Factory testing is a mandatory step in the manufacturing process of power and distribution transformers. It verifies that the transformer has been designed, manufactured, and assembled in accordance with applicable standards and customer specifications before it is energized in the field. Mandatory factory testing reduces technical risks, ensures safety, and protects both the manufacturer and the end user from costly failures after installation.

What Is Factory Testing in Transformer Manufacturing?

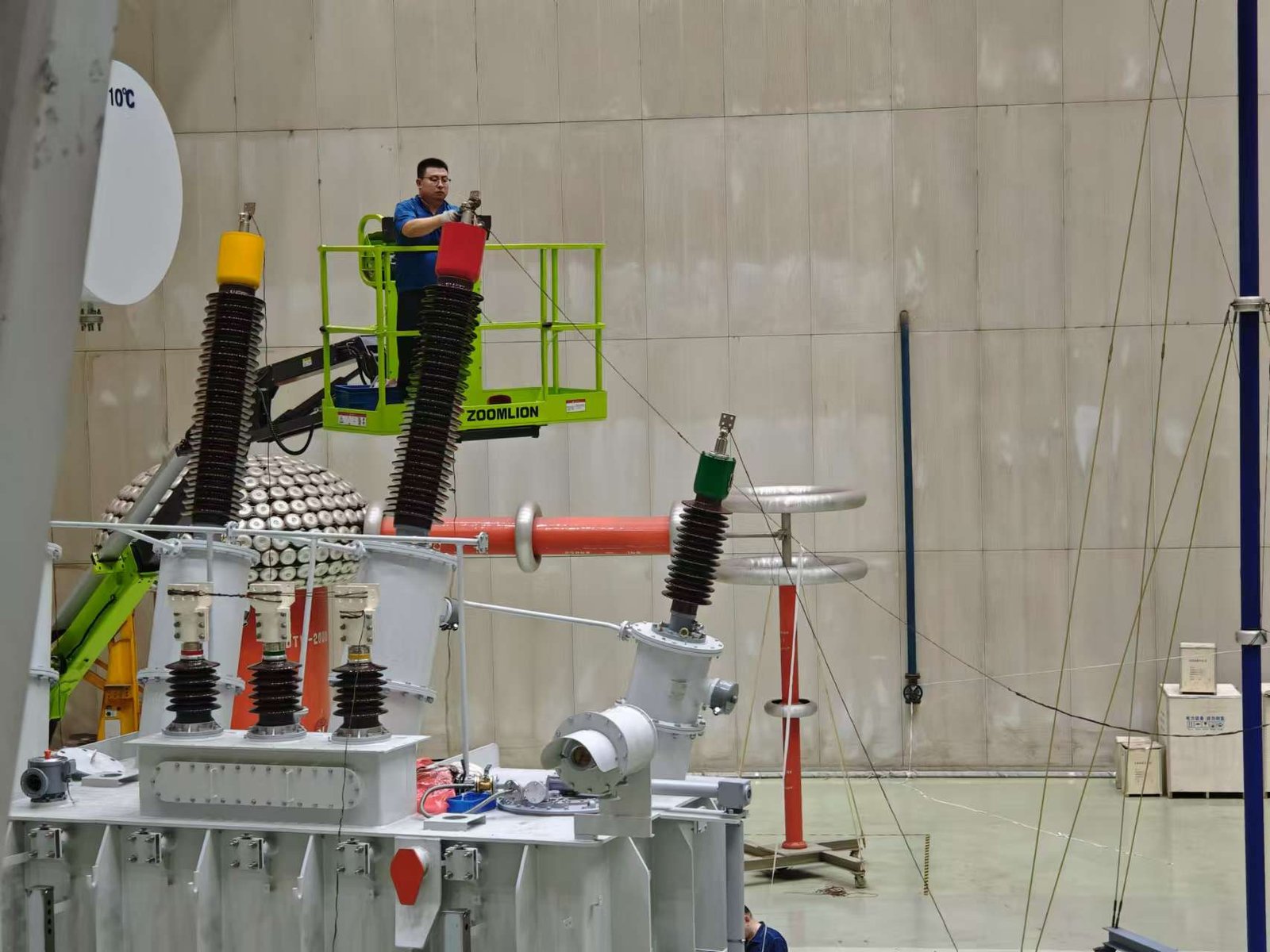

In transformer manufacturing, one of the greatest risks for utilities, EPC contractors, and industrial users is discovering defects only after installation. A transformer may appear robust externally, yet hidden issues in insulation, winding integrity, or core construction can lead to catastrophic failures once energized. The consequences include unplanned outages, safety hazards, costly replacements, and reputational damage. Factory testing exists precisely to prevent these outcomes. It is the final and most critical quality gate that verifies whether a transformer truly meets its design, performance, and safety requirements before it ever leaves the factory.

Factory testing in transformer manufacturing is a comprehensive series of standardized electrical, mechanical, and thermal tests performed at the manufacturer’s facility to verify compliance with design specifications, international standards, and customer requirements before shipment.

Factory testing is not a formality. It is the point at which design assumptions are validated, workmanship is proven, and long-term reliability is either confirmed or compromised.

Factory testing is essential to ensure transformer safety, reliability, and compliance before installation.True

Testing identifies defects and performance deviations that cannot be corrected economically after field installation.

Most transformer failures in early service life can be traced to manufacturing or assembly defects detectable during factory testing.True

Electrical and mechanical faults often originate from insulation, winding, or core issues that factory tests are designed to reveal.

Understanding the Purpose of Factory Testing

Factory testing serves multiple stakeholders simultaneously.

For manufacturers, it:

- Confirms workmanship quality

- Protects brand reputation

- Reduces warranty risk

For customers, it:

- Verifies contractual compliance

- Reduces commissioning risk

- Ensures long-term asset reliability

For regulators and insurers, it:

- Demonstrates compliance with standards

- Reduces safety and liability exposure

Factory testing is therefore a cornerstone of trust between transformer supplier and end user.

Factory Testing vs. Field Testing

It is important to distinguish factory testing from site commissioning tests.

Factory testing:

- Is performed under controlled conditions

- Uses calibrated, specialized equipment

- Allows correction of defects before delivery

Field testing:

- Confirms installation integrity

- Is limited in scope and test voltage

- Cannot correct manufacturing defects

A transformer that passes field tests but fails factory tests is already a latent risk.

International Standards Governing Factory Testing

Factory testing is strictly defined by international standards.

The most widely applied include:

- IEC 60076 series

- IEEE C57 series

- ANSI standards

- Customer or utility-specific specifications

These standards define:

- Test types

- Test sequences

- Acceptance criteria

- Measurement accuracy

Compliance ensures global consistency and comparability.

Classification of Factory Tests

Factory tests are typically divided into three main categories:

- Routine tests

- Type tests

- Special tests

Each category serves a different purpose and level of verification.

Routine Tests: Performed on Every Transformer

Routine tests are mandatory for every transformer manufactured.

They verify basic electrical integrity and performance.

Common routine tests include:

- Winding resistance measurement

- Voltage ratio and phase displacement test

- No-load loss and current measurement

- Load loss and impedance measurement

- Dielectric routine tests

These tests ensure that each individual transformer meets its guaranteed values.

| Routine Test | Purpose | Risk Mitigated |

|---|---|---|

| Winding resistance | Detect poor joints | Overheating |

| Ratio test | Verify turns ratio | Circulating currents |

| No-load loss | Core performance | Continuous losses |

| Load loss | Winding design | Thermal stress |

| Dielectric tests | Insulation integrity | Electrical failure |

Type Tests: Design Validation

Type tests are performed on representative units.

They validate that a design meets standard requirements.

Typical type tests include:

- Temperature rise test

- Lightning impulse test

- Switching impulse test (for high voltage)

Once a design is validated, identical units may not require repeated type testing unless design changes occur.

Special Tests: Application-Specific Assurance

Special tests are performed when required by customer or application.

Examples include:

- Partial discharge measurement

- Sound level measurement

- Zero-sequence impedance test

- Short-circuit withstand test

Special tests address specific risks such as noise limits, sensitive loads, or harsh grid conditions.

Electrical Performance Verification

Electrical tests confirm that the transformer performs as designed.

Key parameters verified include:

- Voltage ratio accuracy

- Impedance within tolerance

- Losses within guaranteed limits

These parameters directly affect efficiency, load sharing, and operating cost.

Dielectric Testing and Insulation Integrity

Dielectric tests are among the most critical.

They verify:

- Insulation strength

- Clearance and creepage distances

- Absence of partial discharge

Typical dielectric tests include:

- Applied AC voltage test

- Induced overvoltage test

- Impulse voltage test

Failure at this stage indicates serious insulation defects that could lead to catastrophic failure in service.

Mechanical Integrity and Assembly Quality

Factory testing also indirectly verifies mechanical quality.

Abnormal results may indicate:

- Loose windings

- Poor clamping

- Core vibration issues

Mechanical defects often manifest electrically under test conditions.

Temperature Rise and Thermal Design Validation

The temperature rise test is a cornerstone type test.

It verifies:

- Cooling system performance

- Hot-spot temperature limits

- Insulation class utilization

Excessive temperature rise accelerates aging and shortens service life.

Loss Measurement and Efficiency Guarantees

Loss testing has direct economic and environmental impact.

Losses are:

- Guaranteed contractually

- Used for efficiency and net-zero assessments

- Converted into lifetime operating cost

Accurate factory measurement is essential for fair comparison and compliance.

Noise and Vibration Testing

Transformer noise is a growing concern in urban and renewable applications.

Sound level tests:

- Verify compliance with noise limits

- Identify core or mechanical resonance issues

Excessive noise often indicates deeper mechanical problems.

Partial Discharge Testing

Partial discharge is a key indicator of insulation quality.

PD tests:

- Detect voids, contamination, or sharp edges

- Predict long-term dielectric reliability

Low PD levels are critical for high-voltage and digital substations.

Quality Control and Documentation

Factory testing is inseparable from documentation.

Test reports include:

- Measured values

- Acceptance criteria

- Deviations and corrective actions

These records become part of the transformer’s lifetime technical file.

Witness Testing and Customer Involvement

Many customers require witness testing.

This allows:

- Transparency and confidence

- Immediate clarification of results

- Acceptance at factory before shipment

Witness testing reduces disputes and delays later.

Risk Reduction Through Factory Testing

The cost of factory testing is minimal compared to failure costs.

Factory testing prevents:

- Site rework

- Emergency replacement

- Environmental and safety incidents

It is one of the highest ROI activities in transformer procurement.

Factory Testing and Net-Zero Objectives

From a net-zero perspective, factory testing plays a critical role.

By ensuring:

- Guaranteed low losses

- Correct cooling performance

- Long service life

factory testing supports:

- Reduced lifecycle emissions

- Lower replacement frequency

- Reliable renewable integration

A poorly tested transformer undermines decarbonization goals.

Typical Factory Test Flow

| Stage | Activity | Outcome |

|---|---|---|

| Pre-test inspection | Visual and dimensional checks | Assembly verified |

| Electrical routine tests | Core and winding verification | Compliance confirmed |

| Dielectric tests | Insulation strength | Safety assured |

| Type/special tests | Design validation | Application fit |

| Final review | Documentation and acceptance | Release for shipment |

Consequences of Inadequate Factory Testing

Skipping or minimizing factory testing can lead to:

- Early-life failures

- Warranty disputes

- Safety incidents

- Regulatory non-compliance

In many jurisdictions, inadequate testing exposes both manufacturer and owner to legal liability.

Why Is Factory Testing Required by International Standards?

In global power systems, a single transformer failure can cascade into outages, safety incidents, environmental damage, and massive financial loss. The pain point faced by utilities, regulators, and insurers is simple but severe: once a transformer is installed and energized, correcting hidden defects becomes extremely expensive or impossible. The consequence of insufficient verification is early-life failure, shortened service life, and loss of confidence in power infrastructure. International standards therefore mandate factory testing as the solution—ensuring every transformer is proven safe, compliant, and fit for decades of operation before it ever leaves the manufacturer’s facility.

Factory testing is required by international standards to verify safety, performance, insulation integrity, and contractual compliance under controlled conditions, thereby minimizing technical risk, protecting public safety, and ensuring long-term reliability of power systems.

This requirement is not optional or regional; it is a globally accepted foundation of transformer engineering.

International standards require factory testing to detect manufacturing defects before transformers are installed in service.True

Defects identified after installation are costly, dangerous, and often impossible to repair effectively.

Factory testing is a primary risk-control mechanism mandated by IEC and IEEE standards.True

Standards recognize factory testing as essential for grid reliability, safety, and asset lifecycle assurance.

The Role of International Standards in Power Infrastructure

International standards such as IEC and IEEE exist to protect entire power systems, not just individual assets.

They aim to:

- Ensure interoperability across borders

- Maintain consistent safety margins

- Reduce systemic risk in interconnected grids

- Protect utilities, users, and the public

Transformers are high-value, high-risk assets. As a result, standards impose stricter verification requirements than for most electrical equipment.

Why Design Compliance Alone Is Not Enough

A transformer can fully comply on paper yet still fail in practice.

Design calculations cannot guarantee:

- Correct assembly

- Clean insulation systems

- Proper clamping and mechanical integrity

- Absence of manufacturing defects

Factory testing is required because standards recognize that manufacturing variability exists, even in high-quality factories. Testing is the only way to validate real-world execution.

Controlled Conditions Are Essential

International standards explicitly require factory testing because of environmental control.

Factories provide:

- Stable temperature and humidity

- Calibrated test equipment

- Controlled voltage and frequency sources

- Repeatable test conditions

Field environments cannot replicate these conditions reliably, making factory testing the only trustworthy verification stage.

Safety as a Primary Driver

Transformers operate at extremely high voltages and energy levels.

Factory testing verifies:

- Dielectric strength

- Clearance and creepage distances

- Insulation coordination

Without mandatory factory dielectric testing, latent insulation defects could lead to:

- Explosions

- Fires

- Fatal electric shock

Standards prioritize public and operator safety, making factory testing non-negotiable.

Verification of Insulation Integrity

Insulation failure is the leading cause of transformer breakdown.

International standards require:

- Applied voltage tests

- Induced overvoltage tests

- Impulse tests for high-voltage units

These tests stress insulation beyond normal operating levels to ensure adequate safety margins. No other method provides equivalent assurance.

Ensuring Long-Term Reliability

Power transformers are expected to operate for 30–40 years or more.

Factory testing:

- Screens out early-life failures

- Identifies workmanship defects

- Confirms thermal and electrical margins

Standards require testing because reliability is a system-level concern; failures affect entire networks, not just owners.

Economic Risk Management

Transformer failures are extraordinarily expensive.

Costs include:

- Emergency replacement

- Outage penalties

- Environmental cleanup

- Legal liability

International standards mandate factory testing to reduce these risks systematically, protecting utilities and insurers alike.

Global Consistency and Fair Trade

Standards ensure that transformers built in different countries are evaluated consistently.

Factory testing requirements:

- Create a common technical language

- Prevent unfair cost-cutting

- Ensure performance guarantees are meaningful

Without standardized testing, equipment comparison would be unreliable and markets distorted.

Routine Tests: Mandatory for Every Unit

International standards require routine tests on every transformer because each unit is unique.

Routine tests verify:

- Winding resistance

- Voltage ratio and vector group

- No-load and load losses

- Dielectric integrity

| Reason for Mandatory Routine Tests | Risk Addressed |

|---|---|

| Manufacturing variability | Hidden defects |

| Assembly differences | Performance deviation |

| Material inconsistency | Premature aging |

Standards do not allow sampling in place of routine tests for critical assets.

Type Tests: Design Validation for Safety Margins

Type tests are required to validate that a design concept meets minimum safety and performance thresholds.

They confirm:

- Temperature rise limits

- Short-circuit withstand capability

- Impulse voltage tolerance

Once validated, the design may be reused, but only if manufacturing consistency is maintained.

Special Tests: Application-Specific Risk Control

Standards allow or recommend special tests when risk exposure is higher.

Examples include:

- Partial discharge tests for HV systems

- Sound level tests for urban installations

- Zero-sequence impedance tests for grounding systems

This flexibility ensures standards remain robust across diverse applications.

Protection of Grid Stability

Transformers are core elements of grid stability.

Factory testing ensures:

- Correct impedance for load sharing

- Accurate voltage ratio for synchronization

- Predictable loss behavior

Poorly tested transformers can destabilize parallel operation and increase system losses.

Legal and Regulatory Enforcement

In many jurisdictions, compliance with IEC or IEEE standards is legally binding.

Failure to perform required factory tests may result in:

- Regulatory penalties

- Insurance denial

- Legal liability after failure

Standards therefore function as both technical and legal frameworks.

Insurance and Risk Underwriting

Insurers rely heavily on standards compliance.

Factory testing:

- Reduces underwriting risk

- Is often a prerequisite for coverage

- Influences premium levels

Transformers without proper factory test records may be uninsurable.

Environmental and Net-Zero Considerations

Modern standards increasingly align with sustainability goals.

Factory testing supports net-zero by:

- Verifying guaranteed low losses

- Ensuring efficient cooling performance

- Preventing premature replacement

A transformer that fails early wastes embodied carbon and undermines decarbonization efforts.

Documentation and Traceability

International standards require comprehensive test documentation.

This ensures:

- Traceability across the transformer lifecycle

- Evidence of due diligence

- Confidence during audits and investigations

Documentation is as important as the test itself.

Consequences of Skipping Factory Testing

Standards exist because history has proven the risks.

Without factory testing:

- Early failures increase dramatically

- System reliability degrades

- Public safety is compromised

International standards are built on decades of failure analysis and lessons learned.

Why Factory Testing Cannot Be Replaced by Field Testing

Field tests are limited by:

- Lower test voltages

- Environmental variability

- Inability to disassemble or correct defects

Standards therefore treat field testing as complementary, not substitutive.

How Does Factory Testing Ensure Electrical and Mechanical Safety?

In power transformer manufacturing, the most dangerous risks are often invisible. A transformer may look structurally sound, yet hidden insulation defects, loose windings, or inadequate mechanical clamping can trigger catastrophic failure once the unit is energized or subjected to a system fault. The consequences are severe: electrical explosions, fires, oil leakage, long outages, injuries, and extensive financial loss. Factory testing exists to eliminate these hidden dangers. It is the only stage where both electrical safety and mechanical safety can be systematically verified under controlled, repeatable conditions before the transformer is exposed to real grid stresses.

Factory testing ensures electrical and mechanical safety by deliberately stressing insulation systems, windings, cores, and structural components under controlled conditions to confirm that the transformer can withstand normal operation, abnormal events, and long-term service without failure.

This safety assurance is the reason factory testing is mandated by IEC, IEEE, and other international standards.

Factory testing is the primary method used to verify transformer electrical insulation safety before energization.True Dielectric tests expose insulation weaknesses that could lead to breakdown, fire, or explosion in service. Mechanical defects in transformers are often detected indirectly through electrical factory tests before they cause in-service failures.True Abnormal test results frequently indicate loose windings, poor clamping, or structural instability.

Electrical Safety: Preventing Dielectric Failure and Electrical Hazards

Electrical safety is the first and most critical objective of factory testing because insulation failure is the most dangerous transformer failure mode.

Factory electrical tests verify that insulation can withstand:

- Normal operating voltage

- Temporary overvoltages

- Switching transients

- Lightning impulses

Without these verifications, a transformer becomes a latent safety hazard.

Dielectric Tests: The Foundation of Electrical Safety

Dielectric testing intentionally stresses the insulation system beyond normal operating conditions.

Key dielectric tests include:

- Applied AC voltage test (verifies insulation to ground)

- Induced overvoltage test (verifies inter-turn and inter-layer insulation)

- Impulse voltage test (verifies resistance to lightning and switching surges)

These tests ensure that insulation clearances, creepage distances, and material integrity meet strict safety margins.

| Dielectric Test | Safety Risk Addressed | Failure Consequence |

|---|---|---|

| Applied voltage | Ground insulation failure | Fire, explosion |

| Induced voltage | Turn-to-turn breakdown | Internal arcing |

| Impulse test | Surge withstand failure | Catastrophic rupture |

A transformer that fails any dielectric test is fundamentally unsafe for service.

Partial Discharge Testing: Detecting Invisible Electrical Defects

Partial discharge (PD) is an early indicator of insulation weakness.

Factory PD tests:

- Detect voids, sharp edges, or contamination

- Identify defects before full breakdown occurs

- Prevent long-term insulation erosion

Low PD levels confirm that the insulation system will remain electrically safe throughout its service life.

Verification of Electrical Clearances and Insulation Coordination

Factory testing confirms that real, manufactured clearances match design intent.

Electrical safety depends on:

- Correct spacing between live parts

- Proper insulation grading

- Absence of unintended conductive paths

Testing validates that manufacturing tolerances have not compromised safety margins.

Mechanical Safety: Preventing Structural Failure Under Electrical Stress

Mechanical safety in transformers is inseparable from electrical safety.

High electrical forces occur during:

- Short-circuit events

- Inrush current during energization

- System faults

These forces can deform windings, loosen clamping structures, and damage insulation if mechanical integrity is inadequate.

Winding Resistance and Ratio Tests as Mechanical Indicators

Although classified as electrical tests, these also reveal mechanical issues.

Abnormal results may indicate:

- Loose connections

- Displaced windings

- Poor brazing or joints

Such defects can lead to localized overheating and eventual failure.

Short-Circuit Withstand Capability and Mechanical Robustness

International standards require that transformer designs withstand severe short-circuit forces.

Factory type testing and design validation ensure:

- Windings are properly braced

- Axial and radial forces are safely absorbed

- Core and coil structures remain stable

Mechanical failure during a short circuit is often violent and destructive, making this verification essential for safety.

Core and Clamping System Stability

Mechanical instability in the core can cause:

- Excessive vibration

- Noise

- Insulation abrasion

Factory tests such as:

- No-load current measurement

- Sound level testing

can reveal core looseness or poor clamping that would otherwise lead to long-term mechanical degradation.

Temperature Rise Testing: Thermal Safety and Mechanical Integrity

Temperature rise tests validate the transformer’s thermal design.

They ensure:

- Windings and insulation remain within safe temperature limits

- Mechanical materials do not soften or deform

- Thermal expansion does not loosen clamping systems

Excessive temperature accelerates insulation aging and weakens mechanical structures, directly compromising safety.

Oil and Cooling System Safety

For oil-immersed transformers, factory testing verifies:

- Oil quality and dielectric strength

- Leak-tightness of tanks and radiators

- Proper oil circulation

Oil system failure can lead to:

- Fire hazards

- Environmental contamination

- Loss of insulation strength

Factory testing ensures these risks are minimized before shipment.

Vibration and Noise as Mechanical Safety Indicators

Abnormal noise or vibration during factory tests often indicates:

- Loose components

- Resonance issues

- Structural weaknesses

Identifying these issues at the factory prevents progressive mechanical damage during operation.

Integration of Electrical and Mechanical Safety

Electrical and mechanical safety are not independent.

For example:

- Mechanical movement can damage insulation

- Electrical overheating can weaken mechanical supports

Factory testing evaluates the transformer as an integrated system, not as isolated components.

Controlled Test Conditions: Why Safety Verification Must Happen at the Factory

Factory environments provide:

- Stable temperature and humidity

- Precisely controlled test voltages

- Full access to the transformer for correction

Field testing cannot safely reproduce many of the stress conditions required to validate safety margins.

Documentation and Traceability for Safety Assurance

Every safety-related test result is documented.

These records:

- Prove compliance with standards

- Support insurance and regulatory requirements

- Enable root-cause analysis if issues arise later

Documentation is part of the safety system itself.

Prevention of Early-Life Failures

Most dangerous transformer failures occur early in service.

Factory testing:

- Screens out manufacturing defects

- Eliminates weak insulation systems

- Confirms mechanical robustness

This dramatically reduces the risk of explosive or fire-related incidents shortly after energization.

Protection of Personnel and Public Safety

Transformer failures can endanger:

- Substation operators

- Maintenance personnel

- Nearby communities

International standards require factory testing primarily to protect human life, not just equipment.

Economic and Environmental Safety Implications

Safety failures have cascading impacts:

- Emergency outages

- Oil spills

- Fire damage

- Carbon-intensive replacement

Factory testing prevents these secondary harms by ensuring safe, stable operation from day one.

Factory Testing vs. In-Service Protection Systems

Protection relays respond after a fault begins.

Factory testing prevents faults from occurring in the first place by eliminating latent defects.

Both are necessary, but factory testing is the first and most critical safety barrier.

Consequences of Inadequate Safety Testing

If factory testing is skipped or poorly executed:

- Electrical breakdown risk increases

- Mechanical collapse during faults becomes likely

- Legal and insurance liability escalates

History shows that most catastrophic transformer failures trace back to undetected manufacturing defects.

Role in Net-Zero and Sustainable Power Systems

From a sustainability perspective, safety is also a carbon issue.

A failed transformer:

- Wastes embodied carbon

- Requires emergency manufacturing

- Disrupts renewable energy supply

Factory testing ensures transformers operate safely for decades, supporting net-zero goals through durability and reliability.

What Risks Are Prevented by Mandatory Factory Testing?

In power transformer projects, the most dangerous risks are not the ones engineers can easily see—they are the hidden defects that remain dormant until the transformer is energized, overloaded, or exposed to a fault. When these risks materialize in service, the consequences are often severe: catastrophic failures, fires, oil spills, grid outages, regulatory penalties, and irreversible reputational damage. Mandatory factory testing exists precisely to eliminate these risks before a transformer ever reaches the field. It is a preventive safeguard embedded into international standards to protect power systems, people, and investments from avoidable failure.

Mandatory factory testing prevents electrical, mechanical, thermal, environmental, operational, financial, and legal risks by detecting manufacturing defects, design nonconformities, and hidden weaknesses under controlled conditions before installation.

Factory testing is therefore not a procedural requirement—it is a risk-control system built on decades of failure analysis and operational experience.

Mandatory factory testing prevents the majority of early-life transformer failures by detecting defects before installation.True International failure statistics show that most early transformer failures originate from manufacturing or assembly defects detectable during factory tests. Skipping or reducing factory testing significantly increases the likelihood of catastrophic transformer failure in service.True Undetected insulation, mechanical, or thermal defects can escalate rapidly once a transformer is energized under real grid conditions.

Electrical Breakdown and Insulation Failure Risks

One of the most critical risks prevented by mandatory factory testing is electrical insulation failure.

Transformers operate under:

- High continuous voltages

- Temporary overvoltages

- Switching transients

- Lightning impulses

Factory dielectric tests deliberately stress insulation beyond normal operating levels to ensure adequate safety margins. These tests prevent:

- Internal arcing

- Flashover

- Explosions and fires

Without mandatory testing, insulation defects such as voids, contamination, or incorrect clearances would remain undetected until catastrophic failure occurs.

Partial Discharge and Progressive Insulation Degradation

Partial discharge is a silent killer in transformers.

Mandatory factory PD testing prevents:

- Long-term insulation erosion

- Sudden dielectric collapse after years of operation

- Hidden aging mechanisms that shorten service life

By eliminating PD sources at the factory, standards prevent failures that would otherwise appear random and unexplainable in the field.

Mechanical Failure During Short Circuits

Short-circuit forces inside transformers are extreme.

They can:

- Radially deform windings

- Axially displace coils

- Damage insulation and spacers

Mandatory factory testing and design validation prevent:

- Winding collapse during faults

- Internal mechanical damage leading to secondary electrical failure

- Violent tank rupture under fault conditions

Mechanical robustness is a safety requirement, not a design luxury.

Overheating and Thermal Runaway Risks

Thermal stress is a leading cause of transformer aging and failure.

Mandatory temperature rise and loss tests prevent:

- Undersized cooling systems

- Excessive hot-spot temperatures

- Accelerated insulation degradation

By verifying thermal performance at the factory, standards prevent transformers from entering service already operating near unsafe thermal limits.

Continuous Energy Loss and Efficiency Risks

Transformer losses occur continuously.

Mandatory loss measurement prevents:

- Delivery of inefficient transformers

- Excess operating costs over decades

- Unnecessary carbon emissions

Loss guarantees verified during factory testing protect utilities from lifetime financial and environmental penalties.

| Risk Without Testing | Prevented by Factory Testing |

|---|---|

| Excessive core losses | No-load loss measurement |

| High copper losses | Load loss testing |

| Cooling inefficiency | Temperature rise test |

Fire and Explosion Hazards

Transformer failures can result in fires and explosions, particularly in oil-immersed units.

Mandatory factory testing prevents:

- Insulation breakdown leading to arcing

- Oil ignition due to localized overheating

- Tank rupture under internal pressure

Fire prevention is a primary driver behind strict testing requirements in international standards.

Environmental Contamination and Oil Leakage

Environmental risks are often overlooked until incidents occur.

Factory testing prevents:

- Oil leaks from poor welding or sealing

- Dielectric oil contamination

- Increased risk of soil and groundwater pollution

Preventing leaks at the factory avoids costly cleanup, regulatory fines, and long-term environmental liability.

Grid Instability and System-Level Risks

Transformers are not isolated assets.

Poorly tested transformers can cause:

- Voltage instability

- Circulating currents in parallel operation

- Incorrect impedance affecting fault levels

Mandatory factory testing prevents system-wide risks by ensuring each transformer behaves predictably within the grid.

Early-Life Failures and “Infant Mortality”

The most dangerous transformer failures often occur shortly after energization.

Mandatory factory testing prevents:

- Early-life catastrophic failures

- Emergency outages

- Immediate warranty disputes

By eliminating latent defects, factory testing shifts failure probability far into the future, where risks are lower and more manageable.

Financial and Investment Risks

Transformers are among the most expensive grid assets.

Factory testing prevents:

- Costly replacement or repair

- Project delays and liquidated damages

- Loss of return on infrastructure investment

The cost of testing is negligible compared to the financial impact of a single failure.

Legal, Regulatory, and Compliance Risks

In many jurisdictions, compliance with IEC or IEEE standards is mandatory.

Skipping factory testing exposes owners to:

- Regulatory penalties

- Loss of operating permits

- Legal liability after accidents

Factory test records serve as legal evidence of due diligence.

Insurance and Liability Risks

Insurers closely scrutinize transformer testing records.

Mandatory factory testing prevents:

- Denial of insurance coverage

- Increased premiums

- Disputes after incidents

A transformer without documented factory tests is often considered uninsurable.

Operational and Maintenance Risks

Poorly tested transformers require:

- Increased monitoring

- Frequent maintenance

- Unplanned outages

Factory testing prevents excessive operational burden by ensuring stable, predictable behavior from day one.

Reputational and Public Trust Risks

High-profile transformer failures damage trust.

Mandatory factory testing prevents:

- Public safety incidents

- Media exposure from fires or outages

- Loss of stakeholder confidence

Reputation risk is especially critical for utilities and infrastructure operators.

Net-Zero and Sustainability Risks

From a sustainability perspective, failures are carbon-intensive events.

Mandatory factory testing prevents:

- Premature scrapping of assets

- Emergency manufacturing and transport emissions

- Disruption of renewable energy delivery

Reliable, long-lived transformers are essential to net-zero power systems.

Risks Associated With Global Supply Chains

Global sourcing increases variability in materials and workmanship.

Mandatory factory testing acts as:

- A universal quality filter

- A safeguard against inconsistent manufacturing practices

- A mechanism to ensure global equivalence

Standards-level testing prevents weak links in global supply chains.

Comparative Risk Profile

| Scenario | Risk Level |

|---|---|

| Transformer with full factory testing | Low |

| Limited or selective testing | Medium |

| No factory testing | High |

This risk gradient explains why international standards do not allow factory testing to be optional.

Why Field Testing Cannot Replace Factory Testing

Field tests cannot:

- Apply full dielectric stress

- Replicate controlled conditions

- Correct manufacturing defects

Mandatory factory testing prevents risks that field testing can only react to after damage has already begun.

Lessons From Historical Failures

International standards are built on failure history.

Most catastrophic transformer incidents trace back to:

- Undetected insulation defects

- Mechanical weakness

- Thermal misdesign

Mandatory factory testing directly addresses these root causes.

How Does Factory Testing Protect Customers and Utilities?

In modern power systems, customers and utilities face a shared but often underestimated risk: the failure of critical equipment that was assumed to be reliable. A transformer failure does not only damage hardware—it interrupts electricity supply, threatens public safety, triggers regulatory scrutiny, and creates long-lasting financial and reputational consequences. The pain point is clear: once a transformer is installed and energized, defects are expensive, dangerous, and sometimes impossible to fix without major outages. Factory testing exists to prevent this scenario. It is the last and most powerful line of defense protecting both utilities and end users before equipment enters service.

Factory testing protects customers and utilities by verifying safety, performance, reliability, efficiency, and compliance under controlled conditions, ensuring transformers operate as intended throughout their service life without exposing stakeholders to avoidable risks.

Factory testing transforms uncertainty into assurance, shifting risk away from the grid, the utility balance sheet, and the people who depend on uninterrupted power.

Factory testing is not merely a technical process—it is a customer protection mechanism embedded in international standards.

Factory testing significantly reduces the probability of in-service transformer failure during the early and mid-life stages.True

Testing identifies manufacturing, insulation, and assembly defects that are the primary causes of premature failures.

Utilities relying on fully factory-tested transformers experience lower outage frequency and reduced lifecycle costs.True

Verified electrical and thermal performance reduces unexpected maintenance, failures, and efficiency losses.

Protection of Electrical Safety for Customers

The most fundamental protection factory testing provides is electrical safety.

For customers, unsafe transformers can cause:

- Overvoltages

- Equipment damage

- Fire hazards

- Personal injury

Factory dielectric tests ensure:

- Adequate insulation strength

- Correct clearances and creepage distances

- Resistance to switching and lightning impulses

By proving electrical safety before delivery, factory testing prevents dangerous conditions from ever reaching customer premises.

Prevention of Catastrophic Failures for Utilities

For utilities, transformer failure is one of the most severe operational risks.

Factory testing protects utilities by preventing:

- Internal short circuits

- Winding collapse under fault conditions

- Explosive failures of oil-filled units

Controlled factory tests expose weaknesses safely, where corrective action is possible without service disruption.

Assurance of Grid Reliability and Continuity of Supply

Customers expect continuous power.

Factory testing protects supply reliability by ensuring:

- Correct voltage ratios

- Stable impedance values

- Predictable behavior under load

Utilities rely on this predictability to:

- Maintain voltage regulation

- Balance loads

- Prevent cascading failures

Without factory testing, grid reliability becomes dependent on chance.

Protection Against Early-Life (“Infant Mortality”) Failures

Early failures are the most disruptive and costly.

Factory testing protects customers and utilities by:

- Eliminating latent defects

- Reducing failure probability immediately after energization

- Ensuring stable commissioning

This protection avoids emergency outages that often occur during the first months of operation.

Thermal Safety and Long-Term Reliability Protection

Excessive temperature accelerates insulation aging.

Factory temperature rise tests protect stakeholders by:

- Verifying cooling system performance

- Confirming hot-spot temperatures remain within limits

- Ensuring long insulation life

This translates into decades of reliable service rather than premature replacement.

Financial Protection Through Verified Performance

Transformers operate continuously, making efficiency critical.

Factory testing protects utilities financially by:

- Verifying no-load and load losses

- Ensuring contractual efficiency guarantees

- Preventing hidden lifetime energy costs

For customers, this protection means:

- Stable tariffs

- Lower system losses

- Reduced carbon-related charges

| Protection Area | Customer Benefit | Utility Benefit |

|---|---|---|

| Loss testing | Lower energy costs | Guaranteed efficiency |

| Thermal testing | Reliable supply | Longer asset life |

| Dielectric testing | Safety | Reduced failure risk |

Environmental Protection and ESG Compliance

Transformer failures can cause oil spills and fires.

Factory testing protects:

- Soil and groundwater

- Public health

- Utility ESG commitments

Leak testing, oil quality verification, and insulation checks reduce environmental incident risk.

Legal and Regulatory Risk Protection

Utilities operate under strict regulation.

Factory testing protects by:

- Demonstrating compliance with IEC/IEEE standards

- Providing auditable test records

- Reducing legal exposure after incidents

Customers are indirectly protected by:

- Higher safety margins

- Regulatory oversight enforcement

Test certificates are often critical legal documents.

Insurance and Risk Transfer Protection

Insurance providers assess risk carefully.

Factory testing protects utilities by:

- Maintaining insurability

- Reducing premiums

- Avoiding claim disputes

Without documented testing, insurance coverage may be limited or denied after failures.

Protection of Parallel Operation and System Stability

Modern grids rely on parallel transformer operation.

Factory testing protects system stability by ensuring:

- Correct impedance

- Phase alignment

- Load-sharing capability

This prevents:

- Circulating currents

- Overloading of individual units

- Unplanned outages

Protection Against Manufacturing Variability

Global supply chains introduce variability.

Factory testing protects customers and utilities by:

- Acting as a universal quality checkpoint

- Ensuring consistency regardless of manufacturing location

- Detecting material or workmanship deviations

This is especially critical for large infrastructure projects.

Operational and Maintenance Cost Protection

Poorly tested transformers demand more attention.

Factory testing reduces:

- Unexpected maintenance

- Emergency repairs

- Spare unit requirements

Utilities benefit from predictable operation, while customers benefit from uninterrupted service.

Protection of Utility Reputation and Public Trust

Public confidence depends on reliability.

Factory testing protects reputation by:

- Preventing high-profile failures

- Avoiding media scrutiny after accidents

- Demonstrating responsible asset management

Trust, once lost, is difficult to regain.

Protection of Long-Term Investment Value

Transformers are long-term capital assets.

Factory testing protects investment by:

- Ensuring design life is achievable

- Avoiding premature replacement

- Preserving asset value

For customers, this protection supports stable, long-term energy pricing.

Net-Zero and Sustainability Protection

Failures are carbon-intensive events.

Factory testing supports net-zero goals by:

- Preventing early scrapping

- Reducing emergency manufacturing emissions

- Ensuring efficient energy delivery

Reliable transformers are essential for renewable integration and decarbonization.

Why Factory Testing Protects Better Than Field Testing

Field testing is limited.

Factory testing protects more effectively because it:

- Applies full dielectric stress

- Uses controlled conditions

- Allows corrective action before service

Once installed, many defects can no longer be corrected safely.

Shared Protection Across the Value Chain

Factory testing benefits:

- Utilities (reliability, compliance, cost control)

- Customers (safety, continuity, power quality)

- Regulators (standard enforcement)

- Insurers (risk reduction)

This shared protection is why testing is mandatory.

Why Is Factory Testing Critical Before Shipment and Commissioning?

In large-scale power projects, the most expensive problems are rarely caused by obvious design mistakes—they are caused by hidden defects that escape detection until the transformer is energized on site. At that point, the consequences are severe: delayed commissioning, emergency outages, fire and safety hazards, contractual disputes, and massive financial losses. The pain point for utilities, EPC contractors, and industrial customers is simple but critical: once a transformer leaves the factory, correcting defects becomes exponentially more difficult, costly, and risky. Factory testing exists to eliminate this risk window. It is the final technical, safety, and commercial checkpoint before shipment and commissioning, ensuring that what arrives on site is proven, compliant, and ready for long-term service.

Factory testing is critical before shipment and commissioning because it verifies electrical safety, mechanical integrity, thermal performance, efficiency, and standards compliance under controlled conditions, eliminating latent defects that cannot be safely or economically corrected after installation.

Before a transformer is transported, installed, and connected to a live grid, factory testing converts theoretical design compliance into proven operational reality.

Factory testing is not an optional quality step; it is the bridge between manufacturing and real-world operation.

Factory testing is the last opportunity to detect and correct transformer defects before they become high-risk field failures.True

Once shipped and installed, many defects cannot be corrected without major outages, disassembly, or complete replacement.

Transformers that undergo full factory testing have significantly lower commissioning delays and early-life failure rates.True

Pre-shipment testing removes latent electrical, mechanical, and thermal defects that typically surface during commissioning or early operation.

Preventing Shipment of Defective Equipment

The most fundamental reason factory testing is critical before shipment is risk containment.

Before shipment, defects can be:

- Identified safely

- Corrected efficiently

- Verified conclusively

After shipment, the same defects may lead to:

- Site rejection

- Costly return logistics

- Schedule overruns

Factory testing ensures that only conforming transformers leave the manufacturing facility, protecting all downstream stakeholders.

Protecting Commissioning Safety

Commissioning is the first time a transformer is exposed to full operating stress.

Factory testing protects commissioning by:

- Verifying dielectric strength against overvoltages

- Confirming correct voltage ratio and vector group

- Ensuring insulation integrity

Without factory testing, commissioning becomes a dangerous diagnostic exercise rather than a controlled energization process.

Eliminating Electrical Failure Risks Before Energization

Electrical defects are among the most dangerous.

Factory testing before shipment prevents:

- Insulation breakdown

- Internal arcing

- Flashover and fire

High-voltage dielectric and impulse tests intentionally stress the transformer beyond normal operating conditions to confirm adequate safety margins before it ever reaches site.

Ensuring Mechanical Robustness for Transport and Fault Conditions

Transformers experience severe mechanical stress during:

- Transportation

- Installation

- Short-circuit events

Factory testing and inspections verify:

- Winding clamping integrity

- Core stability

- Structural strength

This is critical because mechanical damage during shipment often remains invisible until electrical failure occurs.

Avoiding Commissioning Delays and Project Penalties

Delays during commissioning are extremely costly.

Factory testing protects project schedules by:

- Preventing on-site troubleshooting

- Avoiding re-testing under limited conditions

- Ensuring predictable energization

For EPC projects, this protection directly reduces liquidated damages and contractual penalties.

Verifying Thermal Performance Before Site Constraints Apply

Thermal performance cannot be fully assessed on site.

Factory temperature rise tests verify:

- Cooling system effectiveness

- Hot-spot temperature limits

- Compliance with insulation class

Once installed, thermal deficiencies are difficult or impossible to correct without redesign.

Confirming Efficiency and Lifetime Energy Performance

Transformer losses operate continuously.

Factory loss testing before shipment:

- Verifies guaranteed efficiency

- Prevents hidden lifetime energy costs

- Protects net-zero and ESG commitments

A transformer that fails loss guarantees represents decades of unnecessary energy waste.

| Test Area | Risk If Untested | Protection Provided |

|---|---|---|

| Dielectric tests | Fire, explosion | Electrical safety |

| Loss tests | Excess energy cost | Efficiency assurance |

| Temperature rise | Accelerated aging | Long service life |

Preventing Environmental and Oil-Related Risks

Oil-filled transformers present environmental risk.

Factory testing before shipment prevents:

- Oil leaks from welds and seals

- Oil contamination

- Increased fire risk

Correcting oil-related defects after installation can require full decommissioning.

Ensuring Compliance With IEC/IEEE Standards

Compliance is non-negotiable.

Factory testing:

- Demonstrates conformity to IEC/IEEE requirements

- Provides auditable test records

- Protects utilities from regulatory violations

Without factory test documentation, commissioning approval may be denied.

Reducing Legal and Commercial Disputes

Disputes often arise after failures.

Factory testing protects all parties by:

- Providing objective performance evidence

- Clarifying responsibility boundaries

- Reducing warranty conflicts

Test reports are legally significant documents in infrastructure contracts.

Insurance and Risk Management Protection

Insurance coverage depends on risk profile.

Factory testing before shipment:

- Maintains insurability

- Reduces premiums

- Avoids claim rejection

Un-tested transformers are often classified as high-risk assets.

Protecting Grid Stability During First Energization

First energization is a critical grid event.

Factory testing ensures:

- Correct magnetizing current behavior

- Controlled inrush current

- Stable voltage response

This protects the wider grid from disturbances during commissioning.

Preventing Early-Life (“Infant Mortality”) Failures

Early failures are disproportionately damaging.

Factory testing shifts failure probability:

- Away from commissioning

- Toward far later in service life

This protects system reliability and public confidence.

Transportation Risk Mitigation

Long-distance shipment exposes transformers to:

- Vibration

- Shock

- Climate changes

Factory testing establishes a verified baseline so any post-shipment damage can be clearly identified.

Why Field Testing Cannot Replace Factory Testing

Field testing has inherent limitations:

- Lower voltage stress

- Limited thermal testing

- Restricted diagnostics

Factory testing remains the only stage where full verification is possible.

Economic Comparison: Testing vs. Failure

| Scenario | Cost Impact |

|---|---|

| Full factory testing | Low, predictable |

| On-site failure | Extremely high |

| Post-installation repair | Often impractical |

The economics alone justify mandatory factory testing.

Lessons From Industry Failure Analysis

Industry data consistently shows:

- Most catastrophic failures originate from manufacturing defects

- These defects are detectable during factory tests

Standards are built on these lessons.

Conclusion

Factory testing is mandatory because it confirms transformer performance, safety, and compliance before the equipment enters service. By identifying defects, verifying design parameters, and ensuring conformity with IEC, IEEE, or other standards, factory testing minimizes operational risks, prevents premature failures, and builds confidence in long-term reliability. Ultimately, mandatory factory testing is essential for safe grid operation, asset protection, and dependable power supply.

FAQ

Q1: Why is factory testing mandatory for transformers?

Factory testing is mandatory to verify that a transformer meets design specifications, safety requirements, and international standards before shipment. Power transformers are high-value, critical assets, and failures after installation can lead to outages, safety hazards, and major financial losses.

Testing at the factory ensures defects are identified early, when corrective actions are faster, safer, and far less expensive than on-site repairs or replacements.

Q2: What risks are reduced by mandatory factory testing?

Mandatory factory testing reduces multiple operational and safety risks, including:

Electrical insulation failure

Excessive losses or overheating

Incorrect voltage ratio or polarity

Mechanical weakness during transport or faults

Non-compliance with IEC, IEEE, or contractual requirements

By detecting hidden manufacturing or material defects, factory testing significantly improves transformer reliability and lifespan.

Q3: What types of factory tests are typically required?

Factory testing generally includes:

Routine tests (performed on every transformer)

Type tests (performed on representative designs)

Special tests (performed upon customer or project request)

These tests assess electrical, thermal, mechanical, and dielectric performance to confirm the transformer is safe and fit for service.

Q4: How does factory testing ensure compliance with standards?

International standards such as IEC 60076 and IEEE C57 mandate specific test procedures and acceptance criteria. Factory testing demonstrates compliance by:

Measuring losses, impedance, and efficiency

Verifying insulation strength under high voltage

Confirming temperature rise limits

Checking sound levels and partial discharge

Certified test results provide documented proof that the transformer meets regulatory and contractual obligations.

Q5: Why can’t all transformer tests be done on-site?

Many critical tests require specialized equipment, controlled environments, and high-voltage laboratories that are only available at manufacturing facilities.

Tests such as impulse voltage testing, temperature rise testing, and partial discharge measurement cannot be safely or accurately performed on-site. Factory testing ensures precise results under standardized conditions.

Q6: How does factory testing protect buyers and utilities?

Factory testing protects buyers by:

Confirming they receive exactly what was specified

Preventing delivery of defective or non-conforming equipment

Providing traceable test records for warranty and insurance

Reducing commissioning risks and delays

Many buyers also attend factory acceptance tests (FAT) or appoint third-party inspectors to independently verify results.

Q7: Is factory testing legally required or contractually enforced?

In many regions, factory testing is both legally required and contractually enforced. Utilities, industrial users, and EPC contractors typically specify mandatory factory tests in procurement documents.

Failure to pass required tests may result in rejection, redesign, repair, or replacement—at the manufacturer’s expense.

Q8: Does factory testing improve transformer lifecycle performance?

Yes. Transformers that pass comprehensive factory testing typically exhibit:

Lower failure rates

Longer insulation life

Stable thermal and electrical performance

Reduced maintenance needs

Factory testing is a foundational step in ensuring long-term operational reliability and total cost efficiency.

References

IEC 60076 – Power Transformers

https://webstore.iec.ch/publication/602

IEEE C57 Series – Transformer Testing Standards

https://standards.ieee.org

IEC 60076-1 – General Requirements and Testing

https://webstore.iec.ch

Electrical Engineering Portal – Transformer Routine and Type Tests

https://electrical-engineering-portal.com

CIGRE – Transformer Testing and Reliability Studies

https://www.cigre.org

NEMA – Transformer Test and Certification Guidelines

https://www.nema.org