The core is one of the most fundamental components of a transformer, playing a decisive role in how electrical energy is transferred efficiently from one circuit to another. Although it carries no electrical current itself, the core provides a controlled path for magnetic flux, enabling electromagnetic induction to occur with minimal energy loss. Understanding the function of the transformer core is essential for appreciating transformer efficiency, performance, and reliability.

What Is the Transformer Core and What Is It Made Of?

In a transformer, electrical energy does not flow directly from one winding to another. Instead, it is transferred through a magnetic field, and the transformer core is the component that makes this process efficient, stable, and economical. The quality of the core directly affects efficiency, losses, noise, temperature rise, and the overall lifespan of the transformer, which is why core design and material selection are central to transformer engineering.

The transformer core is a magnetic circuit that provides a controlled, low-reluctance path for alternating magnetic flux, and it is mainly made from laminated electrical steel or advanced low-loss magnetic alloys.

The transformer core reduces magnetic reluctance and enables efficient electromagnetic induction between windings.True

By concentrating magnetic flux, the core improves coupling between windings and minimizes energy loss.

Fundamental Function of the Transformer Core

The core serves as the magnetic backbone of the transformer.

Its primary functions include:

- Carrying and guiding alternating magnetic flux

- Enhancing magnetic coupling between primary and secondary windings

- Reducing magnetizing current

- Limiting energy losses during operation

Without a core, most of the magnetic flux would disperse into air, making voltage transformation highly inefficient.

How the Core Works in Transformer Operation

When alternating current flows through the primary winding:

- A time-varying magnetic field is created

- The transformer core channels this flux efficiently

- The changing magnetic flux induces voltage in the secondary winding

The core itself does not generate energy or move mechanically; it only guides magnetic energy.

Electrical Steel as the Primary Core Material

Electrical steel is the most widely used core material.

Key properties include:

- High magnetic permeability

- Low hysteresis loss

- Adequate mechanical strength

- Good manufacturability and cost balance

Adding silicon to steel increases electrical resistivity and reduces eddy current losses.

Grain-Oriented Electrical Steel

Grain-oriented silicon steel is specifically designed for power transformers.

Its advantages are:

- Very low core loss along the rolling direction

- High permeability at normal operating flux density

- Reduced no-load losses and magnetizing current

Because of these properties, CRGO steel is standard in medium- and high-voltage power transformers.

Non-Grain-Oriented Electrical Steel

Non-grain-oriented steel has uniform magnetic properties in all directions.

It is typically used in:

- Smaller distribution transformers

- Applications with complex flux paths

Although its losses are higher than grain-oriented steel, it offers flexibility in magnetic design.

Amorphous Metal Core Materials

Amorphous alloys represent advanced core technology.

Their characteristics include:

- Extremely low no-load (core) losses

- Reduced lifetime energy consumption

- Lower environmental impact

Amorphous cores are especially attractive for energy-efficient distribution transformers, despite higher initial cost.

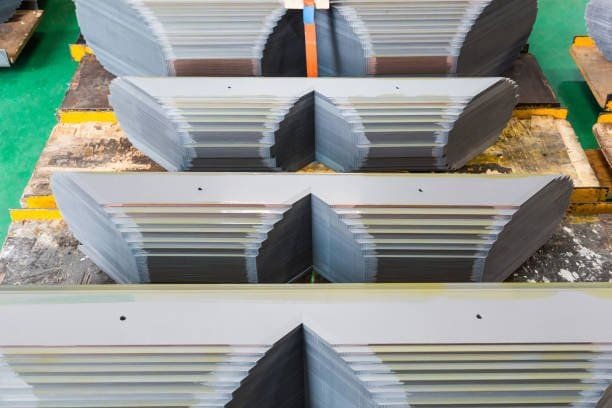

Laminated Core Construction

Transformer cores are built from thin laminated sheets rather than solid metal.

This construction:

- Limits circulating eddy currents

- Reduces heat generation

- Improves overall efficiency

Typical lamination thickness ranges from 0.18 mm to 0.30 mm, depending on design and efficiency targets.

Core Shapes and Structural Types

Common transformer core structures include:

- Core-type construction

- Shell-type construction

Each structure affects magnetic flux distribution, mechanical strength, cooling effectiveness, and short-circuit performance.

Influence of Core Quality on Efficiency and Losses

Core losses occur even when the transformer is unloaded.

They consist of:

- Hysteresis loss due to repeated magnetization

- Eddy current loss induced in the core material

High-quality materials, precision cutting, and advanced joint designs significantly reduce these losses.

Noise and Vibration Considerations

The transformer core is a major source of audible noise.

Magnetostriction causes:

- Core vibration

- Characteristic humming sound

Advanced materials, step-lap joints, and rigid clamping systems help minimize noise levels.

Long-Term Reliability and Service Life

Core material and assembly quality influence long-term performance.

A well-designed core provides:

- Stable magnetic characteristics over decades

- Lower operating temperature

- Reduced mechanical stress

This directly supports transformer reliability and lifespan.

How Does the Core Enable Magnetic Flux Circulation?

In a transformer, magnetic flux is the invisible carrier of energy between windings. If this flux were allowed to spread freely into air, most of the energy would be lost and voltage transformation would become inefficient and unstable. The transformer core exists precisely to control, guide, and sustain this magnetic flux circulation in a predictable and efficient way.

The transformer core enables magnetic flux circulation by providing a continuous, low-reluctance magnetic path that concentrates and guides alternating magnetic flux between the windings.

A transformer core enables efficient magnetic flux circulation by offering a low-reluctance closed magnetic path.True

Magnetic flux naturally follows the path of least reluctance, which the core provides, allowing effective energy transfer between windings.

Creation of Magnetic Flux in the Core

When alternating current flows through the primary winding:

- A time-varying magnetomotive force is produced

- This force generates alternating magnetic flux

- The flux seeks the easiest path to complete its magnetic circuit

Air has very high magnetic reluctance, while ferromagnetic materials have very low reluctance. The core therefore becomes the preferred path for flux circulation.

Low Reluctance Path and Flux Concentration

Reluctance is the magnetic equivalent of electrical resistance.

The core:

- Offers much lower reluctance than air

- Concentrates flux within a defined geometry

- Prevents flux leakage and dispersion

By confining flux inside the core, magnetic coupling between windings is maximized.

Closed Magnetic Circuit Formation

Transformer cores are designed as closed or nearly closed magnetic loops.

This structure:

- Allows flux to circulate continuously

- Minimizes gaps that would increase reluctance

- Reduces magnetizing current requirements

Limbs and yokes work together to form a complete magnetic circuit.

Alternating Flux Circulation

Because the supply current is alternating:

- Flux continuously changes direction

- The core undergoes cyclic magnetization and demagnetization

- Flux oscillates within the same closed path

This alternating flux is essential for inducing voltage in the secondary winding.

Role of Core Lamination in Flux Control

The core is built from thin laminated sheets.

Lamination:

- Restricts circulating eddy currents

- Reduces heating and core losses

- Maintains efficient flux circulation

Each lamination is electrically insulated but magnetically connected, preserving flux continuity.

Magnetic Coupling Between Windings

The core links the windings magnetically.

As flux circulates through the core:

- It passes through both primary and secondary windings

- Changes in flux induce voltage according to Faraday’s law

- Efficient power transfer occurs without physical contact

Strong magnetic coupling depends directly on effective flux circulation.

Reduction of Leakage Flux

Not all flux is perfectly confined.

However, a well-designed core:

- Minimizes leakage flux

- Improves voltage regulation

- Enhances efficiency

Core geometry and winding placement work together to control flux paths.

Influence of Core Material Properties

Material properties strongly affect flux behavior.

High-quality core materials provide:

- High magnetic permeability

- Low hysteresis loss

- Stable flux behavior over time

These properties allow smooth, low-loss flux circulation.

Impact on Efficiency and Performance

Efficient flux circulation results in:

- Lower no-load losses

- Reduced magnetizing current

- Stable voltage transformation

- Improved thermal performance

Poor flux control directly increases losses and operating temperature.

Why Is the Core Essential for Electromagnetic Induction?

Electromagnetic induction is the fundamental process that allows a transformer to transfer energy from one circuit to another without electrical contact. While induction can occur in open air, it would be extremely weak and inefficient in practical power applications. The transformer core is the element that makes electromagnetic induction strong, stable, and controllable enough to handle real-world voltage and power levels.

The transformer core is essential for electromagnetic induction because it concentrates and guides magnetic flux, greatly strengthening the changing magnetic field required to induce voltage efficiently in the secondary winding.

The transformer core is essential for electromagnetic induction because it increases magnetic flux linkage between windings.True

By providing a low-reluctance magnetic path, the core concentrates flux and enhances induced voltage according to Faraday’s law.

Strengthening the Magnetic Field

Electromagnetic induction depends on magnetic flux strength.

The core:

- Provides a low-reluctance path for magnetic flux

- Allows a much higher flux density than air

- Concentrates the magnetic field within a defined circuit

This stronger magnetic field directly increases the induced voltage in the secondary winding.

Improving Flux Linkage Between Windings

Efficient induction requires that most of the magnetic flux links both windings.

The core:

- Channels flux through both primary and secondary windings

- Minimizes flux leakage into surrounding air

- Maximizes mutual inductance

Better flux linkage means more efficient energy transfer.

Reducing Magnetizing Current

Without a core, very large current would be needed to create usable flux.

The core:

- Reduces the magnetizing current required

- Lowers no-load losses

- Improves overall efficiency

This makes transformer operation economical and stable.

Enabling Practical Voltage Transformation

Induced voltage is proportional to the rate of change of magnetic flux.

The core:

- Allows high, stable flux levels at normal supply voltage

- Ensures predictable voltage ratios

- Maintains consistent performance under varying load

Without a core, voltage transformation would be unreliable and inefficient.

Supporting Alternating Flux for Continuous Induction

Transformers operate with alternating current.

The core:

- Supports repeated magnetization and demagnetization

- Maintains flux continuity during each AC cycle

- Ensures smooth, continuous induction

Core materials are specifically designed to handle these cyclic magnetic changes with minimal loss.

Minimizing Energy Losses During Induction

Electromagnetic induction is accompanied by losses.

The core:

- Uses laminated construction to limit eddy currents

- Employs low-loss materials to reduce hysteresis

- Controls heating during flux reversal

These features make induction efficient over long operating periods.

Enhancing Thermal and Mechanical Stability

Stable induction requires stable physical conditions.

The core:

- Maintains consistent magnetic properties under load

- Resists vibration and mechanical stress

- Helps distribute heat generated by losses

This stability supports long-term reliability.

Enabling Compact and High-Power Designs

Without a core, transformers would need to be extremely large.

The core:

- Allows compact designs with high power density

- Supports high voltage and current levels

- Makes modern power systems feasible

Core technology enables transformers to handle megawatts of power safely.

How Does Core Design Affect Transformer Efficiency?

Transformer efficiency is not determined by windings alone. Even when no load is connected, a transformer continuously consumes energy, and most of that energy loss originates in the core. Core design therefore plays a decisive role in overall efficiency, operating cost, and lifetime carbon footprint. Small differences in core material, geometry, and manufacturing quality can translate into large energy losses over decades of service.

Core design affects transformer efficiency by controlling no-load losses, magnetizing current, flux distribution, and heat generation, all of which directly influence total energy consumption.

Optimized transformer core design significantly reduces no-load losses and improves overall efficiency.True

High-quality materials and precise core geometry minimize hysteresis and eddy current losses.

Control of No-Load (Core) Losses

No-load losses occur whenever the transformer is energized.

Core design influences:

- Hysteresis loss from repeated magnetization cycles

- Eddy current loss induced within the core material

Low-loss materials and thin laminations directly reduce these losses, improving efficiency even at light load.

Influence of Core Material Selection

Material choice is fundamental to efficiency.

High-performance core materials offer:

- High magnetic permeability

- Low hysteresis loss

- High electrical resistivity

Grain-oriented silicon steel and amorphous alloys significantly outperform conventional steels in reducing core losses.

Effect of Lamination Thickness and Insulation

Core laminations are electrically insulated from each other.

Design benefits include:

- Suppression of circulating eddy currents

- Reduced heat generation

- Improved thermal stability

Thinner laminations generally lead to lower eddy current losses, enhancing efficiency.

Flux Density Optimization

Core geometry determines operating flux density.

Proper design:

- Avoids magnetic saturation

- Minimizes magnetizing current

- Balances loss and material cost

Excessive flux density increases losses and temperature, while overly conservative design increases size and cost.

Joint Design and Assembly Precision

Core joints are critical loss points.

Advanced techniques such as:

- Step-lap joint design

- Precision cutting and stacking

- Controlled clamping pressure

reduce flux disturbance and localized loss, improving efficiency and reducing noise.

Reduction of Magnetizing Current

Efficient core design lowers magnetizing current.

Benefits include:

- Lower reactive power demand

- Reduced no-load power consumption

- Improved system power factor

This is especially important in large power transformers connected continuously to the grid.

Impact on Thermal Performance

Losses generated in the core become heat.

Good core design:

- Produces less heat overall

- Reduces cooling system load

- Lowers operating temperature

Lower temperature directly improves insulation life and long-term efficiency.

Interaction with Load Losses

Although load losses occur in windings, core design still matters.

Efficient cores:

- Maintain stable flux under load

- Prevent local saturation that increases losses

- Support consistent voltage regulation

This contributes indirectly to better loaded efficiency.

Noise and Vibration Considerations

Core efficiency also affects acoustic performance.

Optimized design:

- Reduces magnetostriction effects

- Lowers vibration-induced losses

- Improves operational environment

Noise reduction often correlates with lower mechanical and magnetic losses.

Long-Term Energy and Cost Impact

Core losses accumulate over time.

Over a transformer’s lifetime:

- Even small efficiency gains save large amounts of energy

- Reduced losses lower carbon emissions

- Operating costs decrease significantly

Core design decisions made at manufacture determine decades of energy performance.

What Role Does the Core Play in Reducing Energy Losses?

In a transformer, energy losses are unavoidable, but their magnitude depends heavily on how well the magnetic circuit is designed. The transformer core is not just a structural element; it is the primary factor that determines no-load losses and strongly influences overall efficiency. A well-designed core minimizes wasted energy every second the transformer is energized, even when no power is being delivered to the load.

The transformer core reduces energy losses by providing a low-reluctance magnetic path, minimizing hysteresis and eddy current losses, and maintaining stable flux distribution during operation.

An optimized transformer core significantly reduces energy losses by minimizing hysteresis and eddy current effects.True

High-permeability, laminated core materials limit magnetic and circulating current losses.

Reduction of Hysteresis Losses

Hysteresis loss occurs due to repeated magnetization and demagnetization of the core.

The core reduces this loss by:

- Using materials with narrow hysteresis loops

- Maintaining stable magnetic domains

- Limiting unnecessary magnetic reversal energy

Grain-oriented silicon steel and amorphous alloys are especially effective in lowering hysteresis losses.

Limitation of Eddy Current Losses

Eddy currents are induced within conductive core materials.

Core design minimizes these losses through:

- Thin laminated sheets

- Electrical insulation between laminations

- High-resistivity magnetic materials

These measures restrict circulating currents and reduce heat generation.

Providing a Low-Reluctance Magnetic Path

Energy is lost when magnetic flux encounters high reluctance.

The core:

- Offers a continuous, low-reluctance path

- Concentrates flux within a controlled region

- Prevents flux leakage into surrounding structures

Lower reluctance reduces magnetizing current and associated losses.

Stabilization of Magnetic Flux Distribution

Unstable flux increases localized losses.

A well-designed core:

- Ensures uniform flux density

- Prevents localized saturation

- Reduces hot spots and uneven heating

This improves both efficiency and reliability.

Reduction of Magnetizing Current

Magnetizing current contributes to no-load loss.

The core:

- Requires less current to establish operating flux

- Reduces reactive power demand

- Improves system power factor

Lower magnetizing current directly lowers energy consumption.

Minimization of Core Joint Losses

Core joints are potential loss points.

Advanced joint designs:

- Step-lap configurations

- Precision cutting and stacking

- Optimized clamping

reduce flux disturbance and localized heating at joints.

Interaction with Cooling and Thermal Performance

Losses appear as heat.

Efficient core design:

- Generates less heat

- Reduces cooling system workload

- Maintains lower operating temperature

Lower temperature further reduces losses and slows insulation aging.

Impact on Lifetime Energy Consumption

Core losses occur continuously.

Over decades of operation:

- Even small reductions in no-load loss save significant energy

- Carbon emissions are reduced

- Operating costs decrease substantially

This makes core efficiency a key factor in lifecycle economics.

Contribution to Regulatory and Efficiency Standards

Modern efficiency standards focus on core losses.

Optimized cores help:

- Meet IEC and DOE efficiency requirements

- Achieve lower loss classifications

- Support grid efficiency and sustainability goals

Compliance increasingly depends on advanced core design.

How Do Different Core Types Influence Transformer Performance?

Although transformers may look similar from the outside, their internal core structures can be very different—and these differences have a profound impact on efficiency, losses, reliability, noise, size, and cost. Selecting the right core type is therefore a strategic engineering decision, not a cosmetic one. The core determines how magnetic flux flows, how losses are generated, and how the transformer behaves throughout its entire service life.

Different transformer core types influence performance by shaping magnetic flux paths, determining loss levels, affecting thermal and mechanical behavior, and defining efficiency, noise, and reliability characteristics.

Transformer core type has a direct impact on efficiency, losses, and operational reliability.True

Core geometry and material determine flux distribution, loss mechanisms, and thermal performance.

Core-Type Transformers and Their Performance Characteristics

Core-type transformers are the most widely used design in power applications.

In this structure:

- Windings surround the core limbs

- Magnetic flux flows primarily through the core limbs and yokes

- The magnetic circuit is relatively simple and direct

Performance impacts include:

- Good cooling access for windings

- Balanced efficiency and cost

- Reliable performance in medium- and high-voltage applications

Core-type designs are common in power and distribution transformers due to their flexibility and proven reliability.

Shell-Type Transformers and Their Performance Characteristics

Shell-type transformers use a different magnetic arrangement.

In this design:

- The core surrounds the windings

- Flux divides into multiple parallel paths

- Windings are more mechanically protected

Performance implications include:

- Excellent short-circuit withstand capability

- Lower leakage reactance

- Higher mechanical strength

Shell-type cores are often preferred in applications with high fault levels or where mechanical robustness is critical.

Grain-Oriented Steel Cores

Grain-oriented silicon steel cores are optimized for unidirectional flux.

Their influence on performance includes:

- Very low no-load (core) losses

- High magnetic permeability along rolling direction

- Reduced magnetizing current

These cores significantly improve efficiency, especially in transformers energized continuously.

Non-Grain-Oriented Steel Cores

Non-grain-oriented cores have uniform magnetic properties.

Performance characteristics include:

- Higher losses compared to grain-oriented steel

- Greater flexibility in flux direction

- Suitability for smaller or special-purpose transformers

They are less common in large power transformers due to higher core losses.

Amorphous Metal Core Transformers

Amorphous core transformers represent advanced low-loss technology.

Their performance advantages include:

- Extremely low no-load losses

- Superior efficiency at light load

- Reduced lifetime energy consumption and emissions

Trade-offs include:

- Higher material cost

- Larger core size

- More complex manufacturing

They are widely used where energy efficiency regulations are strict.

Laminated Core Construction vs Solid Cores

Transformer cores are always laminated rather than solid.

This construction:

- Reduces eddy current losses

- Improves thermal behavior

- Enhances long-term efficiency

Thinner laminations generally improve performance but increase manufacturing complexity.

Core Joint Design and Performance Impact

The way laminations are joined matters.

Advanced joint designs:

- Step-lap joints reduce flux disturbance

- Lower localized losses and noise

- Improve magnetic continuity

Poor joint design increases losses and vibration, degrading performance.

Influence on Thermal Performance

Different core types generate different heat levels.

Efficient core designs:

- Produce less heat

- Reduce cooling system demand

- Maintain lower operating temperature

Lower temperature directly improves insulation life and reliability.

Impact on Acoustic Noise

Core type strongly affects noise.

Key factors include:

- Magnetostriction behavior of material

- Core clamping and geometry

- Flux density distribution

Optimized cores reduce vibration and audible hum.

Effect on Size, Weight, and Cost

Core selection influences physical and economic factors.

High-efficiency cores:

- Reduce operating losses

- May increase initial cost

- Lower total lifecycle cost

Design trade-offs must balance efficiency, footprint, and budget.

Long-Term Reliability and Aging

Core performance affects aging indirectly.

Lower losses lead to:

- Reduced thermal stress

- Slower insulation aging

- Longer service life

Thus, core type influences not just efficiency but transformer longevity.

Conclusion

The core of a transformer serves as the magnetic backbone of the device, guiding and concentrating magnetic flux to ensure efficient energy transfer between windings. By minimizing magnetic reluctance and reducing losses such as hysteresis and eddy currents, the core directly impacts transformer efficiency, thermal performance, and service life. A well-designed core is therefore essential to achieving reliable, energy-efficient transformer operation across a wide range of applications.

FAQ

Q1: What is the primary function of the core in a transformer?

The primary function of the transformer core is to provide a low-reluctance path for magnetic flux generated by the primary winding. This allows magnetic flux to efficiently link the primary and secondary windings, enabling effective transfer of electrical energy through electromagnetic induction.

Without a core, much of the magnetic flux would leak into the surrounding air, significantly reducing efficiency and increasing losses. The core concentrates and directs the magnetic field so that most of it contributes to power transfer.

Q2: How does the transformer core enable electromagnetic induction?

When alternating current flows through the primary winding, it produces a changing magnetic field. The transformer core channels this magnetic flux through a closed magnetic circuit, ensuring it passes through the secondary winding.

According to Faraday’s Law, the changing magnetic flux induces a voltage in the secondary winding. The core ensures strong magnetic coupling between windings, which is essential for stable voltage transformation and efficient operation.

Q3: Why are transformer cores made from silicon steel laminations?

Transformer cores are typically made from laminated silicon steel because this material offers:

High magnetic permeability

Low hysteresis loss

Reduced eddy current loss

Good mechanical strength

Laminating the core into thin sheets insulated from each other limits circulating eddy currents, minimizing heat generation and improving efficiency. Silicon content further reduces core losses and improves magnetic performance.

Q4: How does the core reduce transformer losses?

The core helps reduce losses by:

Minimizing hysteresis loss through optimized magnetic material

Limiting eddy current loss via laminated construction

Ensuring efficient magnetic flux flow

Although core losses cannot be eliminated completely, advanced materials such as grain-oriented silicon steel or amorphous metal significantly reduce no-load losses, especially in distribution transformers.

Q5: What happens if a transformer core is poorly designed?

A poorly designed or damaged core can cause:

Excessive no-load losses

Increased noise and vibration

Overheating

Reduced efficiency

Premature insulation aging

In extreme cases, core saturation can occur, leading to distorted currents and potential protection system malfunctions. Proper core design is critical for reliable transformer operation.

Q6: Does the transformer core affect noise levels?

Yes. The transformer core contributes to audible noise due to magnetostriction, where the core material slightly expands and contracts as the magnetic field changes.

Good core design, tight clamping, and high-quality materials reduce vibration and noise. This is particularly important for transformers installed in urban areas, buildings, or noise-sensitive environments.

Q7: Are there different types of transformer cores?

Yes. Common transformer core types include:

Core-type – Windings surround the core limbs

Shell-type – Core surrounds the windings

Toroidal core – Circular core with very low leakage flux

Each type is selected based on efficiency, size, cost, and application requirements.

Q8: Can a transformer operate without a core?

While air-core transformers exist for special high-frequency applications, power transformers require a magnetic core to operate efficiently at power frequencies (50/60 Hz). Without a core, the transformer would be impractically large and inefficient due to poor magnetic coupling.

References

IEC 60076 – Power Transformers

https://webstore.iec.ch/publication/602

IEEE C57 Series – Transformer Design Standards

https://standards.ieee.org

Schneider Electric – Transformer Core and Losses

https://www.se.com

Electrical Engineering Portal – Transformer Core Explained

https://electrical-engineering-portal.com

NEMA – Transformer Design Fundamentals

https://www.nema.org

CIGRE – Transformer Core Loss Studies

https://www.cigre.org

Encyclopaedia Britannica – Transformer Core

https://www.britannica.com