Overloading is a common operational challenge for power and distribution transformers, especially during peak demand periods or unexpected system conditions. Understanding how transformers respond to overloading is essential for ensuring system reliability, preventing premature aging, and avoiding costly failures. While transformers are designed with certain overload tolerances, their response depends on thermal, electrical, and mechanical limits.

What Is Transformer Overloading?

Transformer overloading is a common but often misunderstood condition in power systems. Many operators assume a transformer can safely carry excess load for long periods as long as it does not trip immediately. In reality, sustained overloading accelerates insulation aging, raises operating temperature, and silently reduces transformer lifespan, eventually leading to costly failures and unplanned outages.

Transformer overloading occurs when a transformer carries electrical load exceeding its rated kVA or MVA capacity, either temporarily or continuously, causing increased losses, overheating, and accelerated insulation degradation.

Transformer overloading increases winding temperature and accelerates insulation aging.True

Excess current raises copper losses and hotspot temperature, which shortens insulation life exponentially.

Definition of Transformer Overloading

Every transformer is designed for a specific rated capacity under defined cooling and ambient conditions. Overloading occurs when:

- The load current exceeds the rated current

- The apparent power demand (kVA/MVA) surpasses nameplate rating

- Thermal limits are exceeded even if voltage remains normal

Overloading is primarily a thermal issue rather than an immediate electrical fault.

Types of Transformer Overloading

Overloading can be categorized based on duration and severity.

Short-term overloading:

- Occurs during peak demand or emergency conditions

- Often permitted within defined limits

- Acceptable if insulation temperature remains within standards

Long-term overloading:

- Continuous operation above rated capacity

- Causes cumulative thermal damage

- Significantly shortens transformer life

Cyclic overloading:

- Load varies above and below rating

- Common in industrial and renewable applications

- Requires careful thermal analysis

Why Transformers Can Withstand Limited Overloading

Transformers are conservatively designed.

Reasons include:

- Thermal inertia of windings and oil

- Safety margins in insulation design

- Allowable short-duration temperature rise

However, this tolerance is not unlimited and depends on cooling effectiveness and ambient temperature.

Thermal Impact of Overloading

Heat generation increases rapidly under overload.

Key effects:

- Copper losses increase with the square of current

- Hotspot temperature rises sharply

- Oil and insulation degrade faster

A small overload can cause a disproportionately large reduction in service life.

Effect on Insulation Aging

Insulation aging follows an exponential relationship with temperature.

Consequences include:

- Reduced dielectric strength

- Increased moisture generation

- Higher risk of partial discharge and breakdown

This damage is irreversible and cumulative.

Operational Risks of Persistent Overloading

Sustained overload introduces multiple risks:

- Reduced reliability and higher failure probability

- Increased maintenance frequency

- Unexpected outages during peak demand

- Higher total lifecycle cost

In extreme cases, thermal runaway and catastrophic failure may occur.

Standards and Allowable Overload Limits

International standards define permissible overload conditions.

Guidelines consider:

- Load duration

- Ambient temperature

- Cooling mode (ONAN, ONAF, etc.)

- Insulation thermal class

Compliance helps balance reliability and operational flexibility.

When Overloading Becomes a Strategic Decision

In some systems, controlled overloading is unavoidable.

Typical scenarios:

- Rapid load growth

- Emergency grid support

- Delayed infrastructure upgrades

In such cases, continuous monitoring and thermal modeling are essential.

How Does Overloading Affect Transformer Temperature?

Transformer overloading is one of the most direct and dangerous causes of abnormal temperature rise in power equipment. While a transformer may continue operating electrically during overload conditions, the thermal stress created inside the windings and insulation system can silently accelerate aging and push the unit toward premature failure. Understanding how overloading affects temperature is essential for preventing hidden damage and protecting long-term asset value.

Overloading increases transformer temperature by raising current-related losses, causing winding hot-spot temperatures to rise rapidly and accelerating thermal aging of insulation and cooling media.

Transformer overloading directly causes excessive temperature rise due to increased current and losses.True

Higher load current increases copper losses and heat generation, leading to elevated winding and oil temperatures.

Relationship Between Load Current and Heat Generation

Transformer temperature is closely linked to electrical load.

Key mechanisms include:

- Copper (I²R) losses increase with the square of current

- Even small overloads produce disproportionately higher heat

- Heat generation occurs mainly in windings and structural components

For example, a 20% overload can increase copper losses by nearly 44%, creating a sharp temperature rise.

Hot-Spot Temperature Rise in Windings

The most critical temperature is the winding hot-spot.

Effects of overloading:

- Localized overheating in inner winding layers

- Reduced heat dissipation efficiency

- Faster deterioration of insulation at the hot-spot

Hot-spot temperature, not average oil temperature, determines insulation life.

Impact on Insulating Oil and Cooling Media

Overloading stresses the cooling system.

Consequences include:

- Higher oil temperature and reduced viscosity

- Faster oxidation and sludge formation

- Lower cooling efficiency over time

As oil ages, its ability to remove heat declines, compounding temperature problems.

Thermal Aging Acceleration

Insulation aging accelerates exponentially with temperature.

Typical impacts:

- Each 6–8°C rise above design limits can halve insulation life

- Paper insulation loses mechanical strength

- Increased risk of dielectric failure

This damage is cumulative and irreversible.

Interaction with Ambient Temperature

Overloading is more dangerous in hot environments.

Factors include:

- Reduced temperature margin during high ambient conditions

- Limited cooling capacity in natural cooling modes

- Seasonal overload risks in summer peak demand

A transformer safe in winter may overheat under the same load in summer.

Cooling System Limitations During Overload

Cooling systems have defined limits.

Issues during overload:

- Natural cooling (ONAN) may become insufficient

- Forced cooling may reach maximum capacity

- Fans and pumps cannot fully offset excessive losses

Once cooling capacity is exceeded, temperature rises uncontrollably.

Short-Term vs Long-Term Overloading Effects

Not all overloads have the same impact.

Short-term overload:

- Acceptable if temperature limits are not exceeded

- Often allowed during emergencies

Long-term overload:

- Causes sustained high temperatures

- Rapid insulation degradation

- Significant reduction in transformer lifespan

Duration matters as much as magnitude.

Warning Signs of Overload-Induced Overheating

Operators should monitor:

- Abnormal oil and winding temperature trends

- Frequent cooling system activation

- Unusual odors or discoloration of oil

- Rising dissolved gas levels

Early detection prevents irreversible damage.

What Are the Short-Term vs. Long-Term Effects of Overloading?

Transformer overloading does not always cause immediate failure, which is why it is often underestimated in daily operation. In reality, the consequences of overloading depend heavily on duration, magnitude, and frequency. Short-term overloading can be manageable under controlled conditions, while long-term overloading silently degrades internal components and leads to premature transformer failure.

Short-term overloading causes temporary temperature rise that may be acceptable within thermal limits, whereas long-term overloading leads to irreversible insulation aging, loss of mechanical strength, and significant reduction in transformer service life.

Short-term transformer overloading may be permissible, but long-term overloading significantly shortens transformer lifespan.True

Temporary overloads can be absorbed by thermal inertia, while sustained overload accelerates insulation degradation and mechanical deterioration.

Short-Term Effects of Transformer Overloading

Short-term overloading typically occurs during peak demand or emergency conditions.

Common short-term effects include:

- Temporary rise in winding and oil temperature

- Increased copper losses and cooling system activity

- Higher thermal stress without immediate physical damage

Because of thermal inertia, insulation does not instantly degrade if temperature limits are respected. Standards allow limited-duration overloads provided hotspot temperature remains within acceptable limits.

Acceptable Conditions for Short-Term Overloading

Short-term overloading can be tolerated when:

- Ambient temperature is moderate or low

- Cooling systems are fully operational

- Overload duration is strictly limited

- Temperature monitoring confirms safe operation

Under these conditions, the transformer can return to normal operation with minimal long-term impact.

Long-Term Effects of Transformer Overloading

Long-term overloading is far more damaging.

Key long-term consequences include:

- Continuous elevated winding hot-spot temperature

- Accelerated aging of paper and oil insulation

- Loss of dielectric strength and mechanical integrity

- Increased risk of partial discharge and internal faults

These effects accumulate over time and cannot be reversed.

Insulation Aging and Life Reduction

Thermal aging follows an exponential relationship.

Long-term overloading causes:

- Rapid reduction in insulation tensile strength

- Increased moisture generation within insulation

- Shortened remaining service life

A transformer overloaded by a modest percentage for years may lose decades of expected life.

Mechanical Stress and Structural Damage

High current levels create mechanical forces.

Long-term overloading leads to:

- Conductor deformation under electromagnetic forces

- Loosening of clamping structures

- Reduced short-circuit withstand capability

This makes the transformer more vulnerable to fault events.

Impact on Reliability and Failure Risk

Persistent overloading increases failure probability.

Risks include:

- Sudden insulation breakdown

- Oil degradation and gas generation

- Unplanned outages during peak demand

Failures under overload conditions are often catastrophic and costly.

Economic and Operational Consequences

Long-term overloading increases total cost of ownership.

Hidden costs include:

- More frequent maintenance and oil treatment

- Reduced asset lifespan and earlier replacement

- Higher risk of regulatory and insurance issues

What appears as a short-term capacity solution often becomes a long-term financial burden.

Strategic Use of Short-Term Overloading

Utilities sometimes accept short-term overloading strategically.

Typical cases:

- Emergency supply restoration

- Temporary load growth before upgrades

- Seasonal peak management

In these cases, strict monitoring and thermal modeling are essential.

How Do Insulation and Aging Respond to Overload Conditions?

Transformer insulation is designed to operate within strict thermal limits, and overloading directly challenges those limits. While a transformer may continue functioning electrically under overload conditions, the insulation system silently absorbs the damage. The way insulation responds to overloading ultimately determines transformer aging rate, reliability, and remaining service life.

Under overload conditions, transformer insulation experiences accelerated thermal aging, loss of mechanical strength, increased moisture generation, and reduced dielectric performance, leading to a rapid decline in transformer lifespan.

Transformer insulation aging accelerates exponentially when overload conditions raise operating temperature beyond design limits.True

Elevated hot-spot temperature caused by overload increases chemical degradation of insulation materials, shortening service life.

Thermal Stress as the Primary Aging Mechanism

Insulation aging is primarily temperature-driven.

Under overload conditions:

- Winding hot-spot temperature rises sharply

- Chemical bonds in cellulose insulation break down faster

- Aging rate increases exponentially rather than linearly

Even moderate overloads can cause disproportionate aging if sustained.

Response of Solid Insulation to Overloading

Paper and pressboard insulation are highly temperature-sensitive.

Overload effects include:

- Loss of tensile strength in cellulose fibers

- Increased brittleness and cracking

- Reduced ability to withstand mechanical and electrical stress

Once mechanical strength is lost, insulation cannot recover.

Oil Degradation and Its Interaction with Insulation Aging

Overloading accelerates oil deterioration.

Key impacts:

- Faster oxidation and acid formation

- Increased sludge that blocks cooling paths

- Higher moisture content released from aging paper

Degraded oil further reduces cooling and insulation effectiveness, creating a feedback loop.

Moisture Generation and Dielectric Weakening

Thermal aging produces water as a byproduct.

Consequences include:

- Moisture migration into solid insulation

- Lower dielectric strength

- Higher risk of partial discharge and breakdown

Moisture dramatically worsens insulation performance under electrical stress.

Hot-Spot Aging vs. Average Temperature

Insulation aging is governed by hot-spot temperature, not average values.

Overload conditions cause:

- Localized overheating in winding regions

- Uneven aging across insulation system

- Early failure triggered by the weakest area

A transformer may appear normal while critical hot-spots deteriorate.

Cumulative and Irreversible Nature of Aging

Overload-induced aging cannot be undone.

Characteristics:

- Damage accumulates over time

- Cooling or load reduction slows but does not reverse aging

- Remaining life is permanently reduced

This makes early overload management critical.

Effect on Electrical and Mechanical Reliability

Aged insulation compromises system performance.

Risks include:

- Increased partial discharge activity

- Reduced impulse and short-circuit withstand capability

- Higher likelihood of catastrophic internal faults

Aging insulation is the dominant failure mode in transformers.

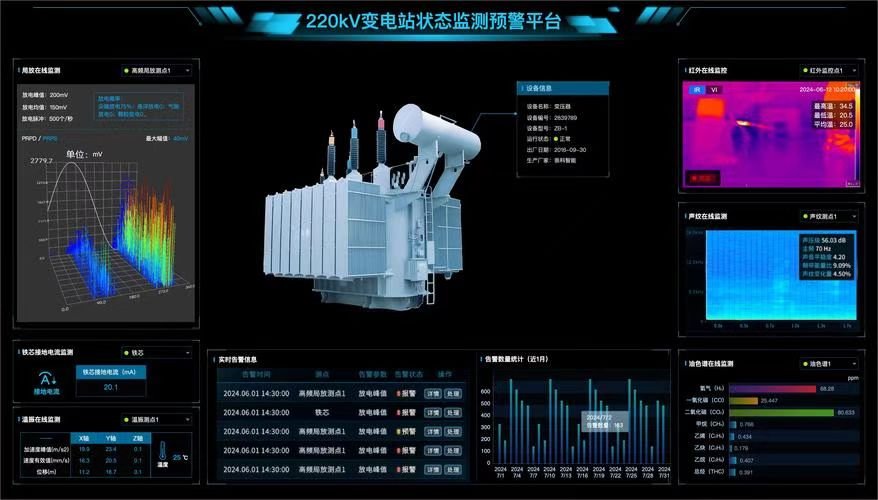

Role of Monitoring in Managing Insulation Aging

Modern monitoring helps detect overload damage.

Key tools include:

- Winding hot-spot temperature sensors

- Dissolved gas analysis (DGA)

- Moisture-in-oil monitoring

- Thermal modeling and load profiling

Early detection allows corrective action before severe damage occurs.

What Protection and Monitoring Systems Manage Overloading?

Transformer overloading rarely causes immediate electrical failure, which makes it particularly dangerous. Without proper protection and monitoring, excessive loading can continue unnoticed while internal temperature and insulation aging accelerate. Modern power systems therefore rely on layered protection and intelligent monitoring to detect, control, and mitigate overload conditions before irreversible damage occurs.

Transformer overloading is managed through a combination of thermal protection, electrical protection, and continuous monitoring systems that limit temperature rise, detect abnormal load conditions, and protect insulation from accelerated aging.

Effective protection and monitoring systems can prevent transformer damage caused by sustained overloading.True

Thermal relays, temperature sensors, and intelligent monitoring systems detect overload conditions early and initiate alarms or protective actions.

Thermal Protection Systems

Thermal protection is the primary defense against overloading.

Key thermal protection devices include:

- Winding temperature indicators (WTI)

- Oil temperature indicators (OTI)

- Thermal image relays and models

These systems estimate or measure winding hot-spot temperature and trigger alarms or trips when thermal limits are exceeded, directly protecting insulation life.

Overcurrent and Electrical Protection

Electrical protection responds to excessive current.

Common devices include:

- Overcurrent relays

- Inverse-time protection relays

- Differential protection schemes

While overcurrent protection is mainly designed for faults, time-delayed characteristics also provide backup protection against severe overload conditions.

Thermal Modeling and Load-Based Protection

Modern transformers use thermal models.

Functions include:

- Calculating real-time hot-spot temperature

- Accounting for ambient temperature and cooling mode

- Predicting insulation aging rate

Thermal models allow controlled short-term overloading while preventing long-term damage.

Cooling System Control and Automation

Cooling systems play a direct role in overload management.

Automated features include:

- Fan and pump staging based on temperature

- Automatic transition from natural to forced cooling

- Cooling failure alarms

Effective cooling control increases permissible load without exceeding thermal limits.

Online Condition Monitoring Systems

Continuous monitoring provides early warning.

Typical monitored parameters:

- Load current and load profile

- Oil and winding temperature

- Dissolved gas analysis (DGA)

- Moisture in oil

These systems detect overload-related stress long before failure occurs.

Smart Sensors and IoT Integration

Digital transformers increasingly use smart sensors.

Benefits include:

- Real-time data collection

- Remote monitoring and diagnostics

- Predictive maintenance analytics

IoT-based systems help operators manage overload risk proactively rather than reactively.

Alarm, Interlock, and Trip Functions

Protection systems act in stages.

Typical hierarchy:

- Alarm at elevated temperature or load

- Load reduction or cooling enhancement

- Automatic trip if safe limits are exceeded

This layered response minimizes unnecessary outages while protecting equipment.

Standards and Coordination of Protection

Protection settings follow international standards.

Considerations include:

- Insulation thermal class

- Cooling mode (ONAN, ONAF, OFAF)

- Expected load cycles

Proper coordination ensures overload protection without compromising system availability.

Role of Operational Procedures

Technology alone is not sufficient.

Operational measures include:

- Load forecasting and planning

- Seasonal overload management strategies

- Emergency loading guidelines

Human oversight complements automated protection.

When Is Overloading Acceptable and When Is It Dangerous?

Transformer overloading is not always a mistake—under certain conditions, it can be a planned and controlled operating strategy. However, the line between acceptable and dangerous overloading is defined by thermal limits, duration, cooling capability, and insulation condition. Misjudging this balance can quietly destroy a transformer long before any obvious failure occurs.

Overloading is acceptable only when it is short-term, well-monitored, and within thermal limits; it becomes dangerous when it is sustained, poorly controlled, or causes winding hot-spot temperatures to exceed insulation design limits.

Controlled short-term overloading can be acceptable, while sustained overloading is a leading cause of premature transformer failure.True

Short-term overloads may not exceed thermal limits, but long-term overload accelerates insulation aging and increases failure risk.

When Transformer Overloading Is Acceptable

Overloading can be acceptable under defined conditions.

Typical acceptable scenarios include:

- Short-duration peak load events

- Emergency supply restoration

- Seasonal or cyclic load variations

- Low ambient temperature conditions

In these cases, thermal inertia allows the transformer to absorb temporary stress without permanent damage.

Key Conditions That Make Overloading Acceptable

Acceptable overloading requires strict control.

Critical factors include:

- Overload duration is limited and defined

- Winding hot-spot temperature remains within standards

- Cooling systems operate correctly and efficiently

- Insulation condition is healthy and well-monitored

Without these safeguards, overload risk increases rapidly.

Role of Cooling in Determining Acceptability

Cooling capacity determines overload tolerance.

Important considerations:

- Forced cooling modes allow higher temporary loads

- Cooling margin must exist before overload begins

- Cooling system reliability is essential

If cooling is already at maximum capacity, overloading becomes unsafe.

Importance of Temperature Monitoring

Temperature is the decisive parameter.

Acceptable overload requires:

- Real-time winding and oil temperature monitoring

- Alarm and trip thresholds correctly set

- Operator response capability

Blind overloading without temperature feedback is inherently dangerous.

When Overloading Becomes Dangerous

Overloading becomes dangerous when thermal limits are exceeded.

High-risk conditions include:

- Continuous or long-term overload operation

- High ambient temperature combined with overload

- Degraded insulation or aged transformers

- Inadequate or failed cooling systems

Under these conditions, insulation aging accelerates dramatically.

Long-Term Overloading as a Hidden Failure Mechanism

Sustained overload causes invisible damage.

Consequences include:

- Permanent loss of insulation mechanical strength

- Increased moisture generation and oil degradation

- Reduced short-circuit withstand capability

Failures caused by overload often occur suddenly and catastrophically.

Interaction with Transformer Age and Condition

Transformer condition affects overload tolerance.

Older units:

- Have reduced insulation margins

- Are more sensitive to temperature rise

- Tolerate less overload than new transformers

Overloading an aged transformer is particularly dangerous.

Economic Risks of Dangerous Overloading

Unsafe overloading has long-term cost implications.

Hidden costs include:

- Shortened asset life and early replacement

- Increased maintenance and monitoring expense

- Higher outage risk and system penalties

What seems like a short-term capacity solution often leads to higher total cost.

Decision Framework for Overloading

Safe overload decisions require data and planning.

Best practices include:

- Thermal modeling and load analysis

- Continuous condition monitoring

- Compliance with IEC/IEEE overload guidelines

- Clear operational procedures and limits

Data-driven decisions reduce risk significantly.

Conclusion

Transformers can tolerate limited overloading under controlled conditions, but excessive or prolonged overloads significantly accelerate insulation aging and increase the risk of failure. Their response is primarily thermal, with rising temperatures affecting oil quality, insulation strength, and overall lifespan. By applying proper loading guidelines, real-time monitoring, and effective protection systems, operators can safely manage overload situations while maintaining transformer performance and long-term reliability.

FAQ

Q1: What does transformer overloading mean?

Transformer overloading occurs when a transformer carries current above its rated capacity for a certain period. This may happen due to peak demand, system contingencies, temporary faults, or unexpected load growth.

Overloading does not cause immediate failure in most cases, but it increases thermal stress, accelerates insulation aging, and raises the risk of long-term damage if not properly controlled.

Q2: How does a transformer physically respond to overloading?

When overloaded, a transformer responds primarily through increased temperature rise:

Winding current increases → higher copper (I²R) losses

Additional heat raises winding and oil temperatures

Insulation experiences greater thermal stress

Because transformers have thermal mass, temperature rise is not instantaneous. This thermal inertia allows short-duration overloads without immediate damage, provided temperature limits are not exceeded.

Q3: Can transformers safely operate under overload conditions?

Yes, transformers are designed to tolerate short-term overloads under controlled conditions. Industry standards such as IEC and IEEE define permissible overload limits based on:

Ambient temperature

Cooling method

Initial load level

Insulation thermal class

For example, a transformer may operate at 120–150% of rated load for limited periods if cooling is adequate and temperatures remain within allowable limits.

Q4: What are the long-term effects of repeated overloading?

Repeated or prolonged overloading significantly accelerates transformer aging. The most critical impact is on insulation life, which roughly halves for every 6–8°C increase in hotspot temperature.

Long-term effects include:

Reduced insulation strength

Increased risk of internal faults

Higher maintenance requirements

Shortened service life

While the transformer may continue operating, its remaining life expectancy is reduced.

Q5: How do cooling systems affect overload capability?

Cooling systems play a major role in overload response:

Transformers with forced cooling (ONAF, OFAF, AF) can handle higher overloads

Additional fans or pumps help limit temperature rise

Multi-stage cooling allows temporary capacity increases

If cooling systems fail or are insufficient, overload tolerance drops sharply, increasing the risk of damage.

Q6: How is transformer overloading monitored and controlled?

Modern transformers use monitoring systems to manage overload conditions, including:

Top-oil and winding hotspot temperature sensors

Load current monitoring

Thermal models and alarms

Automatic cooling control

Protective relays may issue warnings, initiate load shedding, or trip the transformer if thermal limits are exceeded.

Q7: What standards govern transformer overload behavior?

Transformer overloading is guided by international standards, including:

IEC 60076-7 – Loading guide for oil-immersed transformers

IEEE C57.91 – Guide for loading mineral-oil-immersed transformers

These standards define thermal limits, permissible overload durations, and calculation methods to balance reliability and asset life.

Q8: What are best practices for managing transformer overloads?

Best practices include:

Designing transformers with realistic load forecasts

Maintaining cooling systems in optimal condition

Using real-time temperature and load monitoring

Limiting overload duration and frequency

Planning timely capacity upgrades or parallel operation

Proper overload management ensures reliability while maximizing transformer utilization.

References

IEC 60076-7 – Loading Guide for Oil-Immersed Transformers

https://webstore.iec.ch/publication/633

IEEE C57.91 – Guide for Loading Mineral-Oil-Immersed Transformers

https://standards.ieee.org

IEC 60076 – Power Transformers

https://webstore.iec.ch/publication/602

Schneider Electric – Managing Transformer Overloads

https://www.se.com

Electrical Engineering Portal – Transformer Overloading Explained

https://electrical-engineering-portal.com

CIGRE – Transformer Thermal Aging Studies

https://www.cigre.org

U.S. Department of Energy – Transformer Reliability and Loading

https://www.energy.gov