In high-voltage electrical systems, transformers are critical components that must operate reliably under intense thermal and electrical stress. To ensure safe and efficient performance, most power transformers are designed as oil-immersed units. This article explores the reasons behind placing transformers in oil-filled tanks, focusing on the role of transformer oil in insulation, cooling, and equipment protection. It also addresses six key questions commonly raised about oil-filled transformer design and operation.

What Role Does Transformer Oil Play in Insulation?

Transformer oil is far more than just a cooling agent—it is a critical component of the insulation system that ensures the transformer's ability to operate safely at high voltages. Inside power transformers, both windings and solid insulation such as cellulose paper are submerged in oil. This immersion creates a composite insulation system where the oil provides electrical, thermal, and chemical support to maintain the dielectric integrity of the transformer over decades.

Transformer oil serves as an electrical insulator by filling the space between live parts and grounded components, preventing electrical arcing, and enhancing dielectric strength. It also impregnates the cellulose insulation, reducing its moisture content and increasing breakdown voltage, while cooling the windings by convective heat transfer. Without it, the insulation system cannot function reliably.

Transformer oil insulation is a non-negotiable safeguard in high-voltage applications.

Transformer oil only acts as a coolant and not as an insulator.False

Transformer oil provides essential dielectric strength and arc suppression, forming part of the composite insulation system.

Core Insulating Roles of Transformer Oil

| Function | Description |

|---|---|

| Dielectric Separation | Prevents voltage breakdown between energized and grounded parts |

| Impregnating Medium | Saturates paper insulation to eliminate air gaps and enhance strength |

| Arc Suppression | Quenches discharges and local arcs between points of high voltage gradient |

| Moisture Barrier | Displaces water from solid insulation and maintains dryness |

| Cooling / Heat Dissipation | Transfers heat away from windings to radiators via convection |

In oil-immersed transformers, the oil-paper system defines the insulation class and withstand voltage levels.

Dielectric Strength of Oil vs. Air vs. Paper

| Material | Dielectric Strength (kV/mm) |

|---|---|

| Transformer Oil | 10–15 |

| Cellulose Paper | 20–25 |

| Dry Air | ~3 |

| Moist Air | <1 |

Transformer oil enhances overall dielectric strength by filling voids and clearances between components.

Interaction Between Oil and Paper Insulation

| Aspect | Oil's Effect on Paper Insulation |

|---|---|

| Moisture Removal | Draws water out of paper to keep it dry |

| Thermal Stability | Lowers hotspot temperature by cooling |

| Oxidation Delay | Shields paper from oxygen, reducing degradation |

| Dielectric Enhancement | Prevents corona discharge between paper layers |

The oil-paper system works synergistically. If the oil deteriorates, the paper's life shortens rapidly.

Oil’s Arc Suppression Capability

| Condition | Role of Oil |

|---|---|

| Partial Discharge (PD) | Oil delays onset by filling gaps |

| Flashover Pathways | Oil lengthens the dielectric path |

| Corona Ionization | Suppresses electron multiplication |

| Breaker Response Time | Oil absorbs arc energy during delayed trip |

Arc suppression by oil prevents immediate breakdown even under transient faults.

How Oil Quality Affects Insulation Performance

| Oil Condition | Dielectric Effect |

|---|---|

| Dry, Clean Oil | High dielectric, reliable arc suppression |

| Moisture-Contaminated | Reduced strength, increased partial discharge risk |

| Oxidized Oil | Produces acids and sludge, weakens paper |

| Aged Oil | Cannot maintain dielectric gaps or cool effectively |

IEC 60296 and ASTM D3487 standards define oil quality parameters for insulation use.

Real-World Observation – Wind Farm Transformer Deterioration

- 33 kV wind farm transformer experienced repeated tripping

- Oil breakdown strength tested at 21 kV (standard: >30 kV)

- Moisture >80 ppm, interfacial tension <20 mN/m

- Paper insulation at hot spot was brittle, near carbonization

- Cause: failed breather allowed moisture, oil failed to protect insulation

How Does Transformer Oil Help with Cooling?

Transformer oil is not only a dielectric medium but also a crucial thermal management agent in power transformers. As transformers operate, their internal components, especially the windings and core, generate significant amounts of heat due to electrical and magnetic losses. This heat must be effectively removed to maintain operational reliability, avoid insulation degradation, and extend transformer lifespan. Transformer oil serves this purpose by functioning as a fluid coolant.

Transformer oil facilitates cooling by absorbing the heat generated in the windings and core and transporting it through convection to external radiator surfaces or cooling systems, where the heat is released into the atmosphere or secondary cooling fluid. The constant circulation of oil ensures a uniform thermal profile, reduces hot-spot temperatures, and protects the insulation system from thermal aging.

Efficient oil cooling is vital to preventing overheating and ensuring consistent transformer performance over decades of operation.

Transformer oil has no role in cooling, only insulation.False

Transformer oil plays a critical role in dissipating heat from the windings and core through convection and heat transfer to radiators.

Key Functions of Transformer Oil in Cooling

| Function | Description |

|---|---|

| Heat Absorption | Picks up heat from conductors and magnetic core |

| Convection Circulation | Naturally or forcibly moves heated oil away from the source |

| Heat Transfer to Radiators | Transfers thermal energy to external fins or coils |

| Dissipation into Air/Water | Releases heat into the environment through surface exchange |

| Temperature Regulation | Maintains acceptable operational range, protecting insulation |

Transformer Cooling System Types Using Oil

| Cooling Method | Operation Mode | Applicable Ratings |

|---|---|---|

| ONAN | Oil Natural, Air Natural | Up to ~20 MVA |

| ONAF | Oil Natural, Air Forced (fans) | 20–60 MVA |

| OFAF | Oil Forced, Air Forced (pumps + fans) | 60–200 MVA |

| OFWF | Oil Forced, Water Forced | Above 200 MVA |

Each method enhances oil movement and cooling efficiency as the transformer rating increases.

Thermal Properties of Transformer Oil

| Property | Typical Value |

|---|---|

| Specific Heat Capacity | 1.7–2.0 kJ/kg·K |

| Thermal Conductivity | 0.12–0.15 W/m·K |

| Flash Point | >140°C (safe under high temperature) |

| Kinematic Viscosity | ~10–15 cSt at 40°C |

These properties ensure efficient thermal absorption and flow dynamics across varying temperatures.

Transformer Oil Temperature Profile (Typical)

| Component Area | Operating Temperature Range |

|---|---|

| Windings Hot Spot | 95–120°C |

| Bulk Oil Average | 70–90°C |

| Radiator Inlet | 85–95°C |

| Radiator Outlet | 60–75°C |

Maintaining oil temperatures below hot-spot thresholds is essential for long insulation life.

Real-World Benefits of Oil-Based Cooling

| Improvement Area | Impact |

|---|---|

| Hot Spot Control | Reduced by up to 20–30°C |

| Insulation Life | Doubled when thermal limits are respected |

| Load Capacity | Increased by 10–25% with proper cooling |

| Energy Efficiency | Maintained at design level |

When oil cooling is optimized, transformer reliability and load performance increase significantly.

Enhancements and Monitoring for Cooling Performance

| Technology | Purpose |

|---|---|

| Oil Temperature Sensors | Track and report thermal conditions |

| Digital Thermal Modeling | Predicts aging and dynamic heat profiles |

| Oil Pumps and Cooling Fans | Enable forced circulation for high-power units |

| Radiator Maintenance | Prevent blockages that impair heat exchange |

Combining active monitoring and system upgrades ensures effective heat control.

Why Is Oil Preferred Over Air in High-Voltage Transformers?

When it comes to designing transformers for high-voltage applications, oil is overwhelmingly preferred over air as the insulating and cooling medium. This is due to oil’s superior dielectric properties, better thermal conductivity, and ability to create a compact, sealed environment that prevents electrical discharges and moisture ingress. Air, while suitable for low-voltage systems, lacks the necessary dielectric strength and heat removal capacity required for large-scale, high-voltage power systems.

Oil is preferred over air in high-voltage transformers because it offers significantly higher dielectric strength, enabling closer spacing between conductors and grounded parts, and superior heat dissipation through convection. Oil also fills gaps, impregnates insulation, suppresses electrical arcs, and protects components from moisture and contamination—making it essential for safe, efficient, and long-term transformer operation.

This preference underpins virtually all high-voltage power transmission transformer designs globally.

Air insulation is more effective than oil in high-voltage transformers.False

Oil has a far higher dielectric strength and thermal capacity than air, making it more effective and reliable for insulating and cooling high-voltage transformers.

Dielectric Strength Comparison: Oil vs Air

| Medium | Dielectric Strength (kV/mm) |

|---|---|

| Mineral Oil | 10–15 |

| Transformer Paper | 20–25 |

| Dry Air | ~3 |

| Moist Air | <1 |

Oil allows much shorter clearance distances between energized components, enabling more compact and efficient transformer design.

Key Advantages of Oil over Air

| Factor | Transformer Oil | Air |

|---|---|---|

| Dielectric Strength | High, allows compact insulation spacing | Low, requires large air gaps |

| Arc Suppression | Effective; quenches and absorbs arc energy | Limited; susceptible to ionization and flashover |

| Cooling Capability | Excellent via convection and radiator systems | Poor; relies on passive air circulation |

| Moisture Control | Oil displaces and dries internal components | Air admits ambient humidity |

| Dust/Contaminant Isolation | Sealed oil system prevents ingress | Air systems are open and vulnerable |

| Thermal Aging Protection | Slows paper degradation by oxygen exclusion | No protection from oxidation or moisture |

In high-voltage environments, air is not just insufficient—it is often a liability.

Oil-Filled Transformers vs Dry-Type Transformers

| Feature | Oil-Filled (Liquid-Immersed) | Dry-Type (Air-Cooled) |

|---|---|---|

| Voltage Range Supported | Up to 765 kV and above | Up to 36 kV (typically) |

| Cooling Method | Oil + Radiators/Fans | Natural or Forced Air |

| Fire Risk | Moderate (mineral oil); low (ester) | Very Low |

| Installation Location | Outdoor, remote, high load centers | Indoor, urban, sensitive areas |

| Size and Efficiency | More compact, better efficiency | Bulkier for same insulation level |

| Maintenance | Requires oil testing, filtration | Lower maintenance, lower load rating |

Oil-immersed units are universally used in transmission grids, while dry-types are niche solutions for buildings or indoor substations.

Real-World Insight – Why Air Is Risky at High Voltage

- Corona Discharge Risk: Air-insulated units suffer ionization at high field intensities, especially in polluted or humid environments.

- Flashover Susceptibility: In substations, air-insulated switchgear and transformers show higher failure rates during storms or lightning surges.

- Insulation Creep Distance: For 220 kV systems, air requires several meters of clearance; oil allows same rating in a 2–3 m enclosure.

This explains the physical footprint difference between AIS (Air Insulated Switchgear) and GIS (Gas/Oil Insulated Systems).

Case Example – 400 kV Grid Transformer Decision

- A utility considered air vs oil insulation for a 400 kV, 250 MVA grid transformer

- Oil-filled option: 7 m x 3.5 m footprint, 1.1 million liters oil

- Air-insulated equivalent: impractical—would require >12 m height and multiple dry barriers

- Oil system provided: 55 kV/mm withstand, 88°C max hot spot, 45-year life projection

Final decision: Oil-filled transformer with ONAN/ONAF cooling and natural ester fluid to improve safety

What Types of Oil Are Used in Transformers?

Transformer oil plays a dual role—providing both dielectric insulation and thermal dissipation—making its selection a strategic choice based on application, voltage, environment, and fire safety requirements. Over the decades, oil formulations have evolved to enhance thermal performance, fire resistance, biodegradability, and aging stability. Understanding the types of transformer oil available helps engineers choose the most suitable fluid for specific use cases.

The main types of oil used in transformers are mineral oil, natural ester, synthetic ester, and silicone oil. Mineral oil is the most widely used for its cost-effectiveness and high dielectric strength. Natural and synthetic esters offer better fire safety and biodegradability, making them suitable for eco-sensitive or indoor applications. Silicone oil is used where extreme temperatures and high fire resistance are required.

Each oil type serves distinct operational needs, guided by technical and environmental considerations.

All transformer oils are the same and interchangeable.False

Transformer oils vary significantly in dielectric properties, thermal stability, biodegradability, and fire point, and must be selected according to application-specific needs.

Overview of Transformer Oil Types

| Oil Type | Base Material | Key Strengths | Common Applications |

|---|---|---|---|

| Mineral Oil | Petroleum-derived | High dielectric strength, cost-effective | Utilities, substations, outdoor systems |

| Natural Ester | Vegetable-based | Biodegradable, high fire point, moisture tolerance | Indoor transformers, urban and green projects |

| Synthetic Ester | Chemically modified organics | Excellent aging, high temperature stability | Renewable energy, compact stations |

| Silicone Oil | Silicon-based polymer | Very high fire resistance, wide temperature range | Railway, tunnels, offshore, indoor HV |

| Halogenated Fluids (obsolete) | PCB-based (banned) | Toxic, environmentally banned | Historical only (no longer used) |

Comparison Table of Transformer Oil Properties

| Property | Mineral Oil | Natural Ester | Synthetic Ester | Silicone Oil |

|---|---|---|---|---|

| Dielectric Strength (kV/mm) | 10–15 | 15–18 | 15–20 | 10–13 |

| Fire Point (°C) | ~150 | >300 | >300 | >350 |

| Biodegradability | Poor | Excellent | Good | Low |

| Moisture Tolerance | Low | High | Moderate | Low |

| Pour Point (°C) | -40 to -60 | -20 to -30 | -40 to -55 | -65 |

| Flash Point (°C) | ~145 | >250 | >250 | >300 |

| Environmental Impact | Moderate | Minimal | Low | Moderate |

| Cost ($/liter) | Low | Medium-high | High | Very High |

Mineral oil is dominant in outdoor HV systems, while natural esters are gaining ground in urban, indoor, and eco-sensitive sites.

Detailed Descriptions of Oil Types

1. Mineral Oil

- Derived from crude petroleum through refining

- Common types: uninhibited and inhibited (with oxidation stabilizers)

- Best for outdoor applications due to cost, availability, and thermal stability

- Drawback: flammable, poor biodegradability, sensitive to moisture

2. Natural Ester (Vegetable Oil-Based)

- Typically made from rapeseed, soybean, or sunflower oils

- Excellent fire safety and environmental performance (IEC 62770 compliant)

- Moisture absorption lowers aging rate of paper insulation

- Must be carefully managed to avoid oxidation in high oxygen environments

3. Synthetic Ester

- Engineered for high-temperature and high-load environments

- Provides greater oxidation stability than natural esters

- Preferred for renewable energy, wind, solar inverter transformers, and compact systems

4. Silicone Oil

- Offers extremely wide temperature stability (–60°C to +180°C)

- Non-flammable and low toxicity

- High cost restricts use to specialized applications like transit systems, tunnels, submarines

Regulatory and Environmental Considerations

| Regulation | Requirement | Oil Type Alignment |

|---|---|---|

| IEC 61099 | Synthetic ester specifications | Synthetic esters |

| IEC 62770 | Natural ester oil performance | Natural esters |

| IEEE C57.147 | Guide for use of natural ester fluids | All ester oils |

| REACH / RoHS / EPA | Non-toxic, non-hazardous fluids | Excludes PCB and high-aromatic oils |

| FM Global Approvals | Fire safety certification | Silicone, esters (not mineral oil) |

Compliance helps ensure safe, sustainable transformer operation and easier permitting for installation.

Case Application Example

Site: Indoor 132 kV transformer at a university hospital

Constraints: Fire risk, environmental permitting, space

Oil Chosen: Natural ester (bio-based)

Outcome: 310 °C fire point, zero penalty for indoor use, insurance premium reduced by 14%, operational stability with <20 ppm moisture

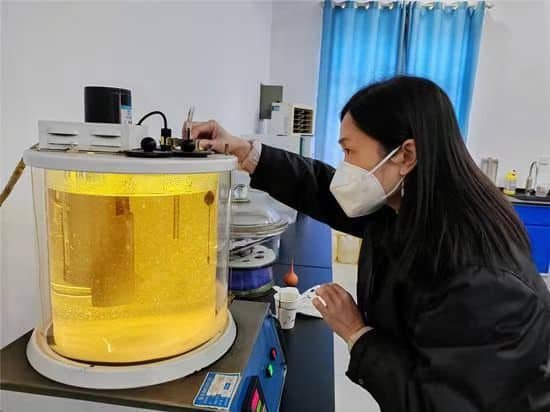

How Is Oil Quality Maintained During Operation?

Maintaining transformer oil quality is essential for the safe and long-term operation of power transformers. Over time, transformer oil is subjected to thermal and electrical stress, environmental contamination, and aging. These processes degrade the oil’s dielectric strength, oxidation stability, and moisture control, all of which are critical to the overall insulation system. If oil quality deteriorates, it can lead to partial discharge, arc faults, insulation collapse, and accelerated transformer failure.

Transformer oil quality is maintained during operation through routine monitoring, laboratory testing, in-service filtration, moisture removal, and gas analysis. Key practices include periodic dielectric breakdown testing, water content analysis, dissolved gas analysis (DGA), acidity and interfacial tension checks, and on-site purification using vacuum dehydration and filtering systems. Preventive maintenance ensures oil remains clean, dry, and chemically stable.

A proactive oil management program is a core pillar of transformer reliability engineering.

Transformer oil quality does not change during operation.False

Transformer oil degrades over time due to heat, oxygen, moisture, and electrical stresses, requiring continuous monitoring and treatment.

Key Parameters That Reflect Oil Quality

| Parameter | Ideal Range (Mineral Oil) | Significance |

|---|---|---|

| Dielectric Breakdown (kV) | >30 kV (IEC), >40 kV (new oil) | Indicates oil's insulation strength |

| Moisture Content (ppm) | <20 ppm (dry), <50 ppm (acceptable) | Water degrades insulation and causes arcing |

| Acidity (mg KOH/g) | <0.1 (new), <0.2 (used) | Measures oxidation products |

| Interfacial Tension (mN/m) | >28 (new), >20 (acceptable) | Low values suggest oil degradation |

| Dissolved Gas Levels | Depends on gas type; trend critical | Identifies electrical/thermal faults |

| Sludge / Visual Clarity | No visible particles or discoloration | Sludge clogs flow paths, impairs cooling |

Maintenance Practices to Preserve Oil Quality

| Method | Purpose | Frequency |

|---|---|---|

| Dielectric Strength Test | Confirms oil can insulate at required voltages | Every 6–12 months |

| Karl Fischer Moisture Test | Quantifies water ppm to prevent discharge risk | Quarterly to semiannually |

| Dissolved Gas Analysis (DGA) | Detects incipient faults via gas patterns | Quarterly or condition-based |

| Oil Filtration / Purification | Removes moisture, acids, particles | As needed or during outages |

| Sludge Control (Preventive) | Prevents deposit formation via inhibitors | Based on condition and age |

| Breather Maintenance | Prevents moisture ingress through air exchange | Monthly to quarterly |

Proper oil testing and filtration extend oil life by 2–3× and transformer life by 30–50%.

Oil Treatment Technologies in Operation

| System Type | Function | Application Scope |

|---|---|---|

| Vacuum Dehydration Unit | Removes water and dissolved gases | Outdoor and HV transformers |

| Fuller's Earth Filtration | Removes acidic oxidation by-products | Aging oil regeneration |

| Micron Filtration System | Removes particulate contaminants down to 1 µm | Continuous online use |

| Mobile Oil Reclamation Units | Performs on-site oil recovery and reconditioning | Grid-level maintenance |

| Smart Breathers | Self-drying silica gel system with sensors | Real-time ambient protection |

Online purification systems allow in-service oil maintenance, minimizing downtime.

Oil Testing Schedule Based on Transformer Type

| Transformer Rating | Oil Testing Frequency | Recommended Tests |

|---|---|---|

| <1 MVA (Distribution) | Every 2–3 years | Dielectric, moisture, visual check |

| 1–10 MVA | Annually | DGA, breakdown, water, IFT, acidity |

| >10 MVA (HV/MV power units) | Quarterly to semiannually | Full chemical + physical analysis |

| Critical infrastructure | Monthly to quarterly | DGA, moisture, continuous monitoring |

DGA is mandatory for units ≥5 MVA or with known fault histories.

Real-World Case – Oil Reconditioning Success

- 220 kV, 63 MVA transformer at an industrial plant

- Oil DGA showed rising CO₂/CO ratio, moisture: 70 ppm, acidity: 0.23

- In-service vacuum filtration, Fuller's earth treatment applied

Results post-treatment:

- Moisture reduced to <15 ppm

- Dielectric strength increased to 54 kV

- No outage required

Maintenance saved ~$110,000 vs oil replacement and prevented emergency failure

What Safety Considerations Are Involved with Oil-Filled Transformers?

Oil-filled transformers are vital for power transmission and distribution, but the presence of combustible liquid (typically mineral oil) introduces unique safety risks that require careful engineering controls and operational vigilance. When operated under high voltage and thermal stress, these transformers can experience internal arcing, insulation breakdown, or oil leakage, all of which can escalate into fire, explosion, or environmental hazards if not properly contained.

The key safety considerations with oil-filled transformers include fire and explosion risk mitigation, containment of oil leaks and spills, proper grounding and overpressure protection, thermal monitoring, arc fault detection, safe clearance distances, routine maintenance, and compliance with environmental and fire protection regulations. Effective implementation of these measures minimizes risk to personnel, equipment, and surroundings.

These safety features must be integrated into the transformer’s design, installation, and operational strategy.

Oil-filled transformers do not pose fire or explosion risks.False

The mineral oil used in most transformers is combustible and can ignite under fault conditions, necessitating fire and explosion protection measures.

Key Safety Risks in Oil-Filled Transformers

| Risk Factor | Description | Consequence |

|---|---|---|

| Internal Arcing | Caused by insulation failure or partial discharge | Rapid pressure buildup, tank rupture |

| Oil Combustion | Mineral oil has a flash point of ~145°C | Fire ignition if exposed to spark/flame |

| Overpressure | Gas expansion due to thermal or electrical fault | Tank rupture or explosion |

| Oil Leakage | Caused by seal or tank failure | Fire hazard, soil/water contamination |

| Thermal Overload | Poor cooling or overload conditions | Accelerated aging, fault risk |

| Environmental Exposure | Exposure to rain, lightning, or mechanical damage | Increases failure likelihood |

Standard Safety Components in Oil-Filled Transformers

| Component | Safety Function |

|---|---|

| Buchholz Relay | Detects gas accumulation from arcing or insulation breakdown |

| Pressure Relief Valve | Releases internal pressure to prevent tank rupture |

| Explosion Vent | Directs energy release safely during severe faults |

| Oil Level Indicator | Alerts to loss of dielectric protection or leaks |

| Conservator with Bladder | Prevents contact between oil and atmosphere |

| Silica Gel Breather | Stops moisture from contaminating insulating oil |

| Thermal Sensors (RTDs) | Monitors winding and oil temperature |

| Fire Barriers / Walls | Contains fire spread between adjacent units |

| Oil Bunding / Containment Pit | Captures leaks and prevents soil/water contamination |

Installation Safety Measures

| Safety Feature | Description |

|---|---|

| Bund Walls | Must hold 110–130% of total oil volume |

| Fire Barriers (IEC 61936) | Required between units to prevent flame spread |

| Minimum Clearance | Based on voltage; ensures personnel safety |

| Surge Arresters / Grounding | Prevents overvoltage damage and induced failures |

| Remote Monitoring Systems | Enables early detection of unsafe conditions |

Oil bunds with flame arrestors are mandatory in high-voltage substations and industrial zones.

Regulatory Standards for Safety Compliance

| Standard / Code | Focus Area | Relevance to Oil-Filled Transformers |

|---|---|---|

| IEC 60076-11 / IEEE C57.12.00 | Transformer safety and construction | General design and operation guidelines |

| IEC 61936-1 / IEEE 980 | Substation installation and fire safety | Mandates bunds, barriers, and clearances |

| NFPA 850 | Fire protection in substations | Recommends fire detection and containment |

| EPA / ISO 14001 | Environmental spill control | Requires bunding, drainage management |

| FM Global Data Sheets | Transformer risk management | Fire-resistant fluids, spacing, protection |

Real-World Fire Event – What Went Wrong

- 66 kV oil-filled transformer caught fire at industrial site

- Cause: undetected Buchholz relay trip + failed breather

- Oil leakage ignited due to arc flash from HV bushing

- Fire suppression delayed due to missing containment pit

- Outcome: full unit loss, $750,000 damage, 4-day plant outage

Prevention: relay monitoring, bund design, oil level sensor alarms, and thermal limiters

Fire-Resistant Alternatives and Fluids

| Oil Type | Fire Point (°C) | Fire Safety Class (IEC 61039) | Use Case Example |

|---|---|---|---|

| Mineral Oil | ~145 | Class 0 (combustible) | General outdoor substations |

| Natural Ester | >300 | Class K (self-extinguishing) | Urban, indoor, eco-sensitive areas |

| Synthetic Ester | >300 | Class K | Railways, renewables, industrial interiors |

| Silicone Oil | >350 | Class K | Underground, tunnels, offshore |

Fire-safe fluids reduce transformer fire risk by over 90% in confined installations.

Conclusion

Transformers are placed in oil-filled tanks primarily to enhance electrical insulation and heat dissipation. Transformer oil prevents electrical breakdowns and transports heat away from the core and windings to external cooling systems. Compared to air, oil offers superior dielectric and thermal performance, making it indispensable in medium- and high-voltage transformer applications. With the evolution of eco-friendly oils and real-time monitoring technologies, oil-filled transformers continue to deliver reliable service while addressing modern safety and environmental standards.

FAQ

Q1: Why is oil used in transformers?

A1: Transformer oil serves two primary purposes:

Insulation – It prevents electrical discharges by insulating internal components.

Cooling – It absorbs heat from windings and core, transferring it to the tank walls and radiators for dissipation.

The oil also provides arc suppression and protects against oxidation and moisture.

Q2: How does oil improve the safety and performance of a transformer?

A2: Oil-filled tanks:

Reduce risk of electrical breakdown through high dielectric strength

Prevent hotspots by circulating heat away from active parts

Extend insulation life by keeping paper windings dry and cool

Suppress arcing and corona discharges, which could lead to explosions

Thus, they help enhance reliability and prevent transformer failures.

Q3: What kind of oil is used in transformers?

A3: Common types include:

Mineral Oil – Most widely used due to low cost and good thermal properties

Natural Esters (Vegetable Oils) – Biodegradable and safer in fire-prone areas

Synthetic Esters – Higher thermal stability, used in critical applications

Silicone-based Oils – High flash point, used in urban or indoor settings

Each type is chosen based on environment, fire safety, and voltage class.

Q4: Can transformers operate without oil?

A4: Yes, dry-type transformers use air or solid insulation and are suitable for:

Indoor, confined, or high-fire-risk areas

Applications with lower voltage and capacity requirements

However, oil-immersed transformers are preferred for high-voltage and outdoor settings due to their superior cooling and insulation performance.

Q5: What happens if water enters transformer oil?

A5: Moisture is highly detrimental:

It lowers dielectric strength, increasing the risk of arcing

Accelerates insulation aging (especially cellulose-based insulation)

Can lead to sludge formation and core corrosion

Therefore, transformers must have sealed tanks, breathers, and regular oil testing to ensure moisture levels remain minimal.

References

"Why Oil is Used in Transformers" – https://www.electrical4u.com/transformer-oil-purpose

"IEEE Guide for Dry vs. Oil-Filled Transformers" – https://ieeexplore.ieee.org/document/6189897

"NREL: Transformer Oil Properties and Testing" – https://www.nrel.gov/docs/fy22ost/transformer-oil-guide.pdf

"Doble Engineering: Transformer Oil Dielectric Analysis" – https://www.doble.com/transformer-oil-analysis

"Hitachi Energy: Types of Insulating Fluids" – https://www.hitachienergy.com/insulation-oils

"ScienceDirect: Oil-Immersed Transformers and Moisture Impact" – https://www.sciencedirect.com/transformer-oil-moisture-study