Class (IEC 60076-2) | Medium | Description | Relative Cost | Typical Rating Range |

|---|---|---|---|---|

| ONAN | Oil Natural, Air Natural | Passive oil and air convection | 1.0× | Up to 10 MVA |

| ONAF | Oil Natural, Air Forced | Radiators + fans | +15–25% | 10–60 MVA |

| OFAF | Oil Forced, Air Forced | Oil pumps + fans | +30–45% | 60–150 MVA |

| OFWF | Oil Forced, Water Forced | Oil-water heat exchangers | +50–70% | Specialized, e.g. marine/nuclear |

| AN / AF | Air Natural / Air Forced (Dry-Type) | Fan-cooled solid insulation | +10–20% | ≤5 MVA |

Each upgrade level adds more auxiliary components — radiators, pumps, fans, heat exchangers, sensors — which raise capital and maintenance costs, but also improve load handling and efficiency stability.

4. Efficiency–Cooling Interdependence

Cooling and efficiency are deeply interconnected.

Lower losses generate less heat, reducing cooling demand; conversely, superior cooling enables lower temperature rise, improving conductivity and efficiency.

| Design Temperature Rise | Cooling Type | Relative Cost | Efficiency Gain | Expected Service Life |

|---|---|---|---|---|

| 65°C | ONAN / AN | Base | — | 25 years |

| 55°C | ONAF / AF | +10–15% | +0.2–0.3% | 30–35 years |

| 45°C | OFAF / OFWF | +20–25% | +0.4–0.5% | 40+ years |

Every 10°C temperature reduction can double insulation lifespan according to Arrhenius’ thermal aging law.

Thus, better cooling not only boosts efficiency but also extends service life — reducing replacement frequency.

Cooling systems only affect transformer temperature, not cost.False

No explanation available.

5. Cooling System Material and Maintenance Costs

| Cooling Medium | Heat Dissipation Efficiency | Maintenance Frequency | Material Cost Index | Safety/Environment |

|---|---|---|---|---|

| Mineral Oil | 100% | Medium | 1.0 | Moderate fire risk |

| Natural Ester Oil | 95% | Low | 1.2 | Biodegradable, fire-safe |

| Air (Dry Type) | 60% | Low | 1.3 | Safe, non-flammable |

| Water (Forced) | 120% | High | 1.4 | Excellent cooling, complex system |

Oil-based systems offer best cooling per dollar spent, while ester and air systems improve safety and environmental performance at higher material cost.

6. Real Cost Impact Example

For a 20 MVA, 132/33 kV transformer:

| Design Option | Cooling Type | Efficiency | Initial Cost (USD) | Annual Energy Loss (kWh) | 25-Year Cost (USD) |

|---|---|---|---|---|---|

| Standard | ONAN | 99.1% | $280,000 | 600,000 | $850,000 |

| Enhanced | ONAF | 99.3% | $310,000 | 420,000 | $790,000 |

| Premium | OFAF | 99.5% | $340,000 | 300,000 | $760,000 |

The higher the cooling efficiency, the lower the total energy cost, even though initial investment rises by up to 20%.

7. Maintenance and Reliability Effects

| Cooling Type | Maintenance Activities | Interval | Impact on Reliability |

|---|---|---|---|

| ONAN | Oil sampling, DGA | 12 months | Good |

| ONAF | Fan servicing + DGA | 6–12 months | Very good |

| OFAF / OFWF | Pump and filter cleaning | 6 months | Excellent |

| Dry Type (AF) | Fan check, thermal relay | 12 months | Good (indoor use) |

Proper cooling lowers hot-spot temperature, preventing insulation cracking, sludge formation, and premature failure — directly saving on unplanned downtime and repair costs.

8. Future Efficiency & Cooling Innovations

Modern transformer designs integrate smart cooling and advanced materials:

- Amorphous metal cores cut no-load losses by 60–70%.

- Smart cooling fans adjust speed based on load and temperature.

- Natural ester fluids combine eco-safety with strong thermal stability.

- Digital temperature sensors monitor hot spots for predictive maintenance.

- Hybrid ONAN/ONAF designs offer load-responsive performance with lower energy use.

Such advancements align with EU Ecodesign 548/2014 and IEC 60076-20 energy efficiency directives.

9. Summary: Efficiency & Cooling vs. Cost Impact

| Aspect | Low-Cost Design (ONAN) | High-Efficiency Cooling (ONAF/OFAF) | Lifecycle Effect |

|---|---|---|---|

| Initial Price | Lower | +10–30% | ↑ Investment |

| Operating Losses | Higher | Much lower | ↓ Energy cost |

| Cooling Complexity | Simple | Radiators, fans, pumps | ↑ Maintenance control |

| Lifespan | 25 years | 35–40 years | ↑ Durability |

| Total Ownership Cost | Higher | Lower | ↑ Long-term savings |

What Are the Typical Price Ranges for Different Voltage Levels in Power Transformers?

For utilities, EPC contractors, and industrial buyers, understanding how voltage level affects transformer price is critical when budgeting for new installations or replacements. Many procurement managers are surprised to discover that cost doesn’t increase linearly with voltage — instead, it grows exponentially due to the complexity of insulation, design, and testing requirements. Choosing the wrong voltage rating can result in overspending, longer delivery times, or compliance risks, while proper selection ensures a balanced cost-performance ratio aligned with grid demand.

In essence, transformer price scales primarily with voltage level, insulation requirements, and MVA capacity — not just physical size. High-voltage units (≥132 kV) require advanced materials, larger clearances, and more rigorous testing, driving costs 2–4 times higher per kVA than low-voltage transformers.

The following paragraphs provide a deep technical and economic analysis to help procurement teams, engineers, and project planners make informed decisions when comparing power transformer price ranges across voltage classes.

1. Relationship Between Voltage Level and Cost Structure

The price of a power transformer increases with voltage because higher ratings demand:

- Thicker insulation layers (oil, paper, or resin)

- Greater creepage distances and mechanical strength

- Enhanced core design to control losses at high flux densities

- More sophisticated bushings, tap changers, and cooling systems

- Higher dielectric test voltages and stricter IEC 60076 compliance

The table below summarizes the major technical cost drivers by voltage level.

| Voltage Class (kV) | Key Technical Requirements | Relative Material & Testing Cost Index |

|---|---|---|

| ≤ 11 kV (Distribution) | Simple insulation, standard copper windings | 1.0 |

| 33 kV (Sub-Transmission) | Larger core, oil or dry cooling | 1.5 |

| 66 kV (Regional Grid) | Improved dielectric insulation, tap changer | 2.2 |

| 132 kV (Transmission) | High dielectric strength, precision assembly | 3.0 |

| 220 kV (High Transmission) | Oil-immersed, advanced cooling and testing | 4.0 |

| 400 kV+ (EHV/UHV) | Multilayer insulation, special steel, extensive tests | 6.0+ |

Transformer voltage level has no significant effect on cost.False

No explanation available.

2. Typical Price Ranges by Voltage Level and Capacity

Below is a general global market reference for oil-immersed power transformers (based on 2025 industrial data from Asia, Europe, and the Middle East). Prices vary by brand, efficiency class, and country of origin.

| Voltage Level | Typical Capacity (MVA) | Average Price Range (USD) | Price per kVA (USD) |

|---|---|---|---|

| 6.6 – 11 kV (Low Voltage) | 0.5 – 2.5 MVA | $8,000 – $45,000 | 9 – 18 |

| 22 – 33 kV (Medium Voltage) | 2.5 – 10 MVA | $40,000 – $120,000 | 8 – 15 |

| 66 kV (Sub-Transmission) | 10 – 30 MVA | $120,000 – $350,000 | 10 – 14 |

| 110 – 132 kV (Transmission) | 20 – 60 MVA | $300,000 – $850,000 | 12 – 18 |

| 220 kV (High Transmission) | 40 – 150 MVA | $800,000 – $2.5 million | 14 – 20 |

| 400 kV (Extra High Voltage) | 100 – 300 MVA | $2.5 – $6 million | 18 – 25 |

| 765 kV (UHV) | 250 – 800 MVA | $6 – $15 million | 25 – 35 |

Note: Prices above are for three-phase, oil-immersed, ONAN/ONAF-cooled units with standard efficiency (IEC 60076 compliant).

Dry-type or eco-friendly designs typically add 15–30% to the cost.

3. Why Costs Rise Disproportionately at Higher Voltages

The primary cost jump from 66 kV upward is due to electrical insulation complexity and testing standards.

| Voltage Range | Major Cost Contributors | IEC Test Voltage (kV) | Impact on Price |

|---|---|---|---|

| 11–33 kV | Core & copper materials | 28–70 | Minor |

| 66–132 kV | Insulation, oil volume, bushings | 170–325 | Moderate |

| 220–400 kV | Field testing, partial discharge, oil cooling | 460–950 | High |

| 500–765 kV | Factory and site type tests, transport logistics | >1200 | Very High |

Each step in voltage class multiplies insulation thickness, clearance distances, and testing duration, thereby increasing labor and factory time.

High-voltage transformers mainly cost more due to larger steel cores.False

No explanation available.

4. Cooling and Loss Class Adjustments by Voltage Level

High-voltage transformers often require advanced cooling systems (ONAF, OFAF, OFWF) to maintain safe temperature rise limits. These systems add 10–40% to the total price depending on load profile.

| Voltage Level | Common Cooling Type | Approx. Cost Impact |

|---|---|---|

| ≤ 33 kV | ONAN (Oil Natural, Air Natural) | Base |

| 66–132 kV | ONAF (Oil Natural, Air Forced) | +15% |

| 220–400 kV | OFAF (Oil & Air Forced) | +25–35% |

| ≥ 500 kV | OFWF (Oil & Water Forced) | +40–50% |

Additionally, transformers meeting EU Tier 2 or DOE 2021 efficiency standards typically cost 5–12% more but reduce long-term energy losses significantly.

5. Regional Price Variation

| Region | Typical Price Difference (vs. Global Average) | Key Influences |

|---|---|---|

| Asia (China, India, Vietnam) | −10 – 20% | Lower labor, strong manufacturing capacity |

| Europe (Germany, Poland, Italy) | +10 – 25% | High material, energy, and compliance costs |

| Middle East & Africa | ±10% | Import tariffs, logistics complexity |

| North America (U.S., Canada) | +15 – 30% | DOE compliance, domestic sourcing requirements |

Freight, packaging, and site installation can add another 3–8% depending on project distance and transformer weight (which can exceed 200 tons for 400 kV units).

6. Long-Term Economic Considerations

While low-voltage units have short ROI periods, high-voltage transformers must be evaluated by total lifecycle cost rather than upfront price.

| Voltage Level | Estimated Service Life (Years) | Typical ROI Period | Efficiency Requirement |

|---|---|---|---|

| 11–33 kV | 20–25 | 5–7 | Medium |

| 66–132 kV | 25–35 | 8–10 | High |

| 220–400 kV | 30–40+ | 10–12 | Premium |

Utilities often justify higher voltage costs through reduced transmission losses and increased grid reliability, which yield lower cost per delivered kWh over time.

7. Cost Breakdown Example for a 132 kV 40 MVA Transformer

| Component | Approx. Share of Total Cost |

|---|---|

| Core and Windings | 35% |

| Tank and Cooling | 20% |

| Insulation and Bushings | 15% |

| Tap Changer | 10% |

| Testing and Quality Control | 8% |

| Logistics and Packaging | 5% |

| Miscellaneous Accessories | 7% |

Even at the same voltage level, factors such as material selection (CRGO vs. amorphous steel) and efficiency grade (Tier 1/Tier 2) cause price differences of up to 20%.

8. Summary Table: Price and Performance Overview

| Voltage Class | Typical Capacity | Approx. Cost (USD) | Cooling Type | Common Applications |

|---|---|---|---|---|

| 11 kV | 1 MVA | $10,000 – $20,000 | ONAN | Distribution networks |

| 33 kV | 5 MVA | $40,000 – $90,000 | ONAN/ONAF | Substations, factories |

| 66 kV | 20 MVA | $150,000 – $250,000 | ONAF | Regional power stations |

| 132 kV | 40 MVA | $350,000 – $700,000 | ONAF | Transmission interface |

| 220 kV | 100 MVA | $1 – 2 million | OFAF | National grid projects |

| 400 kV | 250 MVA | $3 – 5 million | OFWF | Long-distance transmission |

| 765 kV | 500 MVA+ | $8 – 15 million | OFWF | UHV interconnection systems |

How Can Buyers Optimize Costs When Selecting a Transformer Type?

When planning an electrical substation, industrial expansion, or renewable integration project, buyers face one of the most challenging decisions: how to select a transformer type that minimizes cost without compromising performance or safety. Poor selection leads to oversized equipment, higher energy losses, and increased maintenance expenses, while the right choice can reduce total ownership costs by up to 30%.

In essence, optimizing transformer cost is not just about buying the cheapest unit — it’s about selecting the right type, design, and configuration that best aligns with operating conditions, load demand, and lifecycle economics.

In the following in-depth analysis, we explore the technical and economic principles that determine transformer type selection, comparing oil-immersed vs. dry-type, standard vs. customized, and efficiency vs. upfront investment scenarios — to help buyers make truly cost-effective decisions.

1. Identify Application and Environment to Choose Correct Type

The application environment is the first and most decisive factor in transformer type selection.

| Application Scenario | Recommended Transformer Type | Rationale | Cost Impact |

|---|---|---|---|

| Indoor / Commercial Buildings | Dry-Type (Cast Resin / VPI) | Fire-safe, low maintenance | +10–25% higher initial cost |

| Outdoor / Utility Substations | Oil-Immersed (ONAN/ONAF) | Higher efficiency, cheaper per kVA | −15–30% lower cost |

| Renewable Energy (Solar/Wind) | Oil-Immersed / Pad-Mounted | Withstands temperature fluctuation | Moderate |

| Marine / Underground / Tunnel | Dry-Type or Ester-Filled | Fire-resistant, compact | +20–35% |

| Heavy Industrial (Steel, Cement) | Oil-Immersed | Handles overload and dust | Cost-efficient long-term |

Oil-immersed transformers are always more expensive than dry-type transformers.False

No explanation available.

Dry-type transformers cost more upfront but offer superior fire safety and minimal environmental risk, making them ideal for indoor or densely populated installations.

Oil-immersed units, in contrast, are more efficient (up to 99.6%), better at managing load peaks, and significantly cheaper per MVA, but require oil containment, fire protection, and regular maintenance.

2. Match Capacity to Load Profile – Avoid Over-Sizing

A common mistake in transformer procurement is overspecifying capacity for “future expansion.” This increases both initial investment and no-load losses.

| Load Factor (%) | Transformer Utilization | Impact on Cost Efficiency |

|---|---|---|

| 40–60% | Undersized | Overheating, reduced lifespan |

| 70–80% | Optimal | Best cost-efficiency balance |

| 90–100% | Fully utilized | Higher copper losses, faster aging |

For best economics, the rated capacity should align with the average load factor of 70–80% of expected operation.

Example:

Choosing a 5 MVA transformer for a 3.5 MVA steady load yields lower lifecycle cost than a 6 MVA unit that will operate underloaded 90% of the time.

3. Compare Life-Cycle Cost, Not Just Purchase Price

Transformers are long-term assets with lifespans of 25–40 years. Initial price represents only about 15–20% of total lifecycle cost, while energy losses account for 70–80%.

| Cost Component | Share of Total Lifecycle Cost |

|---|---|

| Purchase and Transport | 15% |

| Installation & Commissioning | 5% |

| Energy Losses (Over 25 years) | 65% |

| Maintenance | 10% |

| Decommissioning | 5% |

High-efficiency transformers (IEC Tier 2, DOE 2021) cost 5–10% more but save hundreds of thousands of dollars in energy over their life.

High-efficiency transformers are not worth the higher upfront price.False

No explanation available.

4. Understand Cooling Class and Its Cost Implications

Cooling design directly affects both price and efficiency.

| Cooling Type | Description | Relative Cost Index | Typical Capacity Range (MVA) |

|---|---|---|---|

| ONAN (Oil Natural, Air Natural) | Passive convection | 1.0 | ≤10 |

| ONAF (Oil Natural, Air Forced) | Fans assist cooling | 1.15 | 10–60 |

| OFAF (Oil & Air Forced) | Pumps + fans | 1.3 | 60–150 |

| OFWF (Oil & Water Forced) | Water heat exchangers | 1.5 | ≥150 |

| AN / AF (Dry-Type) | Air Natural / Air Forced | 1.1 | ≤5 |

Buyers should choose the simplest cooling system that meets load and ambient conditions. Complex cooling (e.g., OFAF/OFWF) increases cost, maintenance, and power consumption.

5. Standardization and Modular Design Reduce Costs

Custom-built designs are sometimes necessary, but standardized configurations (common voltage ratios, tap ranges, and accessories) significantly cut:

- Engineering and testing time

- Spare part costs

- Lead time by 30–40%

| Design Type | Custom Level | Typical Lead Time | Relative Price |

|---|---|---|---|

| Standard IEC/ANSI model | Minimal | 10–14 weeks | Base |

| Modified standard | Medium | 14–18 weeks | +10% |

| Fully custom | High | 18–26 weeks | +20–30% |

Therefore, choosing an IEC-standardized voltage ratio (e.g., 33/11 kV or 132/33 kV) offers faster delivery and better pricing due to economies of scale.

6. Optimize Material Selection for Long-Term Value

Transformer materials — particularly core steel and conductor metal — are key cost drivers.

| Material Option | Initial Cost | Efficiency | Best Use Case |

|---|---|---|---|

| CRGO Steel + Copper Windings | Medium | High | General-purpose oil-immersed |

| Amorphous Steel + Copper | +10–15% | Very High | Energy-efficient utilities |

| Aluminum Windings | −10–20% | Medium | Budget-sensitive installations |

| Hybrid Cu/Al Design | Moderate | Balanced | Cost-performance projects |

Selecting aluminum or hybrid windings can reduce initial price while maintaining acceptable performance — suitable for non-critical applications or short operating hours.

7. Regional Manufacturing and Logistics Optimization

Procurement from regional manufacturers can save 10–25% through:

- Lower shipping and handling costs

- Simplified compliance with local grid codes

- Reduced customs and insurance fees

| Region | Average Cost Difference vs. Global Price | Typical Delivery Period |

|---|---|---|

| Asia (China, India) | −10–25% | 12–16 weeks |

| Europe | +10–20% | 14–20 weeks |

| North America | +15–30% | 16–22 weeks |

Strategic sourcing close to project sites also minimizes damage risk during transport — especially for units >100 tons.

8. Smart Accessories and Optional Features: Choose Wisely

While modern transformers can integrate IoT monitoring, OLTC automation, and digital sensors, not all are necessary for every project.

| Optional Feature | Typical Added Cost | Benefit |

|---|---|---|

| OLTC (On-Load Tap Changer) | +10–15% | For fluctuating grid voltage |

| Digital temperature sensors | +3–5% | Predictive maintenance |

| Dissolved Gas Analysis (DGA) | +8–10% | Online fault monitoring |

| SCADA integration | +5–7% | Centralized control |

| Smart cooling fans | +2–3% | Adaptive efficiency |

Only include features that directly support operational reliability — not “nice-to-have” add-ons.

9. Case Study: 33/11 kV 10 MVA Transformer Selection Optimization

| Option | Type | Initial Cost (USD) | Losses (kW) | 25-Year Energy Cost @ $0.1/kWh | Total Life Cost (USD) |

|---|---|---|---|---|---|

| Basic Oil-Immersed | ONAN | $75,000 | 60 | $1,314,000 | $1,389,000 |

| High-Efficiency Oil | ONAF | $85,000 | 45 | $985,500 | $1,070,500 |

| Dry-Type Cast Resin | AF | $95,000 | 55 | $1,204,500 | $1,299,500 |

The ONAF oil-immersed model achieves the best cost-performance ratio with 7–10% lower lifecycle cost.

10. Summary: Key Strategies to Optimize Transformer Costs

| Optimization Area | Strategy | Cost Impact |

|---|---|---|

| Transformer Type | Match to environment (oil vs. dry) | ±20% |

| Capacity | Size for 70–80% utilization | −10–15% |

| Efficiency | Choose Tier 2 standard | −20–30% lifetime energy cost |

| Cooling System | Simplify if load allows | −5–10% |

| Material Selection | Aluminum or hybrid design | −10–20% |

| Regional Sourcing | Local manufacturing | −10–25% |

| Accessories | Select only necessary features | −5–15% |

Conclusion

While step-up transformers generally cost more due to higher insulation requirements, advanced winding designs, and the need to handle higher voltage stresses, step-down transformers tend to be more economical and widely used in industrial and commercial distribution systems. However, cost alone should not determine the choice. Project specifications—such as installation location, load profile, voltage ratio, and efficiency requirements—must guide the selection process.

To achieve the best value, buyers should compare total ownership cost, including efficiency losses, maintenance, and expected lifespan, rather than focusing solely on initial price. Partnering with a reputable manufacturer ensures that both step-up and step-down transformers meet technical standards and deliver reliable performance throughout their service life.

FAQ

Q1: What is the price difference between step-up and step-down transformers?

The price difference between step-up and step-down transformers mainly depends on voltage class, capacity, and application rather than the direction of voltage change.

Step-up transformers (for power generation or long-distance transmission) generally cost more due to higher insulation levels, specialized windings, and testing requirements.

Step-down transformers (for distribution or industrial use) are typically cheaper because of lower voltage ratings and simpler designs.

For example:

Step-up 11kV/132kV, 5 MVA transformer: $70,000–$120,000

Step-down 132kV/11kV, 5 MVA transformer: $60,000–$100,000

Q2: Why are step-up transformers usually more expensive?

Step-up transformers handle higher voltage levels and require:

Enhanced insulation materials and dielectric clearances

Thicker winding insulation and higher BIL (Basic Insulation Level)

More complex core design and cooling systems

These engineering requirements increase both material and manufacturing costs, resulting in a higher price per kVA than step-down units.

Q3: What factors influence step-up and step-down transformer pricing?

Key cost factors include:

Rated capacity (kVA/MVA)

Voltage ratio and insulation level

Core and winding materials (copper vs. aluminum)

Cooling system (ONAN, ONAF, OFWF, or dry type)

Efficiency and regulatory standards (IEC 60076, DOE, etc.)

Customization, protection devices, and accessories

Additionally, transportation, testing, and installation can contribute significantly to total cost.

Q4: How can buyers choose between step-up and step-down transformers cost-effectively?

Identify the voltage and power requirements accurately before procurement.

Choose standard-rated transformers whenever possible to reduce customization costs.

Opt for energy-efficient models that lower long-term operating expenses.

Request multiple quotations from certified suppliers and compare warranties.

Consider total cost of ownership (TCO) rather than just purchase price.

Q5: Are there price differences between oil-immersed and dry-type variants?

Yes.

Oil-immersed step-up and step-down transformers are more cost-effective for outdoor or utility applications.

Dry-type units are 20–40% more expensive but are safer for indoor, commercial, and fire-sensitive environments like hospitals and data centers.

Choosing the right cooling and insulation system can significantly affect both initial and operational costs.

References

IEC 60076 – Power Transformers: General Requirements: https://webstore.iec.ch

IEEE C57 – Standard for Power Transformer Design: https://ieeexplore.ieee.org

Electrical4U – Step-Up vs. Step-Down Transformer Price Comparison: https://www.electrical4u.com

EEP – Transformer Cost and Specification Guide: https://electrical-engineering-portal.com

DOE – Transformer Efficiency and Cost Standards: https://www.energy.gov