Transformer noise is a common concern in both residential and industrial environments. This low-frequency hum—often referred to as the "60 Hz hum"—originates from internal electromagnetic and mechanical processes within the transformer. While typically harmless, excessive noise can be a sign of design issues or improper installation and may lead to complaints or even regulatory problems in noise-sensitive areas. Understanding the causes of transformer noise and how to control it is essential for ensuring quiet and reliable operation.

What Causes Transformer Noise?

In many electrical environments—from substations to pad-mounted units near homes—you may notice a persistent low-frequency humming or buzzing sound coming from transformers. While often considered harmless, this transformer noise is not random. It is a direct result of the physical forces at play within the transformer's magnetic core and windings, and understanding it is essential for diagnosing issues, designing quieter systems, and ensuring regulatory compliance in noise-sensitive zones.

Transformer noise is primarily caused by magnetostriction in the core, which leads to mechanical vibrations at twice the power frequency (e.g., 100 Hz or 120 Hz). Additional noise can come from winding vibrations, structural resonance, cooling systems (fans or oil pumps), and loose fittings. The dominant hum is mechanical, not electrical, and increases with core flux density, loading, and excitation.

This article explores the physics behind transformer noise, its contributing factors, and what engineers and facility managers can do to manage or reduce it.

Transformer noise originates mainly from the core and is driven by magnetostriction under alternating magnetic fields.True

The expansion and contraction of the core steel laminations at twice the supply frequency causes the characteristic humming sound.

Transformer noise is a sign of electrical malfunction and should always be treated as a fault.False

Some level of humming is normal and expected in transformers due to magnetic effects; only abrupt or changing noise suggests a problem.

1. Core Magnetostriction – The Primary Cause

What is Magnetostriction?

Magnetostriction is the physical deformation of ferromagnetic materials (like the transformer's steel core) when subjected to a magnetic field. As the alternating current (AC) energizes the core:

- The core expands and contracts microscopically

This mechanical vibration occurs twice per AC cycle

- 50 Hz system → 100 Hz noise

- 60 Hz system → 120 Hz noise

| Frequency | Audible Effect |

|---|---|

| 100 Hz | Deep hum (most common) |

| 120 Hz | Slightly sharper hum |

Factors Affecting Magnetostriction Noise:

- Core material grade (CRGO steel is better than non-oriented)

- Flux density (higher density = more vibration)

- Core geometry and clamping

- Operating voltage (overvoltage increases hum)

2. Winding Vibration and Lorentz Forces

What Happens:

When current flows through windings, electromagnetic forces (Lorentz forces) cause the coils to vibrate radially and axially.

| Cause | Result |

|---|---|

| High load current | Increases magnetic field |

| Short-circuit stresses | Windings may loosen |

| Loose bracing or tie rods | Causes rattle or buzz |

These vibrations can couple with the tank and amplify audible sound if not properly damped.

3. Tank and Structural Resonance

The vibrations in the core and windings are transmitted to the tank and enclosure, where they:

- Excite natural frequencies of steel plates

- Cause resonant amplification of certain tones

- Result in audible hum, buzz, or mechanical ringing

| Contributing Factors | Impact on Noise |

|---|---|

| Improper bolting or welding | Increased vibration transfer |

| Thin tank walls | More resonance |

| Poor base support | Amplifies low-frequency hum |

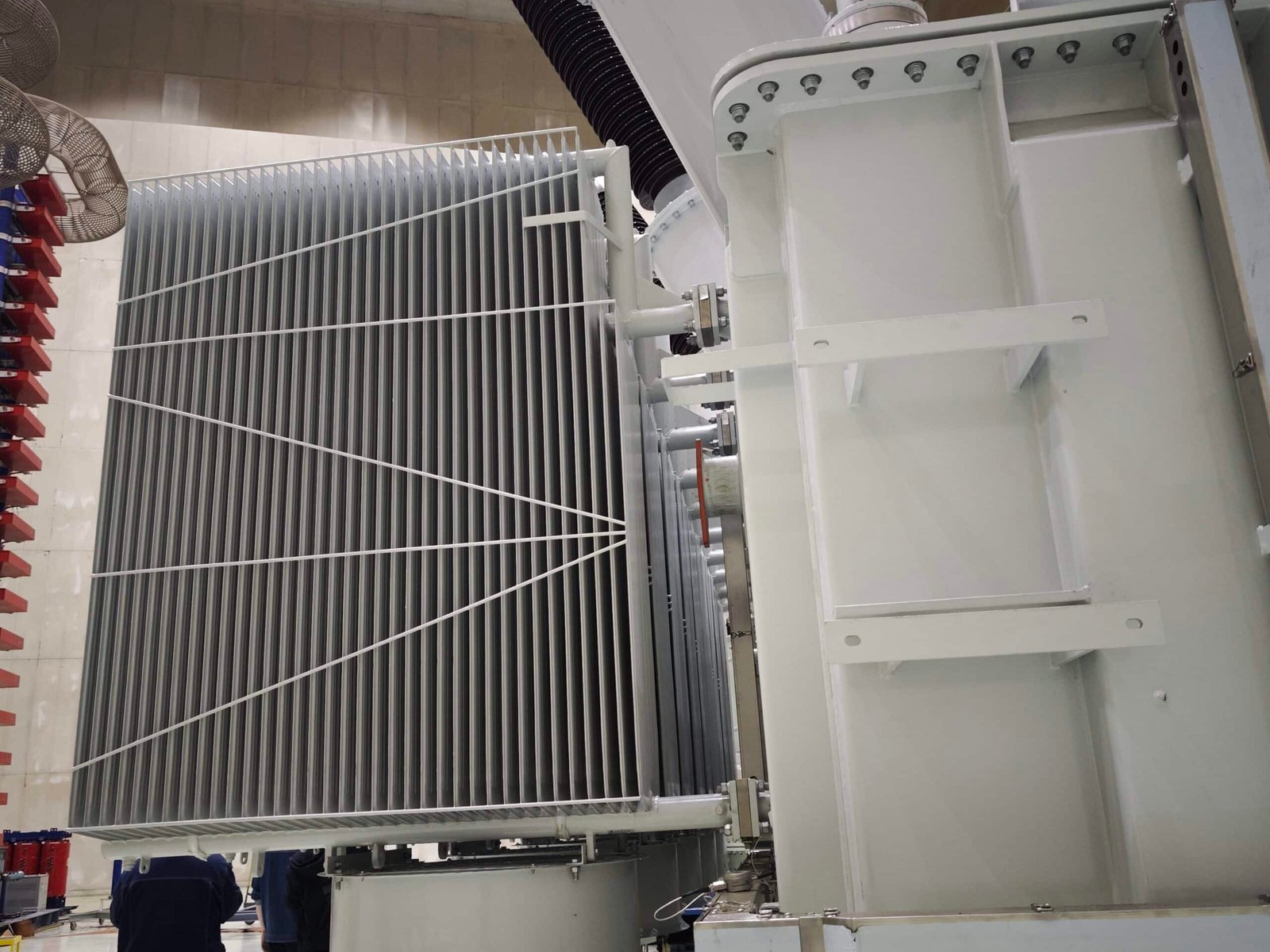

4. Cooling System Noise (Ancillary Sources)

Not all transformer noise comes from the core or windings. Other sources include:

| Component | Noise Characteristics |

|---|---|

| Cooling fans | Whirring or humming at high speeds |

| Oil circulation pumps | Low-frequency mechanical buzz |

| Radiator vibration | High-pitch clinking or rattling |

These are typically intermittent and vary with temperature or load.

5. Noise Levels and Regulatory Guidelines

| Transformer Type | Typical Noise Level (dB @ 1 meter) |

|---|---|

| 100 kVA oil-immersed | 45–50 dB |

| 630 kVA outdoor unit | 55–65 dB |

| 1600 kVA pad-mounted | 65–75 dB |

| 2500+ kVA substation unit | 75–85 dB (with fans running) |

Standards:

- IEC 60076-10: Measurement of sound levels

- NEMA TR-1: Noise limits for dry-type transformers

- Local zoning laws: May require <55 dB in residential zones

6. Visual Summary: Noise Sources in a Transformer

| Noise Source | Type | Dominant Frequency | Condition |

|---|---|---|---|

| Core magnetostriction | Mechanical vibration | 100/120 Hz | Normal |

| Winding movement | Electromagnetic | Broadband | Load-dependent |

| Tank resonance | Structural | Varies | Poor design |

| Cooling fans/pumps | Mechanical rotation | 400–1200 Hz | Ancillary |

| Loose fasteners | Mechanical knock | Random | Fault condition |

7. How to Reduce Transformer Noise

| Mitigation Method | How It Works |

|---|---|

| Low-magnetostriction core steel | Reduces core deformation |

| Proper clamping and bracing | Minimizes winding movement |

| Acoustic barriers and baffles | Blocks sound propagation (especially outdoors) |

| Vibration isolation pads | Decouple tank from ground resonance |

| Tank stiffening ribs | Prevent tank wall vibration |

| Fan/pump silencers | Reduces cooling system noise |

Design-stage noise mitigation is always more effective than retrofit solutions.

How Does Core Design Influence Noise Levels?

Transformer noise, especially the characteristic low-frequency hum, is directly tied to the design and behavior of the magnetic core. The core is the physical heart of the transformer and also the main source of mechanical vibrations, which translate into audible sound. Therefore, how the core is designed—its material, geometry, lamination, and clamping—significantly affects the intensity, frequency, and character of the noise produced.

Core design influences noise levels in a transformer by affecting how much magnetostriction-induced vibration is generated and transmitted. Factors such as core material (CRGO vs. amorphous), geometry (core vs. shell type), lamination thickness, stacking methods, and clamping techniques all play key roles in either amplifying or reducing the mechanical deformations that cause audible noise.

This article provides a deep technical dive into the relationship between transformer core design and acoustic performance, helping engineers design quieter systems and troubleshoot noise issues effectively.

Transformer core design—including material selection, lamination technique, and core geometry—has a direct and measurable impact on the transformer’s noise output.True

Noise originates from the core due to magnetostriction, and optimized core designs minimize mechanical vibrations and sound radiation.

Transformer noise is completely unrelated to the physical design of the core and depends only on electrical current.False

While electrical current energizes the core, the core’s physical design determines how much vibration it produces and transmits.

1. The Physics: Magnetostriction and Core Noise

What Is Magnetostriction?

- Magnetostriction refers to the microscopic expansion and contraction of ferromagnetic materials (like silicon steel) when magnetized.

- As AC current alternates in the windings, the magnetic field in the core reverses 50 or 60 times per second, causing physical dimensional changes at 100 Hz or 120 Hz, depending on the frequency.

Core Vibration Chain:

- Magnetic field variation

- Core deformation

- Structural vibration

- Audible hum or buzz

The stronger and more abrupt the deformation, the louder the noise—making the core’s mechanical behavior critical.

2. Core Material Selection

| Material Type | Magnetostriction Behavior | Noise Impact |

|---|---|---|

| CRGO Steel (Cold Rolled Grain Oriented) | Low magnetostriction | Standard noise levels |

| Amorphous Metal Core | Very low magnetostriction | Significantly quieter |

| Non-oriented Steel | High magnetostriction | Very noisy |

Benefits of Amorphous Core:

- Reduces core losses by \~70%

- Decreases noise by 8–12 dB

- Ideal for urban or indoor environments

Amorphous core transformers are used in low-noise, high-efficiency designs, especially where acoustic emissions are a concern.

3. Core Type and Geometry

| Core Type | Description | Noise Characteristics |

|---|---|---|

| Core-Type | Windings on limbs, magnetic flux in closed loop | Standard hum levels, widely used |

| Shell-Type | Windings enclosed by core on both sides | More rigid structure, slightly quieter |

| Toroidal Core | Ring-shaped core with continuous winding path | Very low vibration and hum, rare in high-power transformers |

Influence of Core Shape:

- Symmetrical core designs distribute flux more evenly and reduce localized stress points.

- Shell-type cores are more acoustically rigid and better at vibration damping.

4. Lamination Thickness and Stacking

| Parameter | Description | Noise Impact |

|---|---|---|

| Lamination Thickness | 0.23 mm (low) vs. 0.35 mm (standard) | Thinner laminations reduce eddy currents and mechanical vibration |

| Stacking Factor | Degree of lamination compression | Looser stacking increases noise |

| Interleaving | Interlaced lamination edges | Helps distribute magnetic flux and reduce hot spots and hum |

Precision-cut laminations and high stacking density help minimize air gaps and vibration movement, reducing noise generation.

5. Core Assembly and Clamping Techniques

Proper mechanical clamping and bracing of the core is essential to control vibration:

| Clamping Design | Effect on Noise |

|---|---|

| Tight, rigid clamps | Dampens vibration, prevents rattling |

| Loose core clamps | Amplify resonance, increase hum |

| Dampening pads | Absorb vibration at mounting points |

Poor mechanical clamping can turn a modest vibration into a resonant, amplified sound—especially in metal tanks or loose enclosures.

6. Core Flux Density

Noise increases dramatically with higher core flux levels:

| Core Flux (Tesla) | Noise Tendency |

|---|---|

| <1.4 T | Quiet operation |

| 1.5–1.7 T | Normal design range |

| >1.7 T | Noticeable increase in noise |

Overfluxing, due to overvoltage or harmonic content, will increase magnetostriction and the resulting noise output.

7. Noise Comparison Chart by Core Design

| Core Design Feature | Estimated Noise Reduction |

|---|---|

| Use of amorphous metal | ↓ 8–12 dB |

| Shell-type geometry | ↓ 2–5 dB |

| Thin laminations (0.23 mm) | ↓ 2–4 dB |

| Tight mechanical clamping | ↓ 3–6 dB |

| Low flux density design | ↓ 5–7 dB |

Cumulative design optimizations can reduce total transformer noise by 15–20 dB, which is a major reduction on a logarithmic sound scale.

Summary Table: How Core Design Affects Noise

| Design Parameter | Effect on Noise Level |

|---|---|

| Core material | Amorphous metal = lowest noise |

| Core type | Shell-type = better damping than core-type |

| Lamination thickness | Thinner = less vibration |

| Assembly/clamping | Tight clamping = less resonance |

| Flux density | Higher flux = more vibration and noise |

| Interleaving and stacking | Smoother flux = reduced hot spots and hum |

What is the Role of Load and Voltage in Noise Production?

While transformer noise is often associated with its magnetic core, electrical operating conditions—especially load and voltage—play a significant role in determining the intensity, frequency, and characteristics of the sound it emits. From a low hum under light load to a louder buzz at high flux density, understanding the impact of voltage and load on transformer noise is critical for engineers designing, installing, or operating transformers in environments where acoustics matter.

Load and voltage influence transformer noise by affecting the intensity of magnetic flux in the core and the magnitude of electromagnetic forces in the windings. Overvoltage increases core flux density, leading to stronger magnetostriction and louder hums. Higher loads increase winding currents, which in turn intensify Lorentz forces and vibration. Together, these conditions can amplify audible transformer noise significantly.

This article provides a comprehensive explanation of how varying electrical load and voltage impact noise generation in transformers—and how engineers can use this knowledge for design and operation improvements.

Transformer noise increases with higher load and voltage because both intensify magnetic and mechanical forces within the core and windings.True

Voltage affects magnetic flux density and core vibration, while load impacts current-induced mechanical forces in the windings.

Load and voltage have no influence on transformer noise levels because transformers only hum due to fixed structural properties.False

Transformer noise varies dynamically with electrical operating conditions like overloading and overvoltage.

1. How Voltage Affects Transformer Noise

Key Principle:

Voltage directly determines magnetic flux density (B) in the core:

$$B = \frac{V}{4.44 \times f \times N \times A}$$

Where:

$V$ = applied voltage,

$f$ = frequency,

$N$ = number of turns,

$A$ = core area

Higher Voltage → Higher Flux Density:

- Increased magnetostriction

- Greater core deformation

- Louder fundamental hum at 100 Hz (50 Hz system) or 120 Hz (60 Hz system)

| Voltage Condition | Noise Effect |

|---|---|

| Rated voltage | Nominal hum level |

| +5% overvoltage | Noticeable hum increase |

| +10% overvoltage | Sharp rise in noise and vibration |

Overvoltage = louder noise, even at no-load.

2. How Load Current Influences Noise

Key Principle:

Load increases current through the windings, which induces:

- Lorentz forces that cause vibrations

- Magnetic field interactions between turns

- Radial and axial compression/expansion of coils

Load-Related Noise Characteristics:

- Dynamic and reactive (varies with time and system conditions)

- Increases with asymmetrical or unbalanced loads

- Can cause rattling if winding support is weak or degraded

| Load Level | Noise Observation |

|---|---|

| No load | Mostly core hum (magnetostriction) |

| Partial load | Increased vibration, slight buzz |

| Full load | Noticeable increase in buzz + hum |

| Overload (>100%) | Loud resonance, potential structural noise |

Loose windings or poor bracing amplify load-related noise significantly.

3. Interaction Between Voltage and Load

| Condition | Resulting Acoustic Effect |

|---|---|

| High voltage + no load | Strong core hum due to high flux (100/120 Hz) |

| Normal voltage + high load | Moderate hum + increased winding buzz |

| High voltage + high load | Maximum overall noise (core + winding vibration) |

| Low voltage + light load | Quieter operation, minimal core flux |

The worst-case noise condition is often when overvoltage and high load occur simultaneously.

4. Harmonic Distortion and Noise

Harmonics from non-linear loads (e.g., VFDs, computers, UPS systems) exacerbate noise:

| Harmonic Effect | Acoustic Result |

|---|---|

| 3rd and 5th harmonics | Excite core at odd multiples of base frequency |

| Harmonic saturation | Increases flux distortion |

| Audible effect | Harsh buzzing, unpredictable tone |

Transformers in harmonic-rich environments should use derated or K-rated designs to limit excessive noise and heat.

5. Quantifying the Impact: Typical Sound Level Increases

| Operating Condition | Approximate Sound Increase (dB) |

|---|---|

| Voltage at +5% above nominal | +3 to 5 dB |

| Voltage at +10% | +6 to 8 dB |

| Full load from no-load | +4 to 7 dB |

| Harmonic-rich industrial load | +5 to 10 dB |

Sound pressure levels follow a logarithmic scale, so every +10 dB represents a perceived doubling of loudness.

6. Engineering Measures to Mitigate Load/Voltage-Induced Noise

| Method | Benefit |

|---|---|

| Voltage regulation (tap changer) | Maintains optimal core flux density |

| Load balancing | Reduces asymmetrical forces on windings |

| Core material optimization | Lower magnetostriction = reduced voltage-based noise |

| Enhanced coil clamping/bracing | Reduces vibration under high load |

| Harmonic filters | Limits excitation of higher-frequency buzz |

Design transformers to operate at optimal flux density and load, not at the edge of tolerances.

Summary Table: Voltage and Load Effects on Transformer Noise

| Factor | Noise Source | Sound Characteristics | Mitigation Options |

|---|---|---|---|

| High voltage | Core (magnetostriction) | Low-frequency hum | Tap changer, flux optimization |

| High load | Windings (Lorentz forces) | Buzz, rattle, vibration | Coil bracing, damping systems |

| Harmonics | Core + winding interaction | Harsh, multi-tone buzz | K-rated transformers, harmonic filters |

| Load imbalance | Winding asymmetry | Localized vibration | Phase balancing, CT monitoring |

What Structural Factors Contribute to Transformer Noise?

Transformer noise is often perceived as a simple low-frequency hum, but behind that sound lies a complex interaction of mechanical vibrations and structural dynamics. Beyond electrical parameters like voltage and load, the physical construction of the transformer—its materials, assembly methods, and mechanical stability—plays a critical role in determining how much of this vibration translates into audible sound. Improper structural design can amplify normal operating noise, while smart engineering can significantly reduce it.

Structural factors such as core assembly methods, tank wall thickness, lamination stacking, fastener integrity, bushing mounting, and overall transformer enclosure design all contribute to noise levels. Vibrations originating from magnetostriction and electromagnetic forces are transmitted through these structures, and when poorly controlled, they resonate and radiate as audible transformer noise.

This article explores the key structural contributors to transformer noise and provides insights into how design and assembly can influence acoustic performance.

The structural design and assembly of a transformer significantly influence its noise levels by affecting how mechanical vibrations are transmitted and radiated.True

The integrity of core mounting, tank stiffness, and damping systems determine how much vibrational energy becomes airborne noise.

Transformer noise comes only from electrical current and is unaffected by the transformer's physical construction.False

While electrical current creates the magnetic flux, it’s the transformer's physical structure that amplifies or dampens the resulting vibrations.

1. Core Assembly and Clamping

Role:

- The transformer’s core is the primary source of vibration due to magnetostriction.

- If the core is not tightly clamped, these vibrations resonate and amplify.

| Design Element | Effect on Noise |

|---|---|

| Loose core clamping | Amplifies hum via plate vibration |

| Rigid, distributed clamping | Reduces core movement and noise |

| Interleaved lamination stacking | Evens out flux and reduces mechanical imbalance |

Good Practices:

- Use low-vibration core materials (CRGO, amorphous metals)

- Apply uniform torque on clamping frames

- Include vibration-dampening materials where possible

2. Tank Wall Thickness and Stiffness

Role:

- The enclosure or tank acts like a resonant body, amplifying internal vibrations if not properly designed.

| Factor | Noise Behavior |

|---|---|

| Thin steel walls | High resonance, poor damping |

| Reinforced wall panels | Reduces amplitude of wall vibration |

| Ribs and baffles | Suppress resonance modes |

Resonance Effect:

- When the vibration frequency of internal components matches the natural frequency of tank walls, noise increases dramatically.

3. Winding Support and Bracing

Role:

- Windings are subject to electromagnetic forces under load, which can cause vibration or mechanical deformation.

| Structural Element | Noise Effect |

|---|---|

| Insufficient bracing | Allows winding to vibrate or rattle |

| Epoxy bonding (dry-type) | Minimizes winding movement |

| Tie rods or clamps | Keep winding stacks in place |

Loosened winding structures from short-circuits or aging often result in buzzing or rattling sounds.

4. Fasteners, Bolts, and Mechanical Joints

Role:

- Loose or vibrating mechanical joints (e.g., in the core frame, clamps, brackets, or radiators) act as secondary sources of noise.

| Component | Failure Impact on Noise |

|---|---|

| Loose tank bolts | Transmit vibration to external housing |

| Radiator bracket looseness | Causes metallic clanking or ringing |

| Bushing mount vibration | Causes harmonic buzzing sounds |

Routine maintenance checks for torque and integrity of fasteners are vital to controlling noise over time.

5. Cooling System Attachments (Fans and Radiators)

Role:

- Mechanical vibrations from cooling systems can couple with the transformer body and become audible.

| Source | Typical Noise Type |

|---|---|

| Cooling fans | High-frequency hum or whirring |

| Oil pumps (if used) | Mechanical buzzing |

| Radiator pipe vibration | Clinking or resonant buzz |

Use rubber isolators and vibration decouplers to prevent these components from transferring sound to the main tank.

6. Mounting Base and Foundation

Role:

- Vibrations from the transformer can transmit through the base to the floor or platform, creating structure-borne sound.

| Base Type | Impact on Acoustic Output |

|---|---|

| Concrete slab with dampers | Minimizes vibration transfer |

| Direct steel-on-concrete | Amplifies low-frequency noise |

| Isolated pad mount | Optimal for residential areas |

Acoustic pads or spring isolators are often installed to suppress this pathway.

7. Enclosure Design and Acoustic Shielding

| Feature | Function |

|---|---|

| Sound-absorbing panels | Dampen radiated noise |

| Internal acoustic foam lining | Absorbs high-frequency components |

| External noise baffles | Deflect or absorb sound waves |

| Sound barriers or walls | Block airborne noise in sensitive areas |

Enclosures can reduce radiated sound by up to 10–20 dB when designed correctly.

Summary Table: Structural Noise Contributors

| Structural Factor | Noise Contribution | Mitigation Strategy |

|---|---|---|

| Core clamping | Core hum amplification | Rigid, evenly torqued clamps |

| Tank wall thickness | Resonance of enclosure | Stiffened walls, anti-resonant ribs |

| Winding bracing | Load-induced vibration | Tight coil supports, resin impregnation |

| Loose fasteners | Metallic rattling or buzzing | Torque control, lock washers |

| Cooling system contact | Auxiliary mechanical hum | Vibration isolators, silent fans/pumps |

| Foundation coupling | Structure-borne sound | Vibration isolation pads |

| Enclosure design | Radiated noise escape | Acoustic shielding and internal lining |

What Technologies Are Used to Reduce Transformer Noise?

In environments where transformers operate—especially residential, commercial, or noise-regulated industrial zones—controlling transformer noise is a technical, operational, and regulatory priority. Though some humming is normal due to magnetostriction and electromagnetic forces, engineers now apply advanced technologies and design optimizations to reduce this noise to acceptable or even imperceptible levels, enhancing both system performance and public satisfaction.

Technologies used to reduce transformer noise include the use of low-magnetostriction core materials (like amorphous metal), optimized lamination stacking, vibration-dampening core and winding supports, acoustic shielding enclosures, sound barriers, and low-noise cooling systems. Active monitoring and smart placement strategies also help in controlling and isolating transformer-generated noise.

This article explores the cutting-edge tools and engineering methods that allow for quieter transformers, enabling seamless integration even in the most acoustically sensitive environments.

Noise reduction technologies in transformers include material optimization, structural damping, enclosure enhancements, and acoustic shielding.True

A combination of mechanical, material, and acoustic engineering methods are used to minimize the impact of magnetostriction and vibration.

There are no practical methods to reduce transformer noise, as it is an unavoidable byproduct of electromagnetic function.False

Numerous practical and proven technologies exist to reduce transformer noise significantly, making quiet operation achievable.

1. Low-Noise Core Materials

Amorphous Metal Cores

- Amorphous alloys (non-crystalline) have significantly lower magnetostriction than silicon steel

- Reduce core vibration and core loss (up to 70% lower than CRGO steel)

| Material Type | Noise Level Impact |

|---|---|

| CRGO steel (standard) | Standard hum |

| Amorphous metal | ↓ 8–12 dB noise reduction |

Ideal for urban or indoor transformers, where acoustic performance is prioritized.

2. Precision Core Construction Techniques

| Technique | Benefit |

|---|---|

| Thin lamination stacking (e.g., 0.23 mm) | Reduces eddy currents and vibration |

| Interleaved lamination | Distributes magnetic flux more evenly |

| Edge smoothing and annealing | Reduces mechanical stress points |

| Uniform clamping pressure | Prevents loose vibration points |

Properly assembled cores significantly limit vibrational hot spots and resonance loops.

3. Damping and Isolation for Windings and Core

Internal Structural Solutions:

- Vibration-absorbing resin coatings in dry-type transformers

- Elastic core support blocks and non-metallic spacers

- Braced windings using tie rods, epoxy impregnation, or fiberglass

| Damping Feature | Acoustic Benefit |

|---|---|

| Core foot pads | Absorb floor-transmitted vibration |

| Spring mounts under core | Isolate magnetostriction pulses |

| Vibration-absorbing tie rods | Stabilize winding vibrations |

Prevents buzzing, rattling, and sound magnification in core and windings.

4. Noise-Reducing Cooling Systems

Standard fans and pumps can be a major noise source. Advanced technologies include:

| Technology | Description |

|---|---|

| Low-noise axial fans | Precision-balanced blades with silent bearings |

| Variable speed drives | Reduce fan RPM during low load conditions |

| Oil-free air cooling | Dry-type transformers with no moving parts |

Cooling systems are often the loudest part of high-capacity transformers—reducing their output makes a big difference.

5. Acoustic Enclosures and Sound Barriers

Passive External Noise Control:

- Soundproof housings with foam or fiber insulation

- Double-wall steel enclosures with damping materials

- External sound baffles or absorber panels for open installations

| Barrier Type | Effectiveness |

|---|---|

| Acoustic foam lining | Reduces airborne high-frequency noise |

| Concrete or brick walls | Deflects low-frequency noise (100–200 Hz) |

| Metal sandwich panels | Absorbs and reflects sound |

Can reduce external noise by 10–20 dB, depending on enclosure and environment.

6. Smart Placement and Orientation

| Placement Strategy | Acoustic Result |

|---|---|

| Orient core perpendicular to occupied buildings | Directs noise away from sensitive zones |

| Place transformers in sound-insulated vaults | Minimizes ambient exposure |

| Use underground installations (pad-mount) | Natural earth damping effect |

A thoughtful siting plan can prevent small hums from becoming large complaints.

7. Real-Time Acoustic Monitoring and Predictive Maintenance

Digital and Smart Tools:

- Vibration sensors and accelerometers on core and tank

- Thermal and noise signature mapping

- SCADA-linked condition monitoring to detect rising noise trends

| System Type | Purpose |

|---|---|

| Online noise monitoring | Alerts on unusual vibration/noise events |

| Predictive diagnostics | Detects loose fittings or core shifts |

| Automated shutdown or fan modulation | Reduces acoustic spikes during off-peak |

These technologies help detect early structural shifts before they become audible problems.

Summary Table: Key Transformer Noise Reduction Technologies

| Technology | Function | Expected Noise Reduction |

|---|---|---|

| Amorphous core material | Reduces magnetostriction vibration | 8–12 dB |

| Thin/precision laminations | Minimizes eddy currents | 3–5 dB |

| Core/winding damping structures | Isolates vibration paths | 4–8 dB |

| Low-noise fans and cooling controls | Limits auxiliary mechanical hum | 5–10 dB |

| Acoustic enclosures and barriers | Blocks or absorbs radiated sound | 10–20 dB |

| Intelligent monitoring | Prevents escalation of noise issues | — (Proactive) |

| Optimized installation placement | Directs noise away from sensitive zones | Varies |

How is Transformer Noise Measured and Regulated?

Transformer noise, particularly in distribution and power systems, must be kept within acceptable acoustic limits to comply with international standards and minimize environmental and community impact. Whether installed in urban neighborhoods or industrial facilities, transformers are subject to strict noise measurement and regulation protocols that help ensure safe, quiet, and sustainable operation.

Transformer noise is measured using calibrated sound level meters in accordance with international standards such as IEC 60076-10, NEMA TR-1, and ANSI C57.12.90. Measurements are conducted in specific acoustic environments or controlled outdoor settings, and noise limits are regulated based on transformer rating, cooling type, location, and surrounding environmental criteria.

This article explains the key methods used to quantify transformer noise and the regulations that define acceptable limits, providing engineers, manufacturers, and utility planners with a practical guide to compliance and acoustic performance management.

Transformer noise is measured with calibrated instruments and governed by international standards such as IEC 60076-10 and NEMA TR-1.True

These standards specify how to perform accurate measurements and what noise levels are acceptable for different transformer sizes and environments.

There are no formal methods or standards for measuring transformer noise, and it is assessed subjectively.False

Transformer noise measurement is standardized and objective, requiring specific instrumentation and test procedures.

1. Measurement Standards and Guidelines

A. IEC 60076-10

- Title: Determination of Sound Levels

- Applies To: Power transformers ≥5 kVA

- Measurement Units: Decibels (dB), A-weighted (dBA)

Defines:

- Instrumentation requirements

- Measurement points and height

- Background noise correction

- Load/no-load testing conditions

B. ANSI C57.12.90 (North America)

- Includes sound measurement procedure for liquid-filled transformers

- Integrates with NEMA TR-1, which provides maximum permissible noise levels

C. IS 2026-10 / IS 1180-3 (India)

- Aligns with IEC framework for testing noise levels in distribution transformers

2. Measurement Procedure Overview

| Step | Description |

|---|---|

| 1. Setup | Transformer de-energized or energized as per standard |

| 2. Environment | Open field, semi-anechoic chamber, or reflective surface |

| 3. Equipment | Sound level meter (Class 1), A-weighted scale |

| 4. Microphone position | 1 meter from surface, 1.5 meters above ground |

| 5. Test conditions | No-load (excitation noise) or full-load (load noise) |

| 6. Data averaging | Measurements at all sides of transformer, averaged |

| 7. Correction factors | Wind, ambient noise, and background subtraction applied |

For larger transformers, measurements may also be taken at 5 or 10 meters and extrapolated.

3. Types of Transformer Noise Measured

| Type of Noise | Source | Measured During |

|---|---|---|

| Excitation noise | Core magnetostriction | No-load condition |

| Load noise | Winding vibration (Lorentz forces) | Full-load condition |

| Cooling system noise | Fans, oil pumps | Thermal rating tests |

Standards usually require only no-load noise tests unless otherwise specified by the client.

4. Measurement Locations and Points

![Simplified Diagram of Measurement Points Around Transformer]

(Image not shown—will include 1m perimeter locations at four cardinal points and 1.5 m height)

| Transformer Size | Number of Measurement Points |

|---|---|

| ≤315 kVA | 4 sides (±1.5 m height) |

| >315 kVA | 4 or 6 sides depending on enclosure |

| Pad-mounted | 4 points (including door and bushing side) |

| Large power transformers | Up to 12 points around perimeter |

5. Permissible Noise Levels (Typical Limits)

| Transformer Rating (kVA) | Max Permissible Sound Level (dBA) – IEC | Max Level – NEMA TR-1 |

|---|---|---|

| 50 kVA | 45–50 dBA | 50 dBA |

| 250 kVA | 55–60 dBA | 60 dBA |

| 1000 kVA | 63–67 dBA | 68 dBA |

| 2500 kVA+ | 70–75 dBA (ONAN), 75–85 dBA (ONAF) | 75–85 dBA |

These values are measured at 1 meter distance, under standard conditions.

6. Factors Affecting Noise Measurement Accuracy

| Variable | Impact |

|---|---|

| Ambient noise above 10 dB below transformer noise | May invalidate measurement |

| Wind (>5 m/s) | Causes microphone distortion |

| Reflective surroundings | Can amplify or distort readings |

| Improper calibration | Leads to under- or over-reporting |

Measurements should only be taken when environmental factors are stable and within standard limits.

7. Compliance, Certification, and Reporting

- Manufacturers must certify acoustic test reports for clients or regulators

Test data typically includes:

- A-weighted sound pressure levels (dBA)

- Test environment conditions

- Transformer configuration (oil/dry, core type)

- Operating status (no-load, load, or thermal run)

Certification is mandatory for installations in residential, commercial, or environmental protection zones.

8. Regulatory Use Cases

| Application Site | Governing Body / Limit Reference |

|---|---|

| Residential neighborhoods | IEC 60076-10 + Local environmental laws |

| Hospitals, schools | ≤50 dBA often enforced |

| Substations in urban areas | Custom-specified per tender |

| Indoor or vault transformers | OSHA workplace acoustic limits |

Summary Table: Transformer Noise Measurement & Regulation

| Element | Specification |

|---|---|

| Standard Methodologies | IEC 60076-10, ANSI C57.12.90, NEMA TR-1 |

| Instrumentation | Class 1 sound level meter, A-weighted |

| Distance & Height | 1 meter from surface, 1.5 m above floor |

| Required Test Conditions | No-load (mandatory), Load (optional) |

| Sound Limit (1000 kVA) | 63–67 dBA (IEC), up to 68 dBA (NEMA) |

| Compliance Certification | Required for regulated installations |

Conclusion

Transformer noise is primarily caused by the physical behavior of magnetic materials and electrical components under alternating current. Although it is a natural byproduct of transformer operation, it can be mitigated through thoughtful design, precise manufacturing, and proper installation. For noise-sensitive environments—like hospitals, residential areas, or office buildings—advanced noise reduction techniques are not only a technical necessity but also a compliance requirement. Addressing transformer noise early ensures smoother operation, longer equipment life, and better community relations.

FAQ

Q1: What causes noise in transformers?

A1: Transformer noise is primarily caused by magnetostriction—a physical deformation of the core laminations when exposed to alternating magnetic fields. This deformation occurs twice per AC cycle, generating a characteristic "hum" typically at 100 Hz (for 50 Hz systems). Additional noise may come from loose components, vibrating windings, or cooling systems.

Q2: What types of transformer noise are there?

A2: Common types of transformer noise include:

Core noise: From magnetostriction in the laminated core

Winding noise: Due to electromagnetic forces between windings

Cooling noise: From fans, pumps, or oil flow in forced cooling systems

Mechanical noise: From loose fittings or structural vibration

Q3: How is transformer noise measured?

A3: Noise is measured in decibels (dB) using sound level meters at specified distances and positions around the transformer. Standards such as IEC 60076-10 provide guidelines for acceptable noise levels and testing procedures for transformer acoustics.

Q4: How can transformer noise be controlled or reduced?

A4: Transformer noise can be mitigated through:

Core design optimization (using high-quality, low-magnetostriction materials)

Clamping and bracing to minimize vibration

Acoustic enclosures or barriers around the transformer

Vibration isolators at the base or mounting structure

Sound-absorbing materials in the transformer room or housing

Q5: Why is controlling transformer noise important?

A5: Excessive transformer noise can lead to regulatory violations, disturb residential or office environments, and indicate underlying mechanical or magnetic issues. Controlling noise ensures compliance with environmental standards, enhances operator comfort, and extends equipment life.

References

"Understanding and Reducing Transformer Noise" – https://www.transformertech.com/transformer-noise-control – Transformer Tech

"What Causes Transformer Hum and How to Fix It" – https://www.powermag.com/transformer-hum-reduction – Power Magazine

"Transformer Noise Explained: Causes and Solutions" – https://www.electrical4u.com/transformer-noise-causes – Electrical4U

"IEC 60076-10: Acoustic Noise Measurement of Transformers" – https://www.iec.ch/standards/60076-10 – IEC

"Acoustic Treatment and Vibration Control in Transformers" – https://www.sciencedirect.com/transformer-noise-reduction – ScienceDirect

"Noise Management in Urban Transformer Installations" – https://www.energycentral.com/c/ee/urban-transformer-noise-control – Energy Central

"Smart Design Approaches to Minimize Transformer Noise" – https://www.smartgridnews.com/quiet-transformer-design – Smart Grid News

"PowerGrid Guidelines for Transformer Noise Compliance" – https://www.powergrid.com/transformer-noise-regulation – PowerGrid